Comparison of Metal Foam Fabrication: Thermal vs Mechanical Properties

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Evolution and Research Objectives

Metal foams represent a significant advancement in materials science, emerging in the mid-20th century with initial research focused primarily on aluminum-based structures. These cellular materials have evolved from laboratory curiosities to engineered materials with specific performance characteristics, particularly in thermal management and mechanical applications. The evolution of metal foam technology has been marked by significant breakthroughs in manufacturing processes, moving from rudimentary powder metallurgy techniques to sophisticated methods including investment casting, space holder methods, and additive manufacturing approaches.

The historical trajectory of metal foam development reveals a progressive refinement in controlling cellular architecture, which directly influences both thermal and mechanical properties. Early metal foams exhibited inconsistent cell structures and property variations, whereas contemporary fabrication techniques enable precise control over porosity, cell size distribution, and cell wall thickness—parameters that critically determine performance characteristics.

Research objectives in metal foam technology are increasingly focused on establishing clear relationships between fabrication methods and resultant property profiles. Specifically, there exists a compelling need to systematically compare how different manufacturing approaches influence the thermal conductivity, heat transfer efficiency, mechanical strength, and energy absorption capabilities of metal foams. This comparative analysis is essential for advancing application-specific design methodologies.

Current research aims to develop standardized testing protocols that accurately characterize both thermal and mechanical properties across different foam architectures. This standardization would facilitate meaningful comparisons between foams produced via diverse fabrication routes, enabling more informed material selection decisions for specific engineering applications.

Another critical research objective involves developing predictive models that can accurately forecast how modifications in fabrication parameters will affect the thermal-mechanical property balance. Such models would significantly accelerate the development cycle for application-specific metal foams by reducing empirical testing requirements.

The integration of computational simulation with experimental validation represents a frontier research direction, potentially enabling virtual prototyping of metal foam structures with optimized property combinations. This approach could revolutionize the design process for thermal management systems and lightweight structural components.

Ultimately, the overarching goal of current metal foam research is to establish clear fabrication-property relationships that enable engineers to precisely tailor material characteristics to application requirements, whether prioritizing thermal performance, mechanical robustness, or an optimized balance between these often competing properties.

The historical trajectory of metal foam development reveals a progressive refinement in controlling cellular architecture, which directly influences both thermal and mechanical properties. Early metal foams exhibited inconsistent cell structures and property variations, whereas contemporary fabrication techniques enable precise control over porosity, cell size distribution, and cell wall thickness—parameters that critically determine performance characteristics.

Research objectives in metal foam technology are increasingly focused on establishing clear relationships between fabrication methods and resultant property profiles. Specifically, there exists a compelling need to systematically compare how different manufacturing approaches influence the thermal conductivity, heat transfer efficiency, mechanical strength, and energy absorption capabilities of metal foams. This comparative analysis is essential for advancing application-specific design methodologies.

Current research aims to develop standardized testing protocols that accurately characterize both thermal and mechanical properties across different foam architectures. This standardization would facilitate meaningful comparisons between foams produced via diverse fabrication routes, enabling more informed material selection decisions for specific engineering applications.

Another critical research objective involves developing predictive models that can accurately forecast how modifications in fabrication parameters will affect the thermal-mechanical property balance. Such models would significantly accelerate the development cycle for application-specific metal foams by reducing empirical testing requirements.

The integration of computational simulation with experimental validation represents a frontier research direction, potentially enabling virtual prototyping of metal foam structures with optimized property combinations. This approach could revolutionize the design process for thermal management systems and lightweight structural components.

Ultimately, the overarching goal of current metal foam research is to establish clear fabrication-property relationships that enable engineers to precisely tailor material characteristics to application requirements, whether prioritizing thermal performance, mechanical robustness, or an optimized balance between these often competing properties.

Market Applications and Demand Analysis

The metal foam market has witnessed significant growth in recent years, driven by increasing demand across multiple industries seeking lightweight materials with superior thermal and mechanical properties. The global metal foam market was valued at approximately 85 million USD in 2022 and is projected to reach 119 million USD by 2028, growing at a CAGR of around 5.8% during the forecast period.

