Thermoelectric Waste Recovery Efficiency in Renewable Energy Systems

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications in various industries. The fundamental principle, discovered by Thomas Johann Seebeck in 1821, established that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This Seebeck effect forms the cornerstone of thermoelectric generators (TEGs) that convert waste heat directly into electrical energy without moving parts.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved modest efficiency levels of 4-6%. Second-generation materials incorporating advanced semiconductor alloys pushed efficiencies to 7-8%. Current research focuses on nanostructured materials and quantum dot superlattices that theoretically could achieve efficiencies exceeding 15%.

Within renewable energy systems, waste heat represents a significant untapped resource. Solar photovoltaic installations typically convert only 15-22% of incident solar energy to electricity, with the remainder dissipated as heat. Wind turbines generate substantial heat in gearboxes and generators. Biomass and geothermal plants inherently produce excess heat during operation. This abundance of waste heat presents a compelling opportunity for efficiency improvements through thermoelectric recovery.

The primary technical objective in this field is to develop cost-effective thermoelectric systems that can achieve conversion efficiencies above 10% at price points below $1/W, making them economically viable for widespread deployment. Secondary objectives include improving material durability under thermal cycling conditions, reducing rare earth material dependencies, and developing scalable manufacturing processes for mass production.

Global interest in thermoelectric waste heat recovery has accelerated due to increasing energy costs and environmental regulations. The European Union's Circular Economy Action Plan and the United States Department of Energy's Advanced Manufacturing Office have both identified waste heat recovery as a priority area for research funding. Similarly, China's 14th Five-Year Plan emphasizes energy efficiency technologies including thermoelectric systems.

The integration of thermoelectric generators with renewable energy systems represents a promising pathway toward improving overall system efficiency. By capturing and converting waste heat that would otherwise be lost to the environment, these hybrid systems can potentially increase total energy output by 5-15% without requiring additional fuel or resource inputs, thereby enhancing sustainability metrics and improving economic returns on renewable energy investments.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved modest efficiency levels of 4-6%. Second-generation materials incorporating advanced semiconductor alloys pushed efficiencies to 7-8%. Current research focuses on nanostructured materials and quantum dot superlattices that theoretically could achieve efficiencies exceeding 15%.

Within renewable energy systems, waste heat represents a significant untapped resource. Solar photovoltaic installations typically convert only 15-22% of incident solar energy to electricity, with the remainder dissipated as heat. Wind turbines generate substantial heat in gearboxes and generators. Biomass and geothermal plants inherently produce excess heat during operation. This abundance of waste heat presents a compelling opportunity for efficiency improvements through thermoelectric recovery.

The primary technical objective in this field is to develop cost-effective thermoelectric systems that can achieve conversion efficiencies above 10% at price points below $1/W, making them economically viable for widespread deployment. Secondary objectives include improving material durability under thermal cycling conditions, reducing rare earth material dependencies, and developing scalable manufacturing processes for mass production.

Global interest in thermoelectric waste heat recovery has accelerated due to increasing energy costs and environmental regulations. The European Union's Circular Economy Action Plan and the United States Department of Energy's Advanced Manufacturing Office have both identified waste heat recovery as a priority area for research funding. Similarly, China's 14th Five-Year Plan emphasizes energy efficiency technologies including thermoelectric systems.

The integration of thermoelectric generators with renewable energy systems represents a promising pathway toward improving overall system efficiency. By capturing and converting waste heat that would otherwise be lost to the environment, these hybrid systems can potentially increase total energy output by 5-15% without requiring additional fuel or resource inputs, thereby enhancing sustainability metrics and improving economic returns on renewable energy investments.

Market Analysis for Thermoelectric Recovery Solutions

The global market for thermoelectric waste recovery solutions is experiencing significant growth, driven by increasing energy costs and environmental regulations. Currently valued at approximately $626 million in 2023, the market is projected to reach $1.4 billion by 2030, representing a compound annual growth rate (CAGR) of 12.3%. This growth trajectory is supported by the rising adoption of renewable energy systems and the increasing focus on energy efficiency across various industries.

