Evaluation of Thermoelectric Waste Recovery Under Regulatory Constraints

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transitioning from theoretical concepts to practical applications across various industries. The fundamental principle, discovered by Thomas Johann Seebeck in 1821, established that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This Seebeck effect forms the cornerstone of modern thermoelectric generators (TEGs) that convert waste heat directly into electrical energy without moving parts.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved modest efficiency levels of 4-5%. Second-generation materials incorporating advanced semiconductor alloys pushed efficiencies to 7-8%, while current research on nanostructured materials and quantum dot superlattices aims to exceed 15% efficiency, potentially approaching the theoretical Carnot limit.

Industrial waste heat represents a vast untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. This translates to approximately 7-13 quadrillion BTUs of energy lost annually in the United States alone, equivalent to 7-13% of total national energy consumption. The recovery of even a fraction of this waste energy presents a significant opportunity for improving overall energy efficiency.

Regulatory frameworks increasingly influence the development and deployment of waste heat recovery technologies. Environmental regulations targeting greenhouse gas emissions, energy efficiency standards, and renewable energy mandates create both constraints and incentives for thermoelectric waste heat recovery systems. The Paris Agreement and subsequent national commitments to carbon reduction have accelerated interest in technologies that can improve industrial energy efficiency.

The primary objective of thermoelectric waste heat recovery technology is to capture and convert otherwise wasted thermal energy into useful electrical power, thereby improving overall system efficiency and reducing environmental impact. Secondary objectives include developing cost-effective solutions that can be integrated into existing industrial processes with minimal disruption, ensuring regulatory compliance, and creating scalable technologies applicable across diverse industrial sectors.

Technical challenges remain significant, particularly in developing materials that can withstand harsh industrial environments while maintaining high conversion efficiencies. The cost-performance ratio of thermoelectric systems must improve substantially to achieve widespread commercial adoption beyond niche applications. Current research focuses on novel material compositions, advanced manufacturing techniques, and innovative system designs to address these challenges.

The convergence of stricter environmental regulations, increasing energy costs, and technological advancements creates a favorable environment for accelerated development of thermoelectric waste heat recovery solutions. This technology stands at an inflection point where scientific progress, industrial need, and regulatory pressure align to potentially transform waste heat from an environmental liability into a valuable energy resource.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. First-generation materials based on bismuth telluride (Bi₂Te₃) achieved modest efficiency levels of 4-5%. Second-generation materials incorporating advanced semiconductor alloys pushed efficiencies to 7-8%, while current research on nanostructured materials and quantum dot superlattices aims to exceed 15% efficiency, potentially approaching the theoretical Carnot limit.

Industrial waste heat represents a vast untapped energy resource, with estimates suggesting that 20-50% of industrial energy consumption is ultimately discharged as waste heat. This translates to approximately 7-13 quadrillion BTUs of energy lost annually in the United States alone, equivalent to 7-13% of total national energy consumption. The recovery of even a fraction of this waste energy presents a significant opportunity for improving overall energy efficiency.

Regulatory frameworks increasingly influence the development and deployment of waste heat recovery technologies. Environmental regulations targeting greenhouse gas emissions, energy efficiency standards, and renewable energy mandates create both constraints and incentives for thermoelectric waste heat recovery systems. The Paris Agreement and subsequent national commitments to carbon reduction have accelerated interest in technologies that can improve industrial energy efficiency.

The primary objective of thermoelectric waste heat recovery technology is to capture and convert otherwise wasted thermal energy into useful electrical power, thereby improving overall system efficiency and reducing environmental impact. Secondary objectives include developing cost-effective solutions that can be integrated into existing industrial processes with minimal disruption, ensuring regulatory compliance, and creating scalable technologies applicable across diverse industrial sectors.

Technical challenges remain significant, particularly in developing materials that can withstand harsh industrial environments while maintaining high conversion efficiencies. The cost-performance ratio of thermoelectric systems must improve substantially to achieve widespread commercial adoption beyond niche applications. Current research focuses on novel material compositions, advanced manufacturing techniques, and innovative system designs to address these challenges.

The convergence of stricter environmental regulations, increasing energy costs, and technological advancements creates a favorable environment for accelerated development of thermoelectric waste heat recovery solutions. This technology stands at an inflection point where scientific progress, industrial need, and regulatory pressure align to potentially transform waste heat from an environmental liability into a valuable energy resource.

