Comparative Study of Thermoelectric Waste Recovery and CHP Systems

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications across various industries. The fundamental principle, based on the Seebeck effect discovered in 1821, enables direct conversion of temperature differentials into electrical energy without moving parts. This technology has gained substantial attention due to its potential to enhance energy efficiency in systems where waste heat is abundant.

The historical development of thermoelectric materials shows a clear progression from early bismuth telluride compounds with ZT values below 1, to advanced nanostructured materials and quantum dot superlattices achieving ZT values exceeding 2.5. This improvement in the figure of merit (ZT) represents a critical factor in making thermoelectric waste heat recovery economically viable for commercial applications.

Current global energy consumption patterns indicate that approximately 20-50% of industrial energy input is lost as waste heat, presenting a significant opportunity for recovery technologies. The automotive sector alone dissipates roughly 60-70% of fuel energy as waste heat through exhaust gases and cooling systems, highlighting a substantial potential application area for thermoelectric generators (TEGs).

The primary objective of thermoelectric waste heat recovery research is to develop cost-effective, efficient systems capable of converting low to medium-grade waste heat (80-500°C) into usable electricity. This involves addressing multiple technical challenges including thermal management, material durability under thermal cycling, and system integration complexities.

When compared with Combined Heat and Power (CHP) systems, thermoelectric recovery offers distinct advantages in scenarios requiring compact, maintenance-free operation without moving parts. However, CHP systems typically demonstrate higher overall efficiency in large-scale applications where space constraints are less critical.

Recent technological breakthroughs in advanced manufacturing techniques, including additive manufacturing and thin-film deposition, have enabled more complex thermoelectric device architectures that optimize heat flow paths and electrical connections. These innovations are gradually reducing the cost-per-watt metric that has historically limited widespread adoption.

The global push toward carbon neutrality and increasingly stringent efficiency regulations across industries has created a favorable environment for thermoelectric waste heat recovery technologies. Market projections indicate a compound annual growth rate of approximately 8.9% through 2028, with particular acceleration in automotive, industrial processing, and power generation sectors.

This technical exploration aims to comprehensively evaluate the current state and future potential of thermoelectric waste heat recovery compared to conventional CHP systems, with specific focus on efficiency improvements, cost reduction pathways, and application-specific optimization strategies that could enable broader market penetration.

The historical development of thermoelectric materials shows a clear progression from early bismuth telluride compounds with ZT values below 1, to advanced nanostructured materials and quantum dot superlattices achieving ZT values exceeding 2.5. This improvement in the figure of merit (ZT) represents a critical factor in making thermoelectric waste heat recovery economically viable for commercial applications.

Current global energy consumption patterns indicate that approximately 20-50% of industrial energy input is lost as waste heat, presenting a significant opportunity for recovery technologies. The automotive sector alone dissipates roughly 60-70% of fuel energy as waste heat through exhaust gases and cooling systems, highlighting a substantial potential application area for thermoelectric generators (TEGs).

The primary objective of thermoelectric waste heat recovery research is to develop cost-effective, efficient systems capable of converting low to medium-grade waste heat (80-500°C) into usable electricity. This involves addressing multiple technical challenges including thermal management, material durability under thermal cycling, and system integration complexities.

When compared with Combined Heat and Power (CHP) systems, thermoelectric recovery offers distinct advantages in scenarios requiring compact, maintenance-free operation without moving parts. However, CHP systems typically demonstrate higher overall efficiency in large-scale applications where space constraints are less critical.

Recent technological breakthroughs in advanced manufacturing techniques, including additive manufacturing and thin-film deposition, have enabled more complex thermoelectric device architectures that optimize heat flow paths and electrical connections. These innovations are gradually reducing the cost-per-watt metric that has historically limited widespread adoption.

The global push toward carbon neutrality and increasingly stringent efficiency regulations across industries has created a favorable environment for thermoelectric waste heat recovery technologies. Market projections indicate a compound annual growth rate of approximately 8.9% through 2028, with particular acceleration in automotive, industrial processing, and power generation sectors.

This technical exploration aims to comprehensively evaluate the current state and future potential of thermoelectric waste heat recovery compared to conventional CHP systems, with specific focus on efficiency improvements, cost reduction pathways, and application-specific optimization strategies that could enable broader market penetration.