Automotive and aerospace industries represent the largest application segments for metal foam materials, collectively accounting for over 40% of the total market share. In these sectors, the demand is primarily driven by stringent fuel efficiency regulations and the need for lightweight components that maintain structural integrity. Metal foams with optimized thermal-mechanical property balances are particularly sought after for applications in engine components, crash absorption structures, and thermal management systems.

The construction industry has emerged as another significant consumer of metal foams, particularly those with enhanced thermal insulation properties. Energy-efficient building designs increasingly incorporate metal foam panels that provide both structural support and thermal regulation. This sector is expected to grow at the fastest rate among all application segments, with projected annual growth exceeding 7% through 2028.

Medical device manufacturing represents a specialized but rapidly growing application area, where metal foams are utilized for orthopedic implants and prosthetics. The biocompatibility of certain metal foams, combined with their mechanical properties that mimic bone structure, has created a niche market estimated at 12 million USD annually with double-digit growth potential.

Regional analysis indicates that North America and Europe currently dominate the metal foam market, accounting for approximately 65% of global consumption. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate due to rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

Customer requirements across these markets demonstrate a clear trend toward application-specific optimization of thermal versus mechanical properties. While aerospace applications typically prioritize mechanical strength-to-weight ratios, HVAC and thermal management applications focus on thermal conductivity and heat exchange efficiency. This divergence in property requirements has led to market segmentation based on manufacturing techniques that can deliver specific property profiles.

Market research indicates that approximately 70% of end-users are willing to pay premium prices for metal foams with precisely tailored property combinations, highlighting the commercial value of advanced fabrication methods that can optimize both thermal and mechanical characteristics simultaneously.

Automotive and aerospace industries represent the largest application segments for metal foam materials, collectively accounting for over 40% of the total market share. In these sectors, the demand is primarily driven by stringent fuel efficiency regulations and the need for lightweight components that maintain structural integrity. Metal foams with optimized thermal-mechanical property balances are particularly sought after for applications in engine components, crash absorption structures, and thermal management systems.

The construction industry has emerged as another significant consumer of metal foams, particularly those with enhanced thermal insulation properties. Energy-efficient building designs increasingly incorporate metal foam panels that provide both structural support and thermal regulation. This sector is expected to grow at the fastest rate among all application segments, with projected annual growth exceeding 7% through 2028.

Medical device manufacturing represents a specialized but rapidly growing application area, where metal foams are utilized for orthopedic implants and prosthetics. The biocompatibility of certain metal foams, combined with their mechanical properties that mimic bone structure, has created a niche market estimated at 12 million USD annually with double-digit growth potential.

Regional analysis indicates that North America and Europe currently dominate the metal foam market, accounting for approximately 65% of global consumption. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate due to rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

Customer requirements across these markets demonstrate a clear trend toward application-specific optimization of thermal versus mechanical properties. While aerospace applications typically prioritize mechanical strength-to-weight ratios, HVAC and thermal management applications focus on thermal conductivity and heat exchange efficiency. This divergence in property requirements has led to market segmentation based on manufacturing techniques that can deliver specific property profiles.

Market research indicates that approximately 70% of end-users are willing to pay premium prices for metal foams with precisely tailored property combinations, highlighting the commercial value of advanced fabrication methods that can optimize both thermal and mechanical characteristics simultaneously.

Current Fabrication Challenges and Limitations

Despite significant advancements in metal foam fabrication technologies, several critical challenges continue to impede the widespread industrial adoption and optimization of these materials. The primary limitation remains the difficulty in achieving precise control over pore size, distribution, and connectivity during manufacturing processes. This inconsistency directly impacts both thermal and mechanical properties, creating substantial variability in performance characteristics between production batches.

Manufacturing scalability presents another significant hurdle, particularly for processes that can simultaneously optimize both thermal and mechanical properties. While laboratory-scale production can achieve excellent results, translating these processes to industrial-scale manufacturing often results in quality degradation or prohibitive cost increases. The powder metallurgy route, for instance, offers good control over porosity but struggles with uniform distribution in larger components.

