Thermoelectric Waste Recovery in the Context of Vehicle Electrification

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery (TEWHR) technology has evolved significantly over the past decades, transitioning from theoretical concepts to practical applications in various industries. The fundamental principle behind this technology relies on the Seebeck effect, discovered in 1821, which enables direct conversion of temperature differentials into electrical energy. This phenomenon has gained renewed attention in recent years due to increasing global emphasis on energy efficiency and sustainability, particularly in the automotive sector.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency, with figure of merit (ZT) values progressing from less than 1.0 in early materials to exceeding 2.0 in modern nanostructured compounds. This progression has been accelerated by advancements in material science, nanotechnology, and manufacturing processes, enabling more efficient energy harvesting from waste heat sources.

In the context of vehicle electrification, TEWHR presents a compelling opportunity to address energy efficiency challenges. Modern internal combustion engines (ICEs) typically convert only 30-40% of fuel energy into useful mechanical work, with approximately 30% of energy lost as waste heat through exhaust systems. Even in hybrid and electric vehicles, various thermal management systems generate significant waste heat that could potentially be recovered.

The primary objective of thermoelectric waste heat recovery in vehicle electrification is to capture and convert this otherwise wasted thermal energy into usable electricity, thereby improving overall vehicle efficiency. This technology aims to supplement the vehicle's electrical system, potentially reducing alternator load in conventional vehicles or extending the range in electric vehicles by decreasing the demand on the main battery.

Secondary objectives include reducing CO2 emissions through improved fuel economy, meeting increasingly stringent environmental regulations, and enhancing the competitiveness of next-generation vehicles. For fully electric vehicles, TEWHR systems could be integrated with battery thermal management systems to recover heat during charging and discharging processes.

The technological trajectory suggests a convergence of thermoelectric materials development, system integration advancements, and vehicle architecture evolution. As vehicles continue to electrify, the role of TEWHR is expected to evolve from a supplementary technology in conventional vehicles to an integral component of thermal management and energy recovery systems in fully electric platforms.

Current research focuses on overcoming key challenges including cost reduction, durability enhancement, and system integration optimization to achieve commercially viable solutions that deliver meaningful efficiency improvements in real-world driving conditions.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency, with figure of merit (ZT) values progressing from less than 1.0 in early materials to exceeding 2.0 in modern nanostructured compounds. This progression has been accelerated by advancements in material science, nanotechnology, and manufacturing processes, enabling more efficient energy harvesting from waste heat sources.

In the context of vehicle electrification, TEWHR presents a compelling opportunity to address energy efficiency challenges. Modern internal combustion engines (ICEs) typically convert only 30-40% of fuel energy into useful mechanical work, with approximately 30% of energy lost as waste heat through exhaust systems. Even in hybrid and electric vehicles, various thermal management systems generate significant waste heat that could potentially be recovered.

The primary objective of thermoelectric waste heat recovery in vehicle electrification is to capture and convert this otherwise wasted thermal energy into usable electricity, thereby improving overall vehicle efficiency. This technology aims to supplement the vehicle's electrical system, potentially reducing alternator load in conventional vehicles or extending the range in electric vehicles by decreasing the demand on the main battery.

Secondary objectives include reducing CO2 emissions through improved fuel economy, meeting increasingly stringent environmental regulations, and enhancing the competitiveness of next-generation vehicles. For fully electric vehicles, TEWHR systems could be integrated with battery thermal management systems to recover heat during charging and discharging processes.

The technological trajectory suggests a convergence of thermoelectric materials development, system integration advancements, and vehicle architecture evolution. As vehicles continue to electrify, the role of TEWHR is expected to evolve from a supplementary technology in conventional vehicles to an integral component of thermal management and energy recovery systems in fully electric platforms.

Current research focuses on overcoming key challenges including cost reduction, durability enhancement, and system integration optimization to achieve commercially viable solutions that deliver meaningful efficiency improvements in real-world driving conditions.

Market Analysis for Automotive Thermoelectric Systems

The global automotive thermoelectric systems market is experiencing significant growth, driven by increasing focus on vehicle efficiency and emission reduction. Current market valuations indicate a size of approximately 600 million USD in 2023, with projections suggesting expansion to reach 1.2 billion USD by 2030, representing a compound annual growth rate of 10.5% during the forecast period.

The primary market drivers include stringent government regulations on vehicle emissions, growing consumer demand for fuel-efficient vehicles, and automotive manufacturers' push toward more sustainable technologies. The Paris Agreement and similar environmental accords have accelerated the adoption timeline for efficiency technologies across major automotive markets including Europe, North America, and Asia.

Market segmentation reveals distinct categories based on vehicle types, with passenger vehicles currently dominating the thermoelectric waste recovery systems market share at approximately 70%. Commercial vehicles, particularly heavy-duty trucks with substantial heat waste, represent the fastest-growing segment with projected annual growth rates exceeding 12% through 2028.

Regional analysis shows Europe leading the market adoption with approximately 40% market share, driven by stringent EU emission standards and substantial R&D investments. North America follows at 30%, while Asia-Pacific represents the fastest-growing region due to rapid vehicle electrification initiatives in China, Japan, and South Korea.