Market Analysis for Waste Heat Recovery Technologies

The global waste heat recovery (WHR) market is experiencing significant growth, driven by increasing energy costs, environmental regulations, and corporate sustainability initiatives. As of 2023, the market is valued at approximately 68 billion USD with projections indicating growth to reach 114 billion USD by 2030, representing a compound annual growth rate (CAGR) of 7.6%. This growth trajectory is particularly pronounced in regions with stringent emission regulations and high energy costs, such as Europe and parts of Asia.

Industrial sectors contribute the largest share to this market, with manufacturing, power generation, and chemical processing being the primary sources of waste heat. Among these, the manufacturing sector accounts for nearly 35% of the total market share, followed by power generation at 28%. The temperature range of waste heat significantly influences the technology selection, with medium to high-temperature waste heat (120°C to 650°C) offering the most economically viable recovery opportunities.

Thermoelectric waste recovery systems, which convert temperature differentials directly into electricity, currently represent about 12% of the WHR market. These systems are gaining traction due to their solid-state operation, minimal maintenance requirements, and ability to function in harsh environments. The market for thermoelectric generators specifically is growing at a CAGR of 8.9%, outpacing the overall WHR market growth.

Combined Heat and Power (CHP) systems, on the other hand, dominate with approximately 45% of the market share. These systems offer higher efficiency by simultaneously producing electricity and useful thermal energy from a single fuel source. The CHP market is more mature but continues to grow steadily at a CAGR of 6.2%, with natural gas-fired systems being the most prevalent.

Regional analysis reveals that Europe leads the WHR market with a 34% share, followed by North America (28%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization in countries like China and India, coupled with increasing awareness about energy efficiency.

Customer segmentation shows that large industrial enterprises constitute the primary adopters of WHR technologies, accounting for 65% of installations. However, there is growing interest from medium-sized enterprises as technology costs decrease and energy prices rise. The payback period for WHR investments has improved from 5-7 years a decade ago to 3-5 years currently, enhancing the economic attractiveness of these systems.

Industrial sectors contribute the largest share to this market, with manufacturing, power generation, and chemical processing being the primary sources of waste heat. Among these, the manufacturing sector accounts for nearly 35% of the total market share, followed by power generation at 28%. The temperature range of waste heat significantly influences the technology selection, with medium to high-temperature waste heat (120°C to 650°C) offering the most economically viable recovery opportunities.

Thermoelectric waste recovery systems, which convert temperature differentials directly into electricity, currently represent about 12% of the WHR market. These systems are gaining traction due to their solid-state operation, minimal maintenance requirements, and ability to function in harsh environments. The market for thermoelectric generators specifically is growing at a CAGR of 8.9%, outpacing the overall WHR market growth.

Combined Heat and Power (CHP) systems, on the other hand, dominate with approximately 45% of the market share. These systems offer higher efficiency by simultaneously producing electricity and useful thermal energy from a single fuel source. The CHP market is more mature but continues to grow steadily at a CAGR of 6.2%, with natural gas-fired systems being the most prevalent.

Regional analysis reveals that Europe leads the WHR market with a 34% share, followed by North America (28%) and Asia-Pacific (26%). However, the Asia-Pacific region is expected to witness the fastest growth rate due to rapid industrialization in countries like China and India, coupled with increasing awareness about energy efficiency.

Customer segmentation shows that large industrial enterprises constitute the primary adopters of WHR technologies, accounting for 65% of installations. However, there is growing interest from medium-sized enterprises as technology costs decrease and energy prices rise. The payback period for WHR investments has improved from 5-7 years a decade ago to 3-5 years currently, enhancing the economic attractiveness of these systems.

Current State and Challenges in Thermoelectric and CHP Systems

Thermoelectric waste heat recovery systems and Combined Heat and Power (CHP) systems represent two distinct approaches to energy efficiency enhancement, each with its own technological maturity and implementation challenges. Globally, thermoelectric technology remains in a relatively nascent stage of commercial deployment despite decades of research. Current thermoelectric materials achieve conversion efficiencies typically ranging from 5-8% in real-world applications, significantly lower than theoretical maximums due to material limitations and thermal management challenges.

The primary technical barriers for thermoelectric systems include low figure of merit (ZT) values, which rarely exceed 2 in commercially viable materials, and difficulties in maintaining temperature differentials across devices in dynamic waste heat environments. Material cost and durability under thermal cycling conditions further constrain widespread adoption, particularly in automotive and industrial applications where operating conditions are harsh.

