Innovations in Thermoelectric Waste Recovery for Renewable Energy

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications across various industries. The fundamental principle, known as the Seebeck effect, was discovered in 1821 by Thomas Johann Seebeck, who observed that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This discovery laid the groundwork for thermoelectric generators (TEGs), which directly convert thermal energy into electrical energy without moving parts.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved modest efficiency levels of 4-6%. Second-generation materials incorporated advanced semiconductor alloys and nanostructuring techniques, pushing efficiencies to 8-10%. Current research focuses on third-generation materials utilizing quantum confinement effects, phonon engineering, and novel material compositions to potentially achieve efficiencies exceeding 15%.

Industrial waste heat represents an enormous untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. In the United States alone, industrial waste heat accounts for approximately 5-13 quadrillion BTUs annually, equivalent to 7-20% of total primary energy consumption. This presents a compelling opportunity for thermoelectric waste heat recovery systems to contribute significantly to renewable energy portfolios and sustainability goals.

The primary technical objective in this field is to develop cost-effective thermoelectric systems capable of efficiently capturing low to medium-grade waste heat (80-400°C) and converting it into usable electricity. This involves overcoming several key challenges, including improving the figure of merit (ZT) of thermoelectric materials, enhancing thermal management systems, reducing manufacturing costs, and developing modular, scalable designs suitable for diverse industrial applications.

Recent technological breakthroughs in nanomaterials, advanced manufacturing techniques, and system integration have accelerated progress toward these objectives. Specifically, innovations in skutterudite compounds, half-Heusler alloys, and oxide-based thermoelectrics show promise for high-temperature applications, while advances in flexible thermoelectric generators open new possibilities for wearable and IoT applications.

The convergence of global energy challenges, environmental concerns, and technological advancements has created a favorable landscape for thermoelectric waste heat recovery. As industries worldwide face increasing pressure to reduce carbon emissions and improve energy efficiency, thermoelectric technologies offer a viable pathway to recover previously wasted energy resources while contributing to circular economy principles and sustainable industrial practices.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved modest efficiency levels of 4-6%. Second-generation materials incorporated advanced semiconductor alloys and nanostructuring techniques, pushing efficiencies to 8-10%. Current research focuses on third-generation materials utilizing quantum confinement effects, phonon engineering, and novel material compositions to potentially achieve efficiencies exceeding 15%.

Industrial waste heat represents an enormous untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. In the United States alone, industrial waste heat accounts for approximately 5-13 quadrillion BTUs annually, equivalent to 7-20% of total primary energy consumption. This presents a compelling opportunity for thermoelectric waste heat recovery systems to contribute significantly to renewable energy portfolios and sustainability goals.

The primary technical objective in this field is to develop cost-effective thermoelectric systems capable of efficiently capturing low to medium-grade waste heat (80-400°C) and converting it into usable electricity. This involves overcoming several key challenges, including improving the figure of merit (ZT) of thermoelectric materials, enhancing thermal management systems, reducing manufacturing costs, and developing modular, scalable designs suitable for diverse industrial applications.

Recent technological breakthroughs in nanomaterials, advanced manufacturing techniques, and system integration have accelerated progress toward these objectives. Specifically, innovations in skutterudite compounds, half-Heusler alloys, and oxide-based thermoelectrics show promise for high-temperature applications, while advances in flexible thermoelectric generators open new possibilities for wearable and IoT applications.

The convergence of global energy challenges, environmental concerns, and technological advancements has created a favorable landscape for thermoelectric waste heat recovery. As industries worldwide face increasing pressure to reduce carbon emissions and improve energy efficiency, thermoelectric technologies offer a viable pathway to recover previously wasted energy resources while contributing to circular economy principles and sustainable industrial practices.

Market Analysis for Waste Heat Recovery Technologies

The global waste heat recovery (WHR) market is experiencing significant growth, driven by increasing energy costs, environmental regulations, and corporate sustainability initiatives. Currently valued at approximately $68 billion in 2023, the market is projected to reach $114 billion by 2030, representing a compound annual growth rate of 7.6%. This growth trajectory is particularly pronounced in industrial sectors such as manufacturing, power generation, and chemical processing, where substantial amounts of waste heat are generated during operations.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for nearly 40% of global demand, with China and India leading adoption due to their extensive industrial bases and government-backed energy efficiency programs. North America and Europe follow closely, with market shares of approximately 25% and 22% respectively, driven primarily by stringent environmental regulations and corporate sustainability goals.

By application segment, the industrial sector constitutes the largest market share at 65%, followed by commercial buildings (20%) and transportation (15%). Within industrial applications, thermoelectric waste recovery systems are gaining particular traction in energy-intensive industries such as steel, cement, and glass manufacturing, where temperatures often exceed 500°C, providing ideal conditions for efficient energy recovery.

Customer demand patterns indicate growing interest in integrated systems that can be retrofitted to existing industrial infrastructure with minimal disruption to operations. End-users increasingly prioritize solutions with payback periods under three years, highlighting the importance of economic viability alongside technical performance.