Consumer willingness-to-pay studies indicate that end-users are increasingly receptive to thermoelectric technologies when presented as fuel-saving features, with acceptance rates highest among premium vehicle buyers and fleet operators seeking long-term operational cost reductions.

Market penetration analysis reveals that thermoelectric systems currently appear in less than 5% of new vehicles globally, indicating substantial growth potential. Adoption rates are highest in premium and luxury segments where cost sensitivity is lower and technology differentiation is valued.

The competitive landscape features both established automotive suppliers and specialized thermoelectric technology companies. Tier-1 suppliers like Bosch, Continental, and Denso have made strategic investments in thermoelectric waste recovery, while specialized firms such as Gentherm, II-VI Marlow, and Laird Thermal Systems focus on thermoelectric material innovations.

Market challenges include cost barriers, with current thermoelectric systems adding between 300-800 USD to vehicle production costs, and integration complexities that require significant redesign of exhaust systems. Material efficiency limitations also impact the value proposition, with current conversion efficiencies typically ranging between 5-8% in real-world automotive applications.

The primary market drivers include stringent government regulations on vehicle emissions, growing consumer demand for fuel-efficient vehicles, and automotive manufacturers' push toward more sustainable technologies. The Paris Agreement and similar environmental accords have accelerated the adoption timeline for efficiency technologies across major automotive markets including Europe, North America, and Asia.

Market segmentation reveals distinct categories based on vehicle types, with passenger vehicles currently dominating the thermoelectric waste recovery systems market share at approximately 70%. Commercial vehicles, particularly heavy-duty trucks with substantial heat waste, represent the fastest-growing segment with projected annual growth rates exceeding 12% through 2028.

Regional analysis shows Europe leading the market adoption with approximately 40% market share, driven by stringent EU emission standards and substantial R&D investments. North America follows at 30%, while Asia-Pacific represents the fastest-growing region due to rapid vehicle electrification initiatives in China, Japan, and South Korea.

Consumer willingness-to-pay studies indicate that end-users are increasingly receptive to thermoelectric technologies when presented as fuel-saving features, with acceptance rates highest among premium vehicle buyers and fleet operators seeking long-term operational cost reductions.

Market penetration analysis reveals that thermoelectric systems currently appear in less than 5% of new vehicles globally, indicating substantial growth potential. Adoption rates are highest in premium and luxury segments where cost sensitivity is lower and technology differentiation is valued.

The competitive landscape features both established automotive suppliers and specialized thermoelectric technology companies. Tier-1 suppliers like Bosch, Continental, and Denso have made strategic investments in thermoelectric waste recovery, while specialized firms such as Gentherm, II-VI Marlow, and Laird Thermal Systems focus on thermoelectric material innovations.

Market challenges include cost barriers, with current thermoelectric systems adding between 300-800 USD to vehicle production costs, and integration complexities that require significant redesign of exhaust systems. Material efficiency limitations also impact the value proposition, with current conversion efficiencies typically ranging between 5-8% in real-world automotive applications.

Current TEG Technology Status and Barriers

Thermoelectric generators (TEGs) for waste heat recovery in vehicles have made significant progress in recent years, yet remain at a relatively early stage of commercial deployment. Current TEG systems typically achieve conversion efficiencies between 3-8% under real-world operating conditions, significantly lower than their theoretical potential. This efficiency limitation represents one of the primary barriers to widespread adoption in the automotive sector, particularly as vehicle electrification advances.

The state-of-the-art TEG materials predominantly utilize bismuth telluride (Bi₂Te₃) for low-temperature applications (up to 250°C) and lead telluride (PbTe) for medium-temperature ranges (250-600°C). However, these materials face critical challenges including high cost, limited temperature stability, and environmental concerns regarding toxicity. The scarcity of tellurium also presents a significant barrier to mass production and scalability.

Manufacturing complexity constitutes another major obstacle. Current TEG modules require precise fabrication techniques to ensure optimal thermal contact and electrical connections while minimizing parasitic losses. The integration of these systems into vehicle architectures demands custom engineering solutions that add complexity and cost to the manufacturing process, limiting economies of scale.

Thermal management represents a persistent technical challenge. TEGs require substantial temperature differentials to generate meaningful power output, necessitating sophisticated heat exchanger designs and thermal interface materials. The dynamic nature of vehicle operating conditions further complicates this challenge, as exhaust temperatures fluctuate significantly during normal driving cycles, reducing overall system effectiveness.

Durability and reliability concerns also impede widespread adoption. TEG systems must withstand severe thermal cycling, vibration, and potential chemical contamination in automotive environments. Current materials often exhibit degradation over time due to thermal stress, oxidation, and sublimation at elevated temperatures, resulting in performance deterioration and shortened operational lifespans.

From a geographical perspective, research and development in automotive TEG technology is concentrated primarily in North America, Europe, and East Asia. Japan and Germany lead in patent filings and commercial prototypes, while China has rapidly increased investment in this sector. The United States maintains strong fundamental research programs through national laboratories and university partnerships, though commercial implementation lags behind.