In contrast, CHP systems represent a more mature technology with commercial implementations spanning decades. Modern CHP installations routinely achieve total system efficiencies of 60-80%, substantially outperforming conventional separate heat and power generation. However, CHP systems face their own set of challenges, including high initial capital costs, complex integration requirements with existing infrastructure, and operational constraints related to heat-to-power ratio flexibility.

Geographically, thermoelectric technology development is concentrated in research centers across North America, East Asia (particularly Japan and China), and Europe. The United States, Germany, and Japan lead in patent filings for advanced thermoelectric materials. Meanwhile, CHP system deployment shows different regional patterns, with Northern European countries like Denmark, Finland, and Germany having the highest market penetration rates due to supportive regulatory frameworks and district heating infrastructure.

Recent technological advancements in nano-structured thermoelectric materials and module designs have shown promise in laboratory settings, with some demonstrations achieving ZT values approaching 2.5. However, scaling these advances to commercial production volumes while maintaining performance remains problematic. Similarly, micro-CHP systems for residential applications face challenges in cost-effectiveness and integration with renewable energy sources.

Regulatory environments significantly impact both technologies, with carbon pricing mechanisms and energy efficiency standards increasingly favoring waste heat recovery solutions. However, inconsistent policy frameworks across regions create market uncertainties that impede investment and technological development, particularly for thermoelectric systems that require longer commercialization pathways due to their earlier stage of technological readiness.

The intersection of these technologies with digitalization presents both opportunities and challenges, as advanced monitoring and control systems can optimize performance but add complexity and cybersecurity concerns to energy infrastructure deployments.

The primary technical barriers for thermoelectric systems include low figure of merit (ZT) values, which rarely exceed 2 in commercially viable materials, and difficulties in maintaining temperature differentials across devices in dynamic waste heat environments. Material cost and durability under thermal cycling conditions further constrain widespread adoption, particularly in automotive and industrial applications where operating conditions are harsh.

In contrast, CHP systems represent a more mature technology with commercial implementations spanning decades. Modern CHP installations routinely achieve total system efficiencies of 60-80%, substantially outperforming conventional separate heat and power generation. However, CHP systems face their own set of challenges, including high initial capital costs, complex integration requirements with existing infrastructure, and operational constraints related to heat-to-power ratio flexibility.

Geographically, thermoelectric technology development is concentrated in research centers across North America, East Asia (particularly Japan and China), and Europe. The United States, Germany, and Japan lead in patent filings for advanced thermoelectric materials. Meanwhile, CHP system deployment shows different regional patterns, with Northern European countries like Denmark, Finland, and Germany having the highest market penetration rates due to supportive regulatory frameworks and district heating infrastructure.

Recent technological advancements in nano-structured thermoelectric materials and module designs have shown promise in laboratory settings, with some demonstrations achieving ZT values approaching 2.5. However, scaling these advances to commercial production volumes while maintaining performance remains problematic. Similarly, micro-CHP systems for residential applications face challenges in cost-effectiveness and integration with renewable energy sources.

Regulatory environments significantly impact both technologies, with carbon pricing mechanisms and energy efficiency standards increasingly favoring waste heat recovery solutions. However, inconsistent policy frameworks across regions create market uncertainties that impede investment and technological development, particularly for thermoelectric systems that require longer commercialization pathways due to their earlier stage of technological readiness.

The intersection of these technologies with digitalization presents both opportunities and challenges, as advanced monitoring and control systems can optimize performance but add complexity and cybersecurity concerns to energy infrastructure deployments.

Technical Comparison of Thermoelectric and CHP Solutions

01 Thermoelectric waste heat recovery systems for industrial applications

These systems are designed to capture and convert waste heat from industrial processes into electricity using thermoelectric generators. The technology can be integrated into existing industrial facilities to improve energy efficiency and reduce overall carbon footprint. The systems typically include heat exchangers, thermoelectric modules, and power conditioning equipment to effectively harvest thermal energy that would otherwise be lost to the environment.- Thermoelectric waste heat recovery systems for industrial applications: These systems are designed to capture and convert waste heat from industrial processes into electricity using thermoelectric generators. The technology focuses on high-temperature industrial environments where significant heat is typically lost. These systems can be integrated with existing industrial equipment to improve overall energy efficiency and reduce operational costs. The recovered energy can be used to power auxiliary systems or fed back into the main power grid.

