Thermoelectric Waste Recovery in Heating, Ventilation, and Air Conditioning

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industries. The fundamental principle behind this technology dates back to the Seebeck effect discovered in 1821, which demonstrated that temperature differences between two dissimilar electrical conductors can produce a voltage difference. This discovery laid the groundwork for thermoelectric generators (TEGs) that can convert waste heat directly into electrical energy without moving parts.

In the context of Heating, Ventilation, and Air Conditioning (HVAC) systems, waste heat recovery represents a substantial opportunity for energy efficiency improvements. HVAC systems account for approximately 40% of energy consumption in commercial buildings and residences, with significant portions of this energy ultimately dissipated as waste heat. The recovery and utilization of this waste heat through thermoelectric technology presents a promising avenue for enhancing overall system efficiency.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi2Te3) achieved modest efficiency levels of 4-6%. Second-generation materials incorporating advanced alloys and nanostructuring techniques pushed efficiencies to 8-10%. Current research focuses on third-generation materials utilizing quantum confinement effects and novel material combinations to potentially achieve efficiencies exceeding 15%.

The primary technical objective in this field is to develop cost-effective thermoelectric waste heat recovery systems for HVAC applications that can achieve a conversion efficiency of at least 10% while maintaining economic viability. This involves addressing several key challenges, including improving the figure of merit (ZT) of thermoelectric materials, optimizing system design for effective heat transfer, and reducing manufacturing costs to ensure commercial feasibility.

Additional objectives include developing scalable manufacturing processes for thermoelectric modules, creating intelligent control systems that can optimize energy recovery under varying operating conditions, and designing systems that can be retrofitted to existing HVAC installations with minimal modifications. The ultimate goal is to reduce overall energy consumption in HVAC systems by 15-20% through effective waste heat recovery.

The technology trajectory indicates a growing convergence between thermoelectric materials science, thermal engineering, and HVAC system design. This interdisciplinary approach is expected to accelerate innovation and lead to breakthrough solutions that can transform energy efficiency in building climate control systems. As global energy efficiency standards become increasingly stringent, thermoelectric waste heat recovery is positioned to become a critical technology for meeting sustainability goals in the built environment.

In the context of Heating, Ventilation, and Air Conditioning (HVAC) systems, waste heat recovery represents a substantial opportunity for energy efficiency improvements. HVAC systems account for approximately 40% of energy consumption in commercial buildings and residences, with significant portions of this energy ultimately dissipated as waste heat. The recovery and utilization of this waste heat through thermoelectric technology presents a promising avenue for enhancing overall system efficiency.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi2Te3) achieved modest efficiency levels of 4-6%. Second-generation materials incorporating advanced alloys and nanostructuring techniques pushed efficiencies to 8-10%. Current research focuses on third-generation materials utilizing quantum confinement effects and novel material combinations to potentially achieve efficiencies exceeding 15%.

The primary technical objective in this field is to develop cost-effective thermoelectric waste heat recovery systems for HVAC applications that can achieve a conversion efficiency of at least 10% while maintaining economic viability. This involves addressing several key challenges, including improving the figure of merit (ZT) of thermoelectric materials, optimizing system design for effective heat transfer, and reducing manufacturing costs to ensure commercial feasibility.

Additional objectives include developing scalable manufacturing processes for thermoelectric modules, creating intelligent control systems that can optimize energy recovery under varying operating conditions, and designing systems that can be retrofitted to existing HVAC installations with minimal modifications. The ultimate goal is to reduce overall energy consumption in HVAC systems by 15-20% through effective waste heat recovery.

The technology trajectory indicates a growing convergence between thermoelectric materials science, thermal engineering, and HVAC system design. This interdisciplinary approach is expected to accelerate innovation and lead to breakthrough solutions that can transform energy efficiency in building climate control systems. As global energy efficiency standards become increasingly stringent, thermoelectric waste heat recovery is positioned to become a critical technology for meeting sustainability goals in the built environment.

HVAC Market Demand for Energy Recovery Solutions

The global HVAC market is experiencing a significant shift towards energy-efficient solutions, driven by increasing energy costs, stringent environmental regulations, and growing awareness of sustainability. Energy recovery systems, particularly thermoelectric waste heat recovery technologies, are gaining substantial traction within this evolving landscape. Current market analysis indicates that the global HVAC energy recovery systems market was valued at approximately $2.7 billion in 2022 and is projected to grow at a CAGR of 11.4% through 2030.