Market barriers include high initial capital costs, with advanced thermoelectric waste recovery systems requiring investments of $1,000-$3,000 per kilowatt of capacity. Technical challenges related to efficiency limitations in thermoelectric materials also persist, with current commercial systems typically achieving conversion efficiencies between 5-8%.

Competitive analysis reveals a fragmented market landscape with several tiers of providers. Tier-1 comprises established industrial equipment manufacturers who have expanded into waste heat recovery, controlling approximately 45% of market share. Tier-2 consists of specialized waste heat recovery technology providers (30% market share), while Tier-3 includes emerging startups focused on innovative thermoelectric materials and designs (25% market share).

Future market growth will be significantly influenced by technological advancements in thermoelectric materials, with particular emphasis on improving conversion efficiency and reducing production costs. Regulatory developments, particularly carbon pricing mechanisms and energy efficiency standards, are expected to accelerate market adoption across all regions.

Regional analysis reveals that Asia-Pacific dominates the market, accounting for nearly 40% of global demand, with China and India leading adoption due to their extensive industrial bases and government-backed energy efficiency programs. North America and Europe follow closely, with market shares of approximately 25% and 22% respectively, driven primarily by stringent environmental regulations and corporate sustainability goals.

By application segment, the industrial sector constitutes the largest market share at 65%, followed by commercial buildings (20%) and transportation (15%). Within industrial applications, thermoelectric waste recovery systems are gaining particular traction in energy-intensive industries such as steel, cement, and glass manufacturing, where temperatures often exceed 500°C, providing ideal conditions for efficient energy recovery.

Customer demand patterns indicate growing interest in integrated systems that can be retrofitted to existing industrial infrastructure with minimal disruption to operations. End-users increasingly prioritize solutions with payback periods under three years, highlighting the importance of economic viability alongside technical performance.

Market barriers include high initial capital costs, with advanced thermoelectric waste recovery systems requiring investments of $1,000-$3,000 per kilowatt of capacity. Technical challenges related to efficiency limitations in thermoelectric materials also persist, with current commercial systems typically achieving conversion efficiencies between 5-8%.

Competitive analysis reveals a fragmented market landscape with several tiers of providers. Tier-1 comprises established industrial equipment manufacturers who have expanded into waste heat recovery, controlling approximately 45% of market share. Tier-2 consists of specialized waste heat recovery technology providers (30% market share), while Tier-3 includes emerging startups focused on innovative thermoelectric materials and designs (25% market share).

Future market growth will be significantly influenced by technological advancements in thermoelectric materials, with particular emphasis on improving conversion efficiency and reducing production costs. Regulatory developments, particularly carbon pricing mechanisms and energy efficiency standards, are expected to accelerate market adoption across all regions.

Global Thermoelectric Technology Status and Barriers

Thermoelectric waste heat recovery technology has witnessed significant advancements globally, yet remains constrained by several technological barriers. Current commercial thermoelectric materials predominantly utilize bismuth telluride (Bi2Te3) for low-temperature applications and lead telluride (PbTe) for medium-temperature ranges, achieving conversion efficiencies between 5-8%. However, these efficiency rates fall considerably short of theoretical thermodynamic limits, presenting a substantial performance gap.

The global landscape reveals uneven development patterns, with research leadership concentrated in North America, Europe, and East Asia. The United States maintains technological superiority through substantial investments from the Department of Energy and ARPA-E programs, focusing on automotive and industrial waste heat recovery. Japan and South Korea have established strong industrial applications, particularly in automotive thermoelectric generators, while China has rapidly expanded research capacity but struggles with commercialization pathways.

Material limitations constitute the primary technological barrier, as current thermoelectric materials exhibit insufficient figure of merit (ZT) values, typically below 2 for commercial applications. The ideal thermoelectric material requires contradictory properties: high electrical conductivity coupled with low thermal conductivity—a fundamental challenge in materials science often referred to as the "phonon-glass electron-crystal" paradigm.

Manufacturing scalability presents another significant obstacle. Current production methods for high-performance thermoelectric modules involve complex processes with precise doping requirements and interface engineering, resulting in high production costs that limit widespread adoption. The cost-performance ratio remains unfavorable compared to alternative energy recovery technologies, with current systems priced at $5-20 per watt of generation capacity.

System integration challenges further complicate implementation, as thermoelectric generators require sophisticated heat exchangers and thermal management systems to maintain optimal temperature differentials. The mechanical reliability of thermoelectric modules under thermal cycling conditions remains problematic, with degradation of material properties and interface contacts occurring over time.

Environmental concerns also impact development trajectories, as many high-performance thermoelectric materials contain toxic or rare elements like tellurium, lead, and antimony. Regulatory frameworks in Europe and North America increasingly restrict the use of these materials, necessitating research into alternative compositions.

Despite these barriers, recent breakthroughs in nanostructured materials and organic thermoelectrics show promise for overcoming efficiency limitations. Skutterudites, half-Heusler alloys, and silicon-germanium compounds have demonstrated improved ZT values in laboratory settings, though translating these advances to commercial products remains challenging.