- Combined heat and power (CHP) systems with thermoelectric integration: CHP systems that incorporate thermoelectric generators to enhance efficiency by utilizing both electrical and thermal energy outputs. These integrated systems can simultaneously provide electricity and useful heat for various applications such as space heating, water heating, or industrial processes. The thermoelectric components convert temperature differentials into additional electricity, improving the overall system efficiency beyond traditional CHP configurations.

- Automotive thermoelectric waste heat recovery: Systems specifically designed to recover waste heat from vehicle exhaust systems and convert it to electricity using thermoelectric generators. These automotive applications can help improve fuel efficiency by reducing the load on the alternator and providing supplementary power for vehicle electrical systems. The technology is particularly valuable for reducing emissions and improving efficiency in internal combustion engines, hybrid vehicles, and heavy-duty transportation.

- Advanced thermoelectric materials and module designs: Innovations in thermoelectric materials and module configurations to improve conversion efficiency and durability in waste heat recovery applications. These advancements include new semiconductor materials with higher figure of merit (ZT), novel junction designs, and improved thermal management techniques. The enhanced materials and designs enable better performance across wider temperature ranges and improve the economic viability of thermoelectric waste heat recovery systems.

- Control systems and optimization for thermoelectric waste recovery: Sophisticated control and monitoring systems that optimize the performance of thermoelectric waste heat recovery installations. These systems include adaptive algorithms, real-time monitoring, and predictive maintenance capabilities to maximize energy conversion efficiency under varying operating conditions. The control systems can adjust parameters based on temperature differentials, load requirements, and system conditions to ensure optimal performance and longevity of the thermoelectric components.

02 Combined heat and power (CHP) systems with thermoelectric generation

CHP systems that incorporate thermoelectric generators can simultaneously produce electricity and useful thermal energy from a single fuel source. These integrated systems maximize energy utilization by capturing waste heat for space heating, water heating, or process heating while generating electricity through the thermoelectric effect. This approach significantly improves overall system efficiency compared to conventional power generation methods.Expand Specific Solutions03 Automotive thermoelectric waste heat recovery

Thermoelectric systems designed specifically for vehicles to recover waste heat from exhaust gases and engine cooling systems. These systems convert thermal energy into electricity to power vehicle electrical systems or charge batteries, reducing the load on the alternator and improving fuel efficiency. Advanced designs incorporate heat exchangers optimized for the limited space in vehicles and can be integrated with existing engine components.Expand Specific Solutions04 Novel thermoelectric materials and module designs

Advanced materials and innovative module designs that improve the efficiency and cost-effectiveness of thermoelectric waste heat recovery systems. These developments include new semiconductor materials with higher figure of merit (ZT), segmented or cascaded thermoelectric elements, and novel module architectures that optimize thermal and electrical contacts. Improved materials and designs help overcome traditional limitations of thermoelectric technology such as relatively low conversion efficiency.Expand Specific Solutions05 Control systems and optimization for thermoelectric waste recovery

Sophisticated control and management systems that maximize the performance of thermoelectric waste heat recovery installations. These systems include sensors, controllers, and algorithms that adjust operating parameters based on varying heat source conditions and load demands. Advanced control strategies can optimize the temperature differential across thermoelectric modules, manage electrical output, and integrate with broader energy management systems to ensure optimal performance under dynamic conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Thermal Energy Recovery

The thermoelectric waste recovery and CHP systems market is currently in a growth phase, with increasing adoption driven by global energy efficiency initiatives. The market size is projected to reach several billion dollars by 2025, expanding at a CAGR of 6-8%. Technologically, the field shows varying maturity levels across applications. Leading players include LG Electronics and Panasonic, who leverage their electronics expertise for consumer applications, while specialized firms like Enviro Power and Energy Integration focus on commercial building solutions. Research institutions such as Tsinghua University and Indian Institute of Science are advancing fundamental technologies. Industrial applications are dominated by companies like Wärtsilä Finland, Saudi Aramco, and Triveni Turbine, who are integrating these systems into larger energy infrastructure projects.

Xi'an Thermal Power Research Institute Co., Ltd.