Cost-effectiveness remains a persistent challenge across all fabrication methods. High-performance metal foams with balanced thermal-mechanical properties typically require expensive raw materials, specialized equipment, and energy-intensive processing. The investment casting method, while capable of producing complex geometries, involves multiple processing steps that significantly increase production costs and limit mass production capabilities.

Surface quality and structural integrity issues frequently emerge during fabrication. Methods optimized for thermal conductivity often produce brittle structures with compromised mechanical strength. Conversely, processes focused on mechanical robustness may create closed-cell structures with reduced thermal transfer efficiency. This fundamental trade-off between thermal and mechanical optimization represents perhaps the most significant technical barrier in the field.

Environmental and safety concerns further complicate fabrication processes. Many traditional foaming agents used to create the cellular structure release harmful gases during processing. Additionally, the high temperatures required for metal processing present workplace hazards and increase energy consumption, contributing to higher carbon footprints.

Quality control and characterization methods remain inadequate for comprehensive assessment of both thermal and mechanical properties simultaneously. Non-destructive testing techniques capable of evaluating internal structures without compromising the material integrity are still limited in their precision and accessibility.

The lack of standardized fabrication protocols and property evaluation metrics across the industry creates additional barriers to comparative analysis and quality assurance. This absence of standardization hampers material selection processes for specific applications and impedes the development of application-specific metal foams with optimized property profiles.

Manufacturing scalability presents another significant hurdle, particularly for processes that can simultaneously optimize both thermal and mechanical properties. While laboratory-scale production can achieve excellent results, translating these processes to industrial-scale manufacturing often results in quality degradation or prohibitive cost increases. The powder metallurgy route, for instance, offers good control over porosity but struggles with uniform distribution in larger components.

Cost-effectiveness remains a persistent challenge across all fabrication methods. High-performance metal foams with balanced thermal-mechanical properties typically require expensive raw materials, specialized equipment, and energy-intensive processing. The investment casting method, while capable of producing complex geometries, involves multiple processing steps that significantly increase production costs and limit mass production capabilities.

Surface quality and structural integrity issues frequently emerge during fabrication. Methods optimized for thermal conductivity often produce brittle structures with compromised mechanical strength. Conversely, processes focused on mechanical robustness may create closed-cell structures with reduced thermal transfer efficiency. This fundamental trade-off between thermal and mechanical optimization represents perhaps the most significant technical barrier in the field.

Environmental and safety concerns further complicate fabrication processes. Many traditional foaming agents used to create the cellular structure release harmful gases during processing. Additionally, the high temperatures required for metal processing present workplace hazards and increase energy consumption, contributing to higher carbon footprints.

Quality control and characterization methods remain inadequate for comprehensive assessment of both thermal and mechanical properties simultaneously. Non-destructive testing techniques capable of evaluating internal structures without compromising the material integrity are still limited in their precision and accessibility.

The lack of standardized fabrication protocols and property evaluation metrics across the industry creates additional barriers to comparative analysis and quality assurance. This absence of standardization hampers material selection processes for specific applications and impedes the development of application-specific metal foams with optimized property profiles.

Comparative Analysis of Fabrication Methods

01 Thermal conductivity and insulation properties of metal foams

Metal foams exhibit unique thermal properties, particularly their ability to combine high thermal conductivity with effective insulation capabilities. The porous structure of metal foams creates air pockets that reduce heat transfer while maintaining the inherent conductivity of the metal matrix. This combination makes them valuable for applications requiring thermal management, such as heat exchangers, thermal barriers, and cooling systems. The thermal conductivity can be tailored by adjusting the porosity, pore size, and base metal composition.- Thermal conductivity and heat transfer properties of metal foams: Metal foams exhibit unique thermal properties due to their porous structure. They typically have high thermal conductivity while maintaining low density, making them excellent for heat transfer applications. The interconnected pore structure allows for efficient heat dissipation and thermal management. These properties can be tailored by adjusting the porosity, pore size, and base metal composition, enabling customization for specific thermal requirements in various applications.