Cost-performance ratio remains perhaps the most significant barrier to adoption. Current TEG systems for automotive applications typically cost between $30-50 per watt of generating capacity, significantly higher than the target threshold of $5-10 per watt that industry analysts consider necessary for mass-market viability. This economic challenge is particularly acute as vehicle electrification advances, creating a moving target for the value proposition of waste heat recovery technologies.

The state-of-the-art TEG materials predominantly utilize bismuth telluride (Bi₂Te₃) for low-temperature applications (up to 250°C) and lead telluride (PbTe) for medium-temperature ranges (250-600°C). However, these materials face critical challenges including high cost, limited temperature stability, and environmental concerns regarding toxicity. The scarcity of tellurium also presents a significant barrier to mass production and scalability.

Manufacturing complexity constitutes another major obstacle. Current TEG modules require precise fabrication techniques to ensure optimal thermal contact and electrical connections while minimizing parasitic losses. The integration of these systems into vehicle architectures demands custom engineering solutions that add complexity and cost to the manufacturing process, limiting economies of scale.

Thermal management represents a persistent technical challenge. TEGs require substantial temperature differentials to generate meaningful power output, necessitating sophisticated heat exchanger designs and thermal interface materials. The dynamic nature of vehicle operating conditions further complicates this challenge, as exhaust temperatures fluctuate significantly during normal driving cycles, reducing overall system effectiveness.

Durability and reliability concerns also impede widespread adoption. TEG systems must withstand severe thermal cycling, vibration, and potential chemical contamination in automotive environments. Current materials often exhibit degradation over time due to thermal stress, oxidation, and sublimation at elevated temperatures, resulting in performance deterioration and shortened operational lifespans.

From a geographical perspective, research and development in automotive TEG technology is concentrated primarily in North America, Europe, and East Asia. Japan and Germany lead in patent filings and commercial prototypes, while China has rapidly increased investment in this sector. The United States maintains strong fundamental research programs through national laboratories and university partnerships, though commercial implementation lags behind.

Cost-performance ratio remains perhaps the most significant barrier to adoption. Current TEG systems for automotive applications typically cost between $30-50 per watt of generating capacity, significantly higher than the target threshold of $5-10 per watt that industry analysts consider necessary for mass-market viability. This economic challenge is particularly acute as vehicle electrification advances, creating a moving target for the value proposition of waste heat recovery technologies.

Current Thermoelectric Generator Implementation Approaches

01 Thermoelectric generators for waste heat recovery

Thermoelectric generators (TEGs) can convert waste heat directly into electrical energy through the Seebeck effect. These systems are particularly effective for recovering energy from industrial processes, vehicle exhaust systems, and other high-temperature waste heat sources. The efficiency of these systems depends on the thermoelectric materials used, the temperature gradient maintained, and the overall system design. Advanced TEG systems incorporate optimized heat exchangers and thermal management to maximize energy recovery.- Thermoelectric generators for waste heat recovery: Thermoelectric generators (TEGs) can convert waste heat directly into electrical energy through the Seebeck effect. These systems are particularly effective for recovering energy from industrial processes, vehicle exhaust systems, and other high-temperature waste heat sources. The efficiency of TEGs depends on the temperature gradient and the properties of the thermoelectric materials used. Advanced designs incorporate heat exchangers to maximize the temperature difference across the thermoelectric elements.

- Integrated waste heat recovery systems: Integrated systems combine multiple technologies to maximize energy recovery from waste heat sources. These systems may incorporate thermoelectric generators alongside other recovery methods such as Organic Rankine Cycle (ORC) systems, heat exchangers, or heat pumps. By integrating different technologies, these systems can address various temperature ranges and operating conditions, improving overall energy recovery efficiency and providing flexibility in different industrial applications.

- Vehicle exhaust energy recovery systems: Specialized thermoelectric systems designed specifically for recovering waste heat from vehicle exhaust systems. These systems can generate electrical power to supplement the vehicle's electrical system, reducing the load on the alternator and improving fuel efficiency. Advanced designs integrate with the vehicle's cooling system and can be adapted to various vehicle types including passenger cars, trucks, and heavy machinery. The recovered energy can power auxiliary systems or be stored in batteries for later use.

- Industrial waste heat recovery applications: Systems specifically designed for industrial settings where large amounts of waste heat are generated. These applications include steel mills, cement plants, glass manufacturing, and power generation facilities. The recovered energy can be used to preheat process inputs, generate electricity for on-site use, or be fed back into the grid. These systems often incorporate advanced heat exchangers, thermal storage solutions, and control systems to optimize energy recovery under varying industrial conditions.

- Advanced thermoelectric materials and designs: Development of novel thermoelectric materials and device architectures to improve conversion efficiency and reduce costs. This includes nanostructured materials, skutterudites, half-Heusler alloys, and other advanced compounds with enhanced thermoelectric properties. Innovative module designs focus on optimizing thermal and electrical contacts, reducing thermal losses, and improving durability under thermal cycling conditions. These advancements aim to increase the overall efficiency of thermoelectric waste heat recovery systems.