Industrial sectors, particularly manufacturing, automotive, and power generation, represent the largest market segments for thermoelectric waste recovery technologies. The automotive sector alone accounts for nearly 35% of the current market share, with applications focused on converting waste heat from engine exhaust into usable electricity. Power generation facilities contribute approximately 28% of market demand, while industrial manufacturing represents about 22%.

Geographically, North America and Europe lead the market adoption, collectively accounting for 58% of global installations. However, the Asia-Pacific region is witnessing the fastest growth rate at 15.7% annually, primarily driven by China and India's rapid industrialization and commitment to reducing carbon emissions. Emerging economies in Latin America and Africa are showing increasing interest, though market penetration remains relatively low at 7% and 3% respectively.

Consumer demand patterns indicate a strong preference for integrated systems that offer both waste heat recovery and improved energy efficiency. End-users are increasingly seeking solutions with payback periods under five years, with optimal ROI achieved when thermoelectric systems can recover at least 5-8% of waste heat energy. Market research indicates that price sensitivity varies significantly by region, with developed markets prioritizing efficiency and reliability over initial cost.

Key market drivers include stringent environmental regulations, particularly carbon emission reduction targets set by various governments. The European Union's Green Deal and similar initiatives in North America have created favorable market conditions through incentives and regulatory frameworks. Additionally, volatile energy prices have accelerated adoption as businesses seek to reduce operational costs and energy dependency.

Market barriers include high initial investment costs, with current thermoelectric systems requiring capital expenditures that can be 30-40% higher than conventional energy systems. Technical limitations in conversion efficiency, currently averaging 5-7% for commercial systems, also present significant challenges to widespread adoption. Furthermore, lack of awareness and technical expertise in emerging markets continues to hamper growth potential.

Industrial sectors, particularly manufacturing, automotive, and power generation, represent the largest market segments for thermoelectric waste recovery technologies. The automotive sector alone accounts for nearly 35% of the current market share, with applications focused on converting waste heat from engine exhaust into usable electricity. Power generation facilities contribute approximately 28% of market demand, while industrial manufacturing represents about 22%.

Geographically, North America and Europe lead the market adoption, collectively accounting for 58% of global installations. However, the Asia-Pacific region is witnessing the fastest growth rate at 15.7% annually, primarily driven by China and India's rapid industrialization and commitment to reducing carbon emissions. Emerging economies in Latin America and Africa are showing increasing interest, though market penetration remains relatively low at 7% and 3% respectively.

Consumer demand patterns indicate a strong preference for integrated systems that offer both waste heat recovery and improved energy efficiency. End-users are increasingly seeking solutions with payback periods under five years, with optimal ROI achieved when thermoelectric systems can recover at least 5-8% of waste heat energy. Market research indicates that price sensitivity varies significantly by region, with developed markets prioritizing efficiency and reliability over initial cost.

Key market drivers include stringent environmental regulations, particularly carbon emission reduction targets set by various governments. The European Union's Green Deal and similar initiatives in North America have created favorable market conditions through incentives and regulatory frameworks. Additionally, volatile energy prices have accelerated adoption as businesses seek to reduce operational costs and energy dependency.

Market barriers include high initial investment costs, with current thermoelectric systems requiring capital expenditures that can be 30-40% higher than conventional energy systems. Technical limitations in conversion efficiency, currently averaging 5-7% for commercial systems, also present significant challenges to widespread adoption. Furthermore, lack of awareness and technical expertise in emerging markets continues to hamper growth potential.

Global Status and Technical Barriers in Thermoelectric Technology

Thermoelectric technology has witnessed significant advancements globally, yet remains at varying stages of development across different regions. In North America, research institutions and companies like NASA, BSST, and Alphabet Energy have established leadership in high-performance thermoelectric materials and systems. The European Union has focused on automotive waste heat recovery applications, with companies such as BMW and Volkswagen investing heavily in thermoelectric generators (TEGs) for vehicle efficiency improvements.

Asia, particularly Japan and South Korea, leads in consumer applications of thermoelectric technology, with companies like Panasonic and Samsung developing compact cooling solutions. China has rapidly expanded its research capacity, focusing on mass production capabilities and cost reduction strategies for thermoelectric materials, though often with lower conversion efficiencies compared to Western counterparts.

Despite global progress, thermoelectric waste recovery in renewable energy systems faces significant technical barriers. The primary challenge remains the inherently low conversion efficiency of thermoelectric materials, typically ranging from 5-8% in commercial applications. This limitation stems from the fundamental interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient—known as the "thermoelectric paradox"—making simultaneous optimization extremely difficult.

Material stability presents another major obstacle, particularly in renewable energy applications where temperature fluctuations are common. Current high-performance thermoelectric materials often degrade under thermal cycling conditions, limiting their operational lifespan in real-world applications. Additionally, manufacturing scalability remains problematic, with high-performance materials like skutterudites and half-Heusler alloys requiring complex synthesis processes that are difficult to scale economically.

Interface engineering represents a persistent challenge, as thermal and electrical contact resistances at material interfaces significantly reduce system-level performance. The integration of thermoelectric generators with existing renewable energy infrastructure also presents compatibility issues, particularly regarding thermal management and electrical output conditioning.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current thermoelectric materials with reasonable performance often contain rare or toxic elements like tellurium, making them expensive and environmentally problematic for large-scale deployment. The cost-per-watt of thermoelectric waste heat recovery systems remains substantially higher than competing technologies, limiting market penetration despite the theoretical advantages of maintenance-free, solid-state operation.

These technical barriers collectively explain why, despite decades of research, thermoelectric waste heat recovery has not achieved widespread implementation in renewable energy systems, highlighting the need for breakthrough innovations in materials science and system design.

Asia, particularly Japan and South Korea, leads in consumer applications of thermoelectric technology, with companies like Panasonic and Samsung developing compact cooling solutions. China has rapidly expanded its research capacity, focusing on mass production capabilities and cost reduction strategies for thermoelectric materials, though often with lower conversion efficiencies compared to Western counterparts.

Despite global progress, thermoelectric waste recovery in renewable energy systems faces significant technical barriers. The primary challenge remains the inherently low conversion efficiency of thermoelectric materials, typically ranging from 5-8% in commercial applications. This limitation stems from the fundamental interdependence of thermal conductivity, electrical conductivity, and Seebeck coefficient—known as the "thermoelectric paradox"—making simultaneous optimization extremely difficult.

Material stability presents another major obstacle, particularly in renewable energy applications where temperature fluctuations are common. Current high-performance thermoelectric materials often degrade under thermal cycling conditions, limiting their operational lifespan in real-world applications. Additionally, manufacturing scalability remains problematic, with high-performance materials like skutterudites and half-Heusler alloys requiring complex synthesis processes that are difficult to scale economically.

Interface engineering represents a persistent challenge, as thermal and electrical contact resistances at material interfaces significantly reduce system-level performance. The integration of thermoelectric generators with existing renewable energy infrastructure also presents compatibility issues, particularly regarding thermal management and electrical output conditioning.

Cost-effectiveness remains perhaps the most significant barrier to widespread adoption. Current thermoelectric materials with reasonable performance often contain rare or toxic elements like tellurium, making them expensive and environmentally problematic for large-scale deployment. The cost-per-watt of thermoelectric waste heat recovery systems remains substantially higher than competing technologies, limiting market penetration despite the theoretical advantages of maintenance-free, solid-state operation.

These technical barriers collectively explain why, despite decades of research, thermoelectric waste heat recovery has not achieved widespread implementation in renewable energy systems, highlighting the need for breakthrough innovations in materials science and system design.

Current Thermoelectric Conversion Efficiency Solutions

01 Thermoelectric material optimization for waste heat recovery

Advanced thermoelectric materials can significantly improve the efficiency of waste heat recovery systems. These materials exhibit enhanced Seebeck coefficients and reduced thermal conductivity, allowing for better conversion of temperature differentials into electrical energy. Innovations include nanostructured materials, semiconductor alloys, and composite structures that can operate effectively across various temperature ranges, particularly in industrial waste heat applications.- Material optimization for thermoelectric efficiency: Advanced materials play a crucial role in improving the efficiency of thermoelectric waste heat recovery systems. By developing and utilizing materials with high Seebeck coefficients and low thermal conductivity, the conversion efficiency of thermal energy to electrical energy can be significantly enhanced. These optimized materials can withstand high temperatures in industrial waste heat environments while maintaining their thermoelectric properties, leading to more efficient energy recovery systems.

