Comparative Testing Of Membranes In Simulated Coal Flue Gases

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Membrane Technology Background and Objectives

Membrane technology has evolved significantly over the past five decades, transforming from laboratory curiosities to industrial-scale separation solutions. The application of membranes for gas separation began in earnest during the 1970s with the development of asymmetric cellulose acetate membranes for oxygen/nitrogen separation. By the 1980s, polymeric membranes had found commercial applications in natural gas processing, and the 1990s saw expansion into various industrial gas separation processes.

In the context of coal-fired power generation, membrane technology represents a promising approach for carbon capture and pollutant control. Coal combustion produces flue gases containing primarily nitrogen, carbon dioxide, water vapor, oxygen, and various pollutants including sulfur oxides, nitrogen oxides, and particulate matter. Traditional carbon capture methods such as amine scrubbing are energy-intensive, creating a significant efficiency penalty on power generation.

Membrane-based separation offers several potential advantages for coal flue gas treatment, including lower energy requirements, smaller physical footprint, absence of hazardous chemicals, and operational simplicity. However, the harsh conditions of coal flue gases present substantial challenges for membrane materials, including thermal stability requirements, resistance to plasticization, tolerance to contaminants, and maintaining separation performance under varying conditions.

The current technological trajectory shows increasing focus on mixed matrix membranes, facilitated transport membranes, and thermally rearranged polymers that can withstand the challenging environment of coal flue gases while maintaining high selectivity and permeability. Recent innovations in material science have enabled the development of membranes with improved resistance to sulfur compounds and particulate fouling.

The primary objective of comparative membrane testing in simulated coal flue gases is to identify and characterize membrane materials that can effectively separate carbon dioxide from other flue gas components under realistic operating conditions. Specific goals include quantifying separation performance (selectivity and permeability), assessing durability under extended exposure to contaminants, determining optimal operating parameters, and evaluating economic feasibility compared to conventional technologies.

This research aims to bridge the gap between laboratory-scale membrane development and practical industrial implementation by providing comprehensive performance data under conditions that accurately simulate real-world coal combustion environments. The ultimate goal is to develop membrane technology that can achieve at least 90% CO2 capture with minimal energy penalty, thereby enabling cost-effective carbon capture from coal-fired power plants to meet increasingly stringent emissions regulations worldwide.

In the context of coal-fired power generation, membrane technology represents a promising approach for carbon capture and pollutant control. Coal combustion produces flue gases containing primarily nitrogen, carbon dioxide, water vapor, oxygen, and various pollutants including sulfur oxides, nitrogen oxides, and particulate matter. Traditional carbon capture methods such as amine scrubbing are energy-intensive, creating a significant efficiency penalty on power generation.

Membrane-based separation offers several potential advantages for coal flue gas treatment, including lower energy requirements, smaller physical footprint, absence of hazardous chemicals, and operational simplicity. However, the harsh conditions of coal flue gases present substantial challenges for membrane materials, including thermal stability requirements, resistance to plasticization, tolerance to contaminants, and maintaining separation performance under varying conditions.

The current technological trajectory shows increasing focus on mixed matrix membranes, facilitated transport membranes, and thermally rearranged polymers that can withstand the challenging environment of coal flue gases while maintaining high selectivity and permeability. Recent innovations in material science have enabled the development of membranes with improved resistance to sulfur compounds and particulate fouling.

The primary objective of comparative membrane testing in simulated coal flue gases is to identify and characterize membrane materials that can effectively separate carbon dioxide from other flue gas components under realistic operating conditions. Specific goals include quantifying separation performance (selectivity and permeability), assessing durability under extended exposure to contaminants, determining optimal operating parameters, and evaluating economic feasibility compared to conventional technologies.

This research aims to bridge the gap between laboratory-scale membrane development and practical industrial implementation by providing comprehensive performance data under conditions that accurately simulate real-world coal combustion environments. The ultimate goal is to develop membrane technology that can achieve at least 90% CO2 capture with minimal energy penalty, thereby enabling cost-effective carbon capture from coal-fired power plants to meet increasingly stringent emissions regulations worldwide.

Market Analysis for Coal Flue Gas Filtration Solutions

The global market for coal flue gas filtration solutions is experiencing significant growth driven by increasingly stringent environmental regulations and the continued reliance on coal-fired power generation in many regions. Current market valuation stands at approximately $7.2 billion, with projections indicating a compound annual growth rate of 5.8% through 2028, primarily fueled by retrofitting existing coal plants with advanced filtration technologies.

Asia-Pacific represents the largest market segment, accounting for over 45% of global demand, with China and India leading consumption due to their heavy coal dependency and growing environmental concerns. North America and Europe follow with market shares of 22% and 18% respectively, where the focus has shifted toward upgrading existing infrastructure rather than new installations.

Demand patterns show a clear bifurcation between developed and developing markets. In mature economies, the emphasis is on high-efficiency membrane solutions that can achieve ultra-low emission standards, while emerging economies prioritize cost-effective solutions that balance regulatory compliance with economic feasibility. This dichotomy creates distinct market segments with different price sensitivities and performance requirements.

The membrane technology segment specifically has been growing at 7.3% annually, outpacing conventional filtration methods. This accelerated growth reflects the superior performance of membrane solutions in removing fine particulates, sulfur compounds, and mercury from flue gas streams. Ceramic and polymer-based membranes dominate the market, with the latter gaