What Standards Apply to Thermoelectric Waste Recovery Systems?

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transforming from theoretical concepts to practical applications across multiple industries. The fundamental principle, known as the Seebeck effect discovered in 1821, enables direct conversion of temperature differentials into electrical energy without moving parts. This technology remained largely academic until the mid-20th century when semiconductor advancements made practical applications feasible.

The evolution of thermoelectric materials has been marked by three distinct generations: conventional bulk materials (1950s-1990s), nanostructured materials (1990s-2010s), and complex hierarchical structures (2010s-present). Each generation has progressively improved the figure of merit (ZT), a critical parameter determining conversion efficiency, from below 1 to approaching 2.5 in laboratory settings.

Industrial waste heat represents an enormous untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. In the United States alone, industrial waste heat exceeds 12 quadrillion BTUs annually, equivalent to approximately 12% of total primary energy consumption. Similar patterns exist globally, highlighting the significant potential for energy recovery.

The primary objective of thermoelectric waste heat recovery systems is to capture this otherwise wasted thermal energy and convert it into usable electricity, thereby improving overall energy efficiency and reducing carbon emissions. Secondary objectives include developing systems that are durable, cost-effective, and capable of operating reliably in harsh industrial environments with minimal maintenance requirements.

Current technological goals focus on several key areas: improving thermoelectric material efficiency to achieve ZT values consistently above 2 in commercial applications; reducing manufacturing costs to below $1/W to ensure economic viability; developing modular, scalable system designs adaptable to various industrial settings; and creating integrated solutions that can withstand high temperatures, thermal cycling, and corrosive environments.

The standardization landscape for thermoelectric waste heat recovery systems remains fragmented, with various regional and industry-specific standards addressing different aspects of these systems. This fragmentation presents challenges for global deployment and technology comparison, highlighting the need for comprehensive international standards that address performance metrics, safety requirements, reliability testing, and integration protocols.

As climate change concerns intensify and energy efficiency becomes increasingly critical, thermoelectric waste heat recovery represents a promising technology pathway for industrial decarbonization efforts, particularly in energy-intensive sectors such as steel, cement, glass, and chemical processing.

The evolution of thermoelectric materials has been marked by three distinct generations: conventional bulk materials (1950s-1990s), nanostructured materials (1990s-2010s), and complex hierarchical structures (2010s-present). Each generation has progressively improved the figure of merit (ZT), a critical parameter determining conversion efficiency, from below 1 to approaching 2.5 in laboratory settings.

Industrial waste heat represents an enormous untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. In the United States alone, industrial waste heat exceeds 12 quadrillion BTUs annually, equivalent to approximately 12% of total primary energy consumption. Similar patterns exist globally, highlighting the significant potential for energy recovery.

The primary objective of thermoelectric waste heat recovery systems is to capture this otherwise wasted thermal energy and convert it into usable electricity, thereby improving overall energy efficiency and reducing carbon emissions. Secondary objectives include developing systems that are durable, cost-effective, and capable of operating reliably in harsh industrial environments with minimal maintenance requirements.

Current technological goals focus on several key areas: improving thermoelectric material efficiency to achieve ZT values consistently above 2 in commercial applications; reducing manufacturing costs to below $1/W to ensure economic viability; developing modular, scalable system designs adaptable to various industrial settings; and creating integrated solutions that can withstand high temperatures, thermal cycling, and corrosive environments.

The standardization landscape for thermoelectric waste heat recovery systems remains fragmented, with various regional and industry-specific standards addressing different aspects of these systems. This fragmentation presents challenges for global deployment and technology comparison, highlighting the need for comprehensive international standards that address performance metrics, safety requirements, reliability testing, and integration protocols.

As climate change concerns intensify and energy efficiency becomes increasingly critical, thermoelectric waste heat recovery represents a promising technology pathway for industrial decarbonization efforts, particularly in energy-intensive sectors such as steel, cement, glass, and chemical processing.

Market Analysis for Thermoelectric Recovery Solutions

The global market for thermoelectric waste recovery systems has experienced significant growth in recent years, driven primarily by increasing energy costs and stringent environmental regulations. The market value reached approximately $617 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.3% through 2030, potentially reaching $1.2 billion by the end of the forecast period.