- System design and integration techniques: The architectural design and integration of thermoelectric generators (TEGs) into existing industrial systems significantly impacts overall efficiency. Innovative system configurations that optimize heat flow paths, reduce thermal resistance at interfaces, and incorporate effective heat exchangers can maximize temperature differentials across thermoelectric modules. These design improvements focus on creating more efficient thermal management systems that capture and utilize waste heat that would otherwise be lost to the environment.

- Heat transfer enhancement methods: Various techniques to enhance heat transfer in thermoelectric waste recovery systems can significantly improve conversion efficiency. These include specialized heat sink designs, phase change materials for thermal management, and advanced heat exchanger configurations. By improving the thermal contact between heat sources and thermoelectric modules, these methods maximize the temperature gradient across the thermoelectric material, which directly correlates with increased power generation efficiency.

- Hybrid and cascaded thermoelectric systems: Hybrid systems that combine thermoelectric generators with other waste heat recovery technologies can achieve higher overall efficiency than standalone systems. Cascaded thermoelectric arrangements, where multiple stages of thermoelectric modules operate at different temperature ranges, can harvest energy across broader temperature gradients. These integrated approaches allow for more comprehensive waste heat utilization from various industrial processes, maximizing the total energy recovered.

- Control systems and power conditioning: Advanced electronic control systems and power conditioning circuits play a vital role in optimizing the performance of thermoelectric waste heat recovery systems. Maximum power point tracking (MPPT) algorithms, adaptive control strategies, and efficient DC-DC converters help extract the maximum available power under varying thermal conditions. These sophisticated control mechanisms continuously adjust the operating parameters of thermoelectric generators to maintain optimal efficiency despite fluctuations in waste heat availability.

02 System design and integration for thermoelectric generators

The efficiency of thermoelectric waste recovery systems depends significantly on their design and integration with existing heat sources. Optimized heat exchangers, improved thermal interfaces, and strategic placement of thermoelectric modules relative to heat sources can maximize temperature gradients and power output. Advanced system architectures include cascaded modules, segmented designs, and hybrid systems that can capture waste heat across multiple temperature ranges simultaneously.Expand Specific Solutions03 Heat flow management techniques

Effective heat flow management is crucial for maximizing thermoelectric conversion efficiency. Techniques include the use of specialized heat sinks, thermal interface materials, and flow channel designs that optimize heat transfer to thermoelectric elements while minimizing thermal losses. Advanced heat concentration methods and thermal gradient enhancement approaches help maintain optimal temperature differentials across thermoelectric modules, significantly improving overall system efficiency.Expand Specific Solutions04 Control systems and power conditioning for thermoelectric generators

Sophisticated control systems and power conditioning circuits can significantly enhance the efficiency of thermoelectric waste heat recovery. Maximum power point tracking algorithms, adaptive control strategies, and intelligent load management systems ensure optimal electrical output under varying thermal conditions. Advanced DC-DC converters and power management circuits help maintain stable output voltage and maximize energy extraction from fluctuating waste heat sources.Expand Specific Solutions05 Industrial application-specific thermoelectric solutions

Specialized thermoelectric waste heat recovery systems designed for specific industrial applications show enhanced efficiency compared to general-purpose solutions. These include customized systems for automotive exhaust recovery, industrial furnace waste heat utilization, and process industry heat recovery. Application-specific designs account for unique temperature profiles, space constraints, and operational conditions of different industries, resulting in optimized performance and higher conversion efficiencies.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

Thermoelectric waste recovery in renewable energy systems is currently in a growth phase, with the global market expected to reach significant expansion by 2030. The technology maturity varies across applications, with automotive and industrial sectors leading adoption. Key players demonstrate different specialization levels: Toyota Motor Corp. and Siemens AG have integrated thermoelectric systems into their renewable energy portfolios, while specialized firms like Pyro-E LLC and European Thermodynamics Limited focus on innovative waste heat recovery solutions. Research institutions including Purdue Research Foundation and Tianjin University are advancing fundamental technologies. The competitive landscape features both established industrial conglomerates (BASF, Hitachi) and emerging technology providers, with increasing cross-sector collaboration accelerating commercialization of higher-efficiency thermoelectric materials and systems.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermoelectric waste heat recovery systems specifically designed for hybrid and electric vehicles. Their technology utilizes bismuth telluride and skutterudite-based materials that can operate efficiently at temperatures ranging from 200-600°C. Toyota's system captures exhaust heat and converts it directly into electricity through the Seebeck effect, achieving conversion efficiencies of up to 5-7% in real-world driving conditions[1]. The company has integrated these systems into their latest Prius models, where the recovered energy is used to charge the vehicle's battery, reducing the load on the alternator and improving fuel efficiency by approximately 2-3%[2]. Toyota's approach includes a modular design that allows for strategic placement of thermoelectric generators (TEGs) at multiple heat sources throughout the vehicle, maximizing energy recovery potential while minimizing impact on existing vehicle architecture.

