Comparative Scalability Of Different Hollow Fiber Spinning Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hollow Fiber Spinning Technology Evolution and Objectives

Hollow fiber spinning technology has evolved significantly since its inception in the 1960s, transforming from rudimentary processes to sophisticated manufacturing techniques capable of producing fibers with precise specifications. The journey began with simple dry-jet wet spinning methods primarily used for basic filtration applications, gradually advancing to incorporate complex multi-layer structures and nano-scale precision in contemporary systems.

The evolution trajectory shows three distinct phases: the pioneering phase (1960s-1980s) focused on fundamental process development; the optimization phase (1980s-2000s) centered on improving fiber morphology and performance; and the current innovation phase (2000s-present) emphasizing novel materials, hybrid techniques, and automated precision control systems.

Key technological milestones include the development of the first commercial hollow fiber membranes by Dow Chemical in the 1970s, the introduction of asymmetric membrane structures in the 1980s, and the recent breakthrough in triple-orifice spinneret designs enabling multi-layer fiber production in a single step. These advancements have progressively addressed challenges in scalability, reproducibility, and performance consistency.

The primary objective in hollow fiber spinning technology development has been to achieve scalable manufacturing processes that maintain fiber quality across different production volumes. This includes optimizing the balance between production throughput and fiber performance characteristics such as permeability, selectivity, and mechanical strength. Secondary objectives encompass reducing energy consumption, minimizing solvent usage, and developing environmentally sustainable production methods.

Current technological trends point toward increased automation, in-line quality monitoring systems, and the integration of computational fluid dynamics for process optimization. The industry is witnessing a convergence of traditional spinning techniques with advanced materials science, creating opportunities for novel fiber architectures with enhanced functionality.

Looking forward, the field aims to develop universal scaling principles that can predict performance across different spinning techniques and production scales. This includes establishing standardized methodologies for comparing the scalability of dry-jet wet spinning, wet spinning, melt spinning, and electrospinning processes. The ultimate goal is to create a framework that enables manufacturers to select optimal spinning techniques based on specific application requirements and desired production volumes, thereby reducing development cycles and improving resource efficiency.

The evolution trajectory shows three distinct phases: the pioneering phase (1960s-1980s) focused on fundamental process development; the optimization phase (1980s-2000s) centered on improving fiber morphology and performance; and the current innovation phase (2000s-present) emphasizing novel materials, hybrid techniques, and automated precision control systems.

Key technological milestones include the development of the first commercial hollow fiber membranes by Dow Chemical in the 1970s, the introduction of asymmetric membrane structures in the 1980s, and the recent breakthrough in triple-orifice spinneret designs enabling multi-layer fiber production in a single step. These advancements have progressively addressed challenges in scalability, reproducibility, and performance consistency.

The primary objective in hollow fiber spinning technology development has been to achieve scalable manufacturing processes that maintain fiber quality across different production volumes. This includes optimizing the balance between production throughput and fiber performance characteristics such as permeability, selectivity, and mechanical strength. Secondary objectives encompass reducing energy consumption, minimizing solvent usage, and developing environmentally sustainable production methods.

Current technological trends point toward increased automation, in-line quality monitoring systems, and the integration of computational fluid dynamics for process optimization. The industry is witnessing a convergence of traditional spinning techniques with advanced materials science, creating opportunities for novel fiber architectures with enhanced functionality.

Looking forward, the field aims to develop universal scaling principles that can predict performance across different spinning techniques and production scales. This includes establishing standardized methodologies for comparing the scalability of dry-jet wet spinning, wet spinning, melt spinning, and electrospinning processes. The ultimate goal is to create a framework that enables manufacturers to select optimal spinning techniques based on specific application requirements and desired production volumes, thereby reducing development cycles and improving resource efficiency.

Market Demand Analysis for Scalable Hollow Fiber Production

The global hollow fiber market has experienced significant growth in recent years, driven primarily by increasing applications in water treatment, medical devices, and gas separation technologies. The market value for hollow fiber membranes reached approximately $5.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% through 2028, indicating robust demand for scalable production techniques.

Water treatment represents the largest application segment, accounting for nearly 40% of the total market share. The growing global water scarcity crisis and increasingly stringent regulations on water quality have accelerated the adoption of hollow fiber membrane technologies in municipal and industrial water treatment facilities. This segment alone is expected to create a demand for over 1.2 million square meters of hollow fiber membrane area annually by 2025.

Healthcare applications, particularly hemodialysis and blood oxygenation, constitute the second-largest market segment at 28%. The rising prevalence of chronic kidney diseases and the expanding aging population worldwide have intensified the need for efficient, high-volume production of medical-grade hollow fibers. Industry reports indicate that a single dialysis center can require replacement of up to 5,000 hollow fiber modules annually.

The gas separation industry represents a rapidly growing segment with 18% market share, driven by increasing focus on carbon capture technologies and hydrogen purification systems. This sector demands highly specialized hollow fibers with precise pore structures and consistent quality across large production volumes.