The global landscape reveals uneven development patterns, with research leadership concentrated in North America, Europe, and East Asia. The United States maintains technological superiority through substantial investments from the Department of Energy and ARPA-E programs, focusing on automotive and industrial waste heat recovery. Japan and South Korea have established strong industrial applications, particularly in automotive thermoelectric generators, while China has rapidly expanded research capacity but struggles with commercialization pathways.

Material limitations constitute the primary technological barrier, as current thermoelectric materials exhibit insufficient figure of merit (ZT) values, typically below 2 for commercial applications. The ideal thermoelectric material requires contradictory properties: high electrical conductivity coupled with low thermal conductivity—a fundamental challenge in materials science often referred to as the "phonon-glass electron-crystal" paradigm.

Manufacturing scalability presents another significant obstacle. Current production methods for high-performance thermoelectric modules involve complex processes with precise doping requirements and interface engineering, resulting in high production costs that limit widespread adoption. The cost-performance ratio remains unfavorable compared to alternative energy recovery technologies, with current systems priced at $5-20 per watt of generation capacity.

System integration challenges further complicate implementation, as thermoelectric generators require sophisticated heat exchangers and thermal management systems to maintain optimal temperature differentials. The mechanical reliability of thermoelectric modules under thermal cycling conditions remains problematic, with degradation of material properties and interface contacts occurring over time.

Environmental concerns also impact development trajectories, as many high-performance thermoelectric materials contain toxic or rare elements like tellurium, lead, and antimony. Regulatory frameworks in Europe and North America increasingly restrict the use of these materials, necessitating research into alternative compositions.

Despite these barriers, recent breakthroughs in nanostructured materials and organic thermoelectrics show promise for overcoming efficiency limitations. Skutterudites, half-Heusler alloys, and silicon-germanium compounds have demonstrated improved ZT values in laboratory settings, though translating these advances to commercial products remains challenging.

Current Thermoelectric Waste Heat Recovery Solutions

01 Thermoelectric generators for waste heat recovery

Thermoelectric generators (TEGs) can convert waste heat directly into electrical energy through the Seebeck effect. These systems are particularly effective for recovering energy from industrial processes, vehicle exhaust systems, and other high-temperature waste heat sources. The efficiency of these systems depends on the thermoelectric materials used, the temperature gradient maintained, and the overall system design. Advanced TEG systems incorporate specialized heat exchangers and thermal management to maximize energy recovery.- Thermoelectric generators for waste heat recovery: Thermoelectric generators can be used to convert waste heat from various industrial processes and vehicle exhaust systems into usable electrical energy. These systems utilize the Seebeck effect, where a temperature difference across thermoelectric materials generates an electrical voltage. By placing thermoelectric modules at strategic locations where temperature gradients exist, significant amounts of otherwise wasted thermal energy can be recovered and converted into electricity, improving overall energy efficiency.

- Integrated waste heat recovery systems: Integrated systems combine multiple technologies to maximize waste heat recovery efficiency. These systems may incorporate thermoelectric generators alongside other heat recovery methods such as heat exchangers, Organic Rankine Cycles, or heat pumps. The integration allows for cascading energy recovery, where waste heat from one process becomes the input for another, significantly improving overall system efficiency and energy recovery rates from industrial processes, power generation, and transportation applications.