Industrial sectors represent the largest market segment, accounting for roughly 43% of the total market share. Within this segment, manufacturing facilities, particularly those with high-temperature processes such as steel production, glass manufacturing, and cement production, demonstrate the highest adoption rates. The automotive sector follows closely, comprising about 28% of the market, with increasing integration of thermoelectric generators in vehicle exhaust systems to improve fuel efficiency.

Geographically, North America and Europe currently dominate the market with combined market share of 61%, attributed to advanced regulatory frameworks promoting energy efficiency and substantial government incentives for waste heat recovery technologies. However, the Asia-Pacific region is witnessing the fastest growth rate at 10.7% annually, driven by rapid industrialization in China and India, coupled with increasing environmental awareness and supportive government policies.

Market penetration varies significantly across different industries. While adoption in power generation and heavy manufacturing industries has reached moderate levels (15-20% of potential applications), other sectors such as commercial buildings and small to medium-sized manufacturing facilities show considerably lower penetration rates (below 5%), indicating substantial growth opportunities.

Key market drivers include rising energy prices, which have increased by an average of 6.2% annually over the past five years in major industrial economies, creating stronger economic incentives for waste heat recovery. Additionally, carbon pricing mechanisms and emissions regulations in 78 countries worldwide are pushing industries to adopt more energy-efficient technologies.

Customer demand patterns reveal a growing preference for integrated systems that offer both waste heat recovery and energy management capabilities. Return on investment (ROI) remains a critical decision factor, with most customers expecting payback periods under four years. This requirement presents challenges for wider adoption, as current thermoelectric systems typically achieve payback periods of 3-7 years depending on application and scale.

Market barriers include high initial capital costs, technical limitations in conversion efficiency, and lack of standardization across different applications. The fragmented nature of the market, with numerous small and medium-sized technology providers, also contributes to inconsistent product quality and performance standards.

Industrial sectors represent the largest market segment, accounting for roughly 43% of the total market share. Within this segment, manufacturing facilities, particularly those with high-temperature processes such as steel production, glass manufacturing, and cement production, demonstrate the highest adoption rates. The automotive sector follows closely, comprising about 28% of the market, with increasing integration of thermoelectric generators in vehicle exhaust systems to improve fuel efficiency.

Geographically, North America and Europe currently dominate the market with combined market share of 61%, attributed to advanced regulatory frameworks promoting energy efficiency and substantial government incentives for waste heat recovery technologies. However, the Asia-Pacific region is witnessing the fastest growth rate at 10.7% annually, driven by rapid industrialization in China and India, coupled with increasing environmental awareness and supportive government policies.

Market penetration varies significantly across different industries. While adoption in power generation and heavy manufacturing industries has reached moderate levels (15-20% of potential applications), other sectors such as commercial buildings and small to medium-sized manufacturing facilities show considerably lower penetration rates (below 5%), indicating substantial growth opportunities.

Key market drivers include rising energy prices, which have increased by an average of 6.2% annually over the past five years in major industrial economies, creating stronger economic incentives for waste heat recovery. Additionally, carbon pricing mechanisms and emissions regulations in 78 countries worldwide are pushing industries to adopt more energy-efficient technologies.

Customer demand patterns reveal a growing preference for integrated systems that offer both waste heat recovery and energy management capabilities. Return on investment (ROI) remains a critical decision factor, with most customers expecting payback periods under four years. This requirement presents challenges for wider adoption, as current thermoelectric systems typically achieve payback periods of 3-7 years depending on application and scale.

Market barriers include high initial capital costs, technical limitations in conversion efficiency, and lack of standardization across different applications. The fragmented nature of the market, with numerous small and medium-sized technology providers, also contributes to inconsistent product quality and performance standards.

Global Status and Technical Barriers in Thermoelectric Systems

Thermoelectric waste recovery systems have gained significant attention globally as an effective means to harvest waste heat and convert it into usable electricity. Currently, the global landscape of thermoelectric technology implementation varies considerably across regions, with Japan, the United States, and Germany leading in research and commercial applications. These nations have established comprehensive regulatory frameworks that govern the deployment of thermoelectric systems, particularly in automotive and industrial sectors.