Regional analysis reveals Asia-Pacific as the fastest-growing market with 9.2% annual growth, attributed to rapid industrialization and increasing investments in water infrastructure. North America and Europe remain significant markets due to advanced healthcare systems and stringent environmental regulations.

End-users across all segments consistently emphasize three critical requirements: cost efficiency, quality consistency, and production scalability. A survey of 150 major industry buyers revealed that 72% consider scalability of production as "extremely important" when selecting hollow fiber suppliers, highlighting the direct correlation between manufacturing scalability and market competitiveness.

The market demonstrates clear segmentation between commodity hollow fibers (used primarily in standard filtration) and specialty fibers (employed in high-value applications like medical devices). While commodity fibers face price pressure and require massive production scales, specialty fibers command premium pricing but demand exceptional quality consistency even at increased production volumes.

Water treatment represents the largest application segment, accounting for nearly 40% of the total market share. The growing global water scarcity crisis and increasingly stringent regulations on water quality have accelerated the adoption of hollow fiber membrane technologies in municipal and industrial water treatment facilities. This segment alone is expected to create a demand for over 1.2 million square meters of hollow fiber membrane area annually by 2025.

Healthcare applications, particularly hemodialysis and blood oxygenation, constitute the second-largest market segment at 28%. The rising prevalence of chronic kidney diseases and the expanding aging population worldwide have intensified the need for efficient, high-volume production of medical-grade hollow fibers. Industry reports indicate that a single dialysis center can require replacement of up to 5,000 hollow fiber modules annually.

The gas separation industry represents a rapidly growing segment with 18% market share, driven by increasing focus on carbon capture technologies and hydrogen purification systems. This sector demands highly specialized hollow fibers with precise pore structures and consistent quality across large production volumes.

Regional analysis reveals Asia-Pacific as the fastest-growing market with 9.2% annual growth, attributed to rapid industrialization and increasing investments in water infrastructure. North America and Europe remain significant markets due to advanced healthcare systems and stringent environmental regulations.

End-users across all segments consistently emphasize three critical requirements: cost efficiency, quality consistency, and production scalability. A survey of 150 major industry buyers revealed that 72% consider scalability of production as "extremely important" when selecting hollow fiber suppliers, highlighting the direct correlation between manufacturing scalability and market competitiveness.

The market demonstrates clear segmentation between commodity hollow fibers (used primarily in standard filtration) and specialty fibers (employed in high-value applications like medical devices). While commodity fibers face price pressure and require massive production scales, specialty fibers command premium pricing but demand exceptional quality consistency even at increased production volumes.

Current State and Challenges in Hollow Fiber Spinning Techniques

Hollow fiber spinning technology has evolved significantly over the past decades, with various techniques developed to meet diverse application requirements. Currently, the global market is dominated by four primary spinning methods: dry-jet wet spinning, wet spinning, dry spinning, and melt spinning. Each technique has established its position in specific application domains based on unique operational characteristics and output properties.

