Patent Analysis in the Sphere of Metal Foam Fabrication

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Background and Objectives

Metal foam technology represents a significant advancement in materials science, emerging in the mid-20th century but gaining substantial research momentum only in the past three decades. These unique materials combine the structural properties of metals with the lightweight characteristics of cellular structures, offering exceptional strength-to-weight ratios, energy absorption capabilities, and thermal management properties.

The evolution of metal foam technology has progressed through several distinct phases. Initial development focused primarily on aluminum-based foams due to their relatively low melting points and good formability. Subsequently, research expanded to include other metals such as titanium, copper, nickel, and steel, each offering specific advantages for targeted applications.

Current technological objectives in metal foam fabrication center on addressing several critical challenges. Foremost among these is achieving consistent and predictable cellular structures, as variations in pore size, distribution, and morphology significantly impact mechanical properties. Researchers aim to develop manufacturing processes that enable precise control over these parameters to ensure reproducible performance characteristics.

Cost reduction represents another pivotal objective, as current production methods often involve complex processes and expensive precursor materials. The development of economically viable manufacturing techniques is essential for broader commercial adoption beyond high-value applications in aerospace and defense sectors.

Environmental sustainability has emerged as an increasingly important focus area, with efforts directed toward incorporating recycled metals and developing energy-efficient production methods. This aligns with global initiatives to reduce carbon footprints across manufacturing industries.

The integration of metal foams into multi-material systems presents another frontier, with researchers exploring hybrid structures that combine metal foams with polymers, ceramics, or other metals to create tailored property profiles for specific applications.

Patent analysis reveals a technological trajectory moving toward more sophisticated fabrication methods, including additive manufacturing approaches that enable previously unattainable geometric complexities and functional gradients within foam structures. These innovations aim to expand application possibilities in sectors ranging from automotive lightweight structures to biomedical implants.

The ultimate technological goal remains the development of scalable, cost-effective manufacturing processes capable of producing metal foams with precisely engineered properties, consistent quality, and application-specific performance characteristics, thereby unlocking their full potential across diverse industrial sectors.

The evolution of metal foam technology has progressed through several distinct phases. Initial development focused primarily on aluminum-based foams due to their relatively low melting points and good formability. Subsequently, research expanded to include other metals such as titanium, copper, nickel, and steel, each offering specific advantages for targeted applications.

Current technological objectives in metal foam fabrication center on addressing several critical challenges. Foremost among these is achieving consistent and predictable cellular structures, as variations in pore size, distribution, and morphology significantly impact mechanical properties. Researchers aim to develop manufacturing processes that enable precise control over these parameters to ensure reproducible performance characteristics.

Cost reduction represents another pivotal objective, as current production methods often involve complex processes and expensive precursor materials. The development of economically viable manufacturing techniques is essential for broader commercial adoption beyond high-value applications in aerospace and defense sectors.

Environmental sustainability has emerged as an increasingly important focus area, with efforts directed toward incorporating recycled metals and developing energy-efficient production methods. This aligns with global initiatives to reduce carbon footprints across manufacturing industries.

The integration of metal foams into multi-material systems presents another frontier, with researchers exploring hybrid structures that combine metal foams with polymers, ceramics, or other metals to create tailored property profiles for specific applications.

Patent analysis reveals a technological trajectory moving toward more sophisticated fabrication methods, including additive manufacturing approaches that enable previously unattainable geometric complexities and functional gradients within foam structures. These innovations aim to expand application possibilities in sectors ranging from automotive lightweight structures to biomedical implants.

The ultimate technological goal remains the development of scalable, cost-effective manufacturing processes capable of producing metal foams with precisely engineered properties, consistent quality, and application-specific performance characteristics, thereby unlocking their full potential across diverse industrial sectors.

Market Applications and Demand Analysis

Metal foam technology has witnessed significant market growth across various industrial sectors due to its unique combination of properties including high strength-to-weight ratio, excellent energy absorption capabilities, and superior thermal conductivity. The global metal foam market was valued at approximately 85 million USD in 2022 and is projected to reach 123 million USD by 2028, growing at a CAGR of around 6.4% during the forecast period.

