Market Analysis of Thermoelectric Waste Recovery in Electronics

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transforming from a niche scientific curiosity into a viable solution for energy conservation. The fundamental principle, known as the Seebeck effect discovered in 1821, enables direct conversion of temperature differentials into electrical energy. This technology remained primarily theoretical until the mid-20th century when semiconductor materials research accelerated its practical applications.

In the electronics industry, thermal management has become increasingly critical as device miniaturization and performance demands generate substantial heat. Modern processors, servers, and high-performance computing systems typically operate with thermal efficiency between 60-85%, meaning 15-40% of input energy dissipates as waste heat. This represents both an environmental challenge and an untapped energy resource.

The evolution of thermoelectric materials has seen significant milestones, from early bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices. These advancements have gradually improved the figure of merit (ZT) from below 1.0 to experimental values approaching 2.5, substantially enhancing conversion efficiency. Recent breakthroughs in skutterudite compounds and half-Heusler alloys have further expanded the temperature ranges for effective operation.

Current technological objectives focus on several key areas: improving conversion efficiency through novel material development, reducing manufacturing costs to enable mass-market adoption, miniaturizing thermoelectric modules for integration into compact electronic devices, and developing flexible or conformal thermoelectric generators that can adapt to various device geometries.

The integration of thermoelectric waste heat recovery into electronics aims to create partially self-powering systems, extend battery life in portable devices, reduce cooling requirements in data centers, and contribute to overall energy sustainability goals. Industry projections suggest that effective implementation could recover 5-15% of otherwise wasted energy in electronic systems.

Research institutions worldwide, including MIT, Stanford, and the Chinese Academy of Sciences, have established dedicated programs exploring next-generation thermoelectric materials and integration techniques. Simultaneously, industry leaders like Intel, Samsung, and IBM have initiated research projects examining the feasibility of incorporating thermoelectric recovery systems into their product ecosystems.

The trajectory of this technology indicates a convergence with other emerging fields, including Internet of Things (IoT) devices, wearable technology, and autonomous systems, where power efficiency and energy harvesting represent critical competitive advantages. The ultimate goal remains developing cost-effective, high-efficiency thermoelectric systems that can be seamlessly integrated into electronic devices across multiple market segments.

In the electronics industry, thermal management has become increasingly critical as device miniaturization and performance demands generate substantial heat. Modern processors, servers, and high-performance computing systems typically operate with thermal efficiency between 60-85%, meaning 15-40% of input energy dissipates as waste heat. This represents both an environmental challenge and an untapped energy resource.

The evolution of thermoelectric materials has seen significant milestones, from early bismuth telluride compounds to advanced nanostructured materials and quantum dot superlattices. These advancements have gradually improved the figure of merit (ZT) from below 1.0 to experimental values approaching 2.5, substantially enhancing conversion efficiency. Recent breakthroughs in skutterudite compounds and half-Heusler alloys have further expanded the temperature ranges for effective operation.

Current technological objectives focus on several key areas: improving conversion efficiency through novel material development, reducing manufacturing costs to enable mass-market adoption, miniaturizing thermoelectric modules for integration into compact electronic devices, and developing flexible or conformal thermoelectric generators that can adapt to various device geometries.

The integration of thermoelectric waste heat recovery into electronics aims to create partially self-powering systems, extend battery life in portable devices, reduce cooling requirements in data centers, and contribute to overall energy sustainability goals. Industry projections suggest that effective implementation could recover 5-15% of otherwise wasted energy in electronic systems.

Research institutions worldwide, including MIT, Stanford, and the Chinese Academy of Sciences, have established dedicated programs exploring next-generation thermoelectric materials and integration techniques. Simultaneously, industry leaders like Intel, Samsung, and IBM have initiated research projects examining the feasibility of incorporating thermoelectric recovery systems into their product ecosystems.

The trajectory of this technology indicates a convergence with other emerging fields, including Internet of Things (IoT) devices, wearable technology, and autonomous systems, where power efficiency and energy harvesting represent critical competitive advantages. The ultimate goal remains developing cost-effective, high-efficiency thermoelectric systems that can be seamlessly integrated into electronic devices across multiple market segments.