The primary technical standards governing thermoelectric waste recovery systems include IEEE 1834 for thermoelectric generator performance metrics, ASTM E2716 for material characterization, and ISO 23550 for safety requirements. These standards provide essential guidelines for system design, material selection, performance evaluation, and safety considerations. However, significant regional variations exist, with European standards emphasizing environmental sustainability and safety, while North American standards focus more on performance metrics and reliability.

Despite progress in standardization, several critical technical barriers impede widespread adoption of thermoelectric waste recovery systems. The conversion efficiency of commercial thermoelectric materials remains relatively low (typically 5-8%), significantly below the theoretical limits and other energy conversion technologies. This efficiency challenge is compounded by material degradation issues under thermal cycling conditions, reducing system longevity and reliability in real-world applications.

System integration presents another substantial barrier, as thermoelectric generators must interface effectively with existing industrial or vehicular systems while maintaining thermal management efficiency. Current standards inadequately address these integration challenges, particularly for complex systems with variable heat sources. Additionally, measurement and testing protocols exhibit inconsistencies across different standards, creating difficulties in comparing performance data across different systems and applications.

Cost-effectiveness remains a significant obstacle, with thermoelectric materials and manufacturing processes still relatively expensive compared to alternative energy recovery technologies. The lack of standardized cost-benefit analysis methodologies further complicates economic feasibility assessments for potential adopters.

Emerging markets face additional challenges due to limited access to testing facilities and certification processes that comply with international standards. This creates barriers to entry for innovative solutions from developing economies and restricts global market expansion. Furthermore, the rapid evolution of thermoelectric materials science has outpaced standardization efforts, resulting in outdated technical requirements that fail to accommodate novel materials and system designs.

Addressing these technical barriers requires harmonization of international standards, development of more comprehensive testing protocols, and creation of standards that anticipate future technological developments rather than merely codifying current practices.

The primary technical standards governing thermoelectric waste recovery systems include IEEE 1834 for thermoelectric generator performance metrics, ASTM E2716 for material characterization, and ISO 23550 for safety requirements. These standards provide essential guidelines for system design, material selection, performance evaluation, and safety considerations. However, significant regional variations exist, with European standards emphasizing environmental sustainability and safety, while North American standards focus more on performance metrics and reliability.

Despite progress in standardization, several critical technical barriers impede widespread adoption of thermoelectric waste recovery systems. The conversion efficiency of commercial thermoelectric materials remains relatively low (typically 5-8%), significantly below the theoretical limits and other energy conversion technologies. This efficiency challenge is compounded by material degradation issues under thermal cycling conditions, reducing system longevity and reliability in real-world applications.

System integration presents another substantial barrier, as thermoelectric generators must interface effectively with existing industrial or vehicular systems while maintaining thermal management efficiency. Current standards inadequately address these integration challenges, particularly for complex systems with variable heat sources. Additionally, measurement and testing protocols exhibit inconsistencies across different standards, creating difficulties in comparing performance data across different systems and applications.

Cost-effectiveness remains a significant obstacle, with thermoelectric materials and manufacturing processes still relatively expensive compared to alternative energy recovery technologies. The lack of standardized cost-benefit analysis methodologies further complicates economic feasibility assessments for potential adopters.

Emerging markets face additional challenges due to limited access to testing facilities and certification processes that comply with international standards. This creates barriers to entry for innovative solutions from developing economies and restricts global market expansion. Furthermore, the rapid evolution of thermoelectric materials science has outpaced standardization efforts, resulting in outdated technical requirements that fail to accommodate novel materials and system designs.

Addressing these technical barriers requires harmonization of international standards, development of more comprehensive testing protocols, and creation of standards that anticipate future technological developments rather than merely codifying current practices.

Current Thermoelectric Waste Heat Recovery Solutions

01 Automotive exhaust heat recovery systems

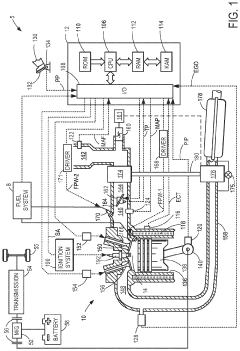

Thermoelectric systems designed specifically for recovering waste heat from vehicle exhaust systems. These systems convert thermal energy from exhaust gases into electrical power that can be used to charge batteries or power vehicle electrical systems, improving overall fuel efficiency. The technology typically involves mounting thermoelectric generators along exhaust pipes or manifolds where temperature differentials are highest.- Automotive exhaust heat recovery systems: Thermoelectric systems designed specifically for recovering waste heat from vehicle exhaust systems. These systems convert thermal energy from exhaust gases into electrical power that can be used to charge batteries, power auxiliary systems, or improve fuel efficiency. The technology typically involves mounting thermoelectric generators on exhaust pipes or manifolds where temperature differentials are highest, enabling effective energy harvesting from otherwise wasted heat.