Commercial buildings represent the largest segment demanding energy recovery solutions, accounting for nearly 45% of the market share. This is primarily due to the substantial energy consumption in commercial spaces, where HVAC systems typically consume 40-60% of the total building energy. Industrial facilities follow closely, particularly those with energy-intensive processes that generate significant waste heat.

Regulatory frameworks are increasingly becoming key market drivers. In North America, ASHRAE Standard 90.1 and various building energy codes mandate energy recovery systems in certain applications. The European Union's Energy Performance of Buildings Directive (EPBD) and Ecodesign requirements similarly push for higher efficiency standards. These regulations have created a compliance-driven demand surge for energy recovery technologies.

Cost considerations remain paramount in market adoption. While initial installation costs for thermoelectric waste heat recovery systems can be 15-25% higher than conventional systems, the operational savings typically result in payback periods of 2-4 years, depending on facility type and energy prices. This favorable economics is accelerating market penetration, particularly in regions with high energy costs.

Regional market analysis reveals that North America and Europe currently lead in adoption rates, collectively accounting for over 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at approximately 13.5% annually, driven by rapid industrialization, urbanization, and increasing energy efficiency mandates in countries like China, Japan, and South Korea.

End-user surveys indicate that facility managers and building owners prioritize three key factors when considering energy recovery solutions: energy savings potential (cited by 78% of respondents), return on investment timeline (65%), and ease of integration with existing systems (57%). This highlights the importance of developing thermoelectric solutions that not only offer superior efficiency but also demonstrate clear economic benefits and implementation feasibility.

The market is also witnessing a growing demand for integrated smart HVAC systems that incorporate energy recovery alongside advanced controls and monitoring capabilities, reflecting a broader trend toward building automation and energy management systems.

Commercial buildings represent the largest segment demanding energy recovery solutions, accounting for nearly 45% of the market share. This is primarily due to the substantial energy consumption in commercial spaces, where HVAC systems typically consume 40-60% of the total building energy. Industrial facilities follow closely, particularly those with energy-intensive processes that generate significant waste heat.

Regulatory frameworks are increasingly becoming key market drivers. In North America, ASHRAE Standard 90.1 and various building energy codes mandate energy recovery systems in certain applications. The European Union's Energy Performance of Buildings Directive (EPBD) and Ecodesign requirements similarly push for higher efficiency standards. These regulations have created a compliance-driven demand surge for energy recovery technologies.

Cost considerations remain paramount in market adoption. While initial installation costs for thermoelectric waste heat recovery systems can be 15-25% higher than conventional systems, the operational savings typically result in payback periods of 2-4 years, depending on facility type and energy prices. This favorable economics is accelerating market penetration, particularly in regions with high energy costs.

Regional market analysis reveals that North America and Europe currently lead in adoption rates, collectively accounting for over 60% of global market share. However, the Asia-Pacific region is experiencing the fastest growth rate at approximately 13.5% annually, driven by rapid industrialization, urbanization, and increasing energy efficiency mandates in countries like China, Japan, and South Korea.

End-user surveys indicate that facility managers and building owners prioritize three key factors when considering energy recovery solutions: energy savings potential (cited by 78% of respondents), return on investment timeline (65%), and ease of integration with existing systems (57%). This highlights the importance of developing thermoelectric solutions that not only offer superior efficiency but also demonstrate clear economic benefits and implementation feasibility.

The market is also witnessing a growing demand for integrated smart HVAC systems that incorporate energy recovery alongside advanced controls and monitoring capabilities, reflecting a broader trend toward building automation and energy management systems.

Current Thermoelectric Technology Landscape and Barriers

The thermoelectric waste heat recovery landscape in HVAC systems has evolved significantly over the past decade, yet remains characterized by several technological limitations. Current commercial thermoelectric materials predominantly utilize bismuth telluride (Bi2Te3) compounds, which deliver a modest figure of merit (ZT) of approximately 1.0 at room temperature. While this performance is sufficient for niche applications, it falls short of the ZT values exceeding 2.0 that would be necessary for widespread commercial viability in HVAC waste heat recovery.