Strengths: Toyota's system demonstrates excellent durability under automotive conditions with over 100,000 miles of testing without significant degradation. Their modular approach allows for flexible implementation across different vehicle platforms. Weaknesses: Current conversion efficiency remains relatively low compared to other energy recovery methods, and the high cost of thermoelectric materials (particularly tellurium) limits mass-market adoption.

Shuangliang Eco-Energy Systems Co., Ltd.

Technical Solution: Shuangliang Eco-Energy has pioneered an integrated thermoelectric waste heat recovery system specifically designed for industrial applications and renewable energy plants. Their technology combines organic Rankine cycle (ORC) principles with advanced thermoelectric materials to create a dual-stage recovery process. The system first captures high-temperature waste heat (>300°C) using conventional heat exchangers, then employs specially developed magnesium silicide and higher manganese silicide thermoelectric modules to convert lower-grade residual heat (100-300°C) into electricity[3]. This cascaded approach has achieved total system efficiencies of up to 12% in biomass power plants and industrial furnaces. Shuangliang's innovation includes a proprietary heat transfer fluid system that optimizes thermal conductivity between heat sources and thermoelectric elements, reducing thermal resistance by approximately 35% compared to conventional designs[4]. The company has successfully deployed these systems in several renewable energy facilities across China, demonstrating consistent performance improvements.

Strengths: Their dual-stage approach maximizes energy recovery across a wide temperature range, making it versatile for various industrial applications. The system uses more abundant and environmentally friendly materials compared to traditional bismuth-telluride based thermoelectrics. Weaknesses: The complexity of the integrated system requires significant initial engineering and installation costs, and the technology shows diminishing returns in applications with highly variable waste heat profiles.

Key Patents and Breakthroughs in Thermoelectric Materials

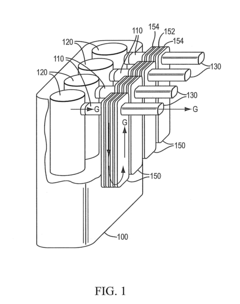

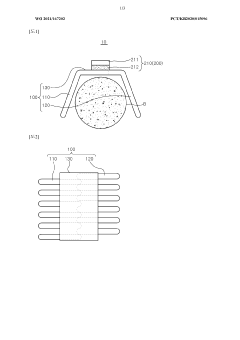

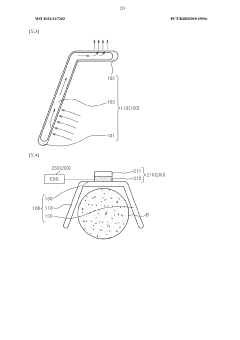

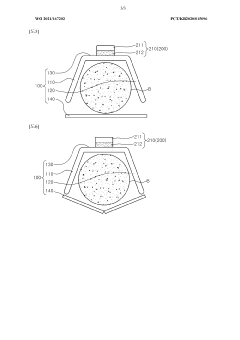

Energy conversion devices and methods

PatentInactiveUS20110197941A1

Innovation

- A thermoelectric device with a hot source chamber for catalytic conversion and a cold source chamber, both made from materials with a low coefficient of thermal expansion, such as glass ceramic, to create a temperature gradient for electric potential generation, minimizing strain and toxicity while efficiently utilizing high temperature exhaust gases.

