Patent Analysis in the Field of Thermoelectric Waste Recovery Techniques

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermoelectric Waste Heat Recovery Background and Objectives

Thermoelectric waste heat recovery technology has evolved significantly over the past several decades, transforming from a niche scientific curiosity into a promising solution for energy efficiency challenges. The fundamental principle, known as the Seebeck effect, was discovered in 1821 by Thomas Johann Seebeck, who observed that a temperature difference between two dissimilar electrical conductors produces a voltage difference. This discovery laid the groundwork for thermoelectric generators (TEGs) that can convert waste heat directly into electrical energy without moving parts.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. Early materials exhibited a figure of merit (ZT) below 1, limiting practical applications. However, recent advancements in nanotechnology and material science have pushed ZT values above 2 for certain materials, making commercial applications increasingly viable across multiple industries.

Global energy consumption patterns reveal a critical inefficiency: approximately 60% of primary energy is lost as waste heat across industrial, transportation, and residential sectors. This represents not only an environmental concern but also a significant economic opportunity. The International Energy Agency estimates that improved waste heat recovery could reduce global CO2 emissions by several hundred million tons annually.

The primary technical objective in this field is to develop thermoelectric systems that achieve higher conversion efficiencies while maintaining cost-effectiveness and durability under real-world operating conditions. This includes enhancing the ZT value of thermoelectric materials, optimizing system design for specific temperature ranges, and developing manufacturing techniques that enable mass production at competitive costs.

Current research focuses on several promising directions: nanostructured materials that reduce thermal conductivity while maintaining electrical conductivity, flexible thermoelectric generators for wearable applications, and hybrid systems that combine thermoelectric technology with other waste heat recovery methods for maximum efficiency.

The automotive industry represents one of the most promising application areas, with potential to recover 5-10% of fuel energy from exhaust heat. Similarly, industrial processes in steel, glass, and cement manufacturing present significant opportunities due to their high-temperature waste streams. The residential sector also offers potential applications in co-generation systems for heating and electricity.

The technological trajectory suggests that thermoelectric waste heat recovery is approaching an inflection point where efficiency improvements and cost reductions may soon enable widespread commercial adoption across multiple sectors, potentially revolutionizing how we approach energy efficiency and waste heat management globally.

The evolution of thermoelectric materials has been marked by continuous improvements in conversion efficiency. Early materials exhibited a figure of merit (ZT) below 1, limiting practical applications. However, recent advancements in nanotechnology and material science have pushed ZT values above 2 for certain materials, making commercial applications increasingly viable across multiple industries.

Global energy consumption patterns reveal a critical inefficiency: approximately 60% of primary energy is lost as waste heat across industrial, transportation, and residential sectors. This represents not only an environmental concern but also a significant economic opportunity. The International Energy Agency estimates that improved waste heat recovery could reduce global CO2 emissions by several hundred million tons annually.

The primary technical objective in this field is to develop thermoelectric systems that achieve higher conversion efficiencies while maintaining cost-effectiveness and durability under real-world operating conditions. This includes enhancing the ZT value of thermoelectric materials, optimizing system design for specific temperature ranges, and developing manufacturing techniques that enable mass production at competitive costs.

Current research focuses on several promising directions: nanostructured materials that reduce thermal conductivity while maintaining electrical conductivity, flexible thermoelectric generators for wearable applications, and hybrid systems that combine thermoelectric technology with other waste heat recovery methods for maximum efficiency.

The automotive industry represents one of the most promising application areas, with potential to recover 5-10% of fuel energy from exhaust heat. Similarly, industrial processes in steel, glass, and cement manufacturing present significant opportunities due to their high-temperature waste streams. The residential sector also offers potential applications in co-generation systems for heating and electricity.

The technological trajectory suggests that thermoelectric waste heat recovery is approaching an inflection point where efficiency improvements and cost reductions may soon enable widespread commercial adoption across multiple sectors, potentially revolutionizing how we approach energy efficiency and waste heat management globally.

Market Demand Analysis for Waste Heat Recovery Solutions

The global market for waste heat recovery solutions has been experiencing significant growth, driven by increasing energy costs, environmental regulations, and corporate sustainability initiatives. The thermoelectric waste heat recovery sector specifically has seen a compound annual growth rate of approximately 8.7% between 2018 and 2023, with projections indicating continued expansion through 2030.

Industrial sectors represent the largest market segment for thermoelectric waste heat recovery technologies, accounting for nearly 60% of the total market share. Manufacturing processes in steel, cement, glass, and chemical industries generate substantial waste heat at various temperature ranges, creating prime opportunities for recovery systems. The automotive sector follows as the second-largest market, where thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to improve fuel efficiency.

Regional analysis reveals that Asia-Pacific dominates the market with over 40% share, led by China's aggressive industrial decarbonization policies and Japan's advanced energy efficiency programs. Europe represents approximately 30% of the market, driven by stringent emissions regulations and high energy costs. North America accounts for about 20%, with growth accelerating due to recent policy shifts toward sustainable energy solutions.