- Industrial waste heat recovery applications: Thermoelectric systems designed for large-scale industrial applications where significant waste heat is generated. These systems capture thermal energy from industrial processes such as manufacturing, power generation, and chemical production. The recovered energy can be converted into electricity to improve overall plant efficiency and reduce energy costs. These solutions often include specialized heat exchangers and thermoelectric modules designed to withstand harsh industrial environments.

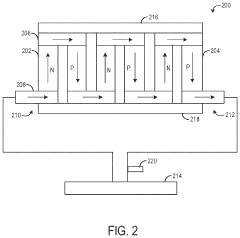

- Advanced thermoelectric materials and module designs: Innovations in thermoelectric materials and module configurations to improve conversion efficiency. These developments focus on novel semiconductor materials, nanostructured elements, and advanced manufacturing techniques to enhance the Seebeck effect and reduce thermal conductivity. Improved module designs address issues of thermal cycling, mechanical stress, and electrical connectivity to increase durability and performance in waste heat recovery applications.

- Integrated cooling and heat management systems: Systems that combine thermoelectric waste heat recovery with cooling functions. These integrated solutions address both waste heat utilization and thermal management challenges simultaneously. By incorporating heat pipes, liquid cooling circuits, or phase change materials, these systems optimize temperature differentials across thermoelectric modules while providing cooling for critical components. This dual functionality improves overall system efficiency and expands application possibilities.

- Low-temperature waste heat recovery solutions: Specialized thermoelectric systems designed to recover energy from low-grade waste heat sources (typically below 200°C). These systems utilize advanced materials and configurations optimized for smaller temperature differentials, enabling energy recovery from sources previously considered unviable. Applications include recovering heat from cooling water, HVAC systems, and low-temperature industrial processes, expanding the range of potential energy recovery opportunities.

02 Industrial waste heat recovery applications

Thermoelectric systems designed for large-scale industrial settings to recover waste heat from manufacturing processes, power generation, or other industrial operations. These systems can capture heat from furnaces, boilers, or other high-temperature industrial processes and convert it into usable electricity, improving energy efficiency and reducing operational costs in industrial facilities.Expand Specific Solutions03 Enhanced thermoelectric materials and structures

Advanced materials and structural designs that improve the efficiency of thermoelectric waste heat recovery. This includes novel semiconductor materials, nanostructured thermoelectric elements, and improved junction designs that enhance the Seebeck effect and reduce thermal conductivity. These innovations aim to increase the conversion efficiency of thermoelectric generators beyond traditional limitations.Expand Specific Solutions04 Compact and modular thermoelectric recovery units

Modular and compact thermoelectric waste heat recovery systems designed for easy installation and scalability. These units feature standardized components that can be assembled in various configurations to match specific waste heat sources. The modular approach allows for flexible deployment across different applications and simplifies maintenance and replacement of components.Expand Specific Solutions05 Cooling and heat management systems for thermoelectric generators

Specialized cooling and heat management technologies designed to optimize the temperature differential across thermoelectric elements. These systems include advanced heat exchangers, cooling fins, liquid cooling circuits, and thermal interface materials that maximize heat transfer efficiency. Proper thermal management is crucial for maintaining optimal operating conditions and extending the lifespan of thermoelectric waste recovery systems.Expand Specific Solutions