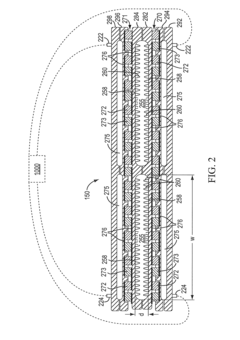

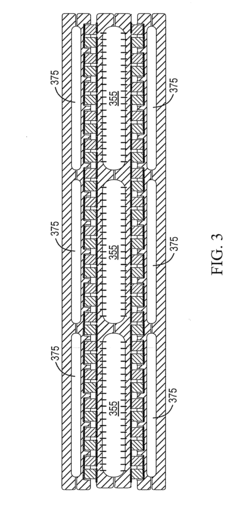

Thermoelectric power generation system for recovering casting waste heat

PatentWO2021167202A1

Innovation

- A thermoelectric power generation system using a waste heat recovery unit with heat pipes and a thermoelectric module that converts waste heat from continuous casting into electrical energy, eliminating the need for separate devices by leveraging heat pipes' ability to transfer heat independently and integrating a thermoelectric module for energy conversion.

Integration Challenges with Renewable Energy Systems

The integration of thermoelectric waste heat recovery systems with existing renewable energy infrastructure presents significant technical and operational challenges. One primary obstacle is the compatibility between thermoelectric generators (TEGs) and various renewable energy systems, each with unique operating parameters and thermal profiles. Solar photovoltaic systems, for instance, generate waste heat at different temperature gradients compared to biomass facilities, requiring customized TEG configurations for optimal performance.

Physical integration constraints also pose considerable challenges. The limited space available in many renewable energy installations necessitates compact TEG designs that can function effectively without compromising the primary system's operation. This spatial limitation often forces engineers to make trade-offs between recovery efficiency and practical implementation, particularly in retrofitting scenarios where systems were not initially designed to accommodate waste heat recovery components.

Electrical integration presents another layer of complexity. TEGs typically produce DC power with variable voltage outputs depending on temperature differentials, requiring sophisticated power conditioning systems to synchronize with the main renewable energy output. This integration must be seamless to prevent disruptions to grid stability, especially in distributed generation contexts where multiple small-scale systems operate in parallel.

Thermal management across integrated systems demands careful engineering consideration. The addition of TEGs can potentially alter the thermal dynamics of the primary renewable energy system, sometimes necessitating redesigned cooling systems or heat transfer mechanisms. Failure to properly address these thermal interactions may result in reduced efficiency of the primary system, negating the benefits gained from waste heat recovery.

Control system integration represents perhaps the most sophisticated challenge. Modern renewable energy systems rely on complex algorithms and monitoring systems to optimize performance under varying conditions. Incorporating TEGs introduces additional variables that must be factored into these control systems, requiring advanced predictive models and adaptive control strategies to maximize overall system efficiency while maintaining operational stability.

Economic viability further complicates integration efforts. The additional capital expenditure for TEG integration must be justified by sufficient efficiency gains, particularly challenging given the relatively low conversion efficiency of current thermoelectric materials. This economic constraint often limits widespread adoption despite technical feasibility, creating a barrier that requires either significant performance improvements or cost reductions to overcome.

Physical integration constraints also pose considerable challenges. The limited space available in many renewable energy installations necessitates compact TEG designs that can function effectively without compromising the primary system's operation. This spatial limitation often forces engineers to make trade-offs between recovery efficiency and practical implementation, particularly in retrofitting scenarios where systems were not initially designed to accommodate waste heat recovery components.

Electrical integration presents another layer of complexity. TEGs typically produce DC power with variable voltage outputs depending on temperature differentials, requiring sophisticated power conditioning systems to synchronize with the main renewable energy output. This integration must be seamless to prevent disruptions to grid stability, especially in distributed generation contexts where multiple small-scale systems operate in parallel.

Thermal management across integrated systems demands careful engineering consideration. The addition of TEGs can potentially alter the thermal dynamics of the primary renewable energy system, sometimes necessitating redesigned cooling systems or heat transfer mechanisms. Failure to properly address these thermal interactions may result in reduced efficiency of the primary system, negating the benefits gained from waste heat recovery.

Control system integration represents perhaps the most sophisticated challenge. Modern renewable energy systems rely on complex algorithms and monitoring systems to optimize performance under varying conditions. Incorporating TEGs introduces additional variables that must be factored into these control systems, requiring advanced predictive models and adaptive control strategies to maximize overall system efficiency while maintaining operational stability.