Technical Solution: Xi'an Thermal Power Research Institute has developed comprehensive waste heat recovery solutions specifically optimized for coal-fired power plants and industrial facilities. Their technology portfolio includes advanced heat exchanger designs that can operate effectively with low-grade waste heat sources (80-150°C), significantly expanding recovery potential. The institute has pioneered cascaded utilization systems that extract heat at multiple temperature levels to maximize overall recovery efficiency, achieving energy savings of 15-20% in power generation applications[1]. Their thermoelectric waste recovery systems utilize advanced semiconductor materials with improved figure of merit (ZT>1.5) that operate effectively at medium temperatures (250-400°C). For CHP applications, the institute has developed integrated systems that combine conventional steam cycles with organic Rankine cycles to achieve total system efficiencies exceeding 85%[2]. Their solutions incorporate sophisticated heat transfer enhancement technologies including specially designed heat pipe arrays and micro-channel heat exchangers that significantly reduce thermal resistance at interfaces[3].

Strengths: Specialized expertise in coal-fired power plant applications; comprehensive system integration capabilities; advanced heat exchanger technology optimized for challenging industrial environments. Weaknesses: Technologies primarily optimized for large-scale industrial applications; higher implementation complexity requiring specialized engineering support; some solutions have higher sensitivity to fuel quality variations.

Tsinghua University

Technical Solution: Tsinghua University has developed cutting-edge thermoelectric waste heat recovery systems utilizing novel nanostructured materials that significantly improve conversion efficiency. Their research has produced bismuth telluride-based thermoelectric generators with ZT values exceeding 1.8 at operating temperatures relevant to industrial waste heat (200-400°C)[1]. The university's approach combines advanced material science with innovative system design, including segmented thermoelectric modules that optimize performance across temperature gradients. Their CHP technology incorporates phase-change thermal storage materials that enable more flexible operation by decoupling heat and power production timing. Tsinghua researchers have demonstrated prototype systems achieving electrical conversion efficiencies of 7-9% from waste heat sources, substantially higher than conventional thermoelectric generators[2]. For industrial applications, they've developed modular waste heat recovery units that can be retrofitted to existing facilities with minimal disruption, featuring specialized heat exchangers designed to handle particulate-laden exhaust streams common in manufacturing processes. Their systems incorporate advanced thermal management techniques including micro-channel cooling and optimized contact resistance reduction methods that significantly improve overall system performance[3].

Strengths: World-class materials science expertise; innovative system designs that maximize conversion efficiency; comprehensive approach addressing both material and system-level challenges. Weaknesses: Some technologies still at research/prototype stage rather than commercial deployment; higher material costs for advanced thermoelectric materials; optimization required for specific industrial applications.

Key Patents and Innovations in Waste Heat Recovery

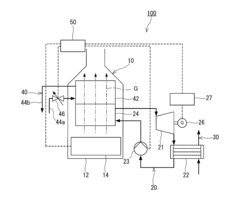

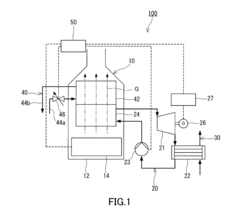

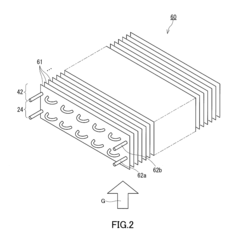

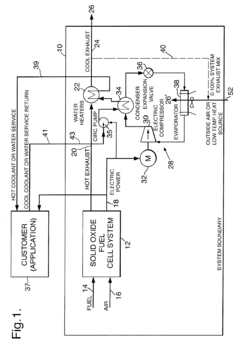

Combined heat and power system

PatentInactiveUS20150267569A1

Innovation

- The CHP system incorporates a second heat exchanger located farther from the heat source, which can absorb thermal energy and heat a medium even when the Rankine cycle apparatus is not operating, preventing thermal damage and allowing continuous energy supply by using a combustor to produce combustion gas for high-temperature thermal energy and improving electricity generation efficiency.