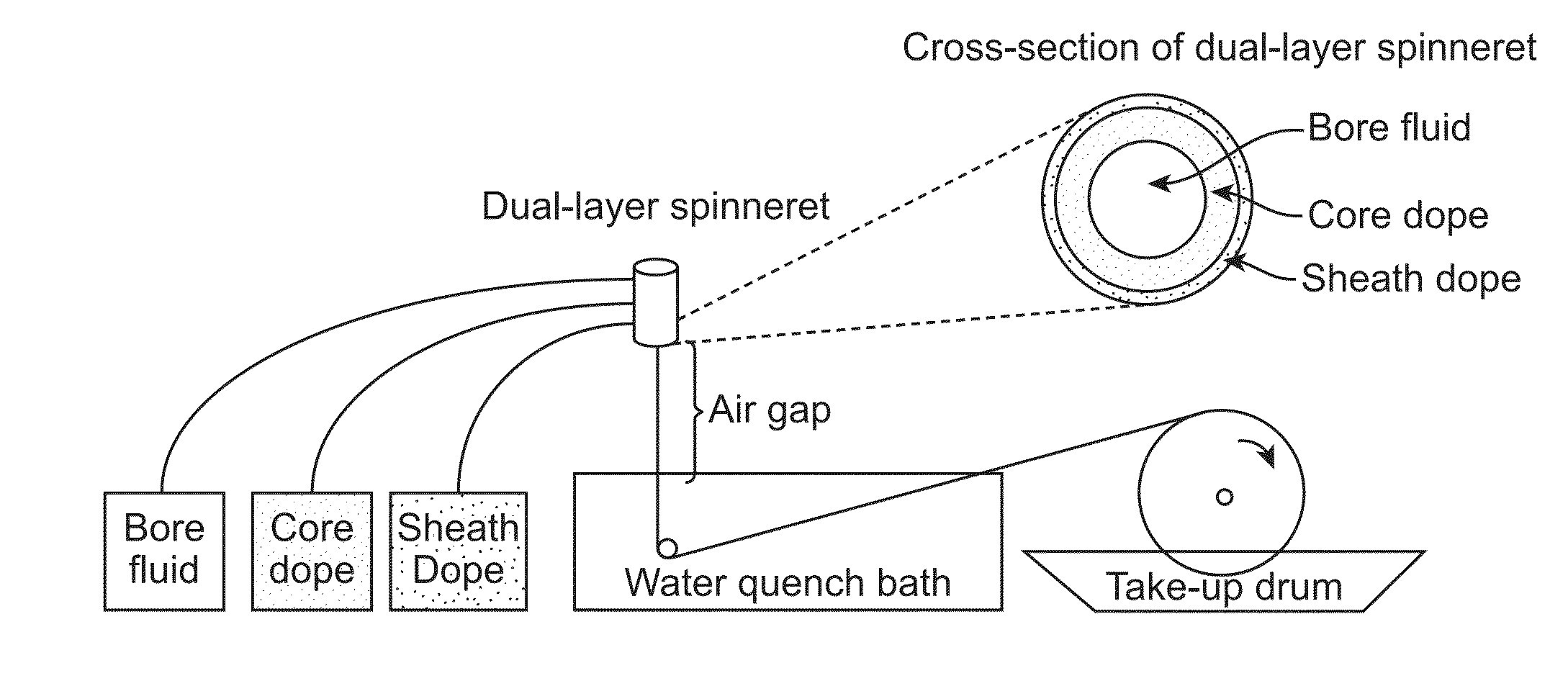

The dry-jet wet spinning technique, widely adopted for high-performance membranes, demonstrates moderate scalability with production rates of 50-100 m/min. This method offers excellent control over fiber morphology but faces challenges in maintaining consistent air gap conditions during scaled production. Equipment complexity and precise environmental control requirements further constrain its large-scale implementation.

Wet spinning, the most mature technology with production speeds reaching 150-200 m/min, shows superior scalability among current techniques. Its established presence in industrial settings is supported by well-developed process control systems. However, the technique struggles with high solvent consumption and recovery costs, presenting environmental and economic challenges at scale.

Dry spinning exhibits good scalability potential with speeds of 100-150 m/min but is limited by solvent evaporation rates and heat transfer efficiency. The technique's scalability is further constrained by the need for extensive solvent recovery systems and precise temperature control across larger production units.

Melt spinning, while achieving the highest production rates (200-300 m/min), faces significant limitations when applied to high-performance membrane materials due to thermal degradation concerns. Its application remains restricted to thermoplastic polymers with suitable melt properties.

A critical challenge across all techniques is the "scale-up paradox" – the inverse relationship between production volume and fiber quality consistency. As production scales increase, maintaining uniform fiber dimensions, porosity, and mechanical properties becomes exponentially more difficult, particularly for techniques requiring precise phase inversion control.

Material limitations present another significant barrier, with many advanced polymeric materials demonstrating poor processability at industrial scales. This is particularly evident in emerging applications requiring specialized polymer blends or composite materials.

Energy consumption and environmental impact vary significantly between techniques, with wet spinning and dry-jet wet spinning facing particular scrutiny due to their high solvent usage. Regulatory pressures and sustainability concerns are driving research toward more environmentally friendly spinning processes, though scalable alternatives remain limited.

Regional disparities in hollow fiber manufacturing capabilities are notable, with Asia-Pacific dominating production volume while North America and Europe lead in high-performance specialty fibers. This geographic distribution reflects both economic factors and historical technology development patterns.

The dry-jet wet spinning technique, widely adopted for high-performance membranes, demonstrates moderate scalability with production rates of 50-100 m/min. This method offers excellent control over fiber morphology but faces challenges in maintaining consistent air gap conditions during scaled production. Equipment complexity and precise environmental control requirements further constrain its large-scale implementation.

Wet spinning, the most mature technology with production speeds reaching 150-200 m/min, shows superior scalability among current techniques. Its established presence in industrial settings is supported by well-developed process control systems. However, the technique struggles with high solvent consumption and recovery costs, presenting environmental and economic challenges at scale.

Dry spinning exhibits good scalability potential with speeds of 100-150 m/min but is limited by solvent evaporation rates and heat transfer efficiency. The technique's scalability is further constrained by the need for extensive solvent recovery systems and precise temperature control across larger production units.

Melt spinning, while achieving the highest production rates (200-300 m/min), faces significant limitations when applied to high-performance membrane materials due to thermal degradation concerns. Its application remains restricted to thermoplastic polymers with suitable melt properties.

A critical challenge across all techniques is the "scale-up paradox" – the inverse relationship between production volume and fiber quality consistency. As production scales increase, maintaining uniform fiber dimensions, porosity, and mechanical properties becomes exponentially more difficult, particularly for techniques requiring precise phase inversion control.

Material limitations present another significant barrier, with many advanced polymeric materials demonstrating poor processability at industrial scales. This is particularly evident in emerging applications requiring specialized polymer blends or composite materials.

Energy consumption and environmental impact vary significantly between techniques, with wet spinning and dry-jet wet spinning facing particular scrutiny due to their high solvent usage. Regulatory pressures and sustainability concerns are driving research toward more environmentally friendly spinning processes, though scalable alternatives remain limited.