Economic viability further complicates integration efforts. The additional capital expenditure for TEG integration must be justified by sufficient efficiency gains, particularly challenging given the relatively low conversion efficiency of current thermoelectric materials. This economic constraint often limits widespread adoption despite technical feasibility, creating a barrier that requires either significant performance improvements or cost reductions to overcome.

Economic Viability and ROI Analysis

The economic viability of thermoelectric waste heat recovery systems in renewable energy applications hinges on several critical factors. Initial capital expenditure represents a significant barrier, with current thermoelectric generator (TEG) systems requiring substantial investment ranging from $2,000 to $10,000 per kilowatt of installed capacity. This cost structure places thermoelectric solutions at a disadvantage compared to alternative waste heat recovery technologies such as Organic Rankine Cycle systems, which typically demonstrate lower per-kilowatt costs at larger scales.

Return on investment calculations reveal promising yet challenging economics. Industrial-scale implementations with continuous waste heat sources can achieve payback periods of 3-5 years, while smaller or intermittent applications may extend beyond 7-10 years. This timeline often exceeds the investment horizons of many commercial entities, particularly in competitive energy markets where capital allocation decisions prioritize shorter-term returns.

Efficiency improvements present the most direct path to economic viability. Current commercial thermoelectric materials achieve conversion efficiencies of 5-8%, whereas laboratory prototypes have demonstrated up to 15% efficiency. Economic modeling indicates that achieving 12% efficiency at current material costs would reduce payback periods by approximately 40%, potentially transforming market adoption rates.

Lifecycle cost analysis reveals additional economic considerations beyond initial investment. Thermoelectric systems benefit from minimal maintenance requirements, with estimated operational costs of $0.005-0.02 per kWh generated, significantly lower than combustion-based generation. Furthermore, the absence of moving parts results in expected operational lifespans of 15-20 years, enhancing long-term value propositions despite higher upfront costs.

Government incentives substantially impact economic viability across different markets. Carbon pricing mechanisms, renewable energy credits, and industrial efficiency subsidies can reduce effective payback periods by 20-50% in supportive regulatory environments. Notably, regions with established carbon markets or aggressive decarbonization targets offer the most favorable economic conditions for thermoelectric waste heat recovery implementation.

Scale economies remain challenging but show improvement trajectories. Manufacturing advances and material innovations have reduced production costs by approximately 15% annually over the past five years. Industry projections suggest continued cost reductions of 8-12% annually through 2030, potentially bringing thermoelectric waste heat recovery systems to cost parity with conventional generation for specific applications within this decade.

Return on investment calculations reveal promising yet challenging economics. Industrial-scale implementations with continuous waste heat sources can achieve payback periods of 3-5 years, while smaller or intermittent applications may extend beyond 7-10 years. This timeline often exceeds the investment horizons of many commercial entities, particularly in competitive energy markets where capital allocation decisions prioritize shorter-term returns.

Efficiency improvements present the most direct path to economic viability. Current commercial thermoelectric materials achieve conversion efficiencies of 5-8%, whereas laboratory prototypes have demonstrated up to 15% efficiency. Economic modeling indicates that achieving 12% efficiency at current material costs would reduce payback periods by approximately 40%, potentially transforming market adoption rates.

Lifecycle cost analysis reveals additional economic considerations beyond initial investment. Thermoelectric systems benefit from minimal maintenance requirements, with estimated operational costs of $0.005-0.02 per kWh generated, significantly lower than combustion-based generation. Furthermore, the absence of moving parts results in expected operational lifespans of 15-20 years, enhancing long-term value propositions despite higher upfront costs.

Government incentives substantially impact economic viability across different markets. Carbon pricing mechanisms, renewable energy credits, and industrial efficiency subsidies can reduce effective payback periods by 20-50% in supportive regulatory environments. Notably, regions with established carbon markets or aggressive decarbonization targets offer the most favorable economic conditions for thermoelectric waste heat recovery implementation.

Scale economies remain challenging but show improvement trajectories. Manufacturing advances and material innovations have reduced production costs by approximately 15% annually over the past five years. Industry projections suggest continued cost reductions of 8-12% annually through 2030, potentially bringing thermoelectric waste heat recovery systems to cost parity with conventional generation for specific applications within this decade.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!