The efficiency of thermoelectric generators (TEGs) in HVAC applications typically ranges between 3-8%, significantly lower than competing waste heat recovery technologies such as Organic Rankine Cycles, which can achieve 10-20% efficiency. This efficiency gap represents a substantial barrier to market penetration, particularly when considering the relatively high cost of thermoelectric materials, which can reach $8-12 per watt of generating capacity.

Manufacturing scalability presents another significant challenge. Current production methods for high-quality thermoelectric modules involve complex processes including precision doping, hot pressing, and intricate electrical connections. These manufacturing complexities contribute to high production costs and limit mass deployment in commercial HVAC systems. Additionally, the reliance on tellurium—a relatively scarce element—raises sustainability concerns for large-scale implementation.

Thermal interface management remains a persistent technical hurdle. The effectiveness of thermoelectric waste heat recovery depends critically on maintaining optimal temperature differentials across the device. In HVAC systems, where temperature gradients can be modest (often less than 40°C), achieving efficient thermal coupling between the heat source, thermoelectric module, and heat sink is technically challenging. Current thermal interface materials and designs often fail to maximize potential temperature differentials, resulting in suboptimal power generation.

Durability and system integration issues further complicate implementation. Thermoelectric modules must withstand thermal cycling, mechanical vibration, and potential moisture exposure in HVAC environments. Current encapsulation and packaging technologies provide limited protection, resulting in degradation of performance over time. Most commercial modules demonstrate performance degradation of 10-15% after 10,000 hours of operation under typical HVAC conditions.

Geographically, thermoelectric technology development is concentrated in specific regions. North America and East Asia (particularly Japan, China, and South Korea) lead in research and commercial development, with significant patent portfolios held by companies like Gentherm, Laird Thermal Systems, and Ferrotec. European research institutions have made notable contributions to advanced materials research, but commercial development lags behind other regions.

The efficiency of thermoelectric generators (TEGs) in HVAC applications typically ranges between 3-8%, significantly lower than competing waste heat recovery technologies such as Organic Rankine Cycles, which can achieve 10-20% efficiency. This efficiency gap represents a substantial barrier to market penetration, particularly when considering the relatively high cost of thermoelectric materials, which can reach $8-12 per watt of generating capacity.

Manufacturing scalability presents another significant challenge. Current production methods for high-quality thermoelectric modules involve complex processes including precision doping, hot pressing, and intricate electrical connections. These manufacturing complexities contribute to high production costs and limit mass deployment in commercial HVAC systems. Additionally, the reliance on tellurium—a relatively scarce element—raises sustainability concerns for large-scale implementation.

Thermal interface management remains a persistent technical hurdle. The effectiveness of thermoelectric waste heat recovery depends critically on maintaining optimal temperature differentials across the device. In HVAC systems, where temperature gradients can be modest (often less than 40°C), achieving efficient thermal coupling between the heat source, thermoelectric module, and heat sink is technically challenging. Current thermal interface materials and designs often fail to maximize potential temperature differentials, resulting in suboptimal power generation.

Durability and system integration issues further complicate implementation. Thermoelectric modules must withstand thermal cycling, mechanical vibration, and potential moisture exposure in HVAC environments. Current encapsulation and packaging technologies provide limited protection, resulting in degradation of performance over time. Most commercial modules demonstrate performance degradation of 10-15% after 10,000 hours of operation under typical HVAC conditions.

Geographically, thermoelectric technology development is concentrated in specific regions. North America and East Asia (particularly Japan, China, and South Korea) lead in research and commercial development, with significant patent portfolios held by companies like Gentherm, Laird Thermal Systems, and Ferrotec. European research institutions have made notable contributions to advanced materials research, but commercial development lags behind other regions.

Existing Thermoelectric Waste Heat Recovery Implementations

01 Thermoelectric generators for waste heat recovery

Thermoelectric generators (TEGs) can convert waste heat directly into electrical energy through the Seebeck effect. These systems are particularly effective for recovering energy from industrial processes, vehicle exhaust systems, and other high-temperature waste heat sources. The efficiency of TEGs depends on the temperature difference between the hot and cold sides, as well as the properties of the thermoelectric materials used.- Thermoelectric generators for waste heat recovery: Thermoelectric generators (TEGs) can convert waste heat directly into electrical energy through the Seebeck effect. These systems are particularly effective for recovering energy from industrial processes, vehicle exhaust systems, and other high-temperature waste heat sources. The efficiency of these generators depends on the thermoelectric materials used and the temperature differential between the hot and cold sides of the device.