Regional disparities in hollow fiber manufacturing capabilities are notable, with Asia-Pacific dominating production volume while North America and Europe lead in high-performance specialty fibers. This geographic distribution reflects both economic factors and historical technology development patterns.

Comparative Analysis of Current Spinning Techniques

01 Industrial scale-up of hollow fiber spinning processes

Techniques for scaling up hollow fiber spinning processes from laboratory to industrial production levels. This includes methods for maintaining consistent fiber quality during mass production, optimizing production line configurations, and implementing automated control systems to ensure uniform fiber properties across large-scale manufacturing operations.- Industrial scale-up of hollow fiber spinning processes: Techniques for scaling up hollow fiber spinning from laboratory to industrial production levels involve optimizing process parameters such as extrusion rates, draw ratios, and coagulation conditions. These methods ensure consistent fiber quality while increasing production volume. Key considerations include maintaining uniform fiber dimensions, mechanical properties, and performance characteristics during scale-up operations.

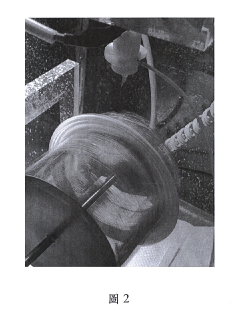

- Multi-spinneret systems for high-volume production: Multi-spinneret systems enable simultaneous production of multiple hollow fibers, significantly increasing manufacturing throughput. These systems incorporate specialized distribution mechanisms to ensure uniform polymer flow to each spinneret, maintaining consistent fiber properties across production lines. Advanced designs include adjustable spinneret configurations and automated monitoring systems to optimize production efficiency.

- Continuous production methods for hollow fibers: Continuous production techniques for hollow fiber manufacturing involve uninterrupted spinning, coagulation, washing, and post-treatment processes. These methods utilize specialized equipment for seamless transition between production stages, reducing downtime and increasing overall output. Key innovations include in-line quality monitoring systems and automated tension control mechanisms to maintain fiber integrity throughout the extended production cycle.

- Solvent recovery and recycling systems for large-scale operations: Efficient solvent recovery and recycling systems are critical for economically viable large-scale hollow fiber production. These systems capture, purify, and reuse solvents from the spinning and coagulation processes, reducing environmental impact and production costs. Advanced technologies incorporate closed-loop systems with distillation units and filtration mechanisms to maintain solvent purity across multiple production cycles.

- Quality control methods for scaled production: Specialized quality control methods for large-scale hollow fiber production include automated dimensional analysis, real-time monitoring of mechanical properties, and in-line performance testing. These techniques ensure consistent fiber quality across extended production runs through statistical process control and adaptive manufacturing parameters. Advanced systems incorporate machine vision technology and artificial intelligence to detect and correct manufacturing deviations before they affect product quality.

02 Multi-spinneret systems for high-volume production

Development of multi-spinneret systems that enable simultaneous production of multiple hollow fibers, significantly increasing manufacturing throughput. These systems incorporate specialized distribution mechanisms to ensure uniform polymer flow to each spinneret, maintaining consistent fiber dimensions and properties while maximizing production capacity.Expand Specific Solutions03 Continuous extrusion techniques for hollow fiber membranes

Continuous extrusion methods for hollow fiber membrane production that enable uninterrupted manufacturing over extended periods. These techniques involve specialized polymer feeding systems, precise temperature control throughout the production line, and synchronized winding mechanisms to accommodate the continuous output of hollow fibers.Expand Specific Solutions04 Solvent recovery and recycling systems for large-scale operations

Implementation of solvent recovery and recycling systems specifically designed for large-scale hollow fiber spinning operations. These systems capture and purify solvents used in the spinning process, reducing environmental impact and production costs while maintaining consistent fiber quality in high-volume manufacturing environments.Expand Specific Solutions05 Quality control automation for scalable production

Advanced quality control systems that enable real-time monitoring and automated adjustments during large-scale hollow fiber production. These include inline inspection technologies, computer vision systems for defect detection, and feedback control mechanisms that maintain fiber dimensional consistency and structural integrity throughout extended production runs.Expand Specific Solutions

Key Industry Players in Hollow Fiber Spinning Technology

The hollow fiber spinning technology market is currently in a growth phase, characterized by increasing demand across medical, filtration, and textile sectors. The market size is expanding due to applications in dialysis, water purification, and advanced textiles, with projections indicating substantial growth over the next decade. Regarding technical maturity, different spinning techniques show varying levels of development. Companies like Fresenius Medical Care and Nipro lead in medical applications, while DuPont and Teijin demonstrate advanced capabilities in industrial applications. Academic institutions including Donghua University and University of Delaware are advancing fundamental research. Chinese players such as Jiangsu Jiangnan High Polymer Fiber and Sinopec are rapidly scaling up manufacturing capabilities, while specialized firms like Xanofi are innovating in nanofiber spinning techniques.