02 Integration with existing energy systems

Thermoelectric waste heat recovery systems can be integrated with existing energy infrastructure to enhance overall energy efficiency. These integrated systems can include combinations with HVAC systems, power plants, manufacturing processes, or automotive applications. By capturing and repurposing waste heat that would otherwise be lost, these integrated solutions provide supplementary power generation while reducing the primary energy consumption of the original system. This approach often requires specialized control systems to manage the energy flow between different components.Expand Specific Solutions03 Advanced materials for thermoelectric conversion

Novel materials with enhanced thermoelectric properties are being developed to improve the efficiency of waste heat recovery systems. These materials include nanostructured semiconductors, skutterudites, half-Heusler alloys, and other compounds with high figure of merit (ZT). By engineering materials at the nanoscale, researchers can enhance electrical conductivity while reducing thermal conductivity, which is crucial for efficient thermoelectric conversion. These advanced materials enable operation across wider temperature ranges and can significantly increase the conversion efficiency of waste heat to electricity.Expand Specific Solutions04 System design optimization for waste heat recovery

Optimized system designs for thermoelectric waste heat recovery focus on maximizing heat transfer, maintaining temperature gradients, and improving overall system efficiency. These designs incorporate advanced heat exchangers, thermal interface materials, and flow optimization to capture more waste heat. Modular approaches allow for scalability and adaptability to different heat sources. Some systems include cascaded thermoelectric generators to handle different temperature ranges efficiently. Computational fluid dynamics and thermal modeling are used to optimize the placement and configuration of thermoelectric elements within the system.Expand Specific Solutions05 Control systems and energy management

Sophisticated control systems and energy management strategies are essential for maximizing the performance of thermoelectric waste heat recovery systems. These systems monitor temperature differentials, adjust load conditions, and optimize power output based on varying waste heat availability. Smart controllers can integrate with building management systems or vehicle control units to ensure optimal operation under changing conditions. Some advanced systems incorporate energy storage solutions to manage intermittent waste heat sources, ensuring consistent power output even when heat availability fluctuates.Expand Specific Solutions

Key Industry Players in Automotive Thermoelectric Solutions

Thermoelectric waste recovery in vehicle electrification is currently in a growth phase, with the market expected to expand significantly as automakers seek improved energy efficiency. The global market size is projected to reach approximately $700 million by 2027, driven by stringent emissions regulations and fuel economy standards. Technologically, the field shows varying maturity levels across companies. Toyota, BMW, and Honda lead with advanced implementations and numerous patents, while Ford, GM, and Hyundai are making substantial R&D investments. Chinese manufacturers like Great Wall Motor and Geely are rapidly advancing their capabilities. Component suppliers such as BorgWarner and Hanon Systems are developing specialized thermoelectric modules. The technology faces integration challenges but offers promising efficiency gains as vehicle electrification accelerates.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed a comprehensive thermoelectric waste heat recovery system called "ThermoVolt" designed for integration across their diverse vehicle portfolio, with particular focus on trucks and SUVs where waste heat availability is substantial. Their approach utilizes a scalable thermoelectric module architecture that can be adapted to different vehicle platforms. GM employs advanced half-Heusler and skutterudite thermoelectric materials with ZT values exceeding 1.2, manufactured using proprietary processes that enhance durability under automotive conditions. The ThermoVolt system features a segmented design that optimizes performance across the temperature gradient of the exhaust system, with high-temperature modules near the engine and lower-temperature modules downstream. Their system can generate between 350-700W depending on vehicle size and driving conditions, contributing to 2-4% improvement in fuel economy or electric range. GM has also developed sophisticated control algorithms that integrate with their vehicle power management systems to optimize energy recovery and utilization.

Strengths: Excellent scalability across different vehicle platforms; robust design for harsh operating environments; strong system integration with vehicle electrical architecture. Weaknesses: Higher system weight impacts vehicle efficiency; thermal cycling durability remains challenging in extreme conditions; cost-effectiveness still needs improvement for mass-market deployment.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed an advanced thermoelectric waste heat recovery system called "H-TEG" (Hyundai Thermoelectric Generator) specifically designed for their next-generation hybrid and electric vehicles. Their system employs a dual-stage architecture that captures waste heat from both the exhaust system and the electric powertrain cooling circuits. Hyundai utilizes advanced skutterudite-based thermoelectric materials with enhanced figure of merit (ZT>1.3) through nano-structuring and interface engineering. The H-TEG system features a proprietary heat exchanger design that optimizes thermal contact while minimizing flow restrictions. Their latest generation system can recover up to 450-600W of electrical power under standard driving cycles, contributing to approximately 3-5% improvement in overall vehicle range. Hyundai has also pioneered integration with their vehicle thermal management system, allowing dynamic allocation of recovered energy based on real-time vehicle needs.

Strengths: Excellent integration with Hyundai's electric vehicle architecture; advanced thermal management capabilities; competitive power recovery rates. Weaknesses: System complexity increases maintenance challenges; higher initial production costs; performance varies significantly with ambient temperature conditions.