Market research indicates that end-users are increasingly demanding solutions with higher conversion efficiencies, reduced payback periods, and minimal maintenance requirements. Current market solutions typically offer conversion efficiencies between 5-8%, but customers are seeking improvements to reach double-digit efficiency rates to justify implementation costs.

Economic factors significantly influence market adoption rates. The return on investment for thermoelectric waste heat recovery systems currently ranges from 2-5 years depending on application scale and energy prices. This payback period represents a critical threshold for many potential adopters, particularly in energy-intensive industries where even marginal efficiency improvements translate to substantial cost savings.

Environmental regulations are creating strong market pull factors. Carbon pricing mechanisms in over 40 countries have established economic incentives for waste heat recovery adoption. Additionally, government subsidies and tax incentives for energy efficiency technologies have created favorable market conditions in key regions, stimulating demand growth.

Market forecasts suggest that the thermoelectric waste heat recovery market will reach significant value by 2028, with particular growth in applications for medium-temperature waste heat streams (200-400°C) where conventional recovery methods face technical and economic limitations.

Industrial sectors represent the largest market segment for thermoelectric waste heat recovery technologies, accounting for nearly 60% of the total market share. Manufacturing processes in steel, cement, glass, and chemical industries generate substantial waste heat at various temperature ranges, creating prime opportunities for recovery systems. The automotive sector follows as the second-largest market, where thermoelectric generators (TEGs) are increasingly being integrated into vehicle exhaust systems to improve fuel efficiency.

Regional analysis reveals that Asia-Pacific dominates the market with over 40% share, led by China's aggressive industrial decarbonization policies and Japan's advanced energy efficiency programs. Europe represents approximately 30% of the market, driven by stringent emissions regulations and high energy costs. North America accounts for about 20%, with growth accelerating due to recent policy shifts toward sustainable energy solutions.

Market research indicates that end-users are increasingly demanding solutions with higher conversion efficiencies, reduced payback periods, and minimal maintenance requirements. Current market solutions typically offer conversion efficiencies between 5-8%, but customers are seeking improvements to reach double-digit efficiency rates to justify implementation costs.

Economic factors significantly influence market adoption rates. The return on investment for thermoelectric waste heat recovery systems currently ranges from 2-5 years depending on application scale and energy prices. This payback period represents a critical threshold for many potential adopters, particularly in energy-intensive industries where even marginal efficiency improvements translate to substantial cost savings.

Environmental regulations are creating strong market pull factors. Carbon pricing mechanisms in over 40 countries have established economic incentives for waste heat recovery adoption. Additionally, government subsidies and tax incentives for energy efficiency technologies have created favorable market conditions in key regions, stimulating demand growth.

Market forecasts suggest that the thermoelectric waste heat recovery market will reach significant value by 2028, with particular growth in applications for medium-temperature waste heat streams (200-400°C) where conventional recovery methods face technical and economic limitations.

Global Thermoelectric Technology Status and Challenges

Thermoelectric waste heat recovery technology has witnessed significant global development in recent decades, with varying levels of advancement across different regions. Currently, the United States, Europe, Japan, and China represent the primary hubs of thermoelectric research and application. The United States maintains leadership in fundamental research and material innovation, with institutions like NASA and major universities pioneering high-efficiency thermoelectric materials. Europe focuses on automotive applications, with companies like BMW and Volkswagen actively integrating thermoelectric generators into vehicle exhaust systems.

Japan has established itself as a leader in miniaturization and consumer applications of thermoelectric technology, with companies like Panasonic and Toshiba developing compact, efficient modules. China has rapidly expanded its research capacity, focusing on mass production capabilities and cost reduction strategies, though often with slightly lower conversion efficiencies compared to Western counterparts.

Despite these advancements, thermoelectric waste heat recovery faces several critical challenges. The primary technical limitation remains conversion efficiency, with most commercial thermoelectric materials achieving only 5-8% efficiency. This fundamental limitation stems from the inherent difficulty in simultaneously optimizing electrical conductivity while minimizing thermal conductivity—a paradox at the heart of thermoelectric material science.

Material stability presents another significant challenge, particularly in high-temperature applications where thermal cycling can lead to degradation, interface delamination, and performance deterioration over time. Manufacturing scalability also remains problematic, with high-performance materials often requiring precise composition control and expensive elements like tellurium, which faces supply constraints.

Cost-effectiveness represents perhaps the most significant barrier to widespread adoption. Current thermoelectric systems typically cost $5-10 per watt of generating capacity, significantly higher than conventional power generation technologies. This economic challenge is compounded by integration difficulties, as retrofitting existing industrial systems with thermoelectric generators often requires substantial redesign of thermal management systems.

Emerging research directions show promise in addressing these challenges, including nanostructured materials that can better manage phonon scattering while maintaining electrical conductivity, and organic thermoelectric materials that offer lower costs and greater flexibility. Additionally, hybrid systems that combine thermoelectric generation with other waste heat recovery technologies are gaining attention for their potential to achieve higher overall system efficiencies.

The global research landscape shows increasing collaboration between academic institutions and industry partners, with patent activity growing at approximately 12% annually over the past decade, indicating sustained interest despite the technical challenges.