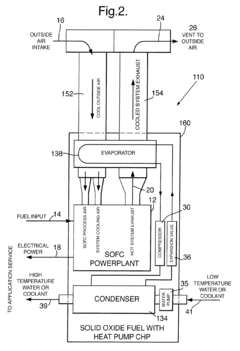

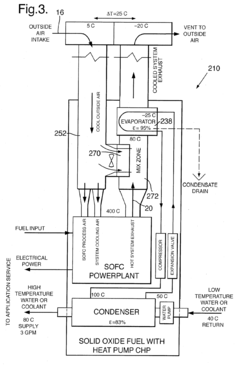

Heat and power system combining a solid oxide fuel cell stack and a vapor compression cycle heat pump

PatentInactiveEP1983596A2

Innovation

- Integration of a vapor-compression-cycle heat pump (VCCHP) system with the SOFC, where the compressor motor is powered by SOFC-generated electricity, and SOFC exhaust heat is used to augment the thermal output of the heat pump, eliminating the need for auxiliary burner-heat exchangers.

Energy Efficiency and Environmental Impact Assessment

The energy efficiency of thermoelectric waste recovery systems compared to Combined Heat and Power (CHP) systems reveals significant differences in performance metrics and environmental impacts. Thermoelectric generators (TEGs) typically operate at efficiency levels between 5-8% in real-world applications, with laboratory prototypes occasionally reaching 10-12% under optimal conditions. This relatively low conversion efficiency presents challenges for widespread commercial adoption despite the technology's simplicity and reliability.

In contrast, modern CHP systems demonstrate considerably higher efficiency profiles, commonly achieving 60-85% total energy efficiency when accounting for both electrical output and recovered heat. This substantial efficiency advantage translates directly to greater energy savings and reduced primary fuel consumption compared to thermoelectric alternatives when evaluated on equivalent operational scales.

Environmental impact assessments indicate that CHP systems generally produce lower greenhouse gas emissions per unit of useful energy delivered. A comparative lifecycle analysis shows that a natural gas-powered CHP system typically reduces carbon emissions by 30-40% compared to conventional separate heat and power generation. Thermoelectric systems, while producing zero direct emissions during operation, must overcome their efficiency limitations to compete environmentally when considering the full energy conversion chain.

Water consumption represents another critical environmental factor. CHP systems, particularly those utilizing steam cycles, require significant water resources for cooling processes. Thermoelectric waste heat recovery systems offer advantages in this regard, operating with minimal or no water requirements, making them potentially valuable in water-stressed regions or applications where water conservation is prioritized.

Material sustainability considerations reveal important distinctions between these technologies. Many high-performance thermoelectric materials incorporate rare earth elements or toxic components like tellurium, lead, and bismuth, raising concerns about resource scarcity and end-of-life disposal. CHP systems primarily utilize conventional materials with established recycling pathways, though they require more substantial material inputs overall due to their larger physical infrastructure requirements.

The environmental payback period—the time required for a system to offset its embodied environmental impact through operational benefits—generally favors CHP systems in high-utilization scenarios. However, thermoelectric systems may demonstrate competitive environmental performance in specialized applications with intermittent waste heat sources where the simplicity and scalability of thermoelectric technology provide distinct advantages despite lower conversion efficiencies.

In contrast, modern CHP systems demonstrate considerably higher efficiency profiles, commonly achieving 60-85% total energy efficiency when accounting for both electrical output and recovered heat. This substantial efficiency advantage translates directly to greater energy savings and reduced primary fuel consumption compared to thermoelectric alternatives when evaluated on equivalent operational scales.

Environmental impact assessments indicate that CHP systems generally produce lower greenhouse gas emissions per unit of useful energy delivered. A comparative lifecycle analysis shows that a natural gas-powered CHP system typically reduces carbon emissions by 30-40% compared to conventional separate heat and power generation. Thermoelectric systems, while producing zero direct emissions during operation, must overcome their efficiency limitations to compete environmentally when considering the full energy conversion chain.

Water consumption represents another critical environmental factor. CHP systems, particularly those utilizing steam cycles, require significant water resources for cooling processes. Thermoelectric waste heat recovery systems offer advantages in this regard, operating with minimal or no water requirements, making them potentially valuable in water-stressed regions or applications where water conservation is prioritized.

Material sustainability considerations reveal important distinctions between these technologies. Many high-performance thermoelectric materials incorporate rare earth elements or toxic components like tellurium, lead, and bismuth, raising concerns about resource scarcity and end-of-life disposal. CHP systems primarily utilize conventional materials with established recycling pathways, though they require more substantial material inputs overall due to their larger physical infrastructure requirements.