Leading Companies and Competitive Landscape

The thermoelectric waste recovery systems market is currently in a growth phase, with increasing adoption driven by global energy efficiency initiatives and sustainability goals. Market size is expanding steadily, projected to reach significant value as industries seek cost-effective waste heat utilization solutions. Technologically, the field shows varying maturity levels across applications, with automotive implementations (Toyota, Samsung SDI) being more advanced than industrial applications. Leading players include established industrial giants like Mitsubishi Heavy Industries and Toyota developing proprietary systems, alongside specialized firms such as InEnTec and Energy Harvesting Tech focusing on innovative recovery solutions. Research institutions like California Institute of Technology and Industrial Technology Research Institute are advancing fundamental technologies, while regional players like Shuangliang Eco-Energy Systems are expanding market reach through localized applications.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang Eco-Energy Systems has developed comprehensive thermoelectric waste heat recovery solutions that comply with Chinese standards GB/T 32751 for industrial waste heat recovery and international ISO 50001 energy management standards. Their technology focuses primarily on industrial applications in cement, steel, and glass manufacturing sectors where substantial waste heat is generated. Shuangliang's systems utilize segmented thermoelectric modules that optimize performance across varying temperature gradients, achieving conversion efficiencies of 5-7% in industrial implementations[1]. Their integrated approach combines thermoelectric generation with traditional heat exchangers to maximize total energy recovery, capturing both electrical and thermal energy from waste heat sources. The company's systems are designed to meet China's increasingly stringent industrial emissions and energy efficiency regulations, including the latest GB 31571 standards. Shuangliang's modular design allows for scalable implementation from 50kW to multi-MW installations, with documented payback periods of 3-5 years in high-energy-consumption industries[3]. Their systems incorporate advanced monitoring and control capabilities that ensure compliance with performance standards while optimizing operation based on varying industrial process conditions.

Strengths: Comprehensive integration with existing industrial processes, cost-effective implementation with reasonable ROI, and strong compliance with rapidly evolving Chinese industrial efficiency standards. Weaknesses: Limited international deployment experience outside Asia, moderate conversion efficiencies compared to cutting-edge laboratory systems, and performance variability in fluctuating industrial environments.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermoelectric waste heat recovery systems for automotive applications that comply with international standards including ISO 14001 and ISO 50001 for environmental management and energy efficiency. Their technology utilizes bismuth telluride and skutterudite-based thermoelectric generators (TEGs) that can convert exhaust heat into electricity with conversion efficiencies of 4-5% in real-world driving conditions[1]. Toyota's systems are designed to meet stringent automotive safety standards (ISO 26262) and electromagnetic compatibility requirements (SAE J1113). Their third-generation TEG systems integrate directly with vehicle exhaust systems and can generate up to 200W of power during highway driving[3], reducing fuel consumption by approximately 2-3% and helping meet increasingly strict emissions standards worldwide.

Strengths: Extensive automotive integration experience, proven durability in harsh operating environments, and compliance with global automotive standards. Weaknesses: Relatively low conversion efficiency compared to other energy recovery methods, high material costs for thermoelectric elements, and limited to specific temperature ranges for optimal performance.

Key Patents and Technical Innovations

Waste heat recovery system and thermoelectric conversion unit

PatentWO2006075571A8

Innovation

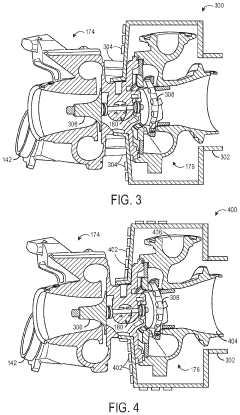

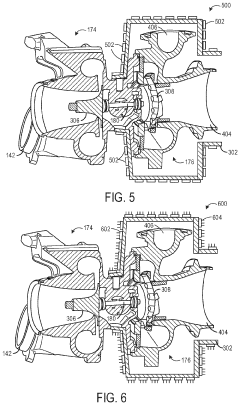

- A waste heat recovery system incorporating a thermoelectric conversion unit with a sintered body of crystals less than 200 µm in size, utilizing a high-temperature side and low-temperature side heat exchanger configuration, and featuring thermal stress relief mechanisms to improve heat transfer and reliability, allowing for efficient conversion of waste heat into electricity and utilization for heating, defrosting, and engine temperature control.

Methods and systems for thermoelectrically recovering waste heat from turbocharger systems

PatentActiveUS10697343B2

Innovation

- Thermoelectric generators are mounted on the turbocharger to recover waste heat and monitor the temperature of the exhaust turbine, wastegate, compressor, and e-booster by adjusting engine operating parameters based on the current generated, allowing for improved heat recovery and diagnostic capabilities.