- Mechanical strength and structural integrity of metal foams: Metal foams offer exceptional mechanical properties including high strength-to-weight ratio, energy absorption capability, and impact resistance. Despite their lightweight nature, they maintain significant structural integrity under various loading conditions. The cellular structure provides excellent compression resistance while allowing controlled deformation under stress. These mechanical properties can be engineered by modifying the cell structure, wall thickness, and base metal alloy composition to meet specific application requirements.

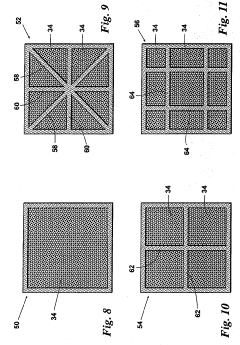

- Manufacturing techniques and their influence on properties: Various manufacturing methods significantly impact the final properties of metal foams. Techniques such as powder metallurgy, melt gas injection, investment casting, and additive manufacturing each produce foams with distinct characteristics. The manufacturing process determines cell size distribution, porosity level, and structural uniformity, which directly affect both thermal and mechanical properties. Advanced production methods allow for precise control over these parameters to achieve optimal performance for specific applications.

- Composite metal foams and property enhancement: Composite metal foams incorporate additional materials or reinforcements to enhance specific properties. By combining different metals or adding ceramic particles, carbon nanotubes, or other reinforcing elements, both thermal and mechanical properties can be significantly improved. These hybrid structures can achieve superior heat dissipation while maintaining or enhancing mechanical strength. The synergistic effect of multiple materials allows for customized property profiles that exceed those of conventional single-metal foams.

- Application-specific metal foam designs: Metal foams can be specifically engineered for targeted applications by optimizing their structure and composition. For thermal management applications, foams with high surface area and open-cell structures maximize heat exchange efficiency. For structural applications, closed-cell foams with optimized density provide the best balance of strength and weight. Gradient structures with varying porosity can deliver tailored performance across different regions of the same component. This application-specific design approach ensures optimal thermal and mechanical performance for each use case.

02 Mechanical strength and lightweight characteristics

Metal foams offer an exceptional strength-to-weight ratio due to their cellular structure. Despite their low density, they maintain significant mechanical strength and stiffness, making them ideal for lightweight structural applications. The mechanical properties can be engineered by controlling the foam density, cell size, and wall thickness. These materials exhibit good energy absorption capabilities under compression and impact, with distinctive plateau regions in their stress-strain curves. The combination of lightweight characteristics with mechanical resilience makes metal foams valuable in automotive, aerospace, and construction applications.Expand Specific Solutions03 Manufacturing methods affecting properties

Various manufacturing techniques significantly influence the final thermal and mechanical properties of metal foams. Processes such as powder metallurgy, melt foaming, investment casting, and additive manufacturing each produce foams with distinct characteristics. The manufacturing method determines cell structure uniformity, density distribution, and interconnectivity of pores, which directly impact thermal conductivity and mechanical strength. Advanced manufacturing techniques allow for precise control over pore size, shape, and distribution, enabling customization of properties for specific applications. Post-processing treatments can further enhance both thermal and mechanical performance.Expand Specific Solutions04 Composite metal foams with enhanced properties

Composite metal foams incorporate additional materials within the metal matrix to enhance specific properties. By introducing ceramic particles, carbon nanotubes, or secondary metals, both thermal and mechanical characteristics can be significantly improved. These composite structures can achieve higher strength, better energy absorption, improved thermal stability, and enhanced heat transfer capabilities compared to conventional metal foams. The synergistic effect between the metal matrix and reinforcement materials creates multifunctional properties that can be tailored for specialized applications in extreme environments, including high-temperature settings and high-impact scenarios.Expand Specific Solutions05 Application-specific property optimization