Japan has established itself as a leader in miniaturization and consumer applications of thermoelectric technology, with companies like Panasonic and Toshiba developing compact, efficient modules. China has rapidly expanded its research capacity, focusing on mass production capabilities and cost reduction strategies, though often with slightly lower conversion efficiencies compared to Western counterparts.

Despite these advancements, thermoelectric waste heat recovery faces several critical challenges. The primary technical limitation remains conversion efficiency, with most commercial thermoelectric materials achieving only 5-8% efficiency. This fundamental limitation stems from the inherent difficulty in simultaneously optimizing electrical conductivity while minimizing thermal conductivity—a paradox at the heart of thermoelectric material science.

Material stability presents another significant challenge, particularly in high-temperature applications where thermal cycling can lead to degradation, interface delamination, and performance deterioration over time. Manufacturing scalability also remains problematic, with high-performance materials often requiring precise composition control and expensive elements like tellurium, which faces supply constraints.

Cost-effectiveness represents perhaps the most significant barrier to widespread adoption. Current thermoelectric systems typically cost $5-10 per watt of generating capacity, significantly higher than conventional power generation technologies. This economic challenge is compounded by integration difficulties, as retrofitting existing industrial systems with thermoelectric generators often requires substantial redesign of thermal management systems.

Emerging research directions show promise in addressing these challenges, including nanostructured materials that can better manage phonon scattering while maintaining electrical conductivity, and organic thermoelectric materials that offer lower costs and greater flexibility. Additionally, hybrid systems that combine thermoelectric generation with other waste heat recovery technologies are gaining attention for their potential to achieve higher overall system efficiencies.

The global research landscape shows increasing collaboration between academic institutions and industry partners, with patent activity growing at approximately 12% annually over the past decade, indicating sustained interest despite the technical challenges.