The environmental payback period—the time required for a system to offset its embodied environmental impact through operational benefits—generally favors CHP systems in high-utilization scenarios. However, thermoelectric systems may demonstrate competitive environmental performance in specialized applications with intermittent waste heat sources where the simplicity and scalability of thermoelectric technology provide distinct advantages despite lower conversion efficiencies.

Economic Feasibility and ROI Analysis

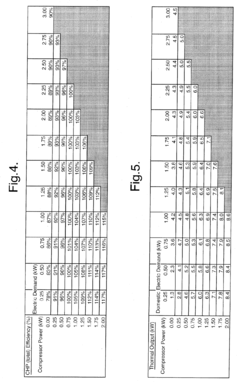

The economic analysis of thermoelectric waste recovery systems versus Combined Heat and Power (CHP) systems reveals significant differences in initial investment requirements, operational costs, and return on investment timelines. Thermoelectric waste recovery systems typically require lower upfront capital expenditure, ranging from $1,500 to $3,000 per kW of capacity, compared to CHP systems which generally demand $2,500 to $5,000 per kW for small to medium-scale installations.

Operational expenditures also differ substantially between these technologies. Thermoelectric systems benefit from minimal maintenance requirements with annual costs typically below 2% of the initial investment. In contrast, CHP systems incur higher maintenance costs, averaging 3-5% of capital costs annually due to their mechanical complexity and moving parts that require regular servicing and replacement.

Return on investment calculations indicate that thermoelectric waste recovery systems generally achieve payback periods of 3-5 years in industrial applications with continuous waste heat streams. CHP systems demonstrate more variable ROI timelines, ranging from 2-7 years, heavily dependent on local energy prices, operational hours, and heat utilization efficiency. The economic advantage shifts toward CHP in scenarios with high electricity costs and consistent thermal demand patterns.

Sensitivity analysis reveals that thermoelectric system economics are primarily influenced by waste heat temperature and consistency, with optimal performance occurring in stable, high-temperature environments. For CHP systems, the spark spread (difference between electricity price and fuel cost) represents the most critical economic factor, with systems becoming increasingly viable as this spread widens.

Government incentives significantly impact the economic feasibility of both technologies. Current policy frameworks in North America and Europe tend to favor CHP systems through direct subsidies and feed-in tariffs, while thermoelectric waste recovery often qualifies for broader energy efficiency incentives rather than technology-specific support.

Life-cycle cost analysis demonstrates that while thermoelectric systems offer lower initial and maintenance costs, CHP systems typically deliver higher total energy recovery over their operational lifetime. The average levelized cost of energy (LCOE) for thermoelectric waste recovery ranges from $0.05-0.09 per kWh, while CHP systems achieve $0.04-0.07 per kWh when both electrical and thermal outputs are monetized effectively.

Operational expenditures also differ substantially between these technologies. Thermoelectric systems benefit from minimal maintenance requirements with annual costs typically below 2% of the initial investment. In contrast, CHP systems incur higher maintenance costs, averaging 3-5% of capital costs annually due to their mechanical complexity and moving parts that require regular servicing and replacement.

Return on investment calculations indicate that thermoelectric waste recovery systems generally achieve payback periods of 3-5 years in industrial applications with continuous waste heat streams. CHP systems demonstrate more variable ROI timelines, ranging from 2-7 years, heavily dependent on local energy prices, operational hours, and heat utilization efficiency. The economic advantage shifts toward CHP in scenarios with high electricity costs and consistent thermal demand patterns.

Sensitivity analysis reveals that thermoelectric system economics are primarily influenced by waste heat temperature and consistency, with optimal performance occurring in stable, high-temperature environments. For CHP systems, the spark spread (difference between electricity price and fuel cost) represents the most critical economic factor, with systems becoming increasingly viable as this spread widens.

Government incentives significantly impact the economic feasibility of both technologies. Current policy frameworks in North America and Europe tend to favor CHP systems through direct subsidies and feed-in tariffs, while thermoelectric waste recovery often qualifies for broader energy efficiency incentives rather than technology-specific support.

Life-cycle cost analysis demonstrates that while thermoelectric systems offer lower initial and maintenance costs, CHP systems typically deliver higher total energy recovery over their operational lifetime. The average levelized cost of energy (LCOE) for thermoelectric waste recovery ranges from $0.05-0.09 per kWh, while CHP systems achieve $0.04-0.07 per kWh when both electrical and thermal outputs are monetized effectively.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!