- Integrated waste heat recovery systems: Integrated systems combine multiple technologies to maximize energy recovery from waste heat sources. These systems may incorporate thermoelectric generators alongside other recovery methods such as Organic Rankine Cycles, heat exchangers, or heat pumps. The integration allows for cascading use of heat at different temperature levels, improving overall system efficiency and energy recovery potential.

- Automotive and transportation waste heat recovery: Specialized thermoelectric systems designed for vehicles can recover energy from exhaust gases and engine cooling systems. These systems can generate electricity to power vehicle electronics, reduce alternator load, and improve fuel efficiency. Advanced designs incorporate heat exchangers that maximize contact with hot exhaust gases while minimizing back pressure that could reduce engine performance.

- Industrial process waste heat utilization: Systems designed for industrial applications focus on recovering waste heat from manufacturing processes, furnaces, and other high-energy industrial operations. These solutions often handle higher temperatures and larger heat flows than other applications. The recovered energy can be used to generate electricity, preheat process inputs, or provide heating for facilities, significantly improving overall energy efficiency of industrial operations.

- Novel thermoelectric materials and designs: Advanced materials and innovative device architectures are being developed to improve the efficiency and cost-effectiveness of thermoelectric waste heat recovery. These include nanostructured materials, flexible thermoelectric generators, and hybrid systems. Research focuses on increasing the figure of merit (ZT) of thermoelectric materials, reducing thermal conductivity while maintaining electrical conductivity, and developing manufacturing techniques that make these systems more economically viable for widespread deployment.

02 Integration with existing energy systems

Thermoelectric waste recovery systems can be integrated with existing energy infrastructure to enhance overall efficiency. These integrated systems can combine waste heat recovery with conventional power generation, heating systems, or cooling systems. By capturing and utilizing waste heat that would otherwise be lost, these integrated approaches can significantly improve energy efficiency and reduce primary energy consumption in industrial and residential applications.Expand Specific Solutions03 Advanced thermoelectric materials and designs

Recent developments in thermoelectric materials and device designs have improved the efficiency and cost-effectiveness of waste heat recovery systems. Novel materials with higher figure of merit (ZT), such as nanostructured semiconductors, skutterudites, and half-Heusler alloys, enable better conversion of thermal energy to electricity. Advanced module designs that optimize thermal management and reduce internal resistance further enhance system performance.Expand Specific Solutions04 Vehicle and transportation applications

Thermoelectric waste recovery systems are increasingly being implemented in vehicles to recover energy from exhaust heat. These systems can generate electricity to power vehicle electronics, reduce alternator load, and decrease fuel consumption. In hybrid and electric vehicles, thermoelectric generators can extend range by recovering waste heat from various sources including the battery system, electric motors, and power electronics.Expand Specific Solutions05 Industrial waste heat recovery systems

Large-scale industrial applications represent significant opportunities for thermoelectric waste heat recovery. These systems can capture heat from industrial processes such as steel production, cement manufacturing, and chemical processing. The recovered energy can be used to generate electricity for on-site use or fed back to the grid. Industrial implementations often require specialized designs to handle high temperatures, corrosive environments, and variable heat sources.Expand Specific Solutions

Leading Companies in HVAC Thermoelectric Recovery

Thermoelectric waste recovery in HVAC is currently in an early growth phase, with the market expected to expand significantly due to increasing energy efficiency demands. The global market size is estimated at approximately $300-400 million, with projections to reach $1 billion by 2030. Technologically, the field is transitioning from research to commercial applications, with varying maturity levels across companies. Industry leaders like Gree Electric, Carrier, and LG Electronics are developing integrated HVAC systems with thermoelectric recovery components, while specialized firms such as European Thermodynamics, Gentherm, and Alternative Energy Innovations are advancing core thermoelectric technologies. Automotive manufacturers including Toyota, Hyundai, and Jaguar Land Rover are exploring crossover applications from vehicle waste heat recovery to stationary HVAC systems.