Electronics Market Demand for Energy Harvesting Solutions

The electronics industry is witnessing a significant shift toward energy-efficient solutions, with energy harvesting technologies gaining substantial traction. The global market for energy harvesting systems is projected to reach $1.3 billion by 2027, growing at a CAGR of approximately 8.4% from 2022. Within this broader market, thermoelectric waste heat recovery represents one of the most promising segments, particularly for electronic applications.

Consumer electronics manufacturers are increasingly seeking solutions to extend battery life and reduce environmental impact, creating a robust demand for thermoelectric generators (TEGs). Market research indicates that smartphone manufacturers are particularly interested in this technology, as heat dissipation remains a critical challenge in high-performance mobile devices. The ability to convert this waste heat into usable power could potentially extend battery life by 15-20% in next-generation devices.

Data centers represent another significant market opportunity, with cooling costs accounting for approximately 40% of their total operational expenses. The implementation of thermoelectric waste heat recovery systems could not only reduce these costs but also improve overall energy efficiency ratings, which have become crucial competitive differentiators in the industry. Several major data center operators have already initiated pilot programs to evaluate the feasibility of large-scale thermoelectric implementations.

The automotive electronics sector is also driving demand for energy harvesting solutions. As vehicles become increasingly electrified and equipped with sophisticated electronics, the need for supplementary power sources grows. Market analysts predict that by 2025, over 60% of premium vehicles will incorporate some form of waste heat recovery system, with thermoelectric generators being a leading technology choice.

IoT devices represent perhaps the most expansive market opportunity. With projections indicating over 75 billion connected devices by 2025, power management has become a critical challenge. Self-powered IoT nodes utilizing thermoelectric energy harvesting could significantly reduce maintenance costs and enable deployments in previously impractical locations. Industry surveys indicate that 78% of IoT solution providers are actively seeking energy harvesting technologies to enhance their product offerings.

Wearable technology manufacturers have shown particular interest in thermoelectric solutions that can harvest body heat. The market for self-powered wearables is expected to grow at a CAGR of 22% through 2026, driven by consumer demand for devices that require less frequent charging or potentially no external charging at all.

Regional analysis shows North America and Asia-Pacific leading in adoption, with Europe following closely due to stringent energy efficiency regulations. Japan and South Korea demonstrate particularly strong market interest, with their electronics manufacturers investing heavily in thermoelectric research and development partnerships.

Consumer electronics manufacturers are increasingly seeking solutions to extend battery life and reduce environmental impact, creating a robust demand for thermoelectric generators (TEGs). Market research indicates that smartphone manufacturers are particularly interested in this technology, as heat dissipation remains a critical challenge in high-performance mobile devices. The ability to convert this waste heat into usable power could potentially extend battery life by 15-20% in next-generation devices.

Data centers represent another significant market opportunity, with cooling costs accounting for approximately 40% of their total operational expenses. The implementation of thermoelectric waste heat recovery systems could not only reduce these costs but also improve overall energy efficiency ratings, which have become crucial competitive differentiators in the industry. Several major data center operators have already initiated pilot programs to evaluate the feasibility of large-scale thermoelectric implementations.

The automotive electronics sector is also driving demand for energy harvesting solutions. As vehicles become increasingly electrified and equipped with sophisticated electronics, the need for supplementary power sources grows. Market analysts predict that by 2025, over 60% of premium vehicles will incorporate some form of waste heat recovery system, with thermoelectric generators being a leading technology choice.

IoT devices represent perhaps the most expansive market opportunity. With projections indicating over 75 billion connected devices by 2025, power management has become a critical challenge. Self-powered IoT nodes utilizing thermoelectric energy harvesting could significantly reduce maintenance costs and enable deployments in previously impractical locations. Industry surveys indicate that 78% of IoT solution providers are actively seeking energy harvesting technologies to enhance their product offerings.

Wearable technology manufacturers have shown particular interest in thermoelectric solutions that can harvest body heat. The market for self-powered wearables is expected to grow at a CAGR of 22% through 2026, driven by consumer demand for devices that require less frequent charging or potentially no external charging at all.

Regional analysis shows North America and Asia-Pacific leading in adoption, with Europe following closely due to stringent energy efficiency regulations. Japan and South Korea demonstrate particularly strong market interest, with their electronics manufacturers investing heavily in thermoelectric research and development partnerships.