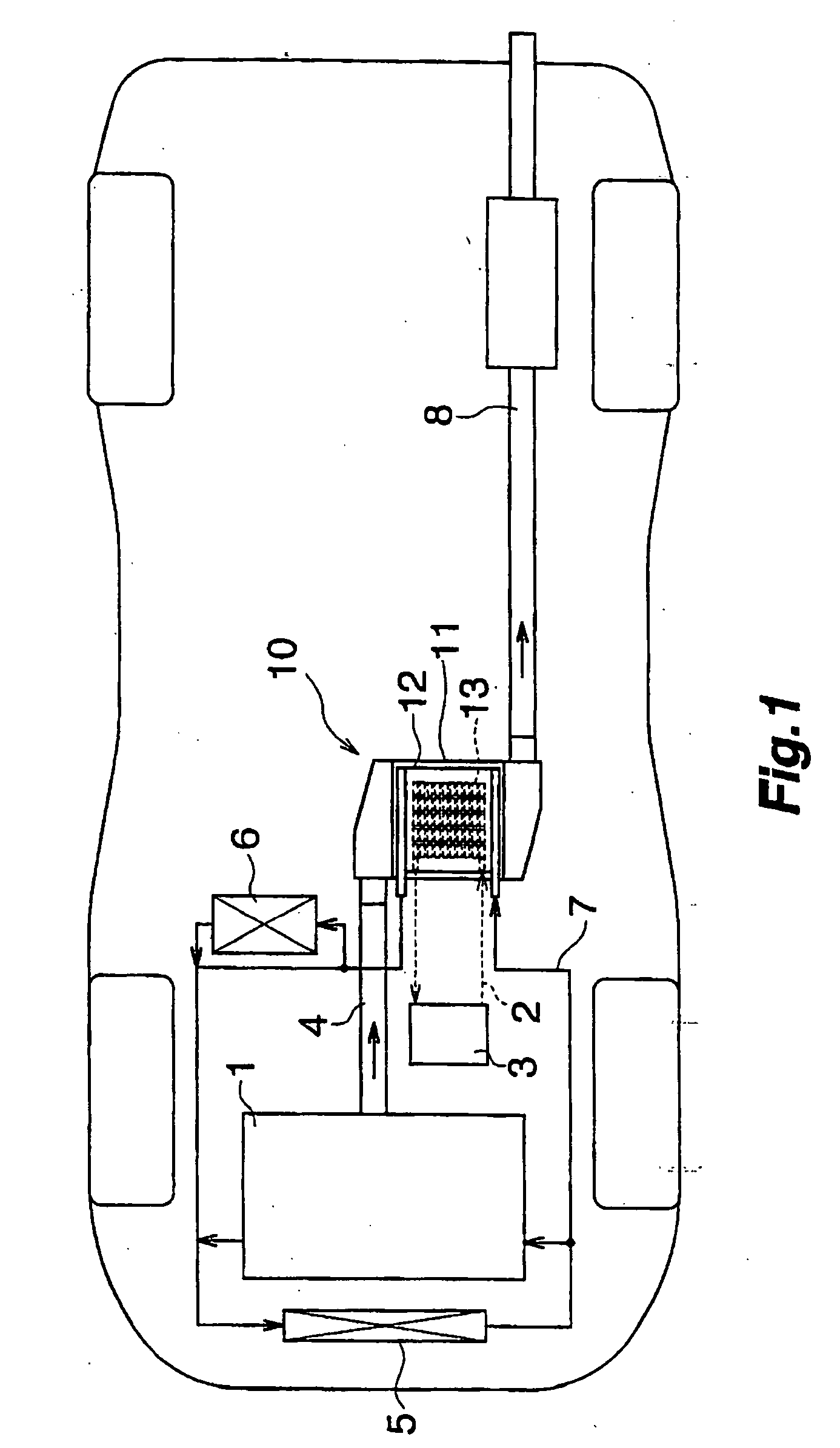

- Vehicle-based thermoelectric waste heat recovery: Specialized thermoelectric systems designed for automotive and transportation applications can recover waste heat from exhaust systems and engine cooling circuits. These systems convert thermal energy that would otherwise be lost to the environment into electrical power that can supplement the vehicle's electrical system, reducing alternator load and fuel consumption. Advanced designs incorporate heat exchangers and thermal management systems to optimize temperature differentials across thermoelectric modules while minimizing impact on engine performance.

- Industrial waste heat recovery solutions: Large-scale thermoelectric systems designed specifically for industrial applications can recover waste heat from manufacturing processes, furnaces, and power generation facilities. These systems are engineered to handle high-temperature waste streams and can be retrofitted to existing industrial equipment. The recovered energy can be used to generate electricity for on-site consumption or fed back into the grid, reducing overall energy costs and carbon emissions from industrial operations.

- Advanced thermoelectric materials and module designs: Novel thermoelectric materials and innovative module designs can significantly improve conversion efficiency in waste heat recovery applications. These advancements include nanostructured materials, segmented elements, and cascaded modules that optimize performance across different temperature ranges. Improved manufacturing techniques and module configurations enhance thermal contact, reduce internal resistance, and increase power density, making thermoelectric waste heat recovery more economically viable for a wider range of applications.

02 Integrated waste heat recovery systems

Integrated systems combine multiple technologies to maximize energy recovery from waste heat sources. These systems may incorporate thermoelectric generators alongside other recovery methods such as Organic Rankine Cycle (ORC) systems, heat exchangers, or heat pumps. By integrating different technologies, these systems can address varying temperature ranges and operating conditions, improving overall efficiency. Such integrated approaches are particularly valuable in industrial settings where multiple waste heat streams exist at different temperature levels.Expand Specific Solutions03 Vehicle-specific thermoelectric waste heat recovery

Specialized thermoelectric systems designed for automotive and transportation applications can recover waste heat from exhaust systems and engine cooling. These systems are engineered to withstand vibration, thermal cycling, and other challenging conditions present in vehicles. The recovered energy can supplement the vehicle's electrical system, reducing alternator load and improving fuel efficiency. Advanced designs integrate with vehicle thermal management systems to optimize overall energy efficiency.Expand Specific Solutions04 Novel thermoelectric materials and structures

Advanced materials and innovative structural designs can significantly improve the efficiency of thermoelectric waste heat recovery. These include nanostructured materials, semiconductor alloys, and composite materials with enhanced thermoelectric properties. Structural innovations such as segmented elements, cascaded designs, and thin-film technologies can optimize performance across different temperature ranges. These advancements aim to increase the figure of merit (ZT) of thermoelectric materials, which directly impacts conversion efficiency.Expand Specific Solutions05 Control systems and power management for thermoelectric recovery

Sophisticated control systems and power management technologies optimize the operation of thermoelectric waste heat recovery systems. These include maximum power point tracking (MPPT), adaptive control algorithms, and intelligent thermal management. Advanced power conditioning circuits ensure efficient integration with existing electrical systems or the grid. These control systems can adjust to varying waste heat conditions, maintaining optimal performance across different operating scenarios and maximizing energy recovery efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