Metal foams can be specifically engineered to optimize properties for targeted applications. For thermal management applications, foams can be designed with open-cell structures to maximize fluid flow and heat exchange. For structural applications requiring specific mechanical responses, closed-cell foams with controlled density gradients can be developed. The ability to create functionally graded metal foams allows for components with varying properties throughout their structure, addressing multiple performance requirements simultaneously. This customization extends to properties such as vibration damping, acoustic absorption, and electromagnetic shielding, in addition to the primary thermal and mechanical characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The metal foam fabrication market is currently in a growth phase, characterized by increasing applications in automotive, aerospace, and energy sectors. The global market size is estimated to reach $95 million by 2025, with a CAGR of approximately 4.5%. Regarding technical maturity, thermal and mechanical properties optimization remains challenging. Leading players include ALANTUM Corp. and its subsidiary Alantum Europe GmbH, who have pioneered commercial-scale alloy foam technology. Fraunhofer-Gesellschaft and North Carolina State University are advancing research in thermal conductivity optimization, while BASF Corp. and LG Chem focus on mechanical strength enhancement. Rolls Royce is exploring aerospace applications, and Evonik Operations is developing specialized chemical treatments to improve foam properties. The industry is witnessing increased collaboration between academic institutions and industrial manufacturers to overcome current technical limitations.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed multiple innovative approaches to metal foam fabrication, with particular emphasis on powder metallurgical routes that optimize both thermal and mechanical properties. Their advanced Powder Space Holder Method (PSHM) combines metal powders with space-holding materials (typically salt or carbamide) that are later removed to create controlled porosity. This technique achieves open-cell structures with 40-80% porosity and pore sizes from 0.1-5 mm. Fraunhofer has also pioneered hybrid metal foams by incorporating ceramic particles into the metal matrix, creating composites with enhanced thermal stability up to 800°C while maintaining mechanical integrity. Their research has demonstrated thermal conductivities ranging from 5-30 W/m·K depending on base metal and porosity levels. Additionally, Fraunhofer has developed specialized sintering protocols that create strong metallurgical bonds between particles without compromising the porous architecture, resulting in compressive strengths of 5-20 MPa for aluminum-based foams with 60-70% porosity.

Strengths: Exceptional control over pore morphology and distribution; ability to create functionally graded structures with varying porosity; excellent reproducibility and quality control; capability to process a wide range of metal alloys including aluminum, copper, titanium, and steel. Weaknesses: Higher production costs compared to conventional casting methods; longer processing times due to multiple manufacturing steps; challenges in scaling to very large components; potential for residual space-holder contamination affecting properties.

BASF Corp.

Technical Solution: BASF has pioneered advanced metal foam fabrication technologies focusing on aluminum-based foams through their proprietary direct foaming method. Their approach involves adding titanium hydride (TiH2) as a foaming agent to molten aluminum alloys, which decomposes at elevated temperatures to release hydrogen gas, creating a cellular structure. BASF's process achieves porosities of 80-90% with cell sizes ranging from 2-8 mm, resulting in foams with thermal conductivity values of 8-20 W/m·K depending on density. Their metal foams exhibit a closed-cell structure that provides enhanced mechanical strength compared to open-cell alternatives. BASF has also developed specialized surface treatments to improve corrosion resistance and bonding capabilities with other materials. Their manufacturing process allows for the production of complex-shaped components through mold casting techniques, enabling direct integration into automotive and aerospace applications requiring both thermal management and structural support.

Strengths: Excellent energy absorption capabilities combined with good thermal insulation properties; relatively low density (0.4-0.8 g/cm³) providing weight advantages; scalable production process suitable for industrial applications; good machinability for post-processing. Weaknesses: Less uniform cell structure compared to some competing technologies; lower thermal conductivity than open-cell alternatives; potential for cell wall rupture under cyclic thermal loading; higher cost compared to traditional materials for thermal management.