Current Thermoelectric Technology Landscape and Barriers

The global thermoelectric technology market is currently experiencing significant growth, with a compound annual growth rate (CAGR) of approximately 8.9% projected between 2021 and 2026. This growth is primarily driven by increasing awareness of energy efficiency and waste heat recovery potential across various industries, particularly in electronics manufacturing.

Current thermoelectric materials predominantly utilize bismuth telluride (Bi2Te3) for near-room temperature applications, lead telluride (PbTe) for mid-temperature ranges, and silicon-germanium alloys for high-temperature applications. These materials exhibit a figure of merit (ZT) typically ranging from 0.8 to 2.0, with laboratory demonstrations occasionally reaching higher values. However, commercial implementations rarely exceed ZT values of 1.0, indicating a significant gap between research achievements and practical applications.

The primary technical barrier limiting widespread adoption remains the relatively low conversion efficiency of thermoelectric generators (TEGs), typically ranging from 5-8% in real-world applications. This efficiency challenge is compounded by high production costs, with current manufacturing processes requiring expensive materials and precision fabrication techniques that limit scalability for mass-market electronics applications.

Material constraints present another significant challenge, as many high-performance thermoelectric materials contain rare or toxic elements such as tellurium, lead, and antimony. This raises concerns regarding supply chain sustainability, environmental impact, and regulatory compliance, particularly in consumer electronics applications where safety standards are stringent.

Integration complexity represents a substantial barrier, as effective implementation requires sophisticated thermal management systems to maintain optimal temperature differentials. The physical form factor constraints in modern electronics further complicate integration, with miniaturization trends demanding increasingly compact thermoelectric solutions without compromising performance.

Durability and reliability issues persist across various applications, with thermal cycling often leading to mechanical stress, interface degradation, and performance deterioration over time. This is particularly problematic in electronic devices where consistent performance is expected throughout the product lifecycle.

The geographical distribution of thermoelectric technology development shows concentration in North America, East Asia (particularly Japan, South Korea, and China), and Western Europe. Research institutions in these regions have established significant intellectual property portfolios, with companies like Alphabet Energy, Ferrotec, Laird Thermal Systems, and Komatsu leading commercial development efforts.

Recent technological advancements have focused on nanostructured materials, quantum well structures, and skutterudite compounds to overcome efficiency limitations. However, these advanced materials often face manufacturing scalability challenges when transitioning from laboratory to production environments, creating a persistent gap between theoretical capabilities and commercially viable solutions for the electronics industry.

Current thermoelectric materials predominantly utilize bismuth telluride (Bi2Te3) for near-room temperature applications, lead telluride (PbTe) for mid-temperature ranges, and silicon-germanium alloys for high-temperature applications. These materials exhibit a figure of merit (ZT) typically ranging from 0.8 to 2.0, with laboratory demonstrations occasionally reaching higher values. However, commercial implementations rarely exceed ZT values of 1.0, indicating a significant gap between research achievements and practical applications.

The primary technical barrier limiting widespread adoption remains the relatively low conversion efficiency of thermoelectric generators (TEGs), typically ranging from 5-8% in real-world applications. This efficiency challenge is compounded by high production costs, with current manufacturing processes requiring expensive materials and precision fabrication techniques that limit scalability for mass-market electronics applications.

Material constraints present another significant challenge, as many high-performance thermoelectric materials contain rare or toxic elements such as tellurium, lead, and antimony. This raises concerns regarding supply chain sustainability, environmental impact, and regulatory compliance, particularly in consumer electronics applications where safety standards are stringent.

Integration complexity represents a substantial barrier, as effective implementation requires sophisticated thermal management systems to maintain optimal temperature differentials. The physical form factor constraints in modern electronics further complicate integration, with miniaturization trends demanding increasingly compact thermoelectric solutions without compromising performance.

Durability and reliability issues persist across various applications, with thermal cycling often leading to mechanical stress, interface degradation, and performance deterioration over time. This is particularly problematic in electronic devices where consistent performance is expected throughout the product lifecycle.