Thermoelectric waste recovery for renewable energy is currently in a growth phase, with the global market expected to reach significant expansion by 2030. The technology maturity varies across applications, with automotive and industrial sectors leading adoption. Key players demonstrate different technological approaches: Toyota Motor Corp. and Gentherm focus on automotive applications, while Resonac Holdings and Corning develop advanced materials. Samsung SDI and Hon Hai Precision are integrating thermoelectric solutions into consumer electronics. Research institutions like Fraunhofer-Gesellschaft and Purdue Research Foundation are advancing fundamental technologies. The competitive landscape shows established industrial players collaborating with specialized technology firms like European Thermodynamics and Pyro-E to accelerate commercialization, while regional competition intensifies with Asian manufacturers like SAMSUNG SDI and Xi'an Thermal Power Research Institute expanding market presence.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermoelectric generators (TEGs) that convert waste heat from vehicle exhaust systems into usable electricity. Their technology utilizes bismuth telluride and skutterudite-based materials with improved figure of merit (ZT) values exceeding 1.5 at operating temperatures. Toyota's system integrates these TEGs directly into the exhaust pathway, capturing thermal energy that would otherwise be lost. Their latest designs incorporate segmented thermoelectric materials optimized for different temperature ranges, allowing efficient operation across the variable thermal conditions experienced in automotive applications. Toyota has demonstrated fuel efficiency improvements of 2-5% in real-world testing conditions by recovering waste heat energy and reducing alternator load. The company has also developed specialized manufacturing techniques to address thermal cycling durability issues that previously limited TEG lifespan in automotive applications.

Strengths: Toyota's extensive automotive manufacturing infrastructure enables large-scale implementation and testing. Their TEG systems are highly optimized for vehicle integration with proven durability under harsh operating conditions. Weaknesses: The technology remains relatively expensive compared to conventional systems, with cost-effectiveness still challenging at current production scales. Performance is also limited by the inherent efficiency constraints of thermoelectric materials.

Gentherm, Inc.

Technical Solution: Gentherm has pioneered Climate Control Seat (CCS) technology that incorporates thermoelectric elements for both heating and cooling applications. Their waste heat recovery systems utilize proprietary semiconductor materials with enhanced thermal conductivity properties. The company's thermoelectric generators are designed with a modular architecture that allows for scalable implementation across different industrial applications. Gentherm's technology employs a unique thermal interface material that maximizes heat transfer between hot surfaces and thermoelectric modules, achieving conversion efficiencies up to 8% in optimal conditions. Their systems incorporate advanced power conditioning electronics that optimize voltage output across varying temperature differentials. Gentherm has also developed specialized manufacturing processes that reduce production costs while maintaining performance, including automated assembly techniques for thermoelectric module construction that ensure consistent quality and reliability. Recent innovations include flexible thermoelectric materials that can conform to irregular heat-producing surfaces, expanding potential application areas.

Strengths: Gentherm possesses extensive expertise in thermal management systems with proven commercialization capabilities. Their modular designs allow for customization across diverse applications from automotive to industrial settings. Weaknesses: The technology still faces efficiency limitations compared to other energy recovery methods, particularly at lower temperature differentials. System complexity can lead to higher maintenance requirements in some applications.

