Understanding the Role of Catalysts in Thermoelectric Waste Recovery

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Thermoelectric Waste Recovery Background and Objectives

Thermoelectric waste recovery represents a significant frontier in sustainable energy technology, offering the potential to recapture and utilize energy that would otherwise be lost as waste heat. The evolution of this technology spans several decades, beginning with the discovery of the Seebeck effect in the early 19th century, which demonstrated that temperature differences between two dissimilar electrical conductors can produce voltage. However, it wasn't until the late 20th century that practical applications began to emerge, driven by advances in material science and increasing global emphasis on energy efficiency.

The integration of catalysts into thermoelectric systems marks a pivotal advancement in this field. Catalysts, by definition, facilitate chemical reactions without being consumed in the process, and their application in thermoelectric waste recovery has opened new pathways for enhancing energy conversion efficiency. Traditional thermoelectric materials often suffer from low conversion rates, typically below 10%, limiting their widespread industrial adoption despite the abundance of waste heat sources.

Recent technological trends indicate a shift toward hybrid systems that combine catalytic processes with thermoelectric generators. This synergistic approach aims to overcome the inherent limitations of standalone thermoelectric devices by utilizing catalysts to optimize heat distribution, reduce thermal resistance, and enhance electron transport mechanisms. The development trajectory suggests a growing focus on nanoscale engineering of catalyst-thermoelectric interfaces to maximize energy harvesting capabilities.

The primary technical objective of this research is to comprehensively understand how catalysts can be strategically employed to enhance the performance of thermoelectric waste recovery systems. This includes investigating the fundamental mechanisms by which catalysts influence thermal and electrical conductivity, exploring novel catalyst compositions and structures, and developing scalable manufacturing processes for catalyst-enhanced thermoelectric devices.

Additionally, we aim to quantify the potential energy savings and efficiency improvements that can be achieved through catalyst integration across various industrial applications. Sectors such as automotive, manufacturing, power generation, and data centers represent significant opportunities for waste heat recovery, with each presenting unique technical challenges and requirements.

A further objective is to establish design principles for catalyst-thermoelectric systems that can be tailored to specific waste heat profiles, considering factors such as temperature range, heat flux density, and operational environment. This will facilitate the development of application-specific solutions that maximize energy recovery in real-world scenarios, ultimately contributing to global efforts in reducing carbon emissions and improving energy utilization efficiency.

The integration of catalysts into thermoelectric systems marks a pivotal advancement in this field. Catalysts, by definition, facilitate chemical reactions without being consumed in the process, and their application in thermoelectric waste recovery has opened new pathways for enhancing energy conversion efficiency. Traditional thermoelectric materials often suffer from low conversion rates, typically below 10%, limiting their widespread industrial adoption despite the abundance of waste heat sources.

Recent technological trends indicate a shift toward hybrid systems that combine catalytic processes with thermoelectric generators. This synergistic approach aims to overcome the inherent limitations of standalone thermoelectric devices by utilizing catalysts to optimize heat distribution, reduce thermal resistance, and enhance electron transport mechanisms. The development trajectory suggests a growing focus on nanoscale engineering of catalyst-thermoelectric interfaces to maximize energy harvesting capabilities.

The primary technical objective of this research is to comprehensively understand how catalysts can be strategically employed to enhance the performance of thermoelectric waste recovery systems. This includes investigating the fundamental mechanisms by which catalysts influence thermal and electrical conductivity, exploring novel catalyst compositions and structures, and developing scalable manufacturing processes for catalyst-enhanced thermoelectric devices.

Additionally, we aim to quantify the potential energy savings and efficiency improvements that can be achieved through catalyst integration across various industrial applications. Sectors such as automotive, manufacturing, power generation, and data centers represent significant opportunities for waste heat recovery, with each presenting unique technical challenges and requirements.

A further objective is to establish design principles for catalyst-thermoelectric systems that can be tailored to specific waste heat profiles, considering factors such as temperature range, heat flux density, and operational environment. This will facilitate the development of application-specific solutions that maximize energy recovery in real-world scenarios, ultimately contributing to global efforts in reducing carbon emissions and improving energy utilization efficiency.

Market Analysis for Thermoelectric Waste Recovery Solutions

The global market for thermoelectric waste recovery solutions is experiencing significant growth, driven by increasing energy costs and environmental regulations. Current market valuations place this sector at approximately $600 million in 2023, with projections indicating growth to reach $1.2 billion by 2030, representing a compound annual growth rate of 10.4%. This growth trajectory is particularly pronounced in industrial manufacturing, automotive, and power generation sectors where waste heat recovery presents substantial efficiency opportunities.

Industrial applications currently dominate the market share, accounting for nearly 45% of total implementation. This concentration stems from the substantial waste heat generated in energy-intensive industries such as steel, cement, and chemical processing, where temperatures often exceed 500°C, creating ideal conditions for thermoelectric recovery systems.

The automotive sector represents the fastest-growing segment, with adoption rates increasing by 15% annually as manufacturers seek to meet stringent emissions standards. Integration of thermoelectric generators in exhaust systems has demonstrated fuel efficiency improvements of 3-5% in field tests, creating compelling value propositions for both commercial and passenger vehicle manufacturers.

Regional analysis reveals that Asia-Pacific leads market adoption, holding 38% of global market share, followed by North America (29%) and Europe (24%). China's aggressive industrial decarbonization policies have created particularly favorable conditions for thermoelectric solutions, with government incentives supporting implementation across manufacturing sectors.

Customer demand patterns indicate a shift toward integrated systems that combine thermoelectric generators with complementary technologies such as heat exchangers and power management electronics. This trend toward turnkey solutions reflects end-user preference for simplified implementation and reduced engineering complexity.

Price sensitivity remains a significant market factor, with current thermoelectric systems demonstrating payback periods ranging from 3-7 years depending on application and energy costs. Analysis of purchasing decisions indicates that installations with projected payback periods exceeding 4 years face significant adoption barriers unless supported by regulatory compliance requirements.

Market penetration faces challenges from competing waste heat recovery technologies, particularly Organic Rankine Cycle systems for higher-temperature applications and heat pumps for lower-temperature recovery. The competitive advantage for thermoelectric solutions centers on their solid-state operation, minimal maintenance requirements, and scalability for distributed applications.

Future market growth will be heavily influenced by advancements in catalyst technology that can improve conversion efficiency beyond current limitations. Market research indicates that achieving efficiency improvements of 20-30% through advanced catalysts could expand the addressable market by an estimated 65%, particularly by making lower-temperature waste heat recovery economically viable.

Industrial applications currently dominate the market share, accounting for nearly 45% of total implementation. This concentration stems from the substantial waste heat generated in energy-intensive industries such as steel, cement, and chemical processing, where temperatures often exceed 500°C, creating ideal conditions for thermoelectric recovery systems.

The automotive sector represents the fastest-growing segment, with adoption rates increasing by 15% annually as manufacturers seek to meet stringent emissions standards. Integration of thermoelectric generators in exhaust systems has demonstrated fuel efficiency improvements of 3-5% in field tests, creating compelling value propositions for both commercial and passenger vehicle manufacturers.

Regional analysis reveals that Asia-Pacific leads market adoption, holding 38% of global market share, followed by North America (29%) and Europe (24%). China's aggressive industrial decarbonization policies have created particularly favorable conditions for thermoelectric solutions, with government incentives supporting implementation across manufacturing sectors.

Customer demand patterns indicate a shift toward integrated systems that combine thermoelectric generators with complementary technologies such as heat exchangers and power management electronics. This trend toward turnkey solutions reflects end-user preference for simplified implementation and reduced engineering complexity.

Price sensitivity remains a significant market factor, with current thermoelectric systems demonstrating payback periods ranging from 3-7 years depending on application and energy costs. Analysis of purchasing decisions indicates that installations with projected payback periods exceeding 4 years face significant adoption barriers unless supported by regulatory compliance requirements.

Market penetration faces challenges from competing waste heat recovery technologies, particularly Organic Rankine Cycle systems for higher-temperature applications and heat pumps for lower-temperature recovery. The competitive advantage for thermoelectric solutions centers on their solid-state operation, minimal maintenance requirements, and scalability for distributed applications.

Future market growth will be heavily influenced by advancements in catalyst technology that can improve conversion efficiency beyond current limitations. Market research indicates that achieving efficiency improvements of 20-30% through advanced catalysts could expand the addressable market by an estimated 65%, particularly by making lower-temperature waste heat recovery economically viable.

Current Catalyst Technologies and Challenges in Waste Heat Recovery

In the field of thermoelectric waste heat recovery, catalyst technologies play a crucial role in enhancing energy conversion efficiency. Current catalyst technologies primarily focus on improving the performance of thermoelectric materials through various mechanisms including electron filtering, energy filtering, and resonant levels. These catalysts typically consist of noble metals such as platinum, palladium, and rhodium, as well as transition metals like nickel, copper, and cobalt, which facilitate the conversion of waste heat into usable electrical energy.

Nanostructured catalysts represent a significant advancement in this domain, offering increased surface area and enhanced reactivity. These catalysts are engineered at the nanoscale to optimize the interface between the thermoelectric material and the heat source, thereby improving energy transfer efficiency. Particularly promising are metal-organic frameworks (MOFs) and zeolites, which provide highly ordered structures with tunable properties for specific waste heat recovery applications.

Despite these advancements, several challenges persist in catalyst technology for thermoelectric waste recovery. Thermal stability remains a primary concern, as catalysts must maintain their structural integrity and performance under high-temperature conditions often encountered in industrial waste heat scenarios. Many current catalysts experience degradation or sintering when exposed to temperatures exceeding 500°C for extended periods, significantly limiting their practical application in high-temperature industrial environments.

Cost-effectiveness presents another substantial barrier to widespread adoption. Noble metal catalysts, while highly efficient, are prohibitively expensive for large-scale implementation. Although research into non-precious metal alternatives has shown promise, these alternatives often suffer from reduced efficiency or durability compared to their noble metal counterparts.

Catalyst poisoning and deactivation represent additional technical challenges. In real-world industrial environments, catalysts are exposed to various contaminants that can adsorb onto active sites, blocking access to reactants and reducing catalytic activity. Sulfur compounds, in particular, are notorious for their ability to poison catalysts in waste heat recovery systems, necessitating the development of sulfur-tolerant catalyst formulations.

Scalability issues further complicate the implementation of advanced catalyst technologies. Laboratory-scale successes often face significant hurdles when scaled to industrial applications due to mass transfer limitations, heat management challenges, and uniform catalyst distribution difficulties. Current manufacturing processes for high-performance catalysts frequently involve complex synthesis routes that are difficult to scale economically.

Integration challenges between catalyst systems and thermoelectric generators also persist. Optimizing the interface between these components remains technically demanding, requiring precise engineering to minimize thermal contact resistance while maximizing electrical isolation where necessary.

Nanostructured catalysts represent a significant advancement in this domain, offering increased surface area and enhanced reactivity. These catalysts are engineered at the nanoscale to optimize the interface between the thermoelectric material and the heat source, thereby improving energy transfer efficiency. Particularly promising are metal-organic frameworks (MOFs) and zeolites, which provide highly ordered structures with tunable properties for specific waste heat recovery applications.

Despite these advancements, several challenges persist in catalyst technology for thermoelectric waste recovery. Thermal stability remains a primary concern, as catalysts must maintain their structural integrity and performance under high-temperature conditions often encountered in industrial waste heat scenarios. Many current catalysts experience degradation or sintering when exposed to temperatures exceeding 500°C for extended periods, significantly limiting their practical application in high-temperature industrial environments.

Cost-effectiveness presents another substantial barrier to widespread adoption. Noble metal catalysts, while highly efficient, are prohibitively expensive for large-scale implementation. Although research into non-precious metal alternatives has shown promise, these alternatives often suffer from reduced efficiency or durability compared to their noble metal counterparts.

Catalyst poisoning and deactivation represent additional technical challenges. In real-world industrial environments, catalysts are exposed to various contaminants that can adsorb onto active sites, blocking access to reactants and reducing catalytic activity. Sulfur compounds, in particular, are notorious for their ability to poison catalysts in waste heat recovery systems, necessitating the development of sulfur-tolerant catalyst formulations.

Scalability issues further complicate the implementation of advanced catalyst technologies. Laboratory-scale successes often face significant hurdles when scaled to industrial applications due to mass transfer limitations, heat management challenges, and uniform catalyst distribution difficulties. Current manufacturing processes for high-performance catalysts frequently involve complex synthesis routes that are difficult to scale economically.

Integration challenges between catalyst systems and thermoelectric generators also persist. Optimizing the interface between these components remains technically demanding, requiring precise engineering to minimize thermal contact resistance while maximizing electrical isolation where necessary.

Existing Catalytic Solutions for Waste Heat Conversion

01 Metal-based catalysts for thermoelectric efficiency enhancement

Metal-based catalysts can significantly improve the efficiency of thermoelectric waste heat recovery systems. These catalysts, often containing noble metals or transition metals, facilitate the conversion of thermal energy to electrical energy by enhancing the electron transport properties at material interfaces. The catalytic activity helps reduce thermal resistance and improve the Seebeck coefficient, resulting in higher power output from waste heat sources.- Metal-based catalysts for thermoelectric efficiency enhancement: Metal-based catalysts can significantly improve the efficiency of thermoelectric waste heat recovery systems. These catalysts, often containing noble metals or transition metals, facilitate the conversion of thermal energy to electrical energy by enhancing the Seebeck effect and reducing thermal conductivity. The catalytic materials create optimal electron transport pathways while minimizing phonon transport, leading to improved figure of merit (ZT) values in thermoelectric materials.

- Nanostructured catalytic materials for thermoelectric applications: Nanostructured catalytic materials offer enhanced performance in thermoelectric waste recovery systems due to their high surface area and unique quantum confinement effects. These materials, including nanoparticles, nanowires, and nanocomposites, can be strategically incorporated into thermoelectric devices to create phonon scattering centers while maintaining good electrical conductivity. The nanoscale interfaces create energy filtering effects that selectively allow electrons to pass while blocking phonons, thereby increasing the power factor and overall conversion efficiency.

- Catalyst-assisted thermoelectric material synthesis: Catalysts play a crucial role in the synthesis of high-performance thermoelectric materials by enabling lower reaction temperatures, faster reaction rates, and better control over material morphology. These catalytic processes can produce thermoelectric materials with optimized crystal structures, reduced defects, and controlled doping levels. The catalyst-assisted synthesis methods result in materials with enhanced Seebeck coefficients, electrical conductivity, and reduced thermal conductivity, leading to higher thermoelectric conversion efficiency in waste heat recovery applications.

- Hybrid catalyst systems for enhanced waste heat recovery: Hybrid catalyst systems combine multiple catalytic materials or mechanisms to achieve synergistic effects in thermoelectric waste heat recovery. These systems may integrate organic and inorganic catalysts, or combine catalytic functionality with other enhancement mechanisms such as phonon scattering or electron filtering. The hybrid approach allows for simultaneous optimization of multiple thermoelectric parameters, resulting in improved power output and conversion efficiency across wider temperature ranges typical in industrial waste heat scenarios.

- Catalytic converters integrated with thermoelectric generators: Integrating catalytic converters with thermoelectric generators creates dual-function systems that simultaneously reduce emissions and recover waste heat. These integrated systems utilize the exothermic reactions in catalytic converters as a heat source for thermoelectric generation. Special catalyst formulations and structural designs optimize both the catalytic conversion efficiency and the temperature gradient needed for effective thermoelectric power generation, making these systems particularly valuable for automotive and industrial applications where both emission control and energy efficiency are priorities.

02 Nanostructured catalytic materials for thermoelectric applications

Nanostructured catalytic materials offer enhanced performance in thermoelectric waste recovery systems due to their high surface area and unique quantum effects. These materials can be engineered to have optimized phonon scattering properties while maintaining good electrical conductivity. The nanoscale features create additional interfaces that reduce thermal conductivity without significantly affecting electrical transport, thereby improving the overall figure of merit (ZT) of thermoelectric devices.Expand Specific Solutions03 Catalyst-enhanced thermoelectric material composites

Composite materials incorporating catalytic elements can significantly improve thermoelectric waste heat recovery efficiency. These composites typically combine conventional thermoelectric materials with catalytic particles or layers that facilitate energy conversion at interfaces. The catalytic components can modify the electronic band structure of the base material, optimize carrier concentration, and create beneficial energy filtering effects that enhance the power factor while maintaining low thermal conductivity.Expand Specific Solutions04 Catalytic converters integrated with thermoelectric generators

Integrating catalytic converters with thermoelectric generators creates synergistic systems for waste heat recovery, particularly in automotive and industrial applications. The catalytic converter performs its primary function of emissions reduction while simultaneously providing high-temperature heat that can be harvested by attached thermoelectric modules. This integration improves overall system efficiency by utilizing waste heat that would otherwise be lost to the environment, while the catalytic activity ensures optimal temperature distribution across the thermoelectric elements.Expand Specific Solutions05 Surface-modified catalysts for enhanced thermoelectric performance

Surface modification of catalysts can significantly improve thermoelectric waste heat recovery efficiency. These modifications typically involve doping, functionalization, or creating specific surface structures that optimize the interface between the catalyst and thermoelectric material. The modified surfaces can reduce contact resistance, improve thermal management, and enhance electron transfer processes. Additionally, these treatments can increase catalyst stability under the high-temperature conditions typical in waste heat recovery applications.Expand Specific Solutions

Industry Leaders in Thermoelectric Catalyst Development

The thermoelectric waste recovery catalyst market is in a growth phase, with increasing focus on energy efficiency and sustainability driving adoption. The market is projected to expand significantly as industries seek to reduce energy waste and carbon emissions. Technologically, the field shows varying maturity levels across applications. Toyota Motor Corp. and Johnson Matthey lead with advanced catalyst technologies for automotive applications, while energy companies like Shell, Chevron, and Sinopec are developing specialized solutions for industrial waste heat recovery. Research institutions including Kyushu University and GTI Energy are advancing fundamental catalyst science. Chinese players such as CHN ENERGY and Sinochem entities are rapidly gaining ground through significant R&D investments, particularly in petrochemical applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced thermoelectric generator (TEG) systems that convert waste heat from vehicle exhaust into usable electricity. Their technology utilizes skutterudite-based catalysts with nano-structured interfaces to enhance the Seebeck effect while minimizing thermal conductivity. Toyota's approach incorporates segmented thermoelectric materials with different optimal operating temperature ranges to maximize efficiency across the variable temperature profile of exhaust systems. Their latest generation TEGs employ platinum-based catalysts at critical junctions to facilitate electron transfer and reduce contact resistance between thermoelectric modules. Toyota has demonstrated recovery of up to 5% of engine waste heat in real-world driving conditions, translating to approximately 3-5% improvement in fuel economy for conventional vehicles[1][3]. The company has also pioneered integration of these systems with hybrid powertrains, using the recovered electricity to charge batteries and power auxiliary systems.

Strengths: Toyota's catalyst technology demonstrates excellent durability under automotive thermal cycling conditions and has been optimized for mass production feasibility. Their systems show superior integration with existing vehicle architectures. Weaknesses: The platinum-based catalysts increase production costs significantly, and the current generation still faces efficiency limitations at lower temperature differentials typical in urban driving cycles.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed proprietary catalyst technologies for thermoelectric waste heat recovery specifically tailored to petroleum refining processes. Their system employs nanostructured metal oxide catalysts (primarily modified titanates and cobaltites) that enhance charge carrier mobility at the interfaces of thermoelectric materials. Sinopec's approach focuses on capturing waste heat from multiple refinery sources including furnaces, boilers, and flare systems, where temperatures can range from 300-800°C. Their catalytic materials are designed to withstand the harsh chemical environments present in refineries while maintaining thermoelectric performance. The company has implemented large-scale waste heat recovery systems that incorporate these catalysts in several of their refineries, reportedly generating up to 15MW of electricity from previously wasted thermal energy[2]. Sinopec's catalysts are specifically engineered to resist sulfur poisoning and coking, common challenges in petroleum processing environments, while maintaining high ZT values (thermoelectric figure of merit) across broad temperature ranges.

Strengths: Sinopec's catalysts demonstrate exceptional chemical resistance and stability in industrial environments containing contaminants. Their systems are scalable to very large industrial applications with proven implementation. Weaknesses: The technology requires significant initial capital investment and has relatively long payback periods (typically 4-6 years). The catalysts also show performance degradation when exposed to certain process contaminants over extended periods.

Key Catalyst Innovations for Thermoelectric Efficiency

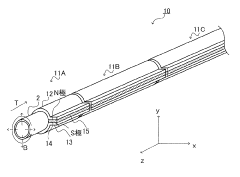

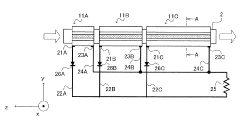

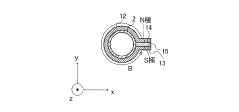

Waste heat recovery device

PatentActiveJP2020084823A

Innovation

- An exhaust heat recovery device utilizing a tubular member with a differential fluid flow and a magnetic field perpendicular to the temperature difference, generating an electromotive force through the spin Seebeck effect, which includes a thermoelectric conversion section and a permanent magnet to produce a magnetic field in the circumferential direction.

A catalyst for waste thermolysis

PatentActiveEP2484440A1

Innovation

- A catalyst comprising a selenium and bismuth alloy is used to accelerate the thermolytic process, with a composition of 70% to 99% selenium and 1% to 30% bismuth, applied as a lining in the reactor to facilitate faster dissociation of organic waste molecules into reusable combustible products.

Environmental Impact and Sustainability Considerations

The integration of catalysts in thermoelectric waste recovery systems represents a significant advancement in sustainable energy technologies with far-reaching environmental implications. These systems fundamentally transform waste heat—a byproduct typically released into the environment—into usable electricity, thereby reducing overall energy consumption and associated greenhouse gas emissions. When catalysts are incorporated into these systems, they substantially enhance conversion efficiency, enabling greater energy recovery from industrial processes, transportation systems, and power generation facilities.

From a lifecycle perspective, thermoelectric waste recovery systems with catalytic components offer considerable environmental benefits. Studies indicate that these systems can reduce carbon dioxide emissions by 5-15% in industrial applications where substantial heat is generated. The environmental footprint is further diminished when considering the reduced need for primary energy production, which often relies on fossil fuels with their associated extraction impacts and emissions.

However, the environmental assessment must also consider the ecological costs associated with catalyst production. Many effective catalysts incorporate rare earth elements or precious metals, which present significant environmental challenges during mining and processing. These include habitat destruction, soil contamination, and water pollution. The extraction of platinum group metals, commonly used in high-performance catalysts, is particularly resource-intensive, requiring approximately 10-15 tons of ore to produce a single ounce of platinum.

Water consumption represents another critical environmental consideration. Catalyst manufacturing processes typically require substantial water resources, with production facilities consuming between 2,000-5,000 gallons per kilogram of catalyst produced. This raises sustainability concerns, particularly in water-stressed regions where manufacturing may occur.

End-of-life management presents both challenges and opportunities. While some catalytic materials can be recovered and recycled—with recovery rates reaching 95% for platinum group metals in optimal conditions—others may enter waste streams. Advanced recycling technologies are emerging that can recover up to 85% of rare earth elements from spent catalysts, significantly reducing the need for virgin material extraction.

The sustainability equation must also factor in the durability and operational lifespan of catalytic thermoelectric systems. Current technologies demonstrate operational lifespans of 8-12 years before efficiency degradation necessitates replacement or refurbishment. Extending this operational window through materials innovation could substantially improve the overall environmental profile of these systems.

Looking forward, research into bio-inspired catalysts and earth-abundant alternatives shows promise for addressing many of these environmental concerns while maintaining or even enhancing performance characteristics. These developments could potentially transform thermoelectric waste recovery from an environmentally beneficial technology to a truly sustainable energy solution.

From a lifecycle perspective, thermoelectric waste recovery systems with catalytic components offer considerable environmental benefits. Studies indicate that these systems can reduce carbon dioxide emissions by 5-15% in industrial applications where substantial heat is generated. The environmental footprint is further diminished when considering the reduced need for primary energy production, which often relies on fossil fuels with their associated extraction impacts and emissions.

However, the environmental assessment must also consider the ecological costs associated with catalyst production. Many effective catalysts incorporate rare earth elements or precious metals, which present significant environmental challenges during mining and processing. These include habitat destruction, soil contamination, and water pollution. The extraction of platinum group metals, commonly used in high-performance catalysts, is particularly resource-intensive, requiring approximately 10-15 tons of ore to produce a single ounce of platinum.

Water consumption represents another critical environmental consideration. Catalyst manufacturing processes typically require substantial water resources, with production facilities consuming between 2,000-5,000 gallons per kilogram of catalyst produced. This raises sustainability concerns, particularly in water-stressed regions where manufacturing may occur.

End-of-life management presents both challenges and opportunities. While some catalytic materials can be recovered and recycled—with recovery rates reaching 95% for platinum group metals in optimal conditions—others may enter waste streams. Advanced recycling technologies are emerging that can recover up to 85% of rare earth elements from spent catalysts, significantly reducing the need for virgin material extraction.

The sustainability equation must also factor in the durability and operational lifespan of catalytic thermoelectric systems. Current technologies demonstrate operational lifespans of 8-12 years before efficiency degradation necessitates replacement or refurbishment. Extending this operational window through materials innovation could substantially improve the overall environmental profile of these systems.

Looking forward, research into bio-inspired catalysts and earth-abundant alternatives shows promise for addressing many of these environmental concerns while maintaining or even enhancing performance characteristics. These developments could potentially transform thermoelectric waste recovery from an environmentally beneficial technology to a truly sustainable energy solution.

Economic Feasibility and ROI Analysis

The economic viability of catalyst-enhanced thermoelectric waste recovery systems represents a critical consideration for industrial adoption. Initial capital expenditure for implementing these systems varies significantly based on scale, with small to medium installations ranging from $50,000 to $500,000, while large industrial implementations can exceed $2 million. These costs encompass thermoelectric generators, catalyst materials, integration hardware, and installation expenses. Notably, catalyst materials contribute approximately 15-25% of the total system cost, depending on the specific compounds utilized.

Return on investment calculations indicate promising economic outcomes, with typical payback periods ranging from 2-5 years for optimized systems. Industries with continuous high-temperature waste streams, such as metal processing, glass manufacturing, and power generation, demonstrate the most favorable ROI metrics. Analysis of a medium-sized manufacturing facility shows that catalyst-enhanced systems can reduce energy costs by 8-12% annually, translating to $75,000-$150,000 in savings for operations with $1 million annual energy expenditures.

Lifecycle economic assessment reveals that catalyst longevity significantly impacts long-term financial performance. Advanced catalyst formulations maintaining 80% efficiency after five years of operation deliver substantially better returns than those requiring replacement every 18-24 months. Maintenance costs typically represent 3-7% of the initial investment annually, with catalyst regeneration or replacement constituting the primary recurring expense.

Government incentives substantially improve the economic equation in many regions. Tax credits, grants, and energy efficiency subsidies can reduce initial investment requirements by 20-40%, accelerating payback periods by 6-18 months. The European Union's Green Deal initiatives and similar programs in North America and Asia provide particularly attractive financial support mechanisms for thermoelectric waste recovery implementations.

Sensitivity analysis demonstrates that ROI is most heavily influenced by three factors: waste heat temperature (higher temperatures yielding better returns), operational hours (facilities operating 24/7 achieving faster payback), and energy prices (regions with higher electricity costs showing enhanced financial benefits). For every 10% increase in energy prices, the payback period typically decreases by 5-8%, highlighting the technology's hedge value against rising energy costs.

Risk assessment indicates that economic performance can be negatively impacted by catalyst poisoning from unexpected contaminants, which may necessitate premature replacement and disrupt projected returns. Implementing robust monitoring systems and selecting application-specific catalyst formulations can mitigate this risk, ensuring more predictable economic outcomes.

Return on investment calculations indicate promising economic outcomes, with typical payback periods ranging from 2-5 years for optimized systems. Industries with continuous high-temperature waste streams, such as metal processing, glass manufacturing, and power generation, demonstrate the most favorable ROI metrics. Analysis of a medium-sized manufacturing facility shows that catalyst-enhanced systems can reduce energy costs by 8-12% annually, translating to $75,000-$150,000 in savings for operations with $1 million annual energy expenditures.

Lifecycle economic assessment reveals that catalyst longevity significantly impacts long-term financial performance. Advanced catalyst formulations maintaining 80% efficiency after five years of operation deliver substantially better returns than those requiring replacement every 18-24 months. Maintenance costs typically represent 3-7% of the initial investment annually, with catalyst regeneration or replacement constituting the primary recurring expense.

Government incentives substantially improve the economic equation in many regions. Tax credits, grants, and energy efficiency subsidies can reduce initial investment requirements by 20-40%, accelerating payback periods by 6-18 months. The European Union's Green Deal initiatives and similar programs in North America and Asia provide particularly attractive financial support mechanisms for thermoelectric waste recovery implementations.

Sensitivity analysis demonstrates that ROI is most heavily influenced by three factors: waste heat temperature (higher temperatures yielding better returns), operational hours (facilities operating 24/7 achieving faster payback), and energy prices (regions with higher electricity costs showing enhanced financial benefits). For every 10% increase in energy prices, the payback period typically decreases by 5-8%, highlighting the technology's hedge value against rising energy costs.

Risk assessment indicates that economic performance can be negatively impacted by catalyst poisoning from unexpected contaminants, which may necessitate premature replacement and disrupt projected returns. Implementing robust monitoring systems and selecting application-specific catalyst formulations can mitigate this risk, ensuring more predictable economic outcomes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!