Current Thermoelectric Waste Heat Recovery Solutions

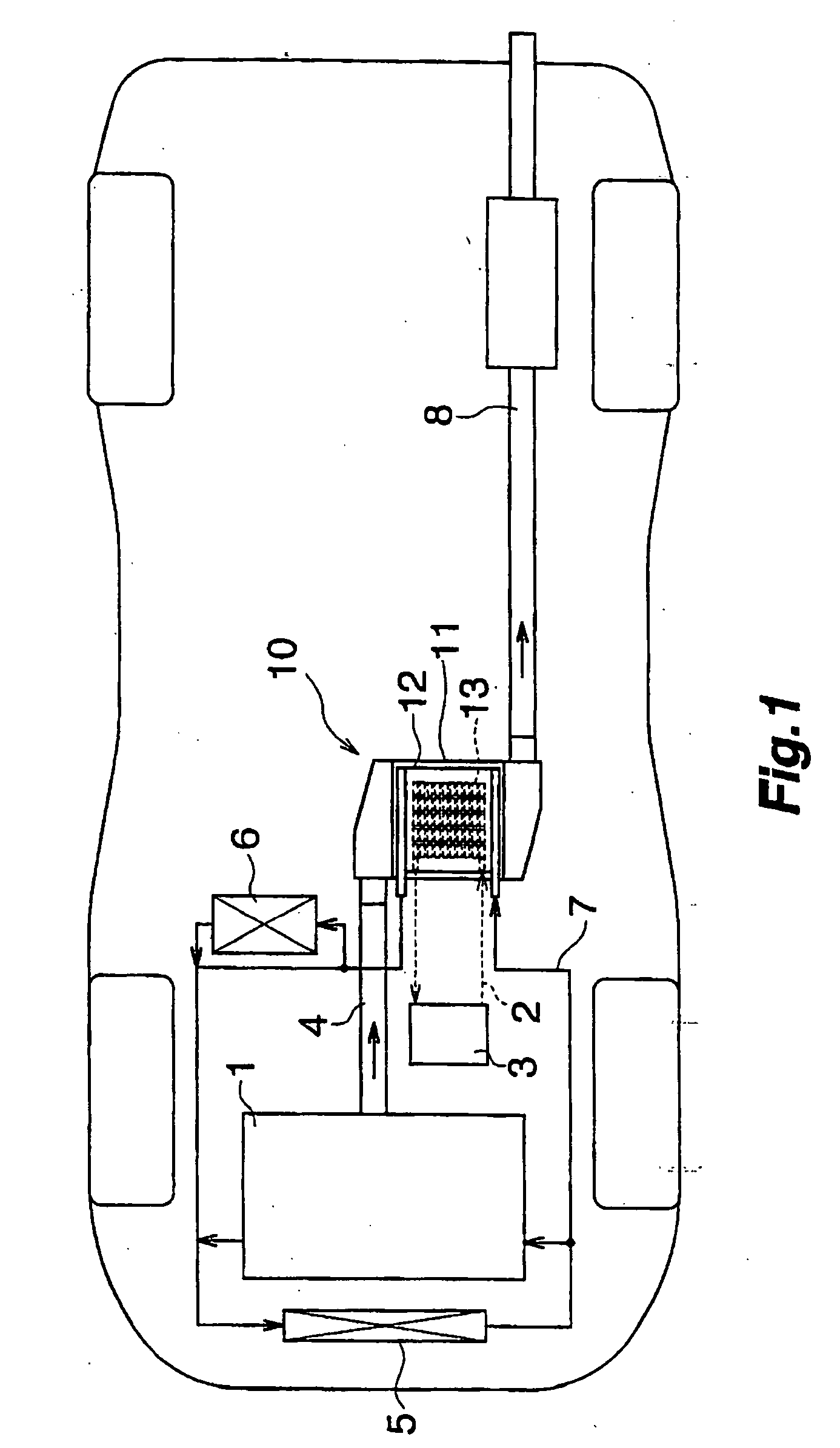

01 Thermoelectric generators for automotive waste heat recovery

Thermoelectric generators can be integrated into automotive exhaust systems to convert waste heat into electrical energy. These systems typically use semiconductor materials with high Seebeck coefficients to generate electricity from the temperature gradient between hot exhaust gases and cooling systems. The recovered energy can be used to power vehicle electrical systems, reducing fuel consumption and emissions. Advanced designs incorporate heat exchangers and thermal management systems to optimize energy conversion efficiency.- Thermoelectric generators for vehicle waste heat recovery: Thermoelectric generators can be integrated into vehicle exhaust systems to convert waste heat from combustion engines into usable electricity. These systems typically use semiconductor materials with high Seebeck coefficients to generate voltage from temperature differentials between the hot exhaust gases and cooling systems. The recovered electrical energy can supplement the vehicle's power system, reducing fuel consumption and emissions by decreasing alternator load.

- Industrial waste heat recovery systems: Industrial processes often generate significant amounts of waste heat that can be recovered using thermoelectric technologies. These systems are designed to capture heat from industrial equipment, furnaces, and manufacturing processes, converting it into electrical power. The implementation includes heat exchangers coupled with thermoelectric modules strategically placed at heat-intensive points in the industrial process flow, maximizing energy recovery efficiency and reducing overall energy consumption.

- Enhanced thermoelectric materials and module designs: Advanced thermoelectric materials and innovative module designs can significantly improve waste heat recovery efficiency. These developments include nanostructured materials, skutterudites, and bismuth telluride compounds with enhanced figure of merit (ZT) values. Module designs focus on optimizing thermal interfaces, reducing internal resistance, and improving heat transfer characteristics. Some approaches incorporate segmented elements using different materials optimized for specific temperature ranges to maximize conversion efficiency across broad temperature gradients.

- Integrated cooling systems for thermoelectric efficiency: Effective cooling systems are crucial for maintaining temperature differentials in thermoelectric waste heat recovery. These systems employ various cooling techniques including liquid cooling circuits, heat pipe technologies, and advanced heat sink designs to maximize the temperature gradient across thermoelectric modules. Some implementations use cascaded cooling approaches or phase-change materials to enhance heat dissipation. The integration of efficient cooling mechanisms significantly improves conversion efficiency and power output of thermoelectric waste heat recovery systems.

- Combined heat and power systems with thermoelectric elements: Hybrid systems that combine conventional heat recovery methods with thermoelectric generation can maximize overall energy recovery efficiency. These systems typically integrate thermoelectric modules into existing heat exchangers, boilers, or heat recovery steam generators to capture residual thermal energy that would otherwise be lost. The approach allows for simultaneous production of electricity through thermoelectric conversion while maintaining traditional heat transfer for heating or process applications, resulting in higher total system efficiency and improved energy utilization.

02 Industrial waste heat recovery systems

Industrial processes generate significant amounts of waste heat that can be recovered using thermoelectric technologies. These systems are designed to capture heat from industrial equipment, furnaces, and manufacturing processes. The recovered thermal energy is converted into electricity through thermoelectric modules, which can then be fed back into the facility's power grid. These systems often include heat exchangers, thermal storage components, and control systems to manage fluctuating heat sources and optimize energy recovery.Expand Specific Solutions03 Novel thermoelectric materials and structures

Advanced materials and innovative structures are being developed to improve the efficiency of thermoelectric waste heat recovery. These include nanostructured materials, organic thermoelectric compounds, and composite materials with enhanced Seebeck coefficients and reduced thermal conductivity. Structural innovations such as segmented thermoelectric legs, cascaded modules, and thin-film thermoelectric generators are designed to maximize power output across different temperature ranges and operating conditions.Expand Specific Solutions04 Integrated cooling and heat management systems

Effective thermal management is crucial for optimizing thermoelectric waste heat recovery. These systems incorporate advanced cooling techniques, heat exchangers, and thermal interface materials to maintain optimal temperature gradients across thermoelectric modules. Some designs use liquid cooling systems, heat pipes, or phase-change materials to enhance heat transfer and prevent overheating. Integrated approaches that combine waste heat recovery with cooling requirements can significantly improve overall system efficiency.Expand Specific Solutions05 Combined cycle waste heat recovery

Combined cycle approaches integrate thermoelectric generators with other waste heat recovery technologies to maximize energy capture across different temperature ranges. These hybrid systems may combine thermoelectric generators with organic Rankine cycles, heat pumps, or other thermal energy conversion technologies. By cascading different recovery methods, these systems can extract energy from both high and low-temperature waste heat sources, significantly improving overall energy recovery efficiency and economic viability.Expand Specific Solutions