Key Patents and Breakthroughs in Thermoelectric Materials

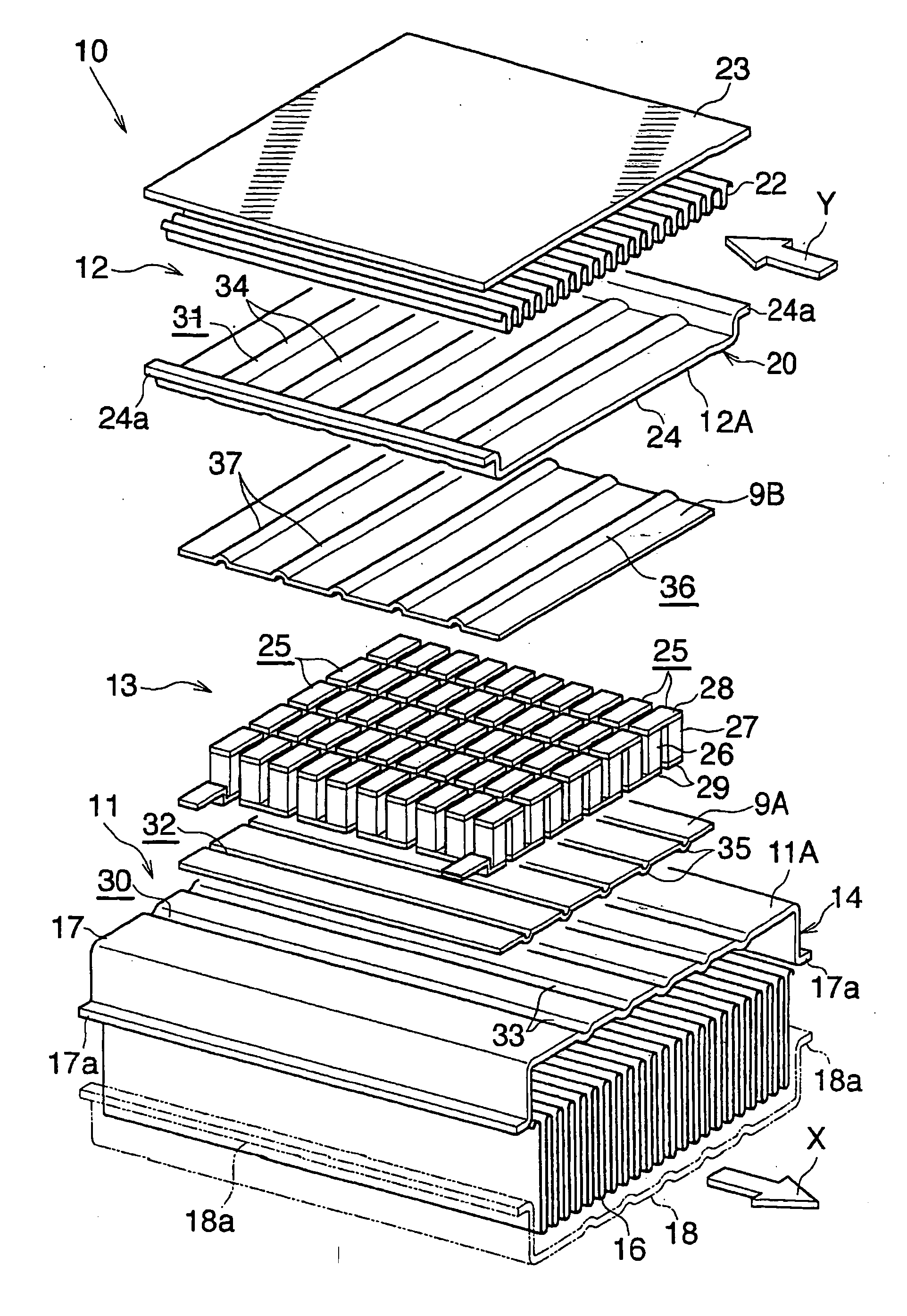

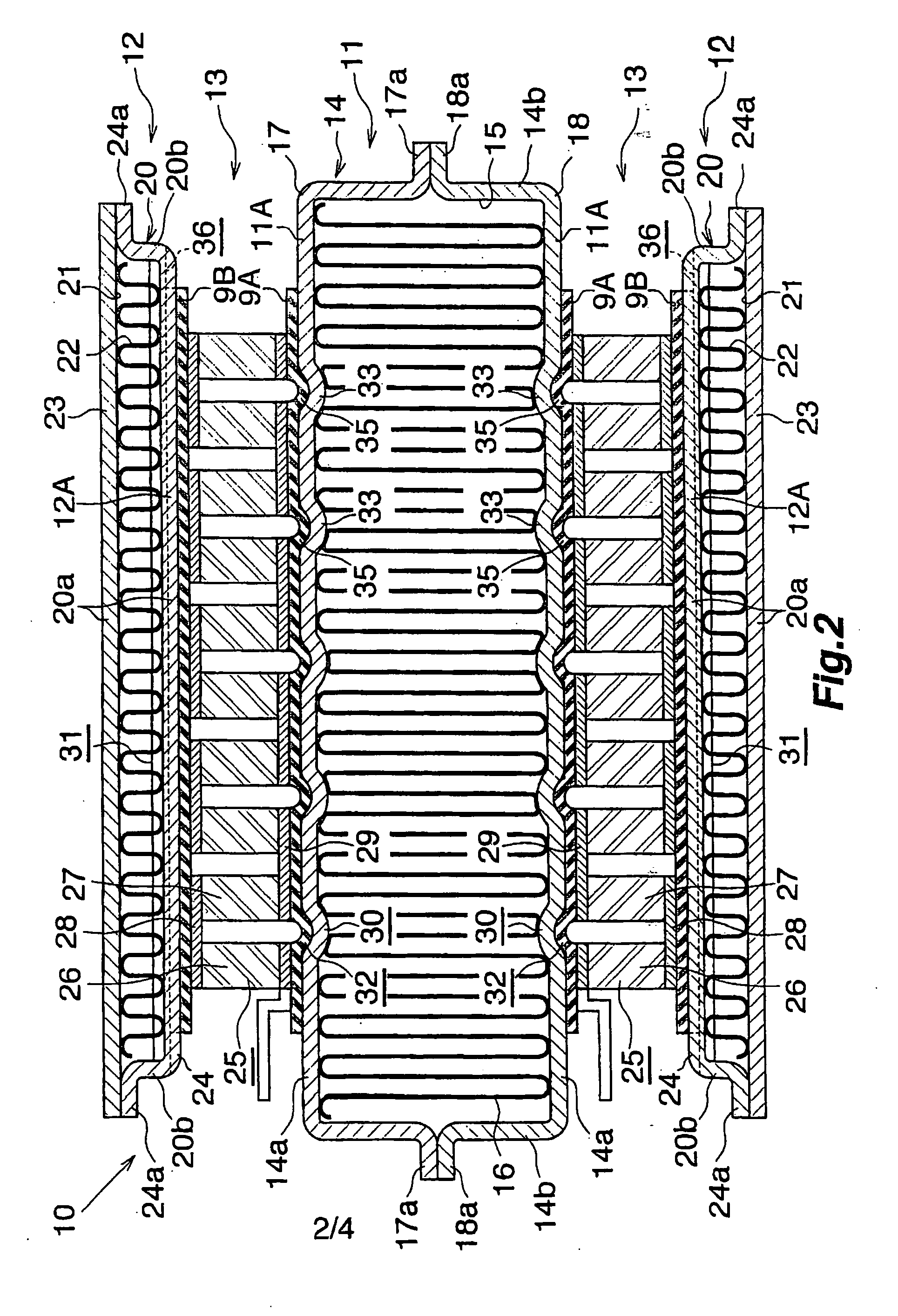

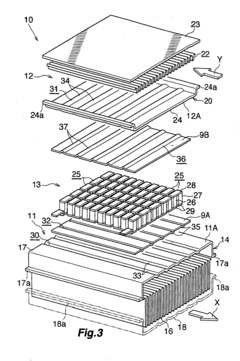

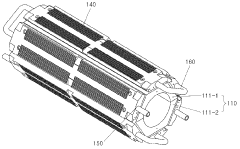

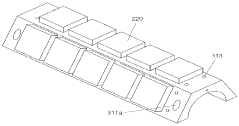

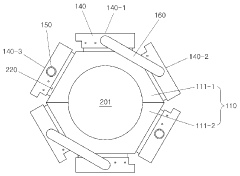

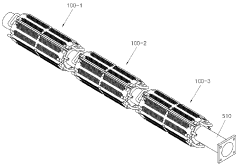

Waste heat recovery system and thermoelectric conversion system

PatentInactiveUS20060157102A1

Innovation

- A waste heat recovery system utilizing a thermoelectric conversion unit with sintered crystals of specific structures, connected in series with high-temperature and low-temperature heat exchangers, and thermal-stress relaxation features to enhance heat transfer and reduce thermal stress, allowing for efficient conversion of waste heat to electricity.

Thermoelectric generation apparatus by using waste heat

PatentActiveKR1020160053519A

Innovation

- A waste heat recovery type thermoelectric generator with a detachable inner plate and cooling pipes that can be directly installed on general pipes, featuring a zigzag cooling fluid circulation and enhanced cooling fins for improved thermal management.

Environmental Impact and Sustainability Assessment

Thermoelectric waste heat recovery systems represent a significant opportunity for enhancing environmental sustainability across multiple industrial sectors. These technologies capture waste heat that would otherwise be released into the atmosphere and convert it into usable electricity, thereby reducing the overall carbon footprint of industrial processes. The environmental benefits extend beyond mere energy efficiency improvements, as they directly contribute to greenhouse gas emission reductions by decreasing the demand for primary energy sources.

When implemented at scale, thermoelectric waste recovery systems can potentially reduce global carbon emissions by millions of tons annually. Studies indicate that industrial waste heat accounts for approximately 20-50% of industrial energy consumption across various sectors, representing a vast untapped resource that could be harnessed through thermoelectric technologies. The recovery of this waste energy directly translates to reduced fossil fuel consumption and associated environmental pollutants.

The life cycle assessment of thermoelectric materials presents both challenges and opportunities from a sustainability perspective. Traditional thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about resource depletion and end-of-life disposal. However, recent innovations in organic and oxide-based thermoelectrics offer more environmentally benign alternatives with reduced ecological footprints, though typically at lower efficiency levels.