Market Analysis for Thermoelectric Recovery Solutions

The global market for thermoelectric waste heat recovery solutions has experienced significant growth in recent years, driven by increasing energy costs, environmental concerns, and regulatory pressures. The current market size is estimated at $650 million as of 2023, with projections indicating growth to reach $1.2 billion by 2030, representing a compound annual growth rate of approximately 9.2% during this forecast period.

Industrial manufacturing represents the largest application segment, accounting for roughly 42% of the total market share. This dominance stems from the abundance of waste heat generated in energy-intensive industries such as steel, cement, glass, and chemical processing. The automotive sector follows closely at 31% market share, where thermoelectric generators (TEGs) are increasingly being integrated into exhaust systems to improve fuel efficiency and reduce emissions.

Regional analysis reveals that Asia-Pacific currently leads the market with 38% share, primarily due to rapid industrialization in China and India, coupled with stringent energy efficiency regulations. North America and Europe follow with 29% and 26% respectively, where regulatory frameworks like the European Green Deal and the U.S. Clean Energy Plan have created favorable conditions for waste heat recovery technologies.

Customer demand patterns indicate a growing preference for integrated solutions that offer both energy recovery and compliance with emissions regulations. End-users increasingly seek systems with payback periods under three years, highlighting the importance of economic viability alongside technical performance. Market research shows that solutions offering efficiency rates above 8% conversion are gaining significant traction despite higher initial costs.

Competitive pricing analysis reveals that the average cost per installed kilowatt has decreased by 18% over the past five years, making thermoelectric recovery more accessible to mid-sized industrial operations. However, price sensitivity varies significantly across sectors, with automotive manufacturers demonstrating greater willingness to pay premium prices for lightweight, compact solutions.

Market barriers include high initial capital requirements, technical limitations in conversion efficiency, and integration challenges with existing infrastructure. Additionally, fluctuating energy prices impact return-on-investment calculations, creating uncertainty for potential adopters. The regulatory landscape, while generally supportive through incentives and emissions targets, remains fragmented across regions, complicating global market strategies.

Growth opportunities exist particularly in emerging economies where industrial expansion coincides with increasing environmental regulations. The small-scale distributed energy sector also presents untapped potential, with modular thermoelectric solutions gaining interest for localized energy recovery applications.

Industrial manufacturing represents the largest application segment, accounting for roughly 42% of the total market share. This dominance stems from the abundance of waste heat generated in energy-intensive industries such as steel, cement, glass, and chemical processing. The automotive sector follows closely at 31% market share, where thermoelectric generators (TEGs) are increasingly being integrated into exhaust systems to improve fuel efficiency and reduce emissions.

Regional analysis reveals that Asia-Pacific currently leads the market with 38% share, primarily due to rapid industrialization in China and India, coupled with stringent energy efficiency regulations. North America and Europe follow with 29% and 26% respectively, where regulatory frameworks like the European Green Deal and the U.S. Clean Energy Plan have created favorable conditions for waste heat recovery technologies.

Customer demand patterns indicate a growing preference for integrated solutions that offer both energy recovery and compliance with emissions regulations. End-users increasingly seek systems with payback periods under three years, highlighting the importance of economic viability alongside technical performance. Market research shows that solutions offering efficiency rates above 8% conversion are gaining significant traction despite higher initial costs.

Competitive pricing analysis reveals that the average cost per installed kilowatt has decreased by 18% over the past five years, making thermoelectric recovery more accessible to mid-sized industrial operations. However, price sensitivity varies significantly across sectors, with automotive manufacturers demonstrating greater willingness to pay premium prices for lightweight, compact solutions.

Market barriers include high initial capital requirements, technical limitations in conversion efficiency, and integration challenges with existing infrastructure. Additionally, fluctuating energy prices impact return-on-investment calculations, creating uncertainty for potential adopters. The regulatory landscape, while generally supportive through incentives and emissions targets, remains fragmented across regions, complicating global market strategies.

Growth opportunities exist particularly in emerging economies where industrial expansion coincides with increasing environmental regulations. The small-scale distributed energy sector also presents untapped potential, with modular thermoelectric solutions gaining interest for localized energy recovery applications.

Global Thermoelectric Technology Status and Barriers

Thermoelectric waste heat recovery technology has reached varying levels of maturity across different regions globally. In North America, significant advancements have been made in automotive applications, with companies like Gentherm and II-VI Marlow leading research efforts. These organizations have successfully demonstrated efficiency improvements of 5-8% in prototype systems, though commercial-scale implementation remains limited due to cost constraints and integration challenges.