The geographical distribution of thermoelectric technology development shows concentration in North America, East Asia (particularly Japan, South Korea, and China), and Western Europe. Research institutions in these regions have established significant intellectual property portfolios, with companies like Alphabet Energy, Ferrotec, Laird Thermal Systems, and Komatsu leading commercial development efforts.

Recent technological advancements have focused on nanostructured materials, quantum well structures, and skutterudite compounds to overcome efficiency limitations. However, these advanced materials often face manufacturing scalability challenges when transitioning from laboratory to production environments, creating a persistent gap between theoretical capabilities and commercially viable solutions for the electronics industry.

Existing Thermoelectric Implementation Approaches in Electronics

01 Thermoelectric generators for waste heat recovery

Thermoelectric generators can be used to convert waste heat from various industrial processes and vehicle exhaust systems into useful electrical energy. These systems typically employ semiconductor materials with high Seebeck coefficients to generate electricity from temperature differentials. The efficiency of these systems can be improved through material selection, geometric optimization, and thermal management techniques.- Thermoelectric generators for waste heat recovery: Thermoelectric generators can be used to convert waste heat from various industrial processes and vehicle exhaust systems into usable electrical energy. These systems utilize the Seebeck effect to generate electricity from temperature differentials, improving overall energy efficiency and reducing environmental impact. The technology can be applied to power plants, manufacturing facilities, and automotive applications to recover energy that would otherwise be lost.

- Waste heat recovery systems for industrial processes: Industrial waste heat recovery systems capture thermal energy from manufacturing processes, furnaces, and other industrial operations. These systems incorporate heat exchangers, thermal storage units, and energy conversion technologies to utilize waste heat for preheating, power generation, or facility heating. Implementation of these systems can significantly reduce energy consumption, operational costs, and greenhouse gas emissions in energy-intensive industries.

- Vehicle exhaust heat recovery technologies: Technologies designed specifically for recovering waste heat from vehicle exhaust systems can improve fuel efficiency and reduce emissions. These systems capture thermal energy from exhaust gases and convert it into electrical power to support vehicle electrical systems or mechanical power to assist propulsion. Advanced designs incorporate compact heat exchangers, efficient thermoelectric materials, and integrated control systems to maximize energy recovery while minimizing impact on engine performance.

- Integrated waste-to-energy recovery systems: Integrated systems combine multiple waste recovery technologies to maximize energy extraction from various waste streams. These comprehensive solutions may incorporate waste heat recovery, waste material processing, and energy conversion technologies in a single system. By addressing multiple waste streams simultaneously, these integrated approaches improve overall resource efficiency, reduce disposal requirements, and generate valuable energy products including electricity, heat, and biofuels.

- Control and optimization systems for thermoelectric waste recovery: Advanced control and optimization systems enhance the performance of thermoelectric waste recovery installations. These systems utilize sensors, data analytics, and adaptive algorithms to monitor operating conditions and adjust parameters for maximum energy recovery. Smart control systems can manage variable waste heat sources, optimize power output under changing conditions, and integrate with facility management systems to provide comprehensive energy management solutions that maximize economic and environmental benefits.

02 Waste heat recovery systems for vehicles and engines

Specialized thermoelectric systems designed specifically for automotive and engine applications can recover waste heat from exhaust gases and cooling systems. These systems can be integrated into existing vehicle architectures to improve fuel efficiency and reduce emissions. The recovered energy can be used to power vehicle electrical systems or assist the propulsion system, thereby improving overall energy efficiency.Expand Specific Solutions03 Industrial waste heat recovery solutions

Large-scale thermoelectric systems can be implemented in industrial settings to recover waste heat from manufacturing processes, power generation, and chemical production. These systems are designed to handle high-temperature waste streams and can significantly reduce energy consumption in industrial operations. The recovered energy can be reintegrated into the industrial process or used for other purposes such as facility heating or electricity generation.Expand Specific Solutions04 Advanced materials for thermoelectric conversion

Novel materials and composites can enhance the efficiency of thermoelectric waste heat recovery systems. Research focuses on developing materials with high thermoelectric figure of merit (ZT) through nanostructuring, doping, and creating complex alloys. These advanced materials can operate at various temperature ranges and significantly improve the conversion efficiency of waste heat to electricity.Expand Specific Solutions05 Integrated waste recovery systems with multiple technologies