Key Patents and Innovations in Metal Foam Production

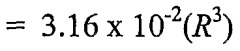

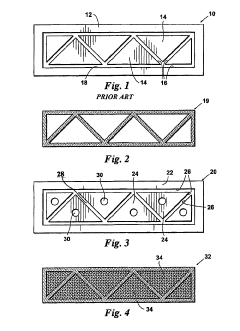

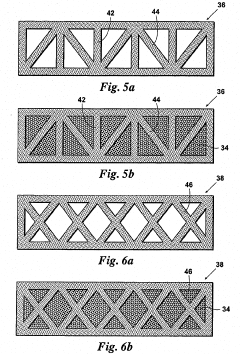

Metal foam comprising hollow metal spheres and solid matrix and methods of preparation thereof

PatentWO2006083375A2

Innovation

- Composite metal foams comprising hollow metallic spheres and a solid metal matrix, prepared through methods like powder metallurgy and casting, where the spaces around the spheres are filled with a metal matrix-forming material to create a uniformly packed and strong foam structure.

Method of producing composite members having increased strength

PatentInactiveUS20190322010A1

Innovation

- Incorporating a conformable foam core material into the extrusion process, tailored to match the coefficient of thermal expansion (CTE) of the structural material, which is injected around internal support members to enhance load-bearing capacity and overall strength, while also reducing material costs by replacing PVC volume with foam.

Material Sustainability and Recyclability Considerations

Sustainability and recyclability considerations are becoming increasingly critical in materials science, particularly for metal foams which involve significant resource utilization. Metal foams, despite their advanced properties, must be evaluated through a lifecycle perspective to ensure their environmental viability alongside their thermal and mechanical advantages.

The recyclability of metal foams varies significantly depending on the base metal and fabrication method. Aluminum-based foams offer excellent recyclability potential, with recovery rates potentially exceeding 90% when proper collection systems are implemented. In contrast, titanium foams present greater recycling challenges due to their complex processing requirements and potential contamination issues during the recycling process.

Thermal fabrication methods, including investment casting and powder metallurgy, typically consume substantial energy during production, creating a larger initial carbon footprint. However, these methods often yield foams with more consistent cell structures that maintain their properties through multiple recycling cycles. This characteristic extends the effective lifecycle of thermally fabricated foams, potentially offsetting their higher production energy requirements.

Mechanical fabrication approaches, such as gas injection and space holder methods, generally require less energy during production but may incorporate binding agents or process additives that complicate end-of-life recycling. These contaminants can reduce the quality of recovered metal or necessitate additional purification steps, diminishing the net environmental benefit.

Life Cycle Assessment (LCA) studies indicate that the sustainability advantage often depends on application context. For thermal management applications where aluminum foams replace more resource-intensive cooling systems, the net environmental impact typically favors metal foams despite their production energy requirements. The extended service life and reduced operational energy consumption create favorable sustainability metrics over time.

Emerging hybrid fabrication techniques are addressing these sustainability concerns by combining the structural advantages of thermal methods with the resource efficiency of mechanical approaches. These innovations include using biodegradable space holders and developing closed-loop manufacturing systems that capture and reuse process materials.

Recent research has also focused on incorporating pre-consumer recycled metal content into foam production without compromising performance. Studies demonstrate that foams containing up to 40% recycled content can maintain comparable thermal conductivity and mechanical strength to those made from virgin materials, particularly when careful alloy composition control is maintained.

The recyclability of metal foams varies significantly depending on the base metal and fabrication method. Aluminum-based foams offer excellent recyclability potential, with recovery rates potentially exceeding 90% when proper collection systems are implemented. In contrast, titanium foams present greater recycling challenges due to their complex processing requirements and potential contamination issues during the recycling process.

Thermal fabrication methods, including investment casting and powder metallurgy, typically consume substantial energy during production, creating a larger initial carbon footprint. However, these methods often yield foams with more consistent cell structures that maintain their properties through multiple recycling cycles. This characteristic extends the effective lifecycle of thermally fabricated foams, potentially offsetting their higher production energy requirements.

Mechanical fabrication approaches, such as gas injection and space holder methods, generally require less energy during production but may incorporate binding agents or process additives that complicate end-of-life recycling. These contaminants can reduce the quality of recovered metal or necessitate additional purification steps, diminishing the net environmental benefit.