European research institutions have focused on industrial waste heat recovery applications, with notable progress in manufacturing sectors. The European Union's Horizon 2020 program has funded several large-scale thermoelectric projects, resulting in pilot installations that have achieved thermal-to-electric conversion efficiencies approaching 12% under optimal conditions. However, these systems typically operate at 7-9% efficiency in real-world industrial environments.

In Asia, particularly Japan and South Korea, miniaturized thermoelectric generators have seen commercial success in specialized applications. Companies like Komatsu and Yamaha have integrated small-scale thermoelectric systems into select product lines, while research institutions have pushed material science boundaries with novel semiconductor compounds that demonstrate ZT values exceeding 2.0 in laboratory settings.

Despite these regional advancements, several significant barriers impede widespread adoption of thermoelectric waste heat recovery technologies. The primary technical limitation remains conversion efficiency, with most commercial systems operating at 5-10% efficiency—substantially lower than competing waste heat recovery technologies. This efficiency challenge is directly tied to the inherent properties of current thermoelectric materials, which struggle to maintain high ZT values across wide temperature ranges.

Cost factors present another substantial barrier, with current thermoelectric systems averaging $20-30 per watt of generation capacity. This high cost structure makes economic justification difficult without regulatory incentives or carbon pricing mechanisms. Manufacturing scalability also remains problematic, particularly for advanced materials that demonstrate promising laboratory performance but encounter production challenges at commercial scales.

Regulatory frameworks present a complex landscape of both opportunities and obstacles. While carbon reduction initiatives in Europe and parts of Asia provide incentive structures for waste heat recovery, inconsistent global standards and certification requirements create market fragmentation. Additionally, the lack of standardized performance metrics specifically for thermoelectric systems complicates comparative analysis against alternative technologies.

Material durability and system reliability under thermal cycling conditions continue to challenge long-term implementation, with degradation rates of 1-3% annually observed in field deployments. This reliability concern particularly impacts applications in harsh industrial environments where maintenance access may be limited.

European research institutions have focused on industrial waste heat recovery applications, with notable progress in manufacturing sectors. The European Union's Horizon 2020 program has funded several large-scale thermoelectric projects, resulting in pilot installations that have achieved thermal-to-electric conversion efficiencies approaching 12% under optimal conditions. However, these systems typically operate at 7-9% efficiency in real-world industrial environments.

In Asia, particularly Japan and South Korea, miniaturized thermoelectric generators have seen commercial success in specialized applications. Companies like Komatsu and Yamaha have integrated small-scale thermoelectric systems into select product lines, while research institutions have pushed material science boundaries with novel semiconductor compounds that demonstrate ZT values exceeding 2.0 in laboratory settings.

Despite these regional advancements, several significant barriers impede widespread adoption of thermoelectric waste heat recovery technologies. The primary technical limitation remains conversion efficiency, with most commercial systems operating at 5-10% efficiency—substantially lower than competing waste heat recovery technologies. This efficiency challenge is directly tied to the inherent properties of current thermoelectric materials, which struggle to maintain high ZT values across wide temperature ranges.

Cost factors present another substantial barrier, with current thermoelectric systems averaging $20-30 per watt of generation capacity. This high cost structure makes economic justification difficult without regulatory incentives or carbon pricing mechanisms. Manufacturing scalability also remains problematic, particularly for advanced materials that demonstrate promising laboratory performance but encounter production challenges at commercial scales.

Regulatory frameworks present a complex landscape of both opportunities and obstacles. While carbon reduction initiatives in Europe and parts of Asia provide incentive structures for waste heat recovery, inconsistent global standards and certification requirements create market fragmentation. Additionally, the lack of standardized performance metrics specifically for thermoelectric systems complicates comparative analysis against alternative technologies.

Material durability and system reliability under thermal cycling conditions continue to challenge long-term implementation, with degradation rates of 1-3% annually observed in field deployments. This reliability concern particularly impacts applications in harsh industrial environments where maintenance access may be limited.