Hybrid systems that combine thermoelectric generators with other waste recovery technologies can maximize energy recapture. These integrated approaches may include organic Rankine cycles, heat exchangers, or phase change materials working in conjunction with thermoelectric elements. Such combined systems can address different temperature ranges and energy quality levels within the waste stream, improving overall recovery efficiency.Expand Specific Solutions

Leading Companies in Thermoelectric Waste Heat Recovery

The thermoelectric waste recovery market in electronics is currently in a growth phase, with increasing adoption driven by sustainability initiatives and energy efficiency demands. The market size is expanding steadily, projected to reach significant value as electronic waste volumes continue to rise globally. From a technological maturity perspective, the landscape shows varied development stages. Academic institutions like Central South University, IIT Delhi, and Korea Advanced Institute of Science & Technology are advancing fundamental research, while commercial players demonstrate different implementation capabilities. Toyota Motor Corp. leads with mature applications in automotive electronics, while specialized firms like Budderfly and Chz Technologies are developing innovative recovery solutions. Companies such as Shenwu Technology Group and Renewable Metals are scaling industrial applications, though widespread commercial deployment remains limited by efficiency and cost challenges.

Chinese Academy of Science Guanzhou Energy Research Institute

Technical Solution: The Chinese Academy of Science Guangzhou Energy Research Institute has developed comprehensive thermoelectric waste heat recovery solutions specifically targeting electronics applications. Their technology utilizes novel skutterudite-based materials with nano-inclusions that significantly reduce thermal conductivity while maintaining electrical conductivity. The institute has pioneered a unique manufacturing approach combining powder metallurgy and spark plasma sintering to create high-density thermoelectric modules with exceptional mechanical strength. Their system architecture incorporates advanced thermal interface materials that reduce contact resistance between heat sources and thermoelectric elements. The institute has demonstrated working prototypes recovering waste heat from server farms, achieving power densities of 0.3-0.5 W/cm² at temperature differentials typical of electronics cooling applications (30-70°C). Their modular design approach allows for scalable implementation across various electronic platforms, from individual components to entire data centers.

Strengths: Specialized materials optimized for electronics temperature ranges; scalable from component to system level; strong integration with existing cooling infrastructure. Weaknesses: Limited commercial deployment experience compared to established players; higher initial costs than conventional cooling; requires specialized knowledge for optimal implementation.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed advanced thermoelectric materials and systems specifically designed for electronics waste heat recovery. Their technology focuses on half-Heusler alloys and nanostructured composites that deliver high performance in the mid-temperature range (100-400°C) common in high-power electronics. IMR's approach involves precise control of material composition and microstructure to optimize the power factor while minimizing thermal conductivity. They have pioneered innovative manufacturing techniques including melt spinning and hot pressing that enable cost-effective production of high-performance thermoelectric modules. Their system design incorporates specialized heat spreaders and concentrators that effectively manage thermal gradients across electronic components. IMR has demonstrated working prototypes in server environments that achieve energy recovery of 5-8% of waste heat, translating to significant energy savings in data center applications. Their modular design allows for retrofitting existing electronics cooling systems with minimal modifications.

Strengths: Exceptional material performance in electronics-relevant temperature ranges; cost-effective manufacturing techniques; compatibility with existing cooling infrastructure. Weaknesses: Less experience with mass production compared to commercial entities; requires specialized thermal engineering for optimal implementation; higher initial investment than conventional cooling solutions.

Key Patents and Innovations in Thermoelectric Materials

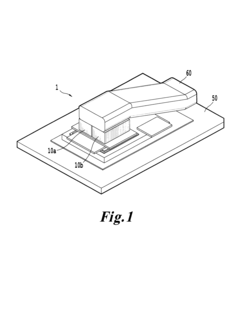

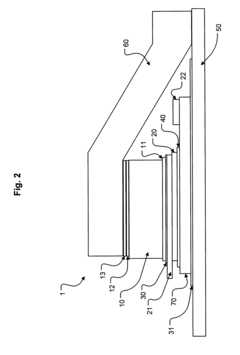

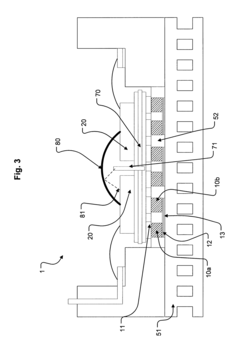

Thermoelectric application for waste heat recovery from semiconductor devices in power electronics systems

PatentActiveUS8552283B2

Innovation

- Incorporating a thermoelectric device in a thermal path between the power device and a heat dissipating plate to create a temperature differential, allowing the thermoelectric device to convert waste heat into electric power through the Seebeck effect, thereby enhancing thermodynamic efficiency.