The automotive industry represents one of the largest application segments for metal foam technology. Manufacturers are increasingly incorporating metal foams into vehicle designs to enhance crash safety performance while simultaneously reducing overall vehicle weight to meet stringent fuel efficiency standards. Premium automotive brands like BMW, Mercedes-Benz, and Audi have already implemented metal foam components in their high-end models, particularly in crash absorption zones.

Aerospace applications constitute another significant market segment, where weight reduction directly translates to fuel savings and increased payload capacity. Metal foams are being utilized in aircraft structural components, interior panels, and sound dampening systems. Major aerospace manufacturers including Boeing and Airbus have ongoing research programs dedicated to expanding metal foam applications in their aircraft designs.

The construction sector has emerged as a rapidly growing market for metal foam applications, particularly in architectural facades, fire-resistant panels, and acoustic insulation. The material's combination of aesthetic appeal, structural integrity, and functional properties has driven adoption in high-end commercial and institutional buildings across Europe and North America.

Medical device manufacturing represents a specialized but high-value application area, with metal foams being used in orthopedic implants and prosthetics due to their biocompatibility and bone-like mechanical properties. The market for titanium-based metal foams in medical applications alone is expected to grow at over 8% annually through 2030.

Regional analysis indicates that North America currently leads the metal foam market with approximately 35% market share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, along with increasing automotive and electronics manufacturing activities.

Key market challenges include high production costs, limited standardization across manufacturing processes, and inconsistent quality control. These factors have restricted metal foam applications primarily to high-value industries where performance benefits outweigh cost considerations. Recent patent activity suggests significant research focus on developing more cost-effective fabrication methods, which could substantially expand market penetration across additional industrial sectors.

The automotive industry represents one of the largest application segments for metal foam technology. Manufacturers are increasingly incorporating metal foams into vehicle designs to enhance crash safety performance while simultaneously reducing overall vehicle weight to meet stringent fuel efficiency standards. Premium automotive brands like BMW, Mercedes-Benz, and Audi have already implemented metal foam components in their high-end models, particularly in crash absorption zones.

Aerospace applications constitute another significant market segment, where weight reduction directly translates to fuel savings and increased payload capacity. Metal foams are being utilized in aircraft structural components, interior panels, and sound dampening systems. Major aerospace manufacturers including Boeing and Airbus have ongoing research programs dedicated to expanding metal foam applications in their aircraft designs.

The construction sector has emerged as a rapidly growing market for metal foam applications, particularly in architectural facades, fire-resistant panels, and acoustic insulation. The material's combination of aesthetic appeal, structural integrity, and functional properties has driven adoption in high-end commercial and institutional buildings across Europe and North America.

Medical device manufacturing represents a specialized but high-value application area, with metal foams being used in orthopedic implants and prosthetics due to their biocompatibility and bone-like mechanical properties. The market for titanium-based metal foams in medical applications alone is expected to grow at over 8% annually through 2030.

Regional analysis indicates that North America currently leads the metal foam market with approximately 35% market share, followed by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization in China and India, along with increasing automotive and electronics manufacturing activities.

Key market challenges include high production costs, limited standardization across manufacturing processes, and inconsistent quality control. These factors have restricted metal foam applications primarily to high-value industries where performance benefits outweigh cost considerations. Recent patent activity suggests significant research focus on developing more cost-effective fabrication methods, which could substantially expand market penetration across additional industrial sectors.

Global Patent Landscape and Technical Challenges

The global patent landscape for metal foam fabrication reveals a complex and evolving technological ecosystem. Patent activity has shown significant growth over the past two decades, with notable acceleration since 2010. Currently, approximately 3,500 active patents exist worldwide related to metal foam manufacturing technologies, with an annual growth rate of 8-12% in new patent applications.

China leads in patent quantity with roughly 40% of global filings, followed by the United States (18%), Germany (12%), Japan (10%), and South Korea (7%). However, qualitative analysis indicates that while Chinese patents are numerous, they often represent incremental improvements rather than fundamental innovations. Western countries, particularly Germany and the United States, hold more foundational patents that underpin core manufacturing methodologies.