Leading Companies and Research Institutions in Thermoelectric Industry

The thermoelectric waste recovery techniques market is currently in a growth phase, with increasing focus on energy efficiency and sustainability driving adoption. The global market size is estimated to reach $1.2 billion by 2027, growing at a CAGR of approximately 8.5%. Technologically, the field is advancing from early commercial applications toward broader implementation, with varying maturity levels across different sectors. Key players include established automotive companies like BorgWarner and Cummins focusing on vehicle applications, while Gentherm and Echogen Power Systems specialize in thermoelectric technologies specifically. Academic institutions such as Colorado State University and Politecnico di Torino contribute significant research advancements. Chinese entities like Wuhan Dongsheng Jieneng and research institutions from Chinese Academy of Sciences are rapidly expanding their patent portfolios, indicating growing competition from emerging markets in this increasingly strategic clean energy technology field.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed an innovative Organic Rankine Cycle (ORC) waste heat recovery system specifically designed for automotive applications. Their technology captures waste heat from both engine exhaust and the exhaust gas recirculation (EGR) system, utilizing a working fluid with optimized thermodynamic properties for automotive temperature ranges (typically 200-500°C). The system features a compact, lightweight design with an integrated expander-generator unit that directly converts thermal energy to electrical power. BorgWarner's solution incorporates advanced control algorithms that optimize system performance across varying driving conditions and engine loads. Their heat exchanger technology employs specialized coatings and materials to resist exhaust fouling while maintaining efficient heat transfer. The recovered electrical energy can be used to power vehicle accessories, charge batteries in hybrid vehicles, or provide supplemental power to the drivetrain. Testing on commercial vehicle platforms has demonstrated fuel economy improvements of 3-8% depending on driving cycle, with the system capable of generating 5-15 kW of electrical power during highway operation.

Strengths: Highly optimized for automotive integration; lightweight, compact design suitable for vehicle packaging constraints; sophisticated control systems for varying operating conditions; dual heat source utilization. Weaknesses: System complexity adds maintenance requirements; additional cost may challenge consumer adoption; performance varies significantly with driving conditions; working fluid environmental and safety considerations.

IFP Energies Nouvelles

Technical Solution: IFP Energies Nouvelles has developed a comprehensive waste heat recovery technology portfolio centered around advanced Rankine cycle systems optimized for various industrial applications. Their approach combines traditional steam Rankine cycles for high-temperature applications (>400°C) with organic Rankine cycles (ORC) for medium and low-temperature heat sources (80-400°C). IFP's technology features proprietary working fluid formulations specifically engineered for different temperature ranges and heat source characteristics. Their system architecture incorporates innovative expander designs including axial turbines for larger installations and scroll or screw expanders for smaller-scale applications. A key innovation in their approach is the development of dynamic control systems that optimize cycle parameters in real-time based on heat source fluctuations and load demands. IFP has demonstrated integrated solutions for various sectors including oil and gas processing, cement production, and maritime applications, with power outputs ranging from 100kW to 15MW and thermal efficiency improvements of 5-15% depending on the application.

Strengths: Versatile technology applicable across multiple temperature ranges and industries; optimized working fluids for specific applications; sophisticated control systems for varying operating conditions; proven track record in industrial implementations. Weaknesses: Complex system design increases capital costs; requires significant space for installation; working fluid environmental considerations; performance highly dependent on stable heat source characteristics.