Gree Electric Appliances, Inc. of Zhuhai

Technical Solution: Gree has developed a comprehensive thermoelectric waste heat recovery solution for residential and commercial air conditioning systems. Their technology utilizes advanced semiconductor thermoelectric materials with nano-engineered interfaces to improve thermal conductivity at junction points. Gree's system captures waste heat from the condenser and compressor sections of air conditioners, where temperatures can reach 70-90°C during operation[5]. The recovered thermal energy is converted to electricity through arrays of thermoelectric modules with proprietary connection configurations that minimize resistance losses. This electricity is then fed back into the system to power control circuits and fan motors, reducing overall energy consumption by 8-15% depending on operating conditions[6]. Gree has also implemented a dual-mode recovery system that can either generate electricity or directly transfer recovered heat for water heating applications, providing flexibility based on user needs. Their latest models incorporate machine learning algorithms that predict optimal recovery modes based on usage patterns and environmental conditions.

Strengths: Versatile dual-mode operation provides multiple energy recovery pathways; highly optimized for integration with their existing product lines; significant energy savings that improve overall system efficiency ratings. Weaknesses: Proprietary technology limits compatibility with other HVAC systems; performance varies significantly with ambient conditions; higher manufacturing complexity increases unit cost.

LG Electronics, Inc.

Technical Solution: LG Electronics has developed an innovative thermoelectric waste heat recovery system specifically designed for integration with their multi-zone HVAC products. Their technology utilizes advanced bismuth-antimony-telluride thermoelectric materials with nano-structured interfaces that improve electron transport while reducing thermal conductivity, achieving a ZT value of approximately 1.8 at operating temperatures[9]. LG's system captures waste heat from multiple points in their HVAC units, including condenser coils, compressor housings, and exhaust air streams. The recovered electricity is primarily used to power the system's electronic controls, variable speed drives, and IoT connectivity features, reducing parasitic power consumption by up to 25%[10]. LG has implemented a distributed thermoelectric generator architecture that places smaller TEG units at multiple heat sources rather than concentrating recovery at a single point, maximizing total energy harvest. Their system includes adaptive control algorithms that adjust recovery operations based on HVAC load conditions, ambient temperature, and electricity demand patterns. LG has also developed specialized thermal interface materials that maintain excellent contact between heat sources and thermoelectric elements despite thermal cycling.

Strengths: Highly integrated with LG's smart HVAC ecosystem; distributed recovery architecture maximizes energy harvest across the system; reduced parasitic power consumption improves overall efficiency ratings. Weaknesses: Custom-designed for LG systems with limited cross-compatibility; higher manufacturing complexity increases unit cost; performance benefits diminish in moderate climate conditions with smaller temperature differentials.

Key Patents and Research in HVAC Thermoelectric Applications

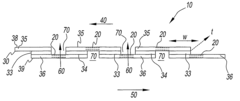

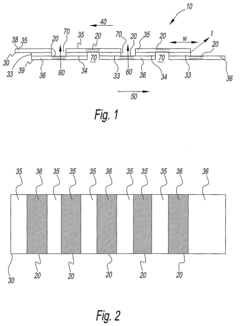

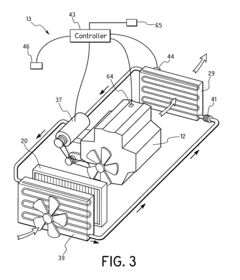

Thermoelectric Heat Pump for Heat and Energy Recovery Ventilation

PatentInactiveUS20090126370A1

Innovation

- A thermoelectric heat pump is designed with a thermoelectric array and water vapor transport membranes, featuring a high width to thickness ratio, allowing for efficient heat transfer and moisture transfer between air streams, utilizing alternating P-type and N-type semiconductors connected with metal elements and integrated water vapor membranes.