Life Cycle Assessment (LCA) studies indicate that the sustainability advantage often depends on application context. For thermal management applications where aluminum foams replace more resource-intensive cooling systems, the net environmental impact typically favors metal foams despite their production energy requirements. The extended service life and reduced operational energy consumption create favorable sustainability metrics over time.

Emerging hybrid fabrication techniques are addressing these sustainability concerns by combining the structural advantages of thermal methods with the resource efficiency of mechanical approaches. These innovations include using biodegradable space holders and developing closed-loop manufacturing systems that capture and reuse process materials.

Recent research has also focused on incorporating pre-consumer recycled metal content into foam production without compromising performance. Studies demonstrate that foams containing up to 40% recycled content can maintain comparable thermal conductivity and mechanical strength to those made from virgin materials, particularly when careful alloy composition control is maintained.

Cost-Performance Optimization Strategies

Optimizing the cost-performance ratio in metal foam fabrication requires strategic approaches that balance manufacturing expenses with desired thermal and mechanical properties. The selection of raw materials represents a significant cost factor, with aluminum being more economical than titanium or nickel-based alloys, yet offering different performance characteristics. Manufacturers can implement material substitution strategies where high-cost materials are used only in critical sections while utilizing more affordable alternatives elsewhere.

Production scale economies significantly impact unit costs. Large-scale production reduces per-unit expenses through better resource utilization and equipment amortization. However, this must be balanced against market demand to avoid overproduction. Hybrid manufacturing approaches that combine different fabrication methods can optimize both cost and performance metrics. For instance, combining powder metallurgy for structural integrity with investment casting for complex geometries may yield superior cost-performance outcomes.

Process parameter optimization represents another crucial strategy. Fine-tuning parameters such as sintering temperature, foaming agent concentration, and cooling rates can significantly enhance property-to-cost ratios. Advanced simulation tools enable manufacturers to predict outcomes before physical production, reducing costly trial-and-error iterations. Additionally, implementing quality control systems that identify defects early in the production process minimizes waste and rework expenses.

Recycling and material recovery systems offer substantial cost benefits, particularly for expensive metal powders. Establishing closed-loop manufacturing systems where scrap material is reprocessed can reduce raw material costs by 15-30%. Furthermore, energy efficiency improvements in high-temperature processes like sintering and casting directly translate to cost savings while potentially enhancing product quality through more consistent thermal profiles.

Design optimization using computational methods represents a forward-looking strategy. Topology optimization algorithms can identify designs that maximize performance while minimizing material usage. This approach is particularly valuable for high-value applications where performance justifies additional design costs. Finally, strategic outsourcing of non-critical components or process steps to specialized manufacturers can leverage external expertise while maintaining control over core technologies and intellectual property.

Production scale economies significantly impact unit costs. Large-scale production reduces per-unit expenses through better resource utilization and equipment amortization. However, this must be balanced against market demand to avoid overproduction. Hybrid manufacturing approaches that combine different fabrication methods can optimize both cost and performance metrics. For instance, combining powder metallurgy for structural integrity with investment casting for complex geometries may yield superior cost-performance outcomes.

Process parameter optimization represents another crucial strategy. Fine-tuning parameters such as sintering temperature, foaming agent concentration, and cooling rates can significantly enhance property-to-cost ratios. Advanced simulation tools enable manufacturers to predict outcomes before physical production, reducing costly trial-and-error iterations. Additionally, implementing quality control systems that identify defects early in the production process minimizes waste and rework expenses.

Recycling and material recovery systems offer substantial cost benefits, particularly for expensive metal powders. Establishing closed-loop manufacturing systems where scrap material is reprocessed can reduce raw material costs by 15-30%. Furthermore, energy efficiency improvements in high-temperature processes like sintering and casting directly translate to cost savings while potentially enhancing product quality through more consistent thermal profiles.

Design optimization using computational methods represents a forward-looking strategy. Topology optimization algorithms can identify designs that maximize performance while minimizing material usage. This approach is particularly valuable for high-value applications where performance justifies additional design costs. Finally, strategic outsourcing of non-critical components or process steps to specialized manufacturers can leverage external expertise while maintaining control over core technologies and intellectual property.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!