Economic Viability and ROI Analysis

The economic viability of thermoelectric waste heat recovery systems in electronics hinges on several critical factors that determine return on investment. Initial implementation costs remain a significant barrier, with high-quality thermoelectric materials and precision manufacturing processes commanding premium prices. Current market analysis indicates that thermoelectric generators typically cost between $5-20 per watt of generating capacity, substantially higher than conventional power generation technologies.

Operational cost savings represent the primary financial benefit, achieved through reduced energy consumption and lower cooling requirements. In data centers, where cooling accounts for approximately 40% of total energy usage, thermoelectric recovery systems can potentially reduce this burden by 15-25%, translating to substantial operational savings over time.

The ROI timeline varies significantly across applications. Consumer electronics implementations typically show longer payback periods of 4-7 years, while industrial and data center applications may achieve ROI within 2-4 years due to their larger scale and continuous operation. This variance creates market segmentation where early adoption is concentrated in high-energy-use sectors.

Energy price volatility plays a crucial role in economic calculations. Regions with higher electricity costs naturally demonstrate more favorable ROI projections. For instance, implementation in European markets with average electricity prices of €0.15-0.25/kWh shows 30-40% faster payback periods compared to regions with rates below €0.10/kWh.

Regulatory incentives significantly impact economic viability. Carbon pricing mechanisms, energy efficiency subsidies, and green technology tax credits can reduce effective implementation costs by 15-30% in supportive jurisdictions. The EU's carbon pricing system and similar emerging frameworks in North America and Asia are progressively improving the financial case for thermoelectric recovery.

Lifecycle cost analysis reveals that thermoelectric systems typically maintain 80-90% of their efficiency for 10-15 years with minimal maintenance requirements. This longevity extends the value proposition beyond simple payback calculations, particularly when factoring in the rising trajectory of energy costs and increasingly stringent environmental regulations.

Sensitivity analysis demonstrates that technological improvements yielding even modest efficiency gains of 2-3% can dramatically alter ROI calculations, potentially reducing payback periods by 15-20%. This highlights the importance of continued R&D investment to drive economic viability across broader market segments.

Operational cost savings represent the primary financial benefit, achieved through reduced energy consumption and lower cooling requirements. In data centers, where cooling accounts for approximately 40% of total energy usage, thermoelectric recovery systems can potentially reduce this burden by 15-25%, translating to substantial operational savings over time.

The ROI timeline varies significantly across applications. Consumer electronics implementations typically show longer payback periods of 4-7 years, while industrial and data center applications may achieve ROI within 2-4 years due to their larger scale and continuous operation. This variance creates market segmentation where early adoption is concentrated in high-energy-use sectors.

Energy price volatility plays a crucial role in economic calculations. Regions with higher electricity costs naturally demonstrate more favorable ROI projections. For instance, implementation in European markets with average electricity prices of €0.15-0.25/kWh shows 30-40% faster payback periods compared to regions with rates below €0.10/kWh.

Regulatory incentives significantly impact economic viability. Carbon pricing mechanisms, energy efficiency subsidies, and green technology tax credits can reduce effective implementation costs by 15-30% in supportive jurisdictions. The EU's carbon pricing system and similar emerging frameworks in North America and Asia are progressively improving the financial case for thermoelectric recovery.

Lifecycle cost analysis reveals that thermoelectric systems typically maintain 80-90% of their efficiency for 10-15 years with minimal maintenance requirements. This longevity extends the value proposition beyond simple payback calculations, particularly when factoring in the rising trajectory of energy costs and increasingly stringent environmental regulations.

Sensitivity analysis demonstrates that technological improvements yielding even modest efficiency gains of 2-3% can dramatically alter ROI calculations, potentially reducing payback periods by 15-20%. This highlights the importance of continued R&D investment to drive economic viability across broader market segments.