Key Patent Analysis and Technical Innovations

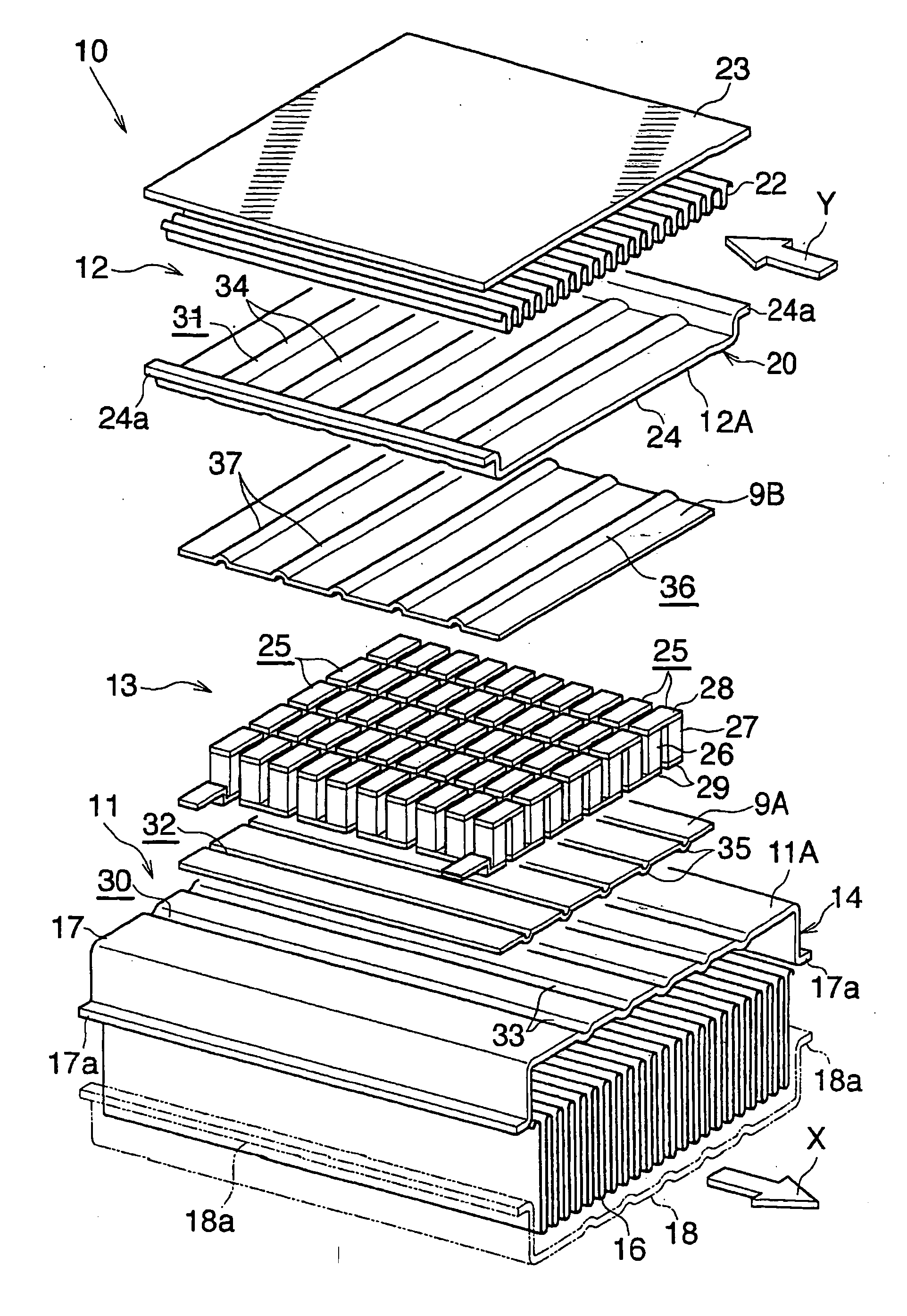

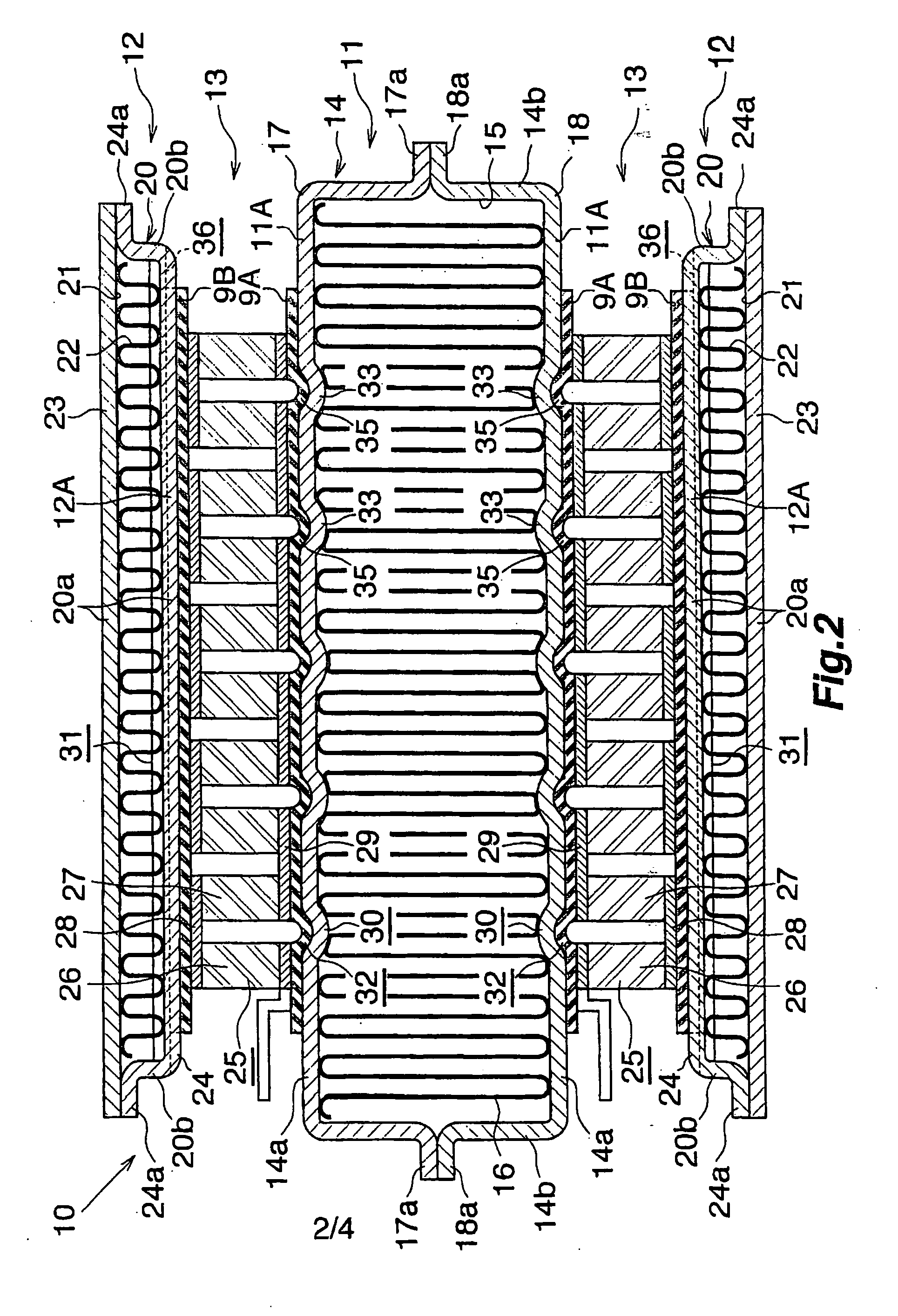

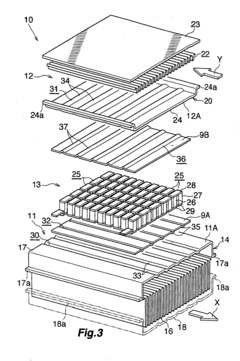

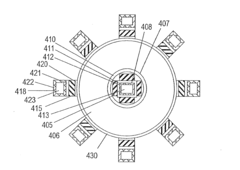

Waste heat recovery system and thermoelectric conversion system

PatentInactiveUS20060157102A1

Innovation

- A waste heat recovery system utilizing a thermoelectric conversion unit with sintered crystals of specific structures, connected in series with high-temperature and low-temperature heat exchangers, and thermal-stress relaxation features to enhance heat transfer and reduce thermal stress, allowing for efficient conversion of waste heat to electricity.

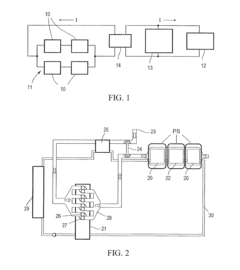

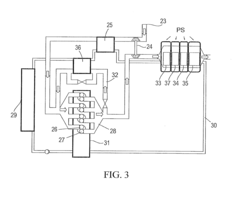

Exhaust gas treatment system including a thermoelectric generator

PatentInactiveUS20110311421A1

Innovation

- Integrating thermoelectric generation elements within the interior volume of exhaust gas after-treatment devices such as catalytic converters and particulate filters, which allows for heat exchange with exhaust gas and engine coolant, thereby enhancing waste heat recovery and expanding the operational window of these devices.

Environmental Impact and Sustainability Benefits

Thermoelectric waste heat recovery technologies represent a significant opportunity for enhancing environmental sustainability across multiple industrial sectors. By capturing and converting waste heat into usable electricity, these systems directly reduce primary energy consumption, thereby decreasing fossil fuel dependency and associated greenhouse gas emissions. Industrial applications of thermoelectric generators can potentially reduce carbon dioxide emissions by 5-15% in energy-intensive industries such as steel manufacturing, cement production, and glass making.

The environmental benefits extend beyond carbon reduction. Thermoelectric waste heat recovery systems operate silently with no moving parts, eliminating noise pollution common in traditional power generation. Additionally, these systems require minimal maintenance and have operational lifespans exceeding 15 years, reducing material consumption and waste associated with equipment replacement.