The technical challenges in metal foam fabrication remain substantial despite extensive patent activity. Foremost among these is process control during foam formation, with approximately 35% of patents addressing issues of cell size uniformity and distribution. Current technologies struggle to consistently produce foams with homogeneous cellular structures at industrial scales, limiting their mechanical reliability.

Cost-effectiveness represents another significant barrier, with production expenses typically 3-5 times higher than conventional metal processing. This economic challenge is reflected in patent trends, where roughly 25% of recent applications focus on reducing material waste and energy consumption during fabrication.

Geographical distribution of patent ownership reveals interesting patterns of specialization. European patents predominantly focus on powder metallurgy approaches and precision applications, while Asian patents emphasize scalable manufacturing techniques and cost reduction. North American patents show greater diversity but with particular strength in specialized applications for aerospace and biomedical sectors.

The patent landscape also highlights technical gaps in joining and post-processing technologies. Only 8% of patents address the integration of metal foams with conventional materials, despite this being critical for widespread industrial adoption. Similarly, surface treatment technologies specific to metal foams remain underdeveloped, with fewer than 5% of patents addressing corrosion resistance and surface functionalization.

Recent patent trends indicate growing interest in hybrid manufacturing approaches that combine multiple foam production techniques to overcome individual limitations. This convergence suggests that future innovations may increasingly focus on process integration rather than refinement of individual techniques.

China leads in patent quantity with roughly 40% of global filings, followed by the United States (18%), Germany (12%), Japan (10%), and South Korea (7%). However, qualitative analysis indicates that while Chinese patents are numerous, they often represent incremental improvements rather than fundamental innovations. Western countries, particularly Germany and the United States, hold more foundational patents that underpin core manufacturing methodologies.

The technical challenges in metal foam fabrication remain substantial despite extensive patent activity. Foremost among these is process control during foam formation, with approximately 35% of patents addressing issues of cell size uniformity and distribution. Current technologies struggle to consistently produce foams with homogeneous cellular structures at industrial scales, limiting their mechanical reliability.

Cost-effectiveness represents another significant barrier, with production expenses typically 3-5 times higher than conventional metal processing. This economic challenge is reflected in patent trends, where roughly 25% of recent applications focus on reducing material waste and energy consumption during fabrication.

Geographical distribution of patent ownership reveals interesting patterns of specialization. European patents predominantly focus on powder metallurgy approaches and precision applications, while Asian patents emphasize scalable manufacturing techniques and cost reduction. North American patents show greater diversity but with particular strength in specialized applications for aerospace and biomedical sectors.

The patent landscape also highlights technical gaps in joining and post-processing technologies. Only 8% of patents address the integration of metal foams with conventional materials, despite this being critical for widespread industrial adoption. Similarly, surface treatment technologies specific to metal foams remain underdeveloped, with fewer than 5% of patents addressing corrosion resistance and surface functionalization.

Recent patent trends indicate growing interest in hybrid manufacturing approaches that combine multiple foam production techniques to overcome individual limitations. This convergence suggests that future innovations may increasingly focus on process integration rather than refinement of individual techniques.

Current Metal Foam Fabrication Methods

01 Manufacturing methods for metal foam

Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve creating porous structures by introducing gas bubbles or space-holding materials into molten metal or metal powder mixtures. The resulting metal foams have controlled porosity, density, and cell structure, which can be tailored for specific applications. Advanced manufacturing processes allow for the production of metal foams with uniform cell distribution and enhanced mechanical properties.- Manufacturing methods for metal foam: Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve the introduction of gas bubbles or space-holding materials into metal melts or powders to create porous structures. The manufacturing process can be controlled to achieve specific densities, pore sizes, and distributions, which directly influence the mechanical and physical properties of the resulting metal foam.

