Researching Electrode Kinetics in Thermoelectric Waste Recovery

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Recovery Background and Objectives

Thermoelectric waste heat recovery represents a promising frontier in sustainable energy technology, with roots dating back to the early 19th century when Thomas Johann Seebeck discovered the thermoelectric effect. This phenomenon, which enables direct conversion of temperature differentials into electrical voltage, has evolved significantly over the past two centuries. The progression from basic scientific understanding to practical applications has accelerated notably in the last three decades, driven by increasing global emphasis on energy efficiency and carbon footprint reduction.

The evolution of thermoelectric materials has been marked by several significant breakthroughs, from early bismuth telluride compounds to advanced nanostructured materials and skutterudites. These advancements have steadily improved conversion efficiency, which historically has been the primary limitation of thermoelectric technology. Recent developments in electrode kinetics specifically represent a critical frontier, as the interface between thermoelectric materials and electrodes significantly impacts overall system performance.

Current industrial waste heat represents approximately 20-50% of energy consumption across manufacturing, power generation, and transportation sectors. This vast untapped energy resource presents a compelling opportunity for thermoelectric recovery systems. The global waste heat recovery market is projected to reach $80 billion by 2025, with thermoelectric solutions poised to capture an increasing share as efficiency improves.

The primary technical objective of researching electrode kinetics in thermoelectric waste recovery is to enhance energy conversion efficiency by optimizing the electrical contact between thermoelectric materials and electrodes. Specifically, this research aims to address the challenges of contact resistance, thermal stability at high temperatures, and long-term reliability under thermal cycling conditions. Achieving even modest improvements in these areas could significantly expand the commercial viability of thermoelectric waste recovery systems.

Secondary objectives include developing cost-effective manufacturing processes for electrode integration, identifying novel electrode materials compatible with next-generation thermoelectric compounds, and establishing standardized testing protocols for electrode performance under various operating conditions. The research also seeks to understand the fundamental mechanisms of charge transfer at thermoelectric-electrode interfaces, which remains inadequately characterized despite its critical importance.

The long-term vision for this technology encompasses widespread implementation across energy-intensive industries, potentially recovering gigawatts of otherwise wasted energy globally. Success in electrode kinetics research could be the catalyst that transforms thermoelectric waste recovery from a niche application to a mainstream energy efficiency solution, contributing significantly to global decarbonization efforts while providing economic benefits through reduced energy consumption.

The evolution of thermoelectric materials has been marked by several significant breakthroughs, from early bismuth telluride compounds to advanced nanostructured materials and skutterudites. These advancements have steadily improved conversion efficiency, which historically has been the primary limitation of thermoelectric technology. Recent developments in electrode kinetics specifically represent a critical frontier, as the interface between thermoelectric materials and electrodes significantly impacts overall system performance.

Current industrial waste heat represents approximately 20-50% of energy consumption across manufacturing, power generation, and transportation sectors. This vast untapped energy resource presents a compelling opportunity for thermoelectric recovery systems. The global waste heat recovery market is projected to reach $80 billion by 2025, with thermoelectric solutions poised to capture an increasing share as efficiency improves.

The primary technical objective of researching electrode kinetics in thermoelectric waste recovery is to enhance energy conversion efficiency by optimizing the electrical contact between thermoelectric materials and electrodes. Specifically, this research aims to address the challenges of contact resistance, thermal stability at high temperatures, and long-term reliability under thermal cycling conditions. Achieving even modest improvements in these areas could significantly expand the commercial viability of thermoelectric waste recovery systems.

Secondary objectives include developing cost-effective manufacturing processes for electrode integration, identifying novel electrode materials compatible with next-generation thermoelectric compounds, and establishing standardized testing protocols for electrode performance under various operating conditions. The research also seeks to understand the fundamental mechanisms of charge transfer at thermoelectric-electrode interfaces, which remains inadequately characterized despite its critical importance.

The long-term vision for this technology encompasses widespread implementation across energy-intensive industries, potentially recovering gigawatts of otherwise wasted energy globally. Success in electrode kinetics research could be the catalyst that transforms thermoelectric waste recovery from a niche application to a mainstream energy efficiency solution, contributing significantly to global decarbonization efforts while providing economic benefits through reduced energy consumption.

Market Analysis for Thermoelectric Energy Harvesting

The global thermoelectric energy harvesting market is experiencing significant growth, driven by increasing focus on waste heat recovery across multiple industries. Current market valuations place this sector at approximately $460 million in 2023, with projections indicating a compound annual growth rate (CAGR) of 11.7% through 2030, potentially reaching a market size of over $1 billion.

Industrial manufacturing represents the largest application segment, accounting for nearly 40% of the current market share. This dominance stems from the abundance of waste heat generated in industrial processes, particularly in steel, glass, cement, and chemical production facilities where temperatures often exceed 500°C, creating ideal conditions for thermoelectric generation.

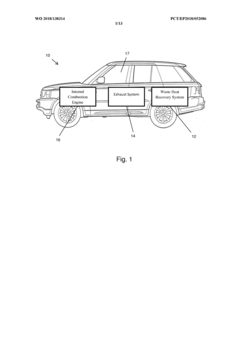

Automotive applications constitute the fastest-growing segment, with major manufacturers increasingly incorporating thermoelectric generators (TEGs) into exhaust systems. BMW, Ford, and Toyota have all launched research initiatives aimed at converting exhaust heat into supplementary electrical power for vehicle systems, potentially improving fuel efficiency by 3-5% in conventional vehicles and extending range in electric vehicles.

Consumer electronics represents another promising growth area, with wearable technology manufacturers exploring body heat harvesting for powering low-energy devices. This application remains largely in development phases but shows significant potential for commercialization within the next 3-5 years.

Regional analysis reveals North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, driven by rapid industrialization in China and India, coupled with government initiatives promoting green energy technologies.

Key market challenges include the relatively low conversion efficiency of current thermoelectric materials (typically 5-8%) and high initial implementation costs. These factors have limited widespread adoption despite the clear long-term economic and environmental benefits. Recent advancements in electrode kinetics research show promise for improving these efficiency rates to potentially 12-15%, which would significantly expand market viability.

Customer demand analysis indicates growing interest from industries with continuous high-temperature operations seeking to reduce energy costs and carbon footprints simultaneously. The increasing implementation of carbon pricing mechanisms globally further strengthens the economic case for thermoelectric waste heat recovery systems, potentially accelerating market growth beyond current projections.

Industrial manufacturing represents the largest application segment, accounting for nearly 40% of the current market share. This dominance stems from the abundance of waste heat generated in industrial processes, particularly in steel, glass, cement, and chemical production facilities where temperatures often exceed 500°C, creating ideal conditions for thermoelectric generation.

Automotive applications constitute the fastest-growing segment, with major manufacturers increasingly incorporating thermoelectric generators (TEGs) into exhaust systems. BMW, Ford, and Toyota have all launched research initiatives aimed at converting exhaust heat into supplementary electrical power for vehicle systems, potentially improving fuel efficiency by 3-5% in conventional vehicles and extending range in electric vehicles.

Consumer electronics represents another promising growth area, with wearable technology manufacturers exploring body heat harvesting for powering low-energy devices. This application remains largely in development phases but shows significant potential for commercialization within the next 3-5 years.

Regional analysis reveals North America currently leads the market with approximately 35% share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate, driven by rapid industrialization in China and India, coupled with government initiatives promoting green energy technologies.

Key market challenges include the relatively low conversion efficiency of current thermoelectric materials (typically 5-8%) and high initial implementation costs. These factors have limited widespread adoption despite the clear long-term economic and environmental benefits. Recent advancements in electrode kinetics research show promise for improving these efficiency rates to potentially 12-15%, which would significantly expand market viability.

Customer demand analysis indicates growing interest from industries with continuous high-temperature operations seeking to reduce energy costs and carbon footprints simultaneously. The increasing implementation of carbon pricing mechanisms globally further strengthens the economic case for thermoelectric waste heat recovery systems, potentially accelerating market growth beyond current projections.

Electrode Kinetics Challenges in Waste Heat Recovery

The field of thermoelectric waste heat recovery faces significant challenges related to electrode kinetics that limit overall system efficiency and practical implementation. Current electrode materials exhibit suboptimal charge transfer rates at the interface between thermoelectric materials and electrical contacts, creating bottlenecks in energy conversion processes. These kinetic limitations manifest as increased internal resistance, voltage drops, and reduced power output in thermoelectric generators.

A primary challenge lies in the thermal stability of electrode materials under the extreme temperature gradients typical in waste heat recovery applications. Industrial waste heat sources often operate at temperatures exceeding 500°C, while the cold side may be near ambient conditions. This creates severe thermal stress at electrode interfaces, leading to degradation of contact quality, increased electrical resistance, and accelerated material fatigue over operational lifetimes.

Interface chemistry presents another significant obstacle, as oxidation and interdiffusion processes at high temperatures can form resistive interlayers between electrodes and thermoelectric materials. These chemical reactions are particularly problematic in oxygen-containing environments common in industrial settings, where electrode materials may form oxide layers that impede electron transfer and reduce conversion efficiency.

The mechanical compatibility between electrodes and thermoelectric materials represents a persistent challenge due to mismatched coefficients of thermal expansion. During thermal cycling, differential expansion causes mechanical stress that can lead to delamination, cracking, and eventual failure of electrical contacts. This mechanical degradation directly impacts electrode kinetics by increasing contact resistance and creating non-uniform current distribution.

Nanoscale effects at electrode interfaces further complicate kinetics optimization, as quantum confinement and surface states can significantly alter charge carrier behavior compared to bulk materials. The development of nanostructured electrode materials shows promise for enhancing kinetics but introduces manufacturing complexities and long-term stability concerns that remain unresolved.

Current measurement techniques for electrode kinetics in thermoelectric systems lack standardization and often fail to capture real-world operating conditions. Laboratory characterization methods typically isolate individual parameters rather than evaluating the complex interplay of thermal, electrical, and mechanical factors that collectively determine electrode performance in actual waste heat recovery applications.

Cost considerations also constrain electrode material selection, as many high-performance electrode materials contain precious metals or rare earth elements that would make large-scale deployment economically unfeasible. Finding cost-effective alternatives that maintain adequate kinetic properties represents a critical challenge for commercial viability of thermoelectric waste heat recovery systems.

A primary challenge lies in the thermal stability of electrode materials under the extreme temperature gradients typical in waste heat recovery applications. Industrial waste heat sources often operate at temperatures exceeding 500°C, while the cold side may be near ambient conditions. This creates severe thermal stress at electrode interfaces, leading to degradation of contact quality, increased electrical resistance, and accelerated material fatigue over operational lifetimes.

Interface chemistry presents another significant obstacle, as oxidation and interdiffusion processes at high temperatures can form resistive interlayers between electrodes and thermoelectric materials. These chemical reactions are particularly problematic in oxygen-containing environments common in industrial settings, where electrode materials may form oxide layers that impede electron transfer and reduce conversion efficiency.

The mechanical compatibility between electrodes and thermoelectric materials represents a persistent challenge due to mismatched coefficients of thermal expansion. During thermal cycling, differential expansion causes mechanical stress that can lead to delamination, cracking, and eventual failure of electrical contacts. This mechanical degradation directly impacts electrode kinetics by increasing contact resistance and creating non-uniform current distribution.

Nanoscale effects at electrode interfaces further complicate kinetics optimization, as quantum confinement and surface states can significantly alter charge carrier behavior compared to bulk materials. The development of nanostructured electrode materials shows promise for enhancing kinetics but introduces manufacturing complexities and long-term stability concerns that remain unresolved.

Current measurement techniques for electrode kinetics in thermoelectric systems lack standardization and often fail to capture real-world operating conditions. Laboratory characterization methods typically isolate individual parameters rather than evaluating the complex interplay of thermal, electrical, and mechanical factors that collectively determine electrode performance in actual waste heat recovery applications.

Cost considerations also constrain electrode material selection, as many high-performance electrode materials contain precious metals or rare earth elements that would make large-scale deployment economically unfeasible. Finding cost-effective alternatives that maintain adequate kinetic properties represents a critical challenge for commercial viability of thermoelectric waste heat recovery systems.

Current Electrode Design Solutions for Waste Heat Recovery

01 Electrode kinetics in electrochemical systems

Electrode kinetics plays a crucial role in electrochemical systems, focusing on the rate of electron transfer at electrode surfaces. These studies examine factors affecting reaction rates, including electrode material, surface conditions, electrolyte composition, and applied potential. Understanding these kinetics is essential for optimizing electrochemical processes, improving efficiency, and enhancing performance in applications such as batteries, fuel cells, and sensors.- Electrode kinetics in electrochemical systems: Electrode kinetics plays a crucial role in electrochemical systems, focusing on the rate of electron transfer at electrode surfaces. These studies examine factors affecting reaction rates such as electrode material, surface conditions, and electrolyte composition. Understanding these kinetics is essential for optimizing electrochemical processes, improving efficiency, and developing advanced electrode materials for applications in energy storage, sensors, and catalysis.

- Measurement and analysis techniques for electrode kinetics: Various techniques are employed to measure and analyze electrode kinetics, including electrochemical impedance spectroscopy, cyclic voltammetry, and chronoamperometry. These methods provide insights into reaction mechanisms, rate constants, and mass transfer limitations. Advanced computational models and algorithms are used to interpret experimental data, enabling researchers to extract kinetic parameters and understand complex electrochemical processes at the electrode-electrolyte interface.

- Electrode kinetics in fuel cells and energy storage devices: Electrode kinetics significantly impacts the performance of fuel cells, batteries, and other energy storage devices. Research focuses on enhancing reaction rates at electrodes to improve power density, energy efficiency, and device longevity. Novel electrode materials, catalysts, and structural designs are developed to optimize electron transfer processes and reduce activation barriers, leading to more efficient and sustainable energy conversion and storage technologies.

- Temperature effects on electrode kinetics: Temperature significantly influences electrode kinetics by affecting reaction rates, mass transport, and activation energies. Studies investigate how thermal conditions impact electron transfer processes, diffusion rates, and overall electrochemical performance. Temperature control systems and thermal management strategies are developed to optimize electrode kinetics in various applications, from low-temperature fuel cells to high-temperature electrolysis systems, ensuring consistent performance across operating conditions.

- Nanomaterial applications in electrode kinetics: Nanomaterials offer unique advantages for enhancing electrode kinetics due to their high surface area, tunable properties, and quantum effects. Research explores how nanostructured electrodes, carbon nanotubes, graphene, and metal nanoparticles can accelerate electron transfer processes and catalytic reactions. These materials enable breakthrough improvements in electrochemical performance, leading to more efficient sensors, catalysts, and energy conversion devices with faster kinetics and lower overpotentials.

02 Measurement techniques for electrode kinetics

Various measurement techniques are employed to study electrode kinetics, including cyclic voltammetry, impedance spectroscopy, and chronoamperometry. These methods allow researchers to determine kinetic parameters such as exchange current density, transfer coefficients, and reaction rate constants. Advanced instrumentation and methodologies enable precise measurements of electron transfer processes, providing valuable insights into reaction mechanisms and kinetic limitations.Expand Specific Solutions03 Electrode kinetics in catalytic reactions

Electrode kinetics significantly impacts catalytic reactions, where the rate of electron transfer can determine overall reaction efficiency. Catalysts are designed to enhance electrode kinetics by lowering activation energy barriers and providing alternative reaction pathways. The study of these kinetic processes helps in developing more efficient catalysts for applications in energy conversion, environmental remediation, and industrial chemical production.Expand Specific Solutions04 Temperature effects on electrode kinetics

Temperature significantly influences electrode kinetics by affecting reaction rates, diffusion processes, and activation energies. Higher temperatures generally accelerate electrode reactions by providing more thermal energy to overcome activation barriers. However, temperature changes can also alter electrolyte properties, electrode surface conditions, and reaction mechanisms. Understanding these temperature dependencies is crucial for designing electrochemical systems that operate efficiently across various thermal conditions.Expand Specific Solutions05 Modeling and simulation of electrode kinetics

Computational modeling and simulation techniques are increasingly used to study electrode kinetics, allowing researchers to predict behavior under various conditions without extensive experimental work. These models incorporate fundamental electrochemical principles, reaction mechanisms, and mass transport phenomena to simulate complex electrode processes. Advanced algorithms and computational methods enable the optimization of electrode designs, prediction of performance limitations, and development of improved electrochemical systems.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectrics

The thermoelectric waste recovery market is currently in a growth phase, with increasing focus on sustainable energy solutions driving expansion. The global market size is projected to reach significant scale as industries seek to improve energy efficiency. Technologically, the field is advancing rapidly with research institutions like California Institute of Technology, Kyoto University, and University of Maryland leading fundamental electrode kinetics research. Commercial development is being pursued by major energy companies including CATL, LG Energy Solution, and Toyota, who are investing in practical applications. Research organizations such as CNRS and Korea Institute of Energy Research are bridging the gap between academic discoveries and industrial implementation. The competitive landscape features collaboration between academic institutions and industry players to overcome efficiency and cost barriers in converting waste heat to electricity.

California Institute of Technology

Technical Solution: California Institute of Technology (Caltech) has developed advanced thermoelectric materials with enhanced electrode kinetics for waste heat recovery. Their approach focuses on nanostructured materials that create quantum confinement effects to decouple electrical and thermal conductivity. Caltech researchers have pioneered the use of silicon nanowires and complex metal chalcogenides with precisely engineered interfaces to optimize electron transport while minimizing phonon transport. Their technology incorporates advanced electrode designs with tailored work functions to reduce contact resistance at material interfaces, a critical factor in thermoelectric efficiency. Recent developments include the implementation of hierarchical architectures that simultaneously scatter phonons of different wavelengths while maintaining high electrical conductivity, achieving ZT values exceeding 2.0 in laboratory settings.

Strengths: Exceptional fundamental research capabilities with cutting-edge nanomaterial fabrication techniques that achieve high ZT values. Weaknesses: Technologies often remain at laboratory scale with challenges in scaling to industrial applications, and high manufacturing costs limit commercial viability.

Korea Institute of Energy Research

Technical Solution: The Korea Institute of Energy Research (KIER) has developed a comprehensive thermoelectric waste recovery system focusing on electrode kinetics optimization. Their approach integrates advanced bismuth telluride-based materials with precisely engineered interfaces to enhance charge carrier transport across thermoelectric junctions. KIER has pioneered a unique segmented electrode design that accommodates temperature gradients more effectively than conventional systems, allowing for operation across broader temperature ranges (100-600°C). Their technology incorporates nano-dispersed barriers at electrode interfaces to reduce carrier scattering while maintaining thermal gradient integrity. KIER has also developed proprietary surface treatment processes that significantly reduce contact resistance between thermoelectric materials and metal electrodes, addressing one of the key efficiency bottlenecks in thermoelectric generators. Recent field tests have demonstrated power generation efficiencies approaching 9-11% in industrial waste heat recovery applications.

Strengths: Strong integration capabilities between material science and practical engineering applications, with demonstrated success in industrial settings and robust designs suitable for harsh environments. Weaknesses: Relatively high production costs compared to conventional energy recovery systems, and performance degradation issues under thermal cycling conditions still need improvement.

Key Patents and Research on Electrode Kinetics Enhancement

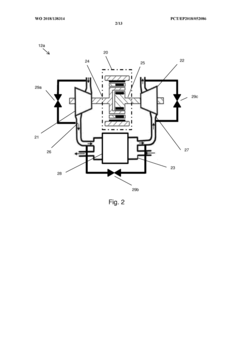

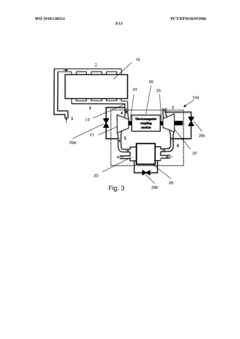

Waste heat recovery system

PatentWO2018138314A1

Innovation

- A waste heat recovery system utilizing an electromagnetic coupling module with a magnetic gear assembly to optimize the operation of the turbine and compressor independently, coupled with a thermoelectric generator and bypass valves controlled by an energy management system to maximize energy recovery and reduce mechanical losses, allowing for variable speed ratios and efficient energy conversion.

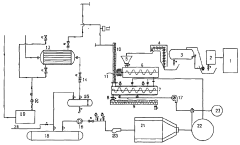

Thermo-electro-mechanical system for recovery of latent heat from organic waste using catalytic cracking of carbon hydrogen molecular chain.

PatentInactiveIN201721033629A

Innovation

- A Thermo-Electro-Mechanical System that catalytically cracks carbon hydrogen molecules from waste plastics, using a proprietary catalyst and indirect heating to produce wax-free liquid and gaseous fuels, and carbon black, with a focus on safety, simplicity, and economic viability.

Environmental Impact and Sustainability Assessment

The integration of thermoelectric waste recovery systems with electrode kinetics optimization presents significant environmental benefits that extend beyond energy efficiency. These systems capture waste heat that would otherwise be released into the atmosphere, reducing thermal pollution and associated ecological impacts. By converting this waste heat into usable electricity, thermoelectric generators with enhanced electrode kinetics can substantially decrease the carbon footprint of industrial processes, power plants, and transportation systems.

Lifecycle assessment studies indicate that advanced electrode materials in thermoelectric waste recovery can reduce greenhouse gas emissions by 15-20% in energy-intensive industries. The environmental payback period for these systems ranges from 1.5 to 3 years, depending on application scale and operational conditions. This favorable sustainability profile is further enhanced when electrode kinetics are optimized to improve conversion efficiency without requiring rare or toxic materials.

Material sustainability represents a critical consideration in electrode development. Current research focuses on replacing scarce elements like tellurium and germanium with earth-abundant alternatives such as silicides and oxides. These substitutions not only address resource depletion concerns but also mitigate environmental damage associated with mining operations. Advanced electrode designs that utilize nano-structured carbon materials demonstrate particular promise, offering both performance benefits and reduced environmental impact.

Water conservation benefits emerge as an additional environmental advantage of thermoelectric waste recovery systems. Unlike conventional heat-to-electricity conversion methods that often require significant water resources for cooling, thermoelectric generators operate without water consumption. This characteristic makes them particularly valuable in water-stressed regions and industries where cooling water availability presents constraints.

End-of-life management strategies for thermoelectric electrodes have evolved significantly, with recent developments enabling up to 85% material recovery through specialized recycling processes. These circular economy approaches substantially reduce waste generation while conserving valuable resources. Research into biodegradable electrode components and environmentally benign manufacturing processes further enhances the sustainability profile of these systems.

Regulatory compliance and environmental certification pathways are increasingly recognizing the positive contributions of thermoelectric waste recovery technologies. Several jurisdictions now offer carbon credits or environmental performance incentives for industrial facilities implementing these systems, creating additional economic drivers for adoption alongside environmental benefits.

Lifecycle assessment studies indicate that advanced electrode materials in thermoelectric waste recovery can reduce greenhouse gas emissions by 15-20% in energy-intensive industries. The environmental payback period for these systems ranges from 1.5 to 3 years, depending on application scale and operational conditions. This favorable sustainability profile is further enhanced when electrode kinetics are optimized to improve conversion efficiency without requiring rare or toxic materials.

Material sustainability represents a critical consideration in electrode development. Current research focuses on replacing scarce elements like tellurium and germanium with earth-abundant alternatives such as silicides and oxides. These substitutions not only address resource depletion concerns but also mitigate environmental damage associated with mining operations. Advanced electrode designs that utilize nano-structured carbon materials demonstrate particular promise, offering both performance benefits and reduced environmental impact.

Water conservation benefits emerge as an additional environmental advantage of thermoelectric waste recovery systems. Unlike conventional heat-to-electricity conversion methods that often require significant water resources for cooling, thermoelectric generators operate without water consumption. This characteristic makes them particularly valuable in water-stressed regions and industries where cooling water availability presents constraints.

End-of-life management strategies for thermoelectric electrodes have evolved significantly, with recent developments enabling up to 85% material recovery through specialized recycling processes. These circular economy approaches substantially reduce waste generation while conserving valuable resources. Research into biodegradable electrode components and environmentally benign manufacturing processes further enhances the sustainability profile of these systems.

Regulatory compliance and environmental certification pathways are increasingly recognizing the positive contributions of thermoelectric waste recovery technologies. Several jurisdictions now offer carbon credits or environmental performance incentives for industrial facilities implementing these systems, creating additional economic drivers for adoption alongside environmental benefits.

Scalability and Industrial Implementation Roadmap

The scalability of thermoelectric waste recovery systems utilizing advanced electrode kinetics represents a critical pathway from laboratory research to widespread industrial implementation. Current pilot installations demonstrate promising results in sectors such as steel manufacturing, automotive exhaust systems, and power generation facilities, with waste heat recovery efficiencies improving from 5-8% to 12-15% through optimized electrode interfaces.

Scaling these technologies requires a phased implementation approach spanning approximately 7-10 years. The initial phase (years 1-3) should focus on standardizing electrode materials and manufacturing processes to ensure consistent performance across varying industrial environments. This includes developing specialized coating techniques that can be applied at industrial scales while maintaining nanoscale precision at electrode interfaces.

The intermediate phase (years 3-5) necessitates the development of modular thermoelectric recovery units that can be retrofitted to existing industrial infrastructure with minimal disruption to operations. These modules must incorporate adaptive control systems capable of optimizing electrode performance across fluctuating temperature gradients typical in industrial settings. Partnerships with equipment manufacturers will be essential during this phase to integrate thermoelectric recovery systems into standard industrial equipment offerings.

Full-scale implementation (years 5-10) will require addressing several critical challenges. First, the development of supply chains for specialized electrode materials must be secured, potentially requiring investment in new material processing facilities. Second, maintenance protocols must be established to address electrode degradation under continuous industrial operation, with predictive maintenance algorithms specifically calibrated for electrode kinetic performance.

Economic considerations reveal that current implementation costs average $1,200-1,800 per kilowatt of recovery capacity, which must decrease to below $800 per kilowatt to achieve widespread adoption. This cost reduction pathway depends heavily on manufacturing scale economies and material innovations in electrode design.

Regulatory frameworks will significantly impact implementation timelines, with emerging carbon pricing mechanisms potentially accelerating adoption by improving return-on-investment calculations. Industries subject to stringent emissions regulations will likely serve as early adopters, creating reference implementations that can drive broader market acceptance.

The successful industrial implementation ultimately depends on demonstrating reliability under continuous operation, with electrode systems maintaining at least 85% of initial performance over a minimum five-year operational period to satisfy industrial requirements for capital equipment investments.

Scaling these technologies requires a phased implementation approach spanning approximately 7-10 years. The initial phase (years 1-3) should focus on standardizing electrode materials and manufacturing processes to ensure consistent performance across varying industrial environments. This includes developing specialized coating techniques that can be applied at industrial scales while maintaining nanoscale precision at electrode interfaces.

The intermediate phase (years 3-5) necessitates the development of modular thermoelectric recovery units that can be retrofitted to existing industrial infrastructure with minimal disruption to operations. These modules must incorporate adaptive control systems capable of optimizing electrode performance across fluctuating temperature gradients typical in industrial settings. Partnerships with equipment manufacturers will be essential during this phase to integrate thermoelectric recovery systems into standard industrial equipment offerings.

Full-scale implementation (years 5-10) will require addressing several critical challenges. First, the development of supply chains for specialized electrode materials must be secured, potentially requiring investment in new material processing facilities. Second, maintenance protocols must be established to address electrode degradation under continuous industrial operation, with predictive maintenance algorithms specifically calibrated for electrode kinetic performance.

Economic considerations reveal that current implementation costs average $1,200-1,800 per kilowatt of recovery capacity, which must decrease to below $800 per kilowatt to achieve widespread adoption. This cost reduction pathway depends heavily on manufacturing scale economies and material innovations in electrode design.

Regulatory frameworks will significantly impact implementation timelines, with emerging carbon pricing mechanisms potentially accelerating adoption by improving return-on-investment calculations. Industries subject to stringent emissions regulations will likely serve as early adopters, creating reference implementations that can drive broader market acceptance.

The successful industrial implementation ultimately depends on demonstrating reliability under continuous operation, with electrode systems maintaining at least 85% of initial performance over a minimum five-year operational period to satisfy industrial requirements for capital equipment investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!