Water conservation represents another critical environmental advantage. Unlike conventional power generation methods that require substantial water resources for cooling, thermoelectric waste heat recovery operates without water consumption. This characteristic becomes increasingly valuable as water scarcity intensifies globally due to climate change and population growth.

Life cycle assessments of thermoelectric waste heat recovery systems demonstrate favorable environmental profiles. Recent studies indicate that most systems achieve energy payback periods of 1-3 years, depending on application and operating conditions. The materials used in modern thermoelectric modules, particularly those moving away from rare earth elements and toxic compounds, further enhance their sustainability credentials.

From a circular economy perspective, thermoelectric waste heat recovery aligns with principles of resource efficiency and waste minimization. By transforming what was previously considered a waste product (heat) into a valuable resource (electricity), these systems exemplify industrial symbiosis and closed-loop thinking. Furthermore, ongoing research into recyclable thermoelectric materials promises to enhance end-of-life management options.

The sustainability benefits also include potential contributions to energy access in remote or developing regions. Small-scale thermoelectric generators can provide reliable electricity from cooking stoves, industrial processes, or vehicle exhaust in areas without reliable grid connections, supporting sustainable development goals while reducing reliance on environmentally harmful energy sources like kerosene or diesel generators.

As regulatory frameworks increasingly emphasize carbon reduction and energy efficiency, thermoelectric waste heat recovery technologies offer industries a pathway to compliance while delivering tangible environmental benefits and potential economic advantages through reduced energy costs and possible carbon credit generation.

The environmental benefits extend beyond carbon reduction. Thermoelectric waste heat recovery systems operate silently with no moving parts, eliminating noise pollution common in traditional power generation. Additionally, these systems require minimal maintenance and have operational lifespans exceeding 15 years, reducing material consumption and waste associated with equipment replacement.