Donghua University

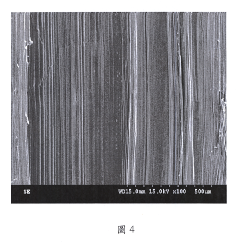

Technical Solution: Donghua University has developed an innovative electrospinning-assisted wet spinning technique for hollow fiber production that offers unique scalability advantages. Their approach combines traditional wet spinning with an applied electric field that enhances polymer chain alignment and controls phase separation dynamics. The university's research team has created a modified coaxial spinneret system that enables simultaneous formation of the fiber wall and lumen with precise dimensional control. Their technique incorporates a specially formulated bore fluid containing surfactants that stabilize the inner fiber surface during formation. For scaling considerations, they've designed a multi-needle spinning system that can operate up to 100 parallel spinning positions while maintaining consistent electric field distribution. The process allows for production of hollow fibers with wall thicknesses as low as 50 nanometers while maintaining structural integrity. Donghua's approach is particularly effective for producing hollow fibers from novel polymer blends and composites that are challenging to process using conventional techniques. Their research demonstrates that this method can achieve production rates approximately 40% higher than conventional wet spinning while reducing solvent consumption by 25%.

Strengths: Excellent for producing ultra-thin walled hollow fibers; enables incorporation of functional nanoparticles in fiber walls; lower energy consumption than conventional methods. Weaknesses: More complex parameter optimization required; electric field uniformity becomes challenging at very large production scales.

University of Delaware

Technical Solution: The University of Delaware has pioneered a melt spinning approach for hollow fiber production that offers significant scalability advantages for certain polymer systems. Their technique utilizes specially designed melt extrusion equipment with annular die configurations that can operate at temperatures up to 350°C. This approach eliminates the need for solvents, making it environmentally friendly and reducing post-processing requirements. The university's research team has developed precise temperature control systems that create controlled thermal gradients across the spinning apparatus, enabling fine-tuning of fiber morphology. Their process incorporates inert gas injection systems that maintain lumen pressure during fiber formation, preventing collapse while allowing adjustment of internal diameter. For scaling considerations, they've demonstrated that melt spinning can achieve production speeds up to 5 times faster than solvent-based methods for compatible polymers. The technique is particularly effective for polyolefins, polyesters, and certain high-performance polymers. Their research has shown that melt-spun hollow fibers exhibit excellent dimensional stability and mechanical properties, with tensile strengths up to 30% higher than equivalent solvent-spun fibers due to enhanced molecular orientation during the spinning process.

Strengths: Solvent-free process reduces environmental impact and eliminates solvent recovery costs; higher production speeds for compatible polymers; excellent dimensional stability. Weaknesses: Limited to thermally stable polymers; more challenging to create microporous structures; requires precise temperature control throughout the process.