Water conservation represents another significant environmental benefit of thermoelectric waste recovery systems. Unlike conventional power generation methods that require substantial water resources for cooling, thermoelectric generators operate without water consumption, making them particularly valuable in water-stressed regions where energy-water nexus challenges are pronounced.

The manufacturing processes for thermoelectric devices themselves are becoming increasingly sustainable. Advances in materials science have enabled lower-temperature synthesis methods and reduced energy-intensive processing steps. Additionally, emerging additive manufacturing techniques allow for optimized material usage and reduced waste in thermoelectric device production.

From a circular economy perspective, thermoelectric waste recovery systems align perfectly with sustainability principles by transforming waste (heat) into a valuable resource (electricity). The potential integration of these systems with other renewable energy technologies creates synergistic environmental benefits, particularly when combined with solar thermal or geothermal systems that generate heat as part of their operation.

Long-term environmental impact assessments suggest that widespread adoption of thermoelectric waste recovery could significantly contribute to meeting international climate goals, particularly in hard-to-decarbonize industrial sectors where process heat is an inevitable byproduct of manufacturing operations.

When implemented at scale, thermoelectric waste recovery systems can potentially reduce global carbon emissions by millions of tons annually. Studies indicate that industrial waste heat accounts for approximately 20-50% of industrial energy consumption across various sectors, representing a vast untapped resource that could be harnessed through thermoelectric technologies. The recovery of this waste energy directly translates to reduced fossil fuel consumption and associated environmental pollutants.

The life cycle assessment of thermoelectric materials presents both challenges and opportunities from a sustainability perspective. Traditional thermoelectric materials often contain rare or toxic elements such as tellurium, bismuth, and lead, raising concerns about resource depletion and end-of-life disposal. However, recent innovations in organic and oxide-based thermoelectrics offer more environmentally benign alternatives with reduced ecological footprints, though typically at lower efficiency levels.