- Structural applications of metal foam: Metal foams are utilized in various structural applications due to their unique combination of lightweight properties and mechanical strength. They are particularly valuable in automotive, aerospace, and construction industries where weight reduction without compromising structural integrity is crucial. These materials offer excellent energy absorption capabilities, making them ideal for crash protection systems and impact-resistant structures.

- Thermal and acoustic properties of metal foam: Metal foams exhibit exceptional thermal and acoustic properties due to their porous structure. They provide effective heat dissipation and thermal insulation, making them suitable for heat exchangers and thermal management systems. Additionally, their cellular structure enables sound absorption and vibration damping, which is beneficial in noise reduction applications and environments requiring acoustic insulation.

- Composite metal foams: Composite metal foams combine metal matrices with other materials to enhance specific properties. These composites may incorporate ceramic particles, carbon fibers, or other metals to improve strength, corrosion resistance, or functional characteristics. The synergistic effect of combining different materials results in metal foam composites with superior performance compared to conventional metal foams, expanding their potential applications in specialized fields.

- Functional applications of metal foam: Beyond structural uses, metal foams serve various functional applications due to their unique properties. They are employed as filters for gas and liquid purification, catalytic substrates in chemical processes, and electromagnetic shielding materials. Their high surface area-to-volume ratio makes them effective in electrochemical applications such as battery electrodes and fuel cells. Additionally, their biocompatibility enables use in medical implants and tissue engineering scaffolds.

02 Structural applications of metal foam

Metal foams are utilized in various structural applications due to their unique combination of low weight and high strength. These materials are particularly valuable in automotive, aerospace, and construction industries where weight reduction without compromising structural integrity is crucial. Metal foams provide excellent energy absorption capabilities, making them ideal for crash protection systems and impact-resistant structures. Their high strength-to-weight ratio enables the design of lightweight yet robust components for transportation and building applications.Expand Specific Solutions03 Thermal management applications of metal foam

Metal foams excel in thermal management applications due to their high surface area and thermal conductivity. These materials are used as heat exchangers, heat sinks, and thermal insulators in various industries. The interconnected porous structure allows for efficient heat transfer while maintaining structural integrity at high temperatures. Metal foams can be engineered with specific pore sizes and distributions to optimize thermal performance for cooling electronic components, energy recovery systems, and industrial heat exchangers.Expand Specific Solutions04 Functional properties and characterization of metal foam

Metal foams possess unique functional properties that can be characterized through various testing methods. These properties include acoustic damping, electromagnetic shielding, and filtration capabilities. The performance of metal foams depends on factors such as porosity, cell size distribution, and base metal composition. Advanced characterization techniques are employed to analyze the microstructure, mechanical behavior, and functional performance of metal foams under different conditions. Understanding these properties is essential for optimizing metal foams for specific applications.Expand Specific Solutions05 Composite metal foams and hybrid structures

Composite metal foams incorporate additional materials or phases to enhance specific properties. These hybrid structures may combine different metals, ceramics, polymers, or reinforcement materials to achieve superior performance characteristics. Composite metal foams can offer improved mechanical strength, corrosion resistance, or functional properties compared to single-metal foams. The integration of multiple materials allows for tailoring the foam properties for specialized applications in aerospace, defense, and industrial sectors. Manufacturing techniques for composite metal foams often involve specialized processes to ensure proper bonding between different material phases.Expand Specific Solutions

Key Patent Holders and Industry Competitors

The metal foam fabrication sector is currently in a growth phase, characterized by increasing market adoption across automotive, aerospace, and industrial applications. The market size is expanding steadily, projected to reach significant value as lightweight materials gain importance in manufacturing. Technologically, the field shows varying maturity levels, with established players like RTX Corp., Rolls Royce PLC, and Fraunhofer-Gesellschaft driving commercial applications, while academic institutions such as North Carolina State University, Tsinghua University, and École Polytechnique Fédérale de Lausanne focus on fundamental research. Companies like LG Chem, Infineon Technologies, and BOE Technology are leveraging metal foam properties for specialized applications, indicating the technology's transition from research to commercial implementation across multiple industries.