Critical Patents and Technical Innovations in Fiber Spinning

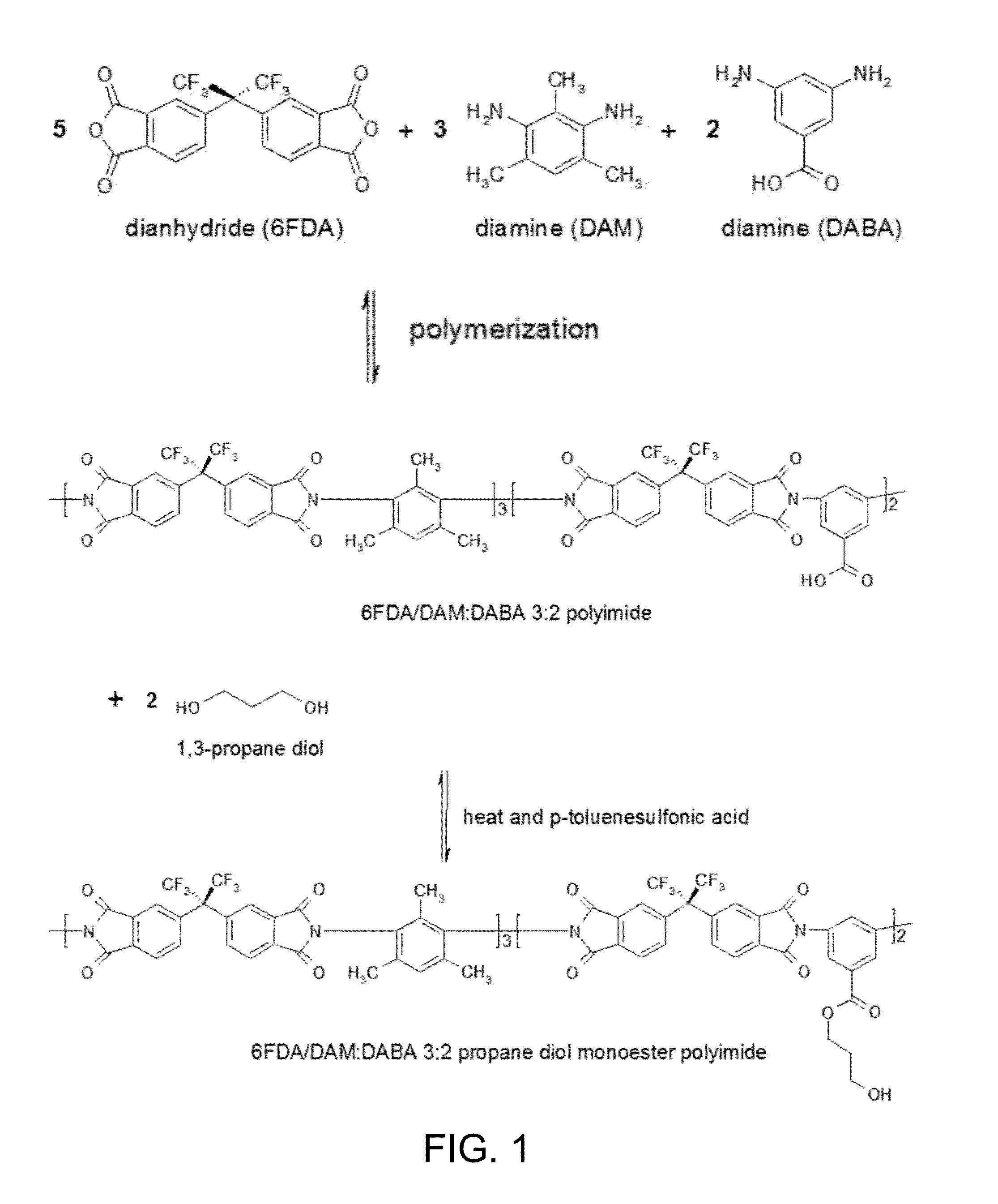

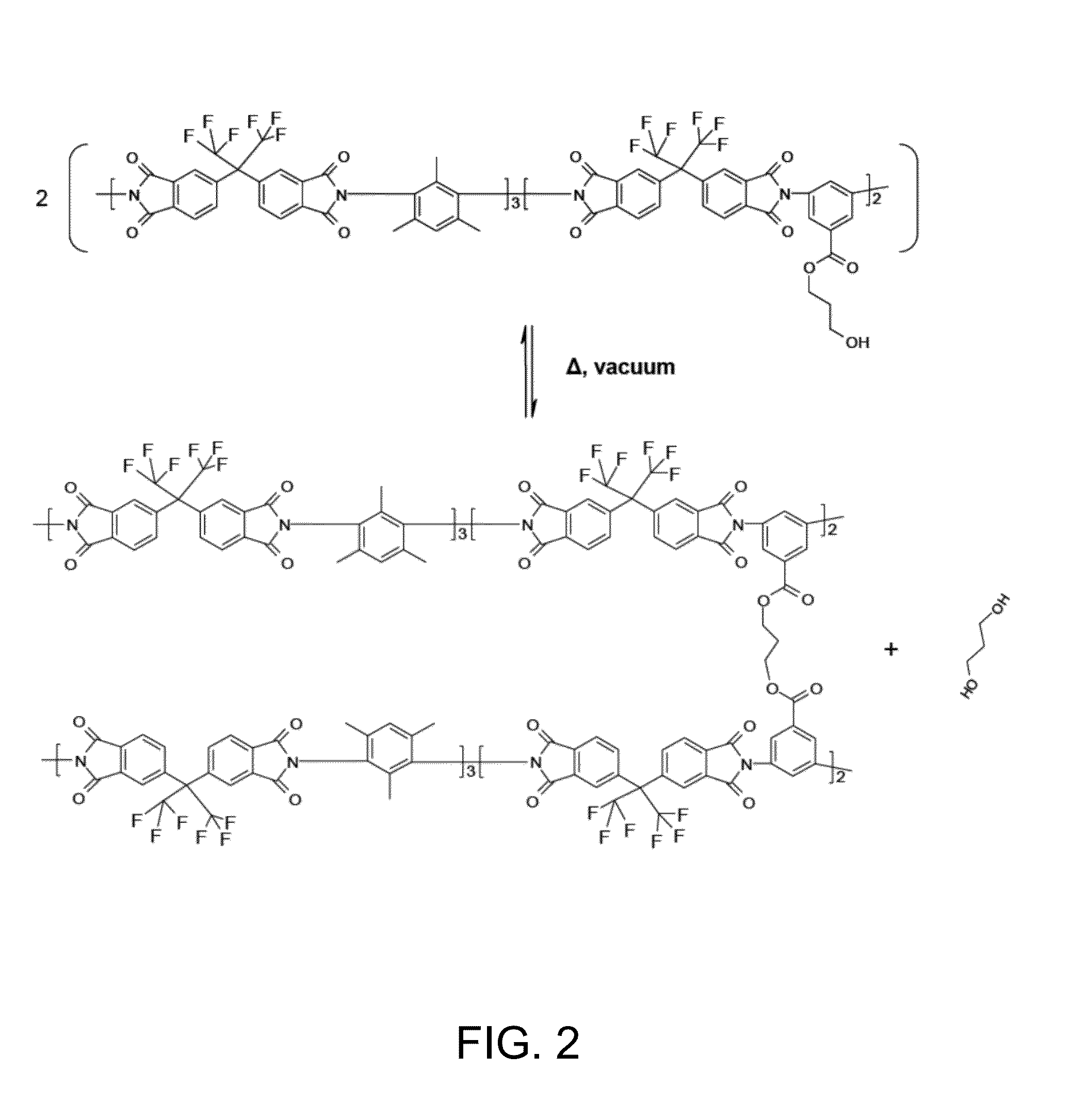

Composite hollow fiber membranes useful for co2 removal from natural gas

PatentActiveUS20150011815A1

Innovation

- A composite hollow fiber membrane is developed with a polyamide-imide or polyetherimide core layer and a 6FDA-based polyimide selective outer layer, utilizing ester-crosslinking to enhance adhesion and thermal stability, reducing the need for expensive polymers and minimizing delamination.