Water conservation represents another significant environmental benefit of thermoelectric waste recovery systems. Unlike conventional power generation methods that require substantial water resources for cooling, thermoelectric generators operate without water consumption, making them particularly valuable in water-stressed regions where energy-water nexus challenges are pronounced.

The manufacturing processes for thermoelectric devices themselves are becoming increasingly sustainable. Advances in materials science have enabled lower-temperature synthesis methods and reduced energy-intensive processing steps. Additionally, emerging additive manufacturing techniques allow for optimized material usage and reduced waste in thermoelectric device production.

From a circular economy perspective, thermoelectric waste recovery systems align perfectly with sustainability principles by transforming waste (heat) into a valuable resource (electricity). The potential integration of these systems with other renewable energy technologies creates synergistic environmental benefits, particularly when combined with solar thermal or geothermal systems that generate heat as part of their operation.

Long-term environmental impact assessments suggest that widespread adoption of thermoelectric waste recovery could significantly contribute to meeting international climate goals, particularly in hard-to-decarbonize industrial sectors where process heat is an inevitable byproduct of manufacturing operations.

Economic Viability and ROI Analysis

The economic viability of thermoelectric waste heat recovery systems represents a critical factor in their widespread adoption across industrial and commercial applications. Current market analysis indicates that the return on investment (ROI) for these systems varies significantly based on installation scale, waste heat temperature differentials, and local energy costs. For large industrial implementations with high-temperature waste streams (>300°C), ROI periods typically range from 2-5 years, while medium-temperature applications (150-300°C) may extend to 3-7 years.

Cost-benefit analyses reveal that capital expenditure for thermoelectric waste recovery systems averages $2,000-4,000 per kilowatt of generating capacity, with maintenance costs remaining relatively low at 1-3% of initial investment annually. These systems demonstrate particular economic advantage in continuous operation environments where traditional energy costs exceed $0.10/kWh, creating favorable conditions for positive net present value calculations.

Sensitivity analysis demonstrates that economic viability is heavily influenced by four key parameters: conversion efficiency of thermoelectric materials, waste heat availability (both temperature and consistency), electricity prices, and installation costs. Recent advancements in bismuth telluride and skutterudite-based materials have improved conversion efficiencies to 7-12% in commercial applications, significantly enhancing ROI metrics compared to earlier generations limited to 3-5% efficiency.

Government incentives substantially impact financial calculations, with several jurisdictions offering tax credits, grants, or renewable energy certificates that can reduce payback periods by 20-40%. Notable examples include the U.S. Investment Tax Credit for waste heat recovery and the European Union's energy efficiency directive incentives, which have catalyzed adoption in regions with otherwise marginal economic cases.

Life-cycle cost assessment reveals that thermoelectric systems maintain performance advantages over their 10-15 year operational lifespan with minimal degradation, unlike competing technologies that may require significant maintenance interventions. This operational stability translates to predictable long-term financial returns, particularly valuable for risk-averse industrial investors seeking reliable energy cost hedging mechanisms.

Emerging financing models, including energy service company (ESCO) arrangements and equipment leasing options, are addressing initial capital barriers by allowing implementation with minimal upfront investment. These models typically guarantee energy savings that exceed financing costs, creating immediate positive cash flow for adopters while distributing capital risk across stakeholders.

Cost-benefit analyses reveal that capital expenditure for thermoelectric waste recovery systems averages $2,000-4,000 per kilowatt of generating capacity, with maintenance costs remaining relatively low at 1-3% of initial investment annually. These systems demonstrate particular economic advantage in continuous operation environments where traditional energy costs exceed $0.10/kWh, creating favorable conditions for positive net present value calculations.

Sensitivity analysis demonstrates that economic viability is heavily influenced by four key parameters: conversion efficiency of thermoelectric materials, waste heat availability (both temperature and consistency), electricity prices, and installation costs. Recent advancements in bismuth telluride and skutterudite-based materials have improved conversion efficiencies to 7-12% in commercial applications, significantly enhancing ROI metrics compared to earlier generations limited to 3-5% efficiency.

Government incentives substantially impact financial calculations, with several jurisdictions offering tax credits, grants, or renewable energy certificates that can reduce payback periods by 20-40%. Notable examples include the U.S. Investment Tax Credit for waste heat recovery and the European Union's energy efficiency directive incentives, which have catalyzed adoption in regions with otherwise marginal economic cases.

Life-cycle cost assessment reveals that thermoelectric systems maintain performance advantages over their 10-15 year operational lifespan with minimal degradation, unlike competing technologies that may require significant maintenance interventions. This operational stability translates to predictable long-term financial returns, particularly valuable for risk-averse industrial investors seeking reliable energy cost hedging mechanisms.

Emerging financing models, including energy service company (ESCO) arrangements and equipment leasing options, are addressing initial capital barriers by allowing implementation with minimal upfront investment. These models typically guarantee energy savings that exceed financing costs, creating immediate positive cash flow for adopters while distributing capital risk across stakeholders.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!