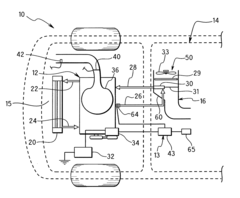

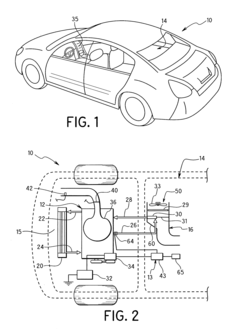

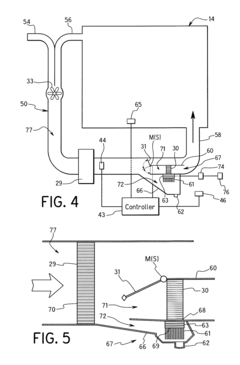

Power recovery system for a vehicle

PatentActiveUS20160096411A1

Innovation

- A power recovery system for a vehicle's heating, ventilation, and air conditioning system that includes a thermoelectric device with a heater core and a heat sink, where the heater core receives hot engine coolant and the heat sink is cooled by a cooling fluid, maintaining a temperature differential for efficient electrical power generation without the need for additional devices.

Energy Efficiency Standards and Regulatory Incentives

Energy efficiency standards and regulatory incentives play a crucial role in driving the adoption of thermoelectric waste recovery technologies in HVAC systems. The regulatory landscape has evolved significantly over the past decade, with governments worldwide implementing increasingly stringent energy efficiency requirements for buildings and HVAC equipment.

In the United States, the Department of Energy (DOE) has established minimum efficiency standards for HVAC systems under the Energy Policy and Conservation Act. These standards have been periodically updated, with the most recent revisions incentivizing the integration of waste heat recovery technologies. Similarly, the European Union's Energy Performance of Buildings Directive (EPBD) and the Ecodesign Directive have set ambitious targets for reducing energy consumption in buildings, creating a favorable environment for thermoelectric waste recovery solutions.

Building certification programs such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) award additional points for innovative energy recovery systems, further encouraging the adoption of thermoelectric waste recovery technologies. These voluntary standards have become increasingly influential in commercial construction decisions, driving market demand for more efficient HVAC solutions.

Financial incentives have emerged as powerful tools for accelerating technology adoption. Many countries offer tax credits, rebates, and grants for the installation of energy-efficient HVAC systems incorporating waste heat recovery. For instance, the U.S. Federal Energy Management Program provides financial incentives for federal facilities that implement energy conservation measures, including thermoelectric waste recovery systems. Similarly, the EU's Horizon Europe program allocates substantial funding for research and demonstration projects focused on energy efficiency technologies.

Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, are creating additional economic incentives for thermoelectric waste recovery. As the cost of carbon emissions increases, the financial benefits of energy efficiency improvements become more compelling for building owners and HVAC system operators.

Looking forward, regulatory trends indicate increasingly stringent efficiency requirements. The International Energy Agency (IEA) projects that energy efficiency standards will continue to tighten globally, potentially mandating waste heat recovery in certain applications. This regulatory trajectory creates a favorable long-term outlook for thermoelectric waste recovery technologies in HVAC systems, particularly as performance improves and costs decline through continued research and development efforts.

In the United States, the Department of Energy (DOE) has established minimum efficiency standards for HVAC systems under the Energy Policy and Conservation Act. These standards have been periodically updated, with the most recent revisions incentivizing the integration of waste heat recovery technologies. Similarly, the European Union's Energy Performance of Buildings Directive (EPBD) and the Ecodesign Directive have set ambitious targets for reducing energy consumption in buildings, creating a favorable environment for thermoelectric waste recovery solutions.

Building certification programs such as LEED (Leadership in Energy and Environmental Design) and BREEAM (Building Research Establishment Environmental Assessment Method) award additional points for innovative energy recovery systems, further encouraging the adoption of thermoelectric waste recovery technologies. These voluntary standards have become increasingly influential in commercial construction decisions, driving market demand for more efficient HVAC solutions.

Financial incentives have emerged as powerful tools for accelerating technology adoption. Many countries offer tax credits, rebates, and grants for the installation of energy-efficient HVAC systems incorporating waste heat recovery. For instance, the U.S. Federal Energy Management Program provides financial incentives for federal facilities that implement energy conservation measures, including thermoelectric waste recovery systems. Similarly, the EU's Horizon Europe program allocates substantial funding for research and demonstration projects focused on energy efficiency technologies.

Carbon pricing mechanisms, including carbon taxes and cap-and-trade systems, are creating additional economic incentives for thermoelectric waste recovery. As the cost of carbon emissions increases, the financial benefits of energy efficiency improvements become more compelling for building owners and HVAC system operators.