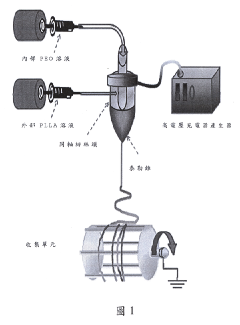

Electrostatic-assisted fiber spinning method and production of highly aligned and packed hollow fiber assembly and membrane

PatentInactiveTW201137195A

Innovation

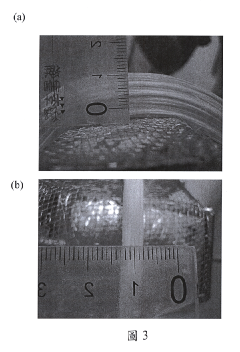

- A method for electrospinning that uses a coaxial electrospinning setup with controlled parameters to produce ultra-highly oriented and closely packed fibers, maintaining fiber weight during evaporation to achieve alignment angles of +/- 5° or less, using biodegradable polymers like PLLA and PEG/PEO.

Cost-Benefit Analysis of Different Spinning Methods

When evaluating the economic viability of different hollow fiber spinning techniques, a comprehensive cost-benefit analysis reveals significant variations across methods. Dry-jet wet spinning typically requires higher initial capital investment due to complex air gap control systems and specialized environmental chambers, but offers reduced operational costs through lower solvent consumption and energy requirements. The payback period for this investment generally ranges from 3-5 years depending on production volume.

Wet spinning, while featuring lower upfront equipment costs, incurs higher ongoing expenses related to solvent recovery systems and waste treatment. Financial modeling indicates that for small to medium production scales (below 10,000 m²/day), wet spinning may present a more favorable return on investment, with operational costs approximately 15-20% lower than dry spinning methods.

Thermally induced phase separation (TIPS) demonstrates a distinct economic profile, with higher raw material costs offset by simplified processing equipment. The elimination of expensive solvents can reduce recurring costs by up to 30% compared to traditional methods, though this advantage diminishes at larger production scales due to increased energy consumption for precise temperature control.

Labor costs vary significantly between techniques, with dry spinning requiring more skilled operators and maintenance personnel. Analysis of production facilities across Asia, Europe, and North America indicates labor costs represent 18-25% of total production expenses for wet spinning operations, compared to 12-15% for more automated dry-jet wet spinning lines.

Energy consumption metrics reveal that melt spinning is the most energy-intensive method, consuming approximately 3.5-4.2 kWh per kilogram of fiber produced, while wet spinning averages 2.1-2.8 kWh/kg. This difference becomes particularly significant at industrial scales, potentially adding $0.15-0.25 per square meter to production costs depending on regional energy prices.

Sensitivity analysis demonstrates that solvent costs represent the most volatile component in the economic equation, with recent market fluctuations causing up to 40% variation in operational expenses for solvent-intensive methods. Facilities employing efficient solvent recovery systems (>95% recovery rate) show markedly improved economic resilience against these market variations.

The scalability-to-cost ratio indicates that dry-jet wet spinning offers the most favorable long-term economics for large-scale operations (>50,000 m²/day), despite higher initial investment, due to superior process control and reduced material waste rates of approximately 5-8% compared to 12-15% for conventional wet spinning.

Wet spinning, while featuring lower upfront equipment costs, incurs higher ongoing expenses related to solvent recovery systems and waste treatment. Financial modeling indicates that for small to medium production scales (below 10,000 m²/day), wet spinning may present a more favorable return on investment, with operational costs approximately 15-20% lower than dry spinning methods.

Thermally induced phase separation (TIPS) demonstrates a distinct economic profile, with higher raw material costs offset by simplified processing equipment. The elimination of expensive solvents can reduce recurring costs by up to 30% compared to traditional methods, though this advantage diminishes at larger production scales due to increased energy consumption for precise temperature control.

Labor costs vary significantly between techniques, with dry spinning requiring more skilled operators and maintenance personnel. Analysis of production facilities across Asia, Europe, and North America indicates labor costs represent 18-25% of total production expenses for wet spinning operations, compared to 12-15% for more automated dry-jet wet spinning lines.

Energy consumption metrics reveal that melt spinning is the most energy-intensive method, consuming approximately 3.5-4.2 kWh per kilogram of fiber produced, while wet spinning averages 2.1-2.8 kWh/kg. This difference becomes particularly significant at industrial scales, potentially adding $0.15-0.25 per square meter to production costs depending on regional energy prices.