Critical Patents and Materials Science Breakthroughs

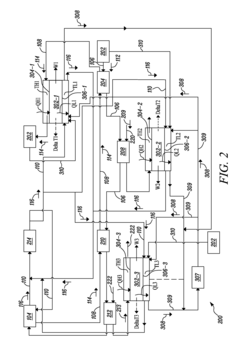

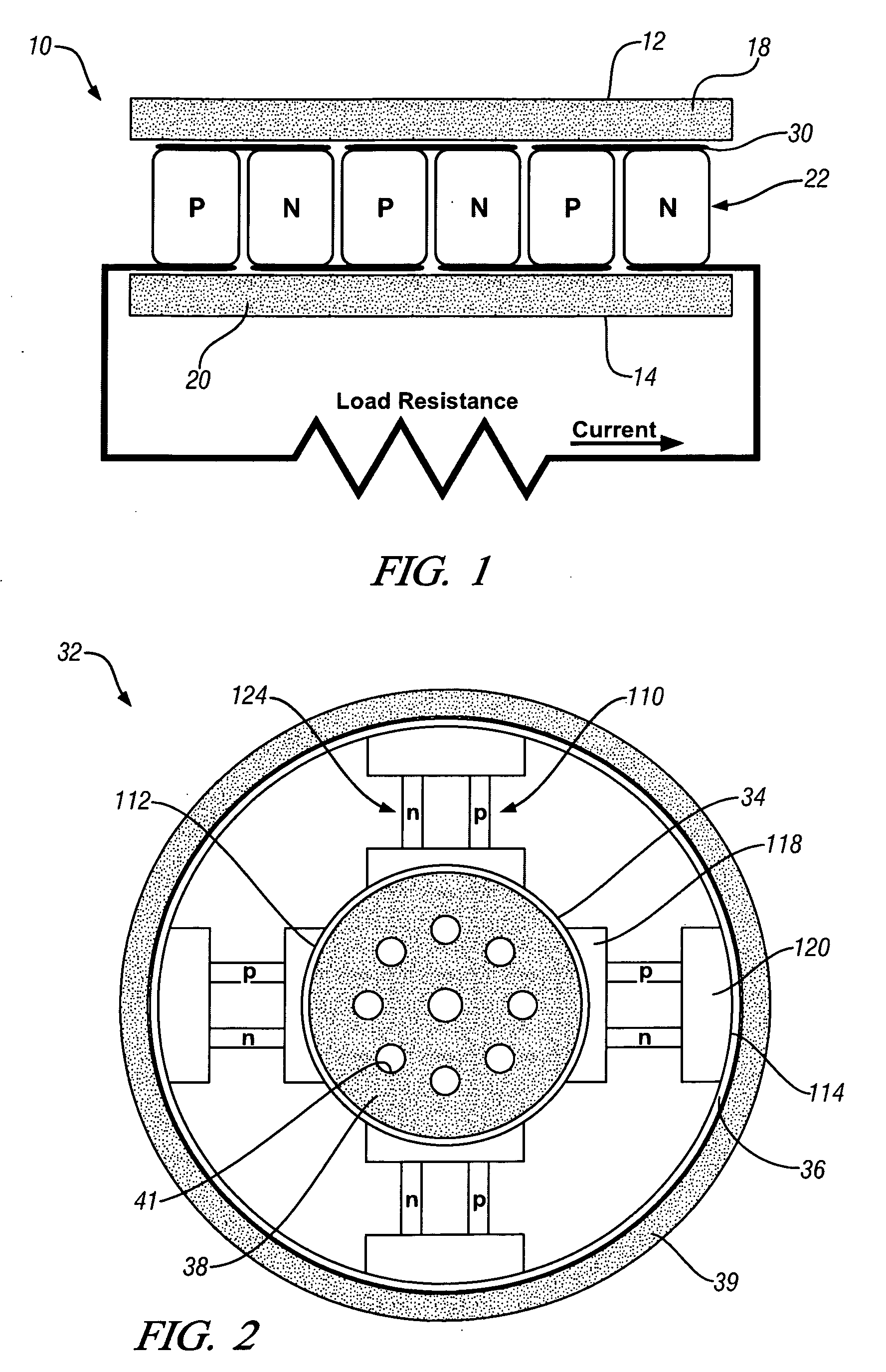

System and method for energy recovery

PatentInactiveUS20150101646A1

Innovation

- A thermoelectric module system is interfaced with various heat sources within a vehicle, including exhaust, intercooler, and aftercooler, to convert temperature differences into electrical power, with a controller optimizing low temperature heat sources based on temperature differences and vehicle operating parameters.