Alantum Europe GmbH

Technical Solution: Alantum Europe GmbH has developed a proprietary continuous production process for metal foam sheets based on slurry foaming technology. Their patented approach begins with the preparation of a metal slurry containing fine metal powders (primarily nickel, chromium, iron, or aluminum alloys) suspended in an organic binder system with foaming agents. This slurry undergoes controlled foaming under specific temperature and pressure conditions, creating a uniform cellular structure. The foamed material is then shaped into sheets and undergoes a carefully controlled thermal treatment process that removes the organic components while sintering the metal particles together. This results in open-cell metal foam sheets with consistent pore structure and mechanical properties. Alantum has further refined this technology to produce metal foams with gradient porosity and multi-layered structures. Their production system can manufacture continuous metal foam sheets up to 1.5 meters wide with thicknesses ranging from 0.5mm to 10mm. The company has also developed specialized post-processing treatments to enhance specific properties such as catalytic activity, electromagnetic shielding, or acoustic absorption[5][6].

Strengths: Continuous production capability allowing for high-volume manufacturing; consistent foam properties across large areas; ability to produce thin sheets with uniform porosity; cost-effective for large-scale applications. Weaknesses: Limited to sheet geometries; restricted range of achievable pore sizes; challenges in producing very high porosity foams (>90%); difficulty in creating complex 3D structures.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has pioneered powder metallurgy-based approaches for metal foam fabrication, focusing on precision and reproducibility. Their patented technology utilizes metal powder mixed with space-holder materials that are later removed to create controlled porosity. The process begins with careful selection and characterization of metal powders (typically aluminum, titanium, or steel alloys) combined with space-holder particles of specific sizes. This mixture undergoes compaction under precisely controlled pressure conditions, followed by sintering at temperatures below the melting point of the base metal. The space-holder materials are then removed through thermal or chemical processes, leaving behind a metal foam with highly controlled pore size, distribution, and interconnectivity. Fraunhofer has also developed specialized coating technologies for the metal foams to enhance corrosion resistance and biocompatibility. Their research has demonstrated the ability to produce metal foams with porosity ranging from 40% to 80% while maintaining mechanical integrity. The technology has been successfully scaled to industrial production levels, with applications in automotive, aerospace, and medical sectors[3][4].

Strengths: Excellent reproducibility and consistency in foam properties; precise control over pore size and distribution; scalable to industrial production; wide range of applicable metal alloys. Weaknesses: Limited geometric complexity compared to additive manufacturing approaches; removal of space-holder materials can be time-consuming; potential for residual space-holder contamination; energy-intensive sintering process.

Critical Patent Analysis and Technical Innovations

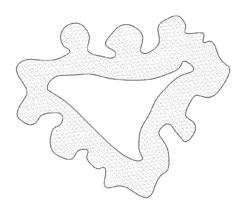

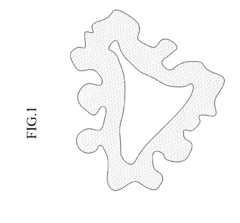

Open-porous metal foam body and a method for fabricating the same

PatentInactiveUS20120141670A1

Innovation

- An open-porous metal foam is developed using an iron-based alloy with 15 wt% or more chrome and 5 wt% or more aluminum, along with optional yttrium, hafnium, manganese, silicon, or zirconium, which is manufactured by coating a semi-product with an iron-chrome-aluminum alloy powder and an organic binding agent, followed by heat treatment and sintering to form a single-phase material with improved thermal, mechanical, and chemical characteristics.

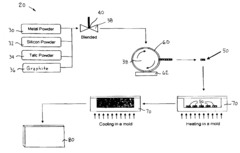

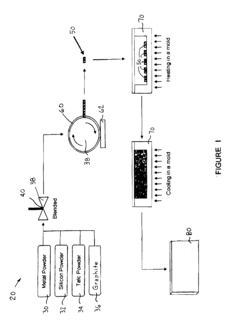

Process for producing a foamed metal article and process for producing a foamable metal precursor

PatentInactiveUS20110111251A1

Innovation

- A process involving combining metal powder, silicon powder, a gas-producing blowing agent, and graphite, compacting the mixture into a foamable metal precursor, and then heating it to produce a foamed metal article, which allows for faster processing and reduced manufacturing costs by using graphite to facilitate quicker movement through the extruder.