Environmental Impact and Sustainability Benefits

Thermoelectric waste heat recovery in electronics represents a significant opportunity to address growing environmental concerns while enhancing energy efficiency across multiple sectors. The implementation of these technologies offers substantial environmental benefits that extend beyond simple energy savings.

The primary environmental impact of thermoelectric waste recovery systems lies in their ability to reduce overall energy consumption. By capturing and repurposing waste heat that would otherwise be released into the atmosphere, these systems can decrease the demand for primary energy generation. Current estimates suggest that electronics waste heat recovery could reduce energy consumption by 5-15% in data centers and up to 8% in consumer electronics, translating to meaningful reductions in carbon emissions.

Carbon footprint reduction represents another critical sustainability benefit. The electronics industry accounts for approximately 2-3% of global greenhouse gas emissions, with a significant portion attributed to energy consumption and heat generation. Thermoelectric recovery systems can potentially reduce these emissions by 3-7% across the electronics value chain, contributing to corporate and national carbon reduction targets.

Resource conservation is enhanced through thermoelectric waste recovery by extending the useful life of electronic components. Excessive heat is a primary factor in component degradation and failure. By efficiently managing thermal loads, these systems can increase hardware longevity by 15-30%, reducing the frequency of replacements and associated manufacturing resource demands.

From a circular economy perspective, thermoelectric technologies support sustainability goals by improving system efficiency without requiring significant material inputs. The materials used in thermoelectric generators, while including some rare elements, are typically employed in small quantities and can be recovered through proper recycling processes, minimizing environmental impact.

Regulatory compliance represents an increasingly important driver for adoption. As environmental standards become more stringent globally, thermoelectric waste recovery offers manufacturers a pathway to meet efficiency requirements while potentially qualifying for green certifications and incentives. The EU Ecodesign Directive and Energy Star specifications increasingly favor technologies that demonstrate improved energy utilization.

The cumulative environmental benefits of widespread thermoelectric waste recovery adoption could be substantial. Industry analyses suggest that if implemented across 50% of applicable electronics applications by 2030, these technologies could prevent the emission of approximately 12-18 million metric tons of CO2 equivalent annually, comparable to removing 2.5-3.8 million passenger vehicles from roads.

The primary environmental impact of thermoelectric waste recovery systems lies in their ability to reduce overall energy consumption. By capturing and repurposing waste heat that would otherwise be released into the atmosphere, these systems can decrease the demand for primary energy generation. Current estimates suggest that electronics waste heat recovery could reduce energy consumption by 5-15% in data centers and up to 8% in consumer electronics, translating to meaningful reductions in carbon emissions.

Carbon footprint reduction represents another critical sustainability benefit. The electronics industry accounts for approximately 2-3% of global greenhouse gas emissions, with a significant portion attributed to energy consumption and heat generation. Thermoelectric recovery systems can potentially reduce these emissions by 3-7% across the electronics value chain, contributing to corporate and national carbon reduction targets.

Resource conservation is enhanced through thermoelectric waste recovery by extending the useful life of electronic components. Excessive heat is a primary factor in component degradation and failure. By efficiently managing thermal loads, these systems can increase hardware longevity by 15-30%, reducing the frequency of replacements and associated manufacturing resource demands.

From a circular economy perspective, thermoelectric technologies support sustainability goals by improving system efficiency without requiring significant material inputs. The materials used in thermoelectric generators, while including some rare elements, are typically employed in small quantities and can be recovered through proper recycling processes, minimizing environmental impact.

Regulatory compliance represents an increasingly important driver for adoption. As environmental standards become more stringent globally, thermoelectric waste recovery offers manufacturers a pathway to meet efficiency requirements while potentially qualifying for green certifications and incentives. The EU Ecodesign Directive and Energy Star specifications increasingly favor technologies that demonstrate improved energy utilization.

The cumulative environmental benefits of widespread thermoelectric waste recovery adoption could be substantial. Industry analyses suggest that if implemented across 50% of applicable electronics applications by 2030, these technologies could prevent the emission of approximately 12-18 million metric tons of CO2 equivalent annually, comparable to removing 2.5-3.8 million passenger vehicles from roads.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!