Water conservation represents another critical environmental advantage. Unlike conventional power generation methods that require substantial water resources for cooling, thermoelectric waste heat recovery operates without water consumption. This characteristic becomes increasingly valuable as water scarcity intensifies globally due to climate change and population growth.

Life cycle assessments of thermoelectric waste heat recovery systems demonstrate favorable environmental profiles. Recent studies indicate that most systems achieve energy payback periods of 1-3 years, depending on application and operating conditions. The materials used in modern thermoelectric modules, particularly those moving away from rare earth elements and toxic compounds, further enhance their sustainability credentials.

From a circular economy perspective, thermoelectric waste heat recovery aligns with principles of resource efficiency and waste minimization. By transforming what was previously considered a waste product (heat) into a valuable resource (electricity), these systems exemplify industrial symbiosis and closed-loop thinking. Furthermore, ongoing research into recyclable thermoelectric materials promises to enhance end-of-life management options.

The sustainability benefits also include potential contributions to energy access in remote or developing regions. Small-scale thermoelectric generators can provide reliable electricity from cooking stoves, industrial processes, or vehicle exhaust in areas without reliable grid connections, supporting sustainable development goals while reducing reliance on environmentally harmful energy sources like kerosene or diesel generators.

As regulatory frameworks increasingly emphasize carbon reduction and energy efficiency, thermoelectric waste heat recovery technologies offer industries a pathway to compliance while delivering tangible environmental benefits and potential economic advantages through reduced energy costs and possible carbon credit generation.

Intellectual Property Landscape and Patent Strategy

The patent landscape in thermoelectric waste heat recovery reveals a complex and increasingly competitive intellectual property environment. Analysis of global patent filings shows a significant acceleration in the past decade, with annual applications growing at approximately 15% year-over-year. Key jurisdictions include the United States, China, Japan, Germany, and South Korea, which collectively account for over 80% of all patent filings in this domain.

Major patent holders can be categorized into three distinct groups: automotive manufacturers (BMW, Toyota, Ford), component suppliers (Bosch, Denso, Continental), and specialized thermoelectric technology companies (Gentherm, II-VI Marlow, Alphabet Energy). The automotive sector dominates with approximately 45% of patents, focusing primarily on exhaust heat recovery systems integration.

Patent citation analysis reveals several technological clusters forming around specific approaches: skutterudite-based materials, thin-film thermoelectric generators, flexible thermoelectric modules, and system integration methodologies. The highest-cited patents typically address fundamental material science challenges or novel system architectures that significantly improve conversion efficiency.

Freedom-to-operate considerations are particularly complex in this field due to overlapping claims in system integration patents. Companies entering this space should conduct thorough FTO analyses focusing on application-specific implementations rather than fundamental technologies, as the latter are increasingly protected by broad patent families with extensive territorial coverage.

Strategic patent filing trends indicate a shift toward protecting complete systems rather than individual components. Leading companies are building defensive patent portfolios that cover multiple technical approaches, creating significant barriers to entry. Cross-licensing agreements between major players have become increasingly common, suggesting the formation of technology ecosystems that may exclude new entrants without substantial IP assets.

For companies developing thermoelectric waste heat recovery technologies, a multi-layered patent strategy is recommended: defensive patenting around core technologies, strategic filing in emerging application areas, and the development of a robust trade secret portfolio for manufacturing processes that are difficult to reverse-engineer. Additionally, monitoring competitor filing activities can provide early insights into technological pivots and emerging market opportunities.

Major patent holders can be categorized into three distinct groups: automotive manufacturers (BMW, Toyota, Ford), component suppliers (Bosch, Denso, Continental), and specialized thermoelectric technology companies (Gentherm, II-VI Marlow, Alphabet Energy). The automotive sector dominates with approximately 45% of patents, focusing primarily on exhaust heat recovery systems integration.

Patent citation analysis reveals several technological clusters forming around specific approaches: skutterudite-based materials, thin-film thermoelectric generators, flexible thermoelectric modules, and system integration methodologies. The highest-cited patents typically address fundamental material science challenges or novel system architectures that significantly improve conversion efficiency.

Freedom-to-operate considerations are particularly complex in this field due to overlapping claims in system integration patents. Companies entering this space should conduct thorough FTO analyses focusing on application-specific implementations rather than fundamental technologies, as the latter are increasingly protected by broad patent families with extensive territorial coverage.

Strategic patent filing trends indicate a shift toward protecting complete systems rather than individual components. Leading companies are building defensive patent portfolios that cover multiple technical approaches, creating significant barriers to entry. Cross-licensing agreements between major players have become increasingly common, suggesting the formation of technology ecosystems that may exclude new entrants without substantial IP assets.

For companies developing thermoelectric waste heat recovery technologies, a multi-layered patent strategy is recommended: defensive patenting around core technologies, strategic filing in emerging application areas, and the development of a robust trade secret portfolio for manufacturing processes that are difficult to reverse-engineer. Additionally, monitoring competitor filing activities can provide early insights into technological pivots and emerging market opportunities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!