Looking forward, regulatory trends indicate increasingly stringent efficiency requirements. The International Energy Agency (IEA) projects that energy efficiency standards will continue to tighten globally, potentially mandating waste heat recovery in certain applications. This regulatory trajectory creates a favorable long-term outlook for thermoelectric waste recovery technologies in HVAC systems, particularly as performance improves and costs decline through continued research and development efforts.

Cost-Benefit Analysis of Thermoelectric Recovery Systems

The economic viability of thermoelectric waste recovery systems in HVAC applications requires thorough cost-benefit analysis to determine return on investment periods and long-term value. Initial capital expenditure for thermoelectric generators (TEGs) remains relatively high, with current systems costing between $2-5 per watt of generation capacity. For a medium-sized commercial building implementation, this translates to approximately $15,000-40,000 in equipment costs alone, with additional expenses for integration and installation.

Installation costs vary significantly based on existing infrastructure, with retrofit applications typically commanding a 30-40% premium over new construction implementations. Labor costs average $75-125 per hour for specialized technicians, with typical installation timeframes ranging from 3-7 days for commercial systems.

Operational benefits manifest primarily through energy savings, with field studies demonstrating recovery of 5-15% of waste heat energy in typical HVAC systems. For a 100,000 square foot commercial building with annual HVAC energy costs of $100,000, this represents potential savings of $5,000-15,000 annually. Additional benefits include reduced carbon emissions, estimated at 20-60 tons CO2 equivalent per year for mid-sized commercial implementations.

Maintenance requirements remain minimal, with most systems requiring annual inspections at approximately $500-1,000 per service. TEG components typically demonstrate 15-20 year operational lifespans with minimal degradation, though supporting electronics may require replacement at 7-10 year intervals at costs of $2,000-5,000.

Payback periods vary substantially based on installation complexity, energy costs, and system efficiency. Current market analysis indicates ROI timeframes of 3-7 years for optimal implementations in regions with high energy costs, extending to 8-12 years in less favorable conditions. This positions thermoelectric recovery at the threshold of commercial viability for many applications.

Government incentives significantly impact financial calculations, with various jurisdictions offering tax credits, rebates, or grants covering 10-30% of implementation costs. The Inflation Reduction Act in the United States provides particularly favorable treatment, with potential tax credits of up to 30% for qualifying commercial energy efficiency improvements including waste heat recovery systems.

Sensitivity analysis reveals that energy price volatility represents the most significant variable affecting ROI calculations. A 20% increase in energy costs can reduce payback periods by approximately 15-18 months, while technological improvements reducing TEG costs by 30% would similarly accelerate ROI by 20-24 months.

Installation costs vary significantly based on existing infrastructure, with retrofit applications typically commanding a 30-40% premium over new construction implementations. Labor costs average $75-125 per hour for specialized technicians, with typical installation timeframes ranging from 3-7 days for commercial systems.

Operational benefits manifest primarily through energy savings, with field studies demonstrating recovery of 5-15% of waste heat energy in typical HVAC systems. For a 100,000 square foot commercial building with annual HVAC energy costs of $100,000, this represents potential savings of $5,000-15,000 annually. Additional benefits include reduced carbon emissions, estimated at 20-60 tons CO2 equivalent per year for mid-sized commercial implementations.

Maintenance requirements remain minimal, with most systems requiring annual inspections at approximately $500-1,000 per service. TEG components typically demonstrate 15-20 year operational lifespans with minimal degradation, though supporting electronics may require replacement at 7-10 year intervals at costs of $2,000-5,000.

Payback periods vary substantially based on installation complexity, energy costs, and system efficiency. Current market analysis indicates ROI timeframes of 3-7 years for optimal implementations in regions with high energy costs, extending to 8-12 years in less favorable conditions. This positions thermoelectric recovery at the threshold of commercial viability for many applications.

Government incentives significantly impact financial calculations, with various jurisdictions offering tax credits, rebates, or grants covering 10-30% of implementation costs. The Inflation Reduction Act in the United States provides particularly favorable treatment, with potential tax credits of up to 30% for qualifying commercial energy efficiency improvements including waste heat recovery systems.

Sensitivity analysis reveals that energy price volatility represents the most significant variable affecting ROI calculations. A 20% increase in energy costs can reduce payback periods by approximately 15-18 months, while technological improvements reducing TEG costs by 30% would similarly accelerate ROI by 20-24 months.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!