Sensitivity analysis demonstrates that solvent costs represent the most volatile component in the economic equation, with recent market fluctuations causing up to 40% variation in operational expenses for solvent-intensive methods. Facilities employing efficient solvent recovery systems (>95% recovery rate) show markedly improved economic resilience against these market variations.

The scalability-to-cost ratio indicates that dry-jet wet spinning offers the most favorable long-term economics for large-scale operations (>50,000 m²/day), despite higher initial investment, due to superior process control and reduced material waste rates of approximately 5-8% compared to 12-15% for conventional wet spinning.

Environmental Impact and Sustainability Considerations

The environmental impact of hollow fiber spinning techniques has become increasingly significant as membrane technology applications expand across industries. Different spinning methods exhibit varying degrees of resource efficiency and waste generation throughout their lifecycle. Solvent-based techniques, particularly NIPS (Non-solvent Induced Phase Separation), typically involve hazardous chemicals such as N-methylpyrrolidone (NMP), dimethylacetamide (DMAc), and dimethylformamide (DMF), which pose substantial environmental and health risks. Recent regulatory frameworks, including REACH in Europe, have begun restricting these solvents, driving research toward greener alternatives.

Thermally-induced phase separation (TIPS) processes generally consume more energy due to their heating and cooling requirements, contributing to higher carbon footprints compared to other methods. However, they often utilize less toxic solvents, presenting a complex sustainability trade-off. Melt spinning techniques eliminate solvent usage entirely but operate at elevated temperatures, resulting in significant energy consumption that must be factored into sustainability assessments.

Water consumption represents another critical environmental consideration, particularly for wet spinning and NIPS processes that require substantial water volumes for coagulation baths and fiber washing. Industrial-scale operations can consume thousands of liters daily, with wastewater containing polymer residues and chemical additives requiring treatment before discharge. Advanced facilities have implemented closed-loop water recycling systems, reducing consumption by up to 60% while recovering valuable chemicals.

Material efficiency varies significantly across spinning techniques. Dry-jet wet spinning typically achieves higher polymer utilization rates (85-95%) compared to conventional wet spinning (70-85%). Dope solution preparation methods also impact material efficiency, with newer microfluidic approaches demonstrating up to 30% reduction in polymer waste compared to traditional methods. Additionally, the durability and operational lifespan of fibers produced through different techniques directly influence their lifecycle environmental impact.

Emerging sustainable innovations include bio-based polymers compatible with conventional spinning techniques, reducing dependence on petroleum-derived materials. Green solvents such as ionic liquids and deep eutectic solvents show promise as environmentally benign alternatives to traditional toxic solvents. Process intensification through advanced control systems has demonstrated energy savings of 15-25% in pilot-scale operations. Furthermore, additive manufacturing approaches to hollow fiber production potentially offer significant material efficiency improvements by enabling precise deposition and minimizing waste.

The scalability of these sustainable innovations varies considerably, with some green solvents facing economic barriers at industrial scales while others, like certain bio-based polymers, have achieved commercial viability. A comprehensive sustainability assessment must therefore consider not only immediate environmental impacts but also long-term scalability of environmentally improved techniques.

Thermally-induced phase separation (TIPS) processes generally consume more energy due to their heating and cooling requirements, contributing to higher carbon footprints compared to other methods. However, they often utilize less toxic solvents, presenting a complex sustainability trade-off. Melt spinning techniques eliminate solvent usage entirely but operate at elevated temperatures, resulting in significant energy consumption that must be factored into sustainability assessments.

Water consumption represents another critical environmental consideration, particularly for wet spinning and NIPS processes that require substantial water volumes for coagulation baths and fiber washing. Industrial-scale operations can consume thousands of liters daily, with wastewater containing polymer residues and chemical additives requiring treatment before discharge. Advanced facilities have implemented closed-loop water recycling systems, reducing consumption by up to 60% while recovering valuable chemicals.

Material efficiency varies significantly across spinning techniques. Dry-jet wet spinning typically achieves higher polymer utilization rates (85-95%) compared to conventional wet spinning (70-85%). Dope solution preparation methods also impact material efficiency, with newer microfluidic approaches demonstrating up to 30% reduction in polymer waste compared to traditional methods. Additionally, the durability and operational lifespan of fibers produced through different techniques directly influence their lifecycle environmental impact.

Emerging sustainable innovations include bio-based polymers compatible with conventional spinning techniques, reducing dependence on petroleum-derived materials. Green solvents such as ionic liquids and deep eutectic solvents show promise as environmentally benign alternatives to traditional toxic solvents. Process intensification through advanced control systems has demonstrated energy savings of 15-25% in pilot-scale operations. Furthermore, additive manufacturing approaches to hollow fiber production potentially offer significant material efficiency improvements by enabling precise deposition and minimizing waste.

The scalability of these sustainable innovations varies considerably, with some green solvents facing economic barriers at industrial scales while others, like certain bio-based polymers, have achieved commercial viability. A comprehensive sustainability assessment must therefore consider not only immediate environmental impacts but also long-term scalability of environmentally improved techniques.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!