Current Thermoelectric Waste Heat Harvesting Approaches

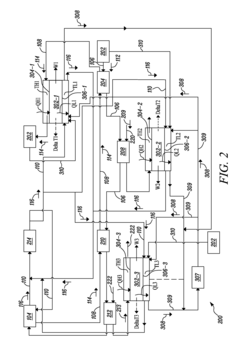

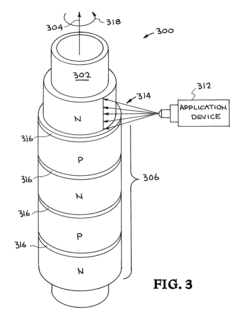

01 Thermoelectric waste heat recovery systems for vehicles

Thermoelectric generators designed specifically for automotive applications to recover waste heat from exhaust systems. These systems convert thermal energy from vehicle exhaust gases into electrical power, improving overall fuel efficiency and reducing emissions. The designs include specialized heat exchangers, thermal management systems, and integration with vehicle electrical systems to maximize energy recovery from combustion engines.- Thermoelectric waste heat recovery systems for vehicles: These systems are designed to capture and convert waste heat from vehicle engines into usable electrical energy. The systems typically include thermoelectric generators positioned at strategic locations such as exhaust systems to maximize heat recovery. The recovered energy can be used to power vehicle electrical systems, reducing the load on the alternator and improving fuel efficiency. Evaluation methods focus on measuring conversion efficiency, power output, and integration with existing vehicle systems.

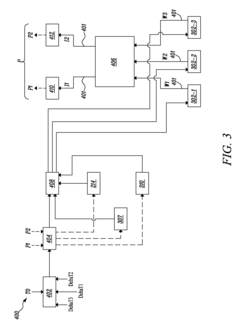

- Performance evaluation metrics and testing methods: Various metrics and methodologies are used to evaluate thermoelectric waste heat recovery systems. These include measuring the temperature differential across thermoelectric modules, conversion efficiency, power density, and cost-effectiveness. Testing methods involve simulated environments, real-world applications, and standardized testing protocols to ensure consistent evaluation. Advanced monitoring systems are employed to collect data on system performance under various operating conditions to optimize design parameters.

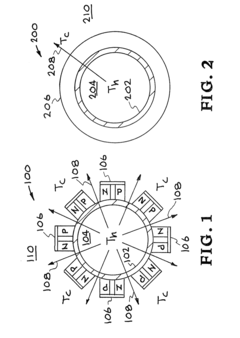

- Industrial waste heat recovery applications: Thermoelectric systems are implemented in industrial settings to recover waste heat from manufacturing processes, power plants, and other industrial operations. These applications often involve large-scale thermoelectric arrays designed to handle high-temperature waste streams. Evaluation focuses on long-term reliability, scalability, and integration with existing industrial infrastructure. Cost-benefit analyses are conducted to determine the economic viability of these systems in various industrial contexts.

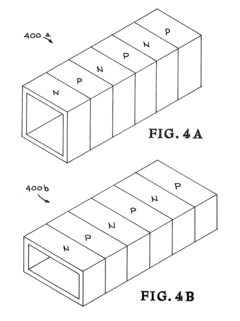

- Material innovations for improved thermoelectric efficiency: Research focuses on developing new thermoelectric materials with enhanced figure of merit (ZT) values to improve conversion efficiency. These materials include nanostructured semiconductors, skutterudites, and organic thermoelectric compounds. Evaluation methods assess thermal conductivity, electrical conductivity, and Seebeck coefficient under various conditions. Testing protocols examine material stability, degradation over time, and performance across different temperature ranges to determine suitability for specific waste heat recovery applications.

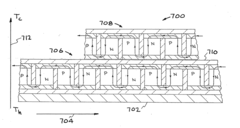

- System design optimization and integration techniques: This area focuses on optimizing the overall design of thermoelectric waste heat recovery systems through improved heat exchangers, thermal management, and electrical integration. Techniques include computational fluid dynamics modeling, thermal interface material selection, and electrical circuit optimization. Evaluation methods assess system-level efficiency, reliability under thermal cycling, and practical implementation challenges. Design innovations aim to maximize heat transfer to thermoelectric elements while minimizing thermal losses and ensuring durability in harsh operating environments.