Regulatory Framework and Compliance Requirements

Thermoelectric waste recovery systems are subject to a complex web of international, national, and industry-specific standards that govern their design, installation, operation, and performance. The International Electrotechnical Commission (IEC) has established IEC 62830-5 specifically for thermoelectric energy harvesting systems, providing guidelines on performance measurement and reliability testing. This standard ensures consistency in evaluating system efficiency and durability across different applications and environments.

In the United States, the Department of Energy (DOE) has implemented efficiency standards through 10 CFR Part 431, which includes provisions relevant to waste heat recovery technologies. These regulations establish minimum performance requirements and testing protocols that manufacturers must adhere to before bringing products to market. Additionally, the Environmental Protection Agency's (EPA) Energy Star program offers voluntary certification for high-efficiency waste heat recovery systems, providing market recognition for products that exceed minimum regulatory requirements.

The European Union's regulatory framework includes the Ecodesign Directive (2009/125/EC) and Energy Labelling Regulation (2017/1369), which set mandatory ecological requirements for energy-related products. For thermoelectric waste recovery systems, these regulations mandate minimum efficiency thresholds and standardized performance reporting. The EU has also incorporated these systems into its broader climate policy through the Renewable Energy Directive (RED II), which recognizes waste heat recovery as a form of renewable energy when certain criteria are met.

Safety standards represent another critical compliance area, with UL 1995 in the US and IEC 60335 internationally establishing requirements for electrical safety, thermal protection, and material compatibility. These standards address potential hazards such as electrical shock, fire risks, and material degradation under operating conditions. For systems integrated into automotive applications, additional standards such as ISO 26262 for functional safety and UN ECE R10 for electromagnetic compatibility must be considered.

Emerging regulatory trends indicate increasing stringency in efficiency requirements and a growing focus on lifecycle assessment. The EU's Circular Economy Action Plan is driving new requirements for product durability, repairability, and end-of-life management that will impact thermoelectric system design and manufacturing. Similarly, China's Energy Conservation Law and associated standards are evolving to place greater emphasis on industrial waste heat recovery, creating both compliance challenges and market opportunities.

Compliance with these diverse regulatory frameworks requires manufacturers to implement comprehensive quality management systems, conduct regular testing and certification, and maintain detailed technical documentation. For global market access, companies must navigate the complexities of multiple jurisdictional requirements, often necessitating strategic partnerships with compliance specialists and testing laboratories familiar with regional variations in standards interpretation and enforcement.

In the United States, the Department of Energy (DOE) has implemented efficiency standards through 10 CFR Part 431, which includes provisions relevant to waste heat recovery technologies. These regulations establish minimum performance requirements and testing protocols that manufacturers must adhere to before bringing products to market. Additionally, the Environmental Protection Agency's (EPA) Energy Star program offers voluntary certification for high-efficiency waste heat recovery systems, providing market recognition for products that exceed minimum regulatory requirements.

The European Union's regulatory framework includes the Ecodesign Directive (2009/125/EC) and Energy Labelling Regulation (2017/1369), which set mandatory ecological requirements for energy-related products. For thermoelectric waste recovery systems, these regulations mandate minimum efficiency thresholds and standardized performance reporting. The EU has also incorporated these systems into its broader climate policy through the Renewable Energy Directive (RED II), which recognizes waste heat recovery as a form of renewable energy when certain criteria are met.

Safety standards represent another critical compliance area, with UL 1995 in the US and IEC 60335 internationally establishing requirements for electrical safety, thermal protection, and material compatibility. These standards address potential hazards such as electrical shock, fire risks, and material degradation under operating conditions. For systems integrated into automotive applications, additional standards such as ISO 26262 for functional safety and UN ECE R10 for electromagnetic compatibility must be considered.

Emerging regulatory trends indicate increasing stringency in efficiency requirements and a growing focus on lifecycle assessment. The EU's Circular Economy Action Plan is driving new requirements for product durability, repairability, and end-of-life management that will impact thermoelectric system design and manufacturing. Similarly, China's Energy Conservation Law and associated standards are evolving to place greater emphasis on industrial waste heat recovery, creating both compliance challenges and market opportunities.

Compliance with these diverse regulatory frameworks requires manufacturers to implement comprehensive quality management systems, conduct regular testing and certification, and maintain detailed technical documentation. For global market access, companies must navigate the complexities of multiple jurisdictional requirements, often necessitating strategic partnerships with compliance specialists and testing laboratories familiar with regional variations in standards interpretation and enforcement.

Environmental Impact and Sustainability Metrics

Thermoelectric waste recovery systems offer significant potential for reducing environmental impacts across various industrial sectors. These systems capture waste heat that would otherwise be released into the environment and convert it into usable electricity, thereby improving overall energy efficiency. The environmental benefits extend beyond energy savings to include reduced greenhouse gas emissions, decreased reliance on fossil fuels, and minimized thermal pollution.

Current sustainability metrics for thermoelectric waste recovery systems primarily focus on energy conversion efficiency, which typically ranges from 5-10% for commercial systems. However, comprehensive environmental assessment requires consideration of broader lifecycle impacts. The manufacturing of thermoelectric materials often involves rare earth elements and other materials with significant extraction footprints. A complete sustainability evaluation must account for these upstream environmental costs against the downstream benefits of energy recovery.

Carbon footprint reduction represents a key environmental performance indicator for these systems. Studies indicate that industrial-scale thermoelectric waste heat recovery can reduce CO2 emissions by 0.1-0.5 tons per MWh of electricity generated, depending on the carbon intensity of the displaced grid electricity. This metric provides a quantifiable measure of environmental benefit that can be standardized across different applications and regions.

Water conservation benefits also merit consideration in environmental impact assessments. Unlike traditional power generation technologies that often require significant water resources for cooling, thermoelectric waste recovery systems operate without additional water consumption, potentially saving 0.4-0.8 gallons of water per kWh compared to conventional thermal power generation.

Standardized lifecycle assessment (LCA) methodologies specific to thermoelectric systems remain underdeveloped. The ISO 14040 series provides general guidance, but industry-specific protocols are needed to address the unique characteristics of thermoelectric materials and applications. Current gaps in LCA standards include insufficient guidance on accounting for end-of-life recycling potential and thermal pollution mitigation benefits.

Emerging sustainability metrics include resource circularity indicators that measure the potential for recovering and reusing thermoelectric materials at end-of-life. The development of non-toxic, abundant material alternatives to traditional bismuth telluride compounds represents another frontier in improving the environmental profile of these systems. Standards that incorporate these forward-looking sustainability considerations will be essential for guiding the industry toward truly sustainable waste heat recovery solutions.

Current sustainability metrics for thermoelectric waste recovery systems primarily focus on energy conversion efficiency, which typically ranges from 5-10% for commercial systems. However, comprehensive environmental assessment requires consideration of broader lifecycle impacts. The manufacturing of thermoelectric materials often involves rare earth elements and other materials with significant extraction footprints. A complete sustainability evaluation must account for these upstream environmental costs against the downstream benefits of energy recovery.

Carbon footprint reduction represents a key environmental performance indicator for these systems. Studies indicate that industrial-scale thermoelectric waste heat recovery can reduce CO2 emissions by 0.1-0.5 tons per MWh of electricity generated, depending on the carbon intensity of the displaced grid electricity. This metric provides a quantifiable measure of environmental benefit that can be standardized across different applications and regions.

Water conservation benefits also merit consideration in environmental impact assessments. Unlike traditional power generation technologies that often require significant water resources for cooling, thermoelectric waste recovery systems operate without additional water consumption, potentially saving 0.4-0.8 gallons of water per kWh compared to conventional thermal power generation.

Standardized lifecycle assessment (LCA) methodologies specific to thermoelectric systems remain underdeveloped. The ISO 14040 series provides general guidance, but industry-specific protocols are needed to address the unique characteristics of thermoelectric materials and applications. Current gaps in LCA standards include insufficient guidance on accounting for end-of-life recycling potential and thermal pollution mitigation benefits.

Emerging sustainability metrics include resource circularity indicators that measure the potential for recovering and reusing thermoelectric materials at end-of-life. The development of non-toxic, abundant material alternatives to traditional bismuth telluride compounds represents another frontier in improving the environmental profile of these systems. Standards that incorporate these forward-looking sustainability considerations will be essential for guiding the industry toward truly sustainable waste heat recovery solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!