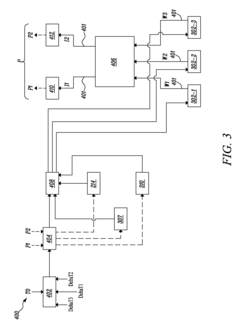

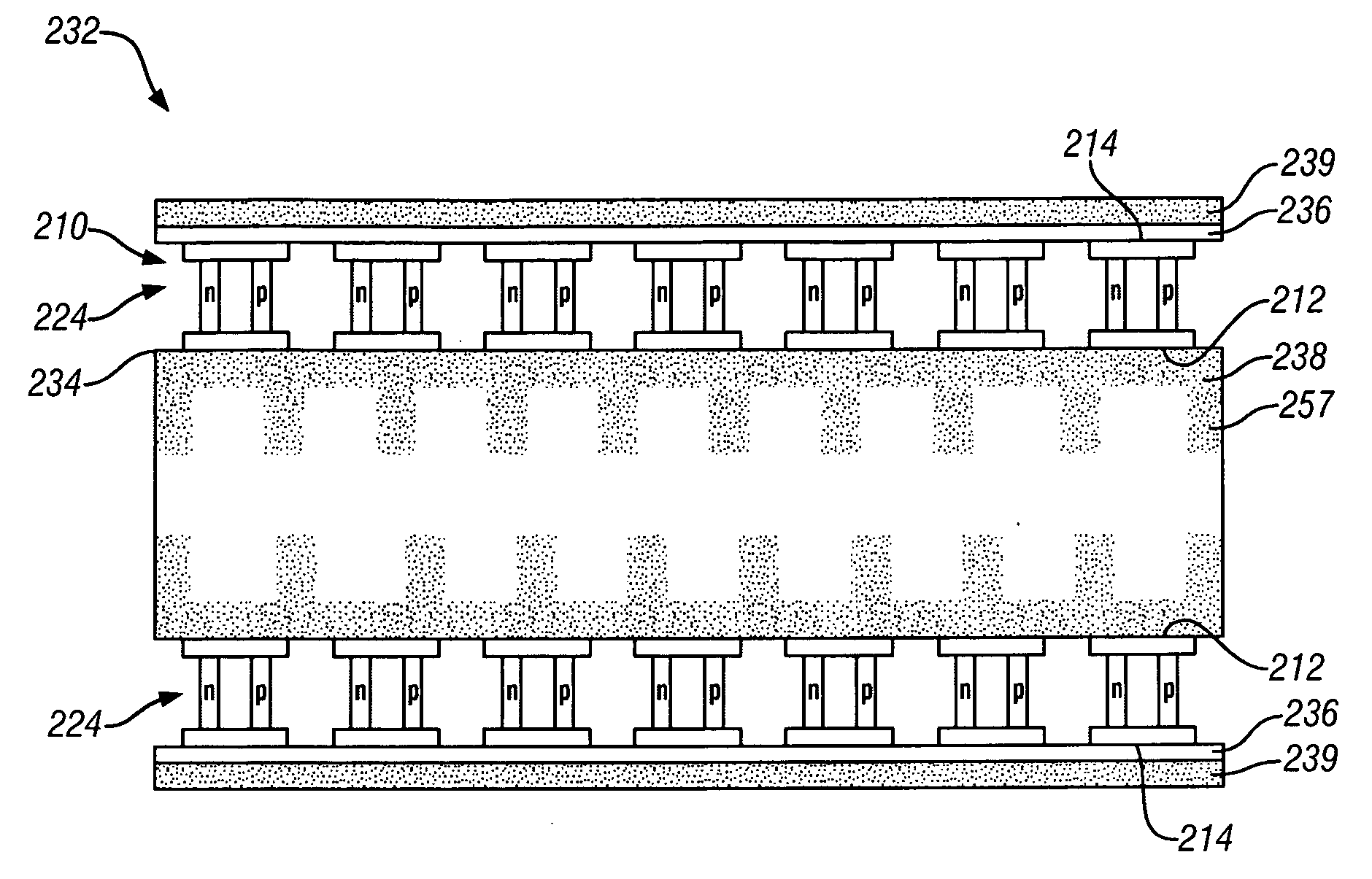

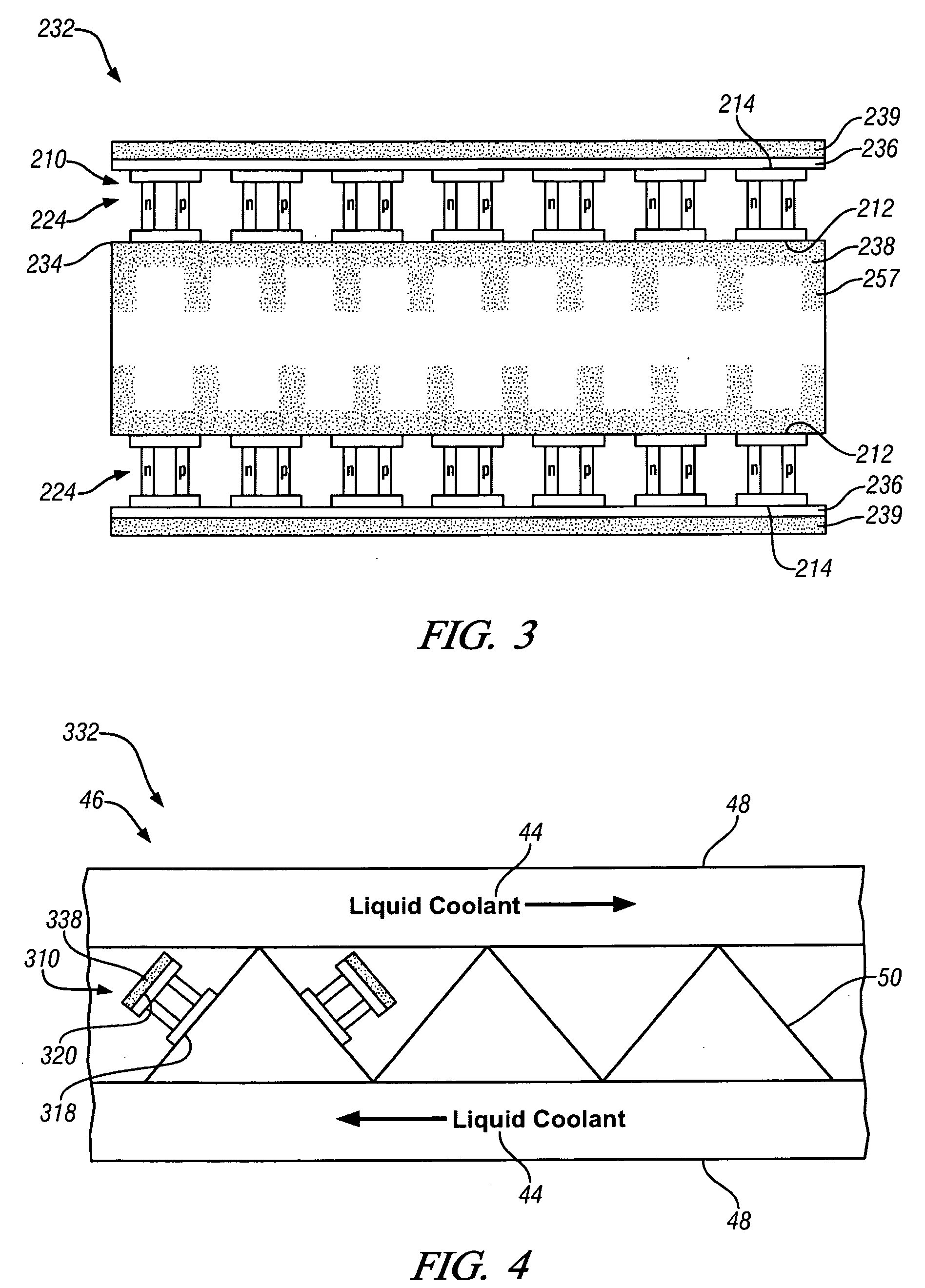

Efficient and light weight thermoelectric waste heat recovery system

PatentInactiveUS20100186422A1

Innovation

- Integration of lightweight, high thermal conductivity open-pore foam materials, such as carbon foam, with thermoelectric devices to enhance heat transfer at both high temperature and low temperature sides, increasing the temperature difference and thus the electrical power output.

Energy Efficiency Regulations and Compliance Standards

The global automotive industry is experiencing increasing regulatory pressure to improve energy efficiency and reduce emissions. These regulations directly impact the development and adoption of thermoelectric waste heat recovery (TEG) systems in vehicle electrification. The European Union's CO2 emission standards for new passenger cars and light commercial vehicles set increasingly stringent targets, with a 37.5% reduction required by 2030 compared to 2021 levels. Similarly, the Corporate Average Fuel Economy (CAFE) standards in the United States mandate fleet-wide fuel economy improvements, creating a regulatory environment that incentivizes the implementation of waste heat recovery technologies.

China's dual-credit policy system combines a Corporate Average Fuel Consumption (CAFC) credit with New Energy Vehicle (NEV) credits, pushing manufacturers toward greater electrification and efficiency improvements. Japan's Top Runner Program establishes efficiency benchmarks based on the most efficient vehicles in each weight class, driving continuous improvement in energy utilization technologies including waste heat recovery systems.

Compliance with these regulations often involves a complex system of credits, penalties, and incentives. Manufacturers can earn regulatory credits by implementing technologies that improve vehicle efficiency beyond minimum requirements. Thermoelectric waste heat recovery systems, capable of converting 3-5% of waste heat into usable electricity, can contribute significantly to meeting these standards, particularly when integrated into hybrid electric vehicle architectures.

The ISO 14064 and GHG Protocol standards provide frameworks for quantifying and reporting greenhouse gas emissions reductions achieved through technologies like thermoelectric generators. These standards are increasingly important as carbon accounting becomes more rigorous in global markets and supply chains. Additionally, the United Nations Economic Commission for Europe (UNECE) has established the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), which provides a more realistic assessment of vehicle emissions and fuel consumption, creating a standardized method to evaluate the benefits of waste heat recovery systems.

Life Cycle Assessment (LCA) requirements are also becoming more prevalent in regulatory frameworks, requiring manufacturers to consider the environmental impact of thermoelectric materials throughout their life cycle. This includes the sourcing of rare earth elements often used in high-performance thermoelectric materials and end-of-life recycling considerations. The European Union's End-of-Life Vehicles Directive specifically addresses the recyclability of vehicle components, which will increasingly affect the design and material selection for thermoelectric systems.

As these regulations continue to evolve, they create both challenges and opportunities for thermoelectric waste heat recovery technologies in the automotive sector. Manufacturers that successfully integrate these systems can gain competitive advantages through regulatory compliance while simultaneously improving vehicle efficiency and reducing environmental impact.

China's dual-credit policy system combines a Corporate Average Fuel Consumption (CAFC) credit with New Energy Vehicle (NEV) credits, pushing manufacturers toward greater electrification and efficiency improvements. Japan's Top Runner Program establishes efficiency benchmarks based on the most efficient vehicles in each weight class, driving continuous improvement in energy utilization technologies including waste heat recovery systems.

Compliance with these regulations often involves a complex system of credits, penalties, and incentives. Manufacturers can earn regulatory credits by implementing technologies that improve vehicle efficiency beyond minimum requirements. Thermoelectric waste heat recovery systems, capable of converting 3-5% of waste heat into usable electricity, can contribute significantly to meeting these standards, particularly when integrated into hybrid electric vehicle architectures.

The ISO 14064 and GHG Protocol standards provide frameworks for quantifying and reporting greenhouse gas emissions reductions achieved through technologies like thermoelectric generators. These standards are increasingly important as carbon accounting becomes more rigorous in global markets and supply chains. Additionally, the United Nations Economic Commission for Europe (UNECE) has established the Worldwide Harmonized Light Vehicles Test Procedure (WLTP), which provides a more realistic assessment of vehicle emissions and fuel consumption, creating a standardized method to evaluate the benefits of waste heat recovery systems.

Life Cycle Assessment (LCA) requirements are also becoming more prevalent in regulatory frameworks, requiring manufacturers to consider the environmental impact of thermoelectric materials throughout their life cycle. This includes the sourcing of rare earth elements often used in high-performance thermoelectric materials and end-of-life recycling considerations. The European Union's End-of-Life Vehicles Directive specifically addresses the recyclability of vehicle components, which will increasingly affect the design and material selection for thermoelectric systems.

As these regulations continue to evolve, they create both challenges and opportunities for thermoelectric waste heat recovery technologies in the automotive sector. Manufacturers that successfully integrate these systems can gain competitive advantages through regulatory compliance while simultaneously improving vehicle efficiency and reducing environmental impact.

Cost-Benefit Analysis of TEG Integration in EVs

The integration of Thermoelectric Generators (TEGs) into Electric Vehicles (EVs) presents a complex cost-benefit equation that requires thorough analysis. Initial implementation costs for TEG systems in EVs range from $800 to $2,500 per vehicle, depending on system complexity and scale of deployment. These costs encompass materials (particularly semiconductor materials like bismuth telluride), manufacturing processes, integration engineering, and necessary thermal management components.

When evaluating return on investment, TEG systems can potentially recover 3-8% of waste heat energy in EVs, translating to approximately 1-3 kWh of additional energy per 100 km driven. This recovered energy can extend vehicle range by 2-5% under optimal conditions, representing potential savings of $50-150 annually for average drivers, based on current electricity costs and usage patterns.

The payback period for TEG integration varies significantly based on driving patterns and environmental conditions. For high-mileage commercial EVs operating in optimal temperature differentials, ROI may be achieved within 3-5 years. However, for average consumer vehicles, the payback period often extends beyond 7 years, challenging the economic justification within typical vehicle ownership cycles.

Manufacturing scalability presents another critical consideration. Current production methods for high-efficiency thermoelectric materials remain costly and difficult to scale. Analysis indicates that production volumes would need to increase tenfold to achieve the 30-40% cost reduction necessary to make TEG integration economically viable for mass-market EVs.

Lifecycle assessment reveals additional complexities. While TEGs can reduce operational carbon footprint by improving energy efficiency, the environmental impact of manufacturing thermoelectric materials—particularly the mining and processing of tellurium, bismuth, and other elements—must be factored into sustainability calculations. Current estimates suggest a net positive environmental impact only after 50,000-70,000 km of vehicle operation.

Regulatory incentives could significantly alter this cost-benefit equation. Several markets are considering efficiency credits or subsidies for advanced heat recovery systems in EVs, potentially offsetting 20-30% of implementation costs. These incentives, combined with projected manufacturing improvements and material innovations, suggest that TEG integration could reach economic viability for mainstream EVs within the next 5-7 years.

When evaluating return on investment, TEG systems can potentially recover 3-8% of waste heat energy in EVs, translating to approximately 1-3 kWh of additional energy per 100 km driven. This recovered energy can extend vehicle range by 2-5% under optimal conditions, representing potential savings of $50-150 annually for average drivers, based on current electricity costs and usage patterns.

The payback period for TEG integration varies significantly based on driving patterns and environmental conditions. For high-mileage commercial EVs operating in optimal temperature differentials, ROI may be achieved within 3-5 years. However, for average consumer vehicles, the payback period often extends beyond 7 years, challenging the economic justification within typical vehicle ownership cycles.

Manufacturing scalability presents another critical consideration. Current production methods for high-efficiency thermoelectric materials remain costly and difficult to scale. Analysis indicates that production volumes would need to increase tenfold to achieve the 30-40% cost reduction necessary to make TEG integration economically viable for mass-market EVs.

Lifecycle assessment reveals additional complexities. While TEGs can reduce operational carbon footprint by improving energy efficiency, the environmental impact of manufacturing thermoelectric materials—particularly the mining and processing of tellurium, bismuth, and other elements—must be factored into sustainability calculations. Current estimates suggest a net positive environmental impact only after 50,000-70,000 km of vehicle operation.

Regulatory incentives could significantly alter this cost-benefit equation. Several markets are considering efficiency credits or subsidies for advanced heat recovery systems in EVs, potentially offsetting 20-30% of implementation costs. These incentives, combined with projected manufacturing improvements and material innovations, suggest that TEG integration could reach economic viability for mainstream EVs within the next 5-7 years.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!