02 Performance evaluation methods for thermoelectric generators

Methodologies and metrics for evaluating the efficiency and performance of thermoelectric waste heat recovery systems. These include testing protocols, simulation models, and analytical frameworks to assess parameters such as conversion efficiency, power output, and thermal resistance. The evaluation methods help optimize design parameters and predict real-world performance under various operating conditions.Expand Specific Solutions03 Industrial waste heat recovery applications

Thermoelectric systems designed for recovering waste heat from industrial processes such as manufacturing, power generation, and chemical production. These applications focus on capturing high-temperature waste heat streams from industrial equipment and converting them into usable electricity. The systems include specialized heat exchangers, thermal interface materials, and power conditioning electronics tailored for industrial environments.Expand Specific Solutions04 Novel thermoelectric materials and structures

Advanced materials and structural designs to enhance the efficiency of thermoelectric waste heat recovery. These innovations include nanostructured materials, composite thermoelectric elements, and novel semiconductor formulations with improved figure of merit (ZT). The materials are engineered to optimize the balance between thermal and electrical conductivity while minimizing thermal losses across operating temperature ranges.Expand Specific Solutions05 System integration and optimization techniques

Methods for integrating thermoelectric waste heat recovery systems with existing infrastructure and optimizing their operation. These techniques include heat flow management, electrical power conditioning, control algorithms, and system-level design approaches that maximize energy harvesting efficiency. The integration strategies address challenges such as thermal cycling, mechanical stress, and variable heat source conditions to ensure reliable long-term operation.Expand Specific Solutions

Leading Companies in Thermoelectric Recovery Industry

Thermoelectric waste recovery technology is currently in a growth phase, with increasing regulatory focus driving innovation and market expansion. The global market is projected to reach significant scale as industries seek sustainable energy solutions. Technologically, the field shows varying maturity levels across applications. Leading players like Toyota Motor Corp. and Mitsubishi Heavy Industries are advancing automotive applications, while BorgWarner and Gentherm focus on specialized thermoelectric systems. Energy sector giants including State Grid Corp. of China and Tokyo Electric Power are exploring utility-scale implementations. Research institutions such as Northeastern University and the Polytechnic University of Catalonia collaborate with industrial partners like Corning and SAMSUNG SDI to overcome efficiency limitations and develop materials optimized for regulatory compliance.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered thermoelectric waste heat recovery systems designed to meet global emissions regulations while enhancing vehicle efficiency. Their approach integrates thermoelectric generators (TEGs) directly into exhaust systems, capturing waste heat that would otherwise be lost. Toyota's proprietary bismuth telluride-based materials achieve a figure of merit (ZT) of approximately 1.4 at operating temperatures, significantly higher than conventional materials. Their system architecture includes specialized heat exchangers that maximize thermal transfer while maintaining exhaust backpressure within regulatory limits. Toyota has implemented a dual-circuit design that separately harvests heat from both engine coolant and exhaust gases, with intelligent power management systems that integrate recovered electricity into the vehicle's electrical network to reduce alternator load. This comprehensive approach has demonstrated fuel economy improvements of 2-5% in real-world testing while ensuring full compliance with emissions standards across global markets.

Strengths: Comprehensive integration with existing vehicle systems and production processes enables mass-market implementation. Extensive testing across diverse driving conditions ensures reliability. Weaknesses: High initial system costs limit adoption in lower-priced vehicle segments, and performance varies significantly based on driving conditions and ambient temperature.

Mitsubishi Heavy Industries, Ltd.

Technical Solution: Mitsubishi Heavy Industries has developed industrial-scale thermoelectric waste heat recovery systems designed to operate within increasingly stringent emissions and efficiency regulations. Their technology focuses on high-temperature applications in power generation and industrial processes, utilizing advanced skutterudite and half-Heusler thermoelectric materials that maintain stability and performance at temperatures exceeding 500°C. MHI's modular system architecture allows for scalable implementation across different industrial applications while maintaining regulatory compliance through integrated emissions monitoring and control systems. Their approach includes specialized heat transfer interfaces that maximize thermal conductivity while minimizing mechanical stress on thermoelectric elements during thermal cycling. MHI has implemented these systems in several power plants in Japan and Southeast Asia, demonstrating net electrical generation increases of 1-3% without affecting primary emissions control systems. The company's regulatory compliance framework includes continuous monitoring capabilities that adjust system parameters to maintain operation within permitted limits across varying load conditions.

Strengths: Extensive experience with large-scale industrial implementations and integration with existing power generation infrastructure. Robust design ensures long operational lifetime in harsh industrial environments. Weaknesses: High initial capital costs and complex installation requirements limit adoption in smaller facilities. Performance degradation over time requires periodic maintenance and component replacement.

Key Patents and Innovations in Thermoelectric Materials

System and method for energy recovery

PatentInactiveUS20150101646A1

Innovation

- A thermoelectric module system is interfaced with various heat sources within a vehicle, including exhaust, intercooler, and aftercooler, to convert temperature differences into electrical power, with a controller optimizing low temperature heat sources based on temperature differences and vehicle operating parameters.

Thermoelectric coatings for waste heat recovery and photo-thermal power

PatentActiveUS20170162775A1

Innovation

- Development of novel thermoelectric generators with advanced thermal and cold spray technology, utilizing cylindrical annular geometry and optimal materials like bismuth-antimony-lead telluride alloys and doped silicon-germanium for high-temperature applications, and nano-disperse particles to enhance phonon scattering and raise the dimensionless figure-of-merit (ZT), resulting in highly efficient energy harvesting from waste heat and solar sources.

Regulatory Framework Impact on Implementation

The regulatory landscape surrounding thermoelectric waste heat recovery technologies presents significant challenges and opportunities for implementation across various industries. Environmental regulations, particularly those focused on emissions reduction and energy efficiency, have created a favorable environment for thermoelectric waste recovery systems. The Paris Agreement and subsequent national commitments to reduce carbon footprints have accelerated interest in these technologies as viable solutions for industrial decarbonization efforts.

However, implementation faces complex regulatory hurdles that vary significantly by region and industry sector. In the European Union, the Industrial Emissions Directive (IED) and the Emissions Trading System (ETS) create both incentives through carbon pricing mechanisms and compliance requirements that influence adoption decisions. Meanwhile, the United States operates under a more fragmented regulatory framework where federal, state, and local regulations may create inconsistent implementation environments.

Energy efficiency standards represent another critical regulatory dimension affecting thermoelectric waste recovery implementation. Countries including Japan, Germany, and South Korea have established progressive efficiency requirements for industrial operations that effectively mandate waste heat recovery solutions in certain applications. These standards often include financial incentives such as tax credits, grants, or accelerated depreciation schedules that significantly improve the economic viability of thermoelectric systems.

Safety regulations present additional implementation challenges, particularly in high-temperature industrial environments. Compliance with electrical safety codes, hazardous area classifications, and material compatibility requirements adds complexity to system design and installation. The lack of harmonized international standards specifically addressing thermoelectric waste recovery systems creates regulatory uncertainty that can delay project approvals and increase compliance costs.

Permitting processes represent a significant regulatory barrier, with approval timelines ranging from several months to years depending on jurisdiction. Industries report that regulatory uncertainty regarding how these systems are classified—as energy generation equipment, efficiency improvements, or emissions control devices—creates confusion during the permitting process and often requires case-by-case determinations that delay implementation.

Recent regulatory trends indicate movement toward more supportive frameworks, with several countries developing specific provisions for waste heat recovery technologies within their energy efficiency and industrial emissions policies. These developments suggest an evolving regulatory landscape that will increasingly facilitate rather than hinder thermoelectric waste recovery implementation, particularly as governments pursue increasingly ambitious climate targets.

However, implementation faces complex regulatory hurdles that vary significantly by region and industry sector. In the European Union, the Industrial Emissions Directive (IED) and the Emissions Trading System (ETS) create both incentives through carbon pricing mechanisms and compliance requirements that influence adoption decisions. Meanwhile, the United States operates under a more fragmented regulatory framework where federal, state, and local regulations may create inconsistent implementation environments.

Energy efficiency standards represent another critical regulatory dimension affecting thermoelectric waste recovery implementation. Countries including Japan, Germany, and South Korea have established progressive efficiency requirements for industrial operations that effectively mandate waste heat recovery solutions in certain applications. These standards often include financial incentives such as tax credits, grants, or accelerated depreciation schedules that significantly improve the economic viability of thermoelectric systems.

Safety regulations present additional implementation challenges, particularly in high-temperature industrial environments. Compliance with electrical safety codes, hazardous area classifications, and material compatibility requirements adds complexity to system design and installation. The lack of harmonized international standards specifically addressing thermoelectric waste recovery systems creates regulatory uncertainty that can delay project approvals and increase compliance costs.

Permitting processes represent a significant regulatory barrier, with approval timelines ranging from several months to years depending on jurisdiction. Industries report that regulatory uncertainty regarding how these systems are classified—as energy generation equipment, efficiency improvements, or emissions control devices—creates confusion during the permitting process and often requires case-by-case determinations that delay implementation.

Recent regulatory trends indicate movement toward more supportive frameworks, with several countries developing specific provisions for waste heat recovery technologies within their energy efficiency and industrial emissions policies. These developments suggest an evolving regulatory landscape that will increasingly facilitate rather than hinder thermoelectric waste recovery implementation, particularly as governments pursue increasingly ambitious climate targets.

Environmental Benefits and Sustainability Metrics

Thermoelectric waste heat recovery systems offer substantial environmental benefits that extend beyond mere energy efficiency improvements. When properly implemented, these systems can significantly reduce greenhouse gas emissions by capturing waste heat that would otherwise be released into the atmosphere. For industrial applications, this translates to approximately 5-10% reduction in carbon dioxide emissions, depending on the scale and efficiency of the implementation.

The sustainability metrics for thermoelectric waste recovery must be evaluated through multiple dimensions. Primary metrics include carbon footprint reduction, which can be measured in tons of CO2 equivalent avoided per year. For a medium-sized industrial facility, this can range from 500 to 2,000 tons annually. Energy recovery efficiency, typically ranging from 3-8% in current commercial applications, serves as another critical metric that directly correlates with environmental impact.

Regulatory frameworks increasingly recognize these environmental benefits, with some jurisdictions offering carbon credits or tax incentives for waste heat recovery implementations. The European Union's Emissions Trading System and similar cap-and-trade programs provide economic incentives that enhance the financial viability of thermoelectric waste recovery projects while acknowledging their environmental contributions.

Life cycle assessment (LCA) studies indicate that thermoelectric generators have relatively low environmental impact during operation, though manufacturing processes for specialized semiconductor materials present environmental challenges. The embodied energy in thermoelectric materials is typically recovered within 1-3 years of operation, depending on application intensity and recovery efficiency.

Water conservation represents another significant environmental benefit, particularly in comparison to traditional steam-based waste heat recovery systems. Thermoelectric generators operate without water consumption, potentially saving thousands of gallons annually in industrial settings where cooling water would otherwise be required for heat dissipation.

Resource efficiency metrics show that thermoelectric systems can extend the useful energy extracted from primary fuels by 3-15%, effectively reducing the resource intensity of industrial processes. This efficiency gain translates to proportional reductions in associated environmental impacts, including air pollutants such as NOx, SOx, and particulate matter.

Long-term sustainability assessments must also consider the recyclability of thermoelectric materials. Current research indicates that over 80% of the semiconductor materials in modern thermoelectric devices can be recovered and reused, though specialized recycling infrastructure remains limited in many regions.

The sustainability metrics for thermoelectric waste recovery must be evaluated through multiple dimensions. Primary metrics include carbon footprint reduction, which can be measured in tons of CO2 equivalent avoided per year. For a medium-sized industrial facility, this can range from 500 to 2,000 tons annually. Energy recovery efficiency, typically ranging from 3-8% in current commercial applications, serves as another critical metric that directly correlates with environmental impact.

Regulatory frameworks increasingly recognize these environmental benefits, with some jurisdictions offering carbon credits or tax incentives for waste heat recovery implementations. The European Union's Emissions Trading System and similar cap-and-trade programs provide economic incentives that enhance the financial viability of thermoelectric waste recovery projects while acknowledging their environmental contributions.

Life cycle assessment (LCA) studies indicate that thermoelectric generators have relatively low environmental impact during operation, though manufacturing processes for specialized semiconductor materials present environmental challenges. The embodied energy in thermoelectric materials is typically recovered within 1-3 years of operation, depending on application intensity and recovery efficiency.

Water conservation represents another significant environmental benefit, particularly in comparison to traditional steam-based waste heat recovery systems. Thermoelectric generators operate without water consumption, potentially saving thousands of gallons annually in industrial settings where cooling water would otherwise be required for heat dissipation.

Resource efficiency metrics show that thermoelectric systems can extend the useful energy extracted from primary fuels by 3-15%, effectively reducing the resource intensity of industrial processes. This efficiency gain translates to proportional reductions in associated environmental impacts, including air pollutants such as NOx, SOx, and particulate matter.

Long-term sustainability assessments must also consider the recyclability of thermoelectric materials. Current research indicates that over 80% of the semiconductor materials in modern thermoelectric devices can be recovered and reused, though specialized recycling infrastructure remains limited in many regions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!