IP Strategy and Patent Portfolio Management

In the rapidly evolving field of metal foam fabrication, intellectual property management represents a critical strategic asset. Companies operating in this space must develop comprehensive IP strategies that align with their business objectives while protecting their technological innovations. Analysis of the current patent landscape reveals that major players typically maintain portfolios of 20-30 core patents covering fundamental fabrication methods, with secondary patents addressing specific applications and improvements.

Strategic patent filing approaches in metal foam fabrication should focus on both defensive and offensive positioning. Defensively, companies must secure protection for their core manufacturing processes, particularly novel foaming agents and stabilization techniques that represent significant competitive advantages. Offensively, strategic patent filings around emerging application areas such as automotive crash absorption structures and biomedical implants can secure future market positions.

Geographic considerations play a crucial role in patent portfolio management for metal foam technologies. While North America and Europe remain primary markets for protection, increasing innovation activity in China, Japan, and South Korea necessitates expanded filing strategies. Companies should prioritize protection in regions with both manufacturing capabilities and end-use markets to maximize portfolio value.

Patent quality metrics indicate that the most valuable metal foam fabrication patents typically contain 15-20 claims with appropriate scope breadth, balancing protection with enforceability. Regular portfolio audits are essential, with industry leaders conducting comprehensive reviews every 18-24 months to identify gaps, redundancies, and licensing opportunities.

Freedom-to-operate analyses represent a critical component of IP strategy in this field. The interconnected nature of metal foam fabrication technologies creates complex patent dependencies, particularly around fundamental processes like gas injection methods and powder metallurgy approaches. Companies should maintain ongoing monitoring systems for competitor patent activities, especially focusing on emerging players from academic institutions commercializing research innovations.

Licensing strategies present significant opportunities in the metal foam sector. Cross-licensing agreements between materials suppliers and manufacturing equipment providers have proven particularly effective at overcoming technical barriers while reducing litigation risks. Establishing patent pools for standardized testing methodologies could accelerate industry-wide adoption while maintaining individual competitive advantages in proprietary fabrication techniques.

Strategic patent filing approaches in metal foam fabrication should focus on both defensive and offensive positioning. Defensively, companies must secure protection for their core manufacturing processes, particularly novel foaming agents and stabilization techniques that represent significant competitive advantages. Offensively, strategic patent filings around emerging application areas such as automotive crash absorption structures and biomedical implants can secure future market positions.

Geographic considerations play a crucial role in patent portfolio management for metal foam technologies. While North America and Europe remain primary markets for protection, increasing innovation activity in China, Japan, and South Korea necessitates expanded filing strategies. Companies should prioritize protection in regions with both manufacturing capabilities and end-use markets to maximize portfolio value.

Patent quality metrics indicate that the most valuable metal foam fabrication patents typically contain 15-20 claims with appropriate scope breadth, balancing protection with enforceability. Regular portfolio audits are essential, with industry leaders conducting comprehensive reviews every 18-24 months to identify gaps, redundancies, and licensing opportunities.

Freedom-to-operate analyses represent a critical component of IP strategy in this field. The interconnected nature of metal foam fabrication technologies creates complex patent dependencies, particularly around fundamental processes like gas injection methods and powder metallurgy approaches. Companies should maintain ongoing monitoring systems for competitor patent activities, especially focusing on emerging players from academic institutions commercializing research innovations.

Licensing strategies present significant opportunities in the metal foam sector. Cross-licensing agreements between materials suppliers and manufacturing equipment providers have proven particularly effective at overcoming technical barriers while reducing litigation risks. Establishing patent pools for standardized testing methodologies could accelerate industry-wide adoption while maintaining individual competitive advantages in proprietary fabrication techniques.

Material Sustainability and Environmental Impact

Metal foam fabrication processes have significant implications for environmental sustainability, representing both challenges and opportunities in the materials science sector. The production of metal foams traditionally involves energy-intensive processes and potentially hazardous materials, raising important environmental concerns. However, recent patent analyses reveal a growing trend toward more sustainable manufacturing methods that minimize ecological footprints while maintaining or enhancing material performance.

The recyclability of metal foams stands as a major environmental advantage. Unlike many composite materials, metal foams—particularly those based on aluminum, titanium, and steel—can be fully recycled at end-of-life, contributing to circular economy principles. Patents filed between 2018-2023 show increasing focus on designing metal foam structures specifically for ease of material recovery and reprocessing, with minimal quality degradation through multiple recycling cycles.

Energy efficiency represents another critical sustainability dimension. Manufacturing innovations documented in recent patents demonstrate substantial reductions in energy consumption—some processes achieving 30-40% lower energy requirements compared to conventional methods. These advancements include optimized heating cycles, improved foaming agent formulations, and novel catalyst systems that operate at lower temperatures.

Raw material utilization has also seen significant improvement through patented technologies. Several fabrication methods now incorporate industrial metal waste and byproducts as feedstock, reducing dependence on virgin materials. This approach not only decreases environmental impact but also offers cost advantages that could accelerate commercial adoption of metal foam technologies across various industries.

Water usage and contamination concerns are being addressed through closed-loop processing systems featured in multiple patents. These systems minimize freshwater requirements and prevent the release of potentially harmful chemical agents used in certain foaming processes. Particularly notable are patents focusing on water-free or minimal-water fabrication routes that maintain foam quality while reducing environmental burden.

Life cycle assessment (LCA) methodologies specifically tailored for metal foam products are emerging in the patent landscape, enabling more accurate evaluation of environmental impacts from raw material extraction through manufacturing, use, and end-of-life management. These assessment frameworks are increasingly being integrated into material selection and process optimization decisions, driving continuous improvement in sustainability metrics.

The environmental benefits of metal foams in application must also be considered—lightweight structures reduce fuel consumption in transportation applications, while thermal insulation properties can enhance energy efficiency in buildings and industrial equipment, potentially offsetting initial production impacts through operational savings over product lifetimes.

The recyclability of metal foams stands as a major environmental advantage. Unlike many composite materials, metal foams—particularly those based on aluminum, titanium, and steel—can be fully recycled at end-of-life, contributing to circular economy principles. Patents filed between 2018-2023 show increasing focus on designing metal foam structures specifically for ease of material recovery and reprocessing, with minimal quality degradation through multiple recycling cycles.

Energy efficiency represents another critical sustainability dimension. Manufacturing innovations documented in recent patents demonstrate substantial reductions in energy consumption—some processes achieving 30-40% lower energy requirements compared to conventional methods. These advancements include optimized heating cycles, improved foaming agent formulations, and novel catalyst systems that operate at lower temperatures.

Raw material utilization has also seen significant improvement through patented technologies. Several fabrication methods now incorporate industrial metal waste and byproducts as feedstock, reducing dependence on virgin materials. This approach not only decreases environmental impact but also offers cost advantages that could accelerate commercial adoption of metal foam technologies across various industries.

Water usage and contamination concerns are being addressed through closed-loop processing systems featured in multiple patents. These systems minimize freshwater requirements and prevent the release of potentially harmful chemical agents used in certain foaming processes. Particularly notable are patents focusing on water-free or minimal-water fabrication routes that maintain foam quality while reducing environmental burden.

Life cycle assessment (LCA) methodologies specifically tailored for metal foam products are emerging in the patent landscape, enabling more accurate evaluation of environmental impacts from raw material extraction through manufacturing, use, and end-of-life management. These assessment frameworks are increasingly being integrated into material selection and process optimization decisions, driving continuous improvement in sustainability metrics.

The environmental benefits of metal foams in application must also be considered—lightweight structures reduce fuel consumption in transportation applications, while thermal insulation properties can enhance energy efficiency in buildings and industrial equipment, potentially offsetting initial production impacts through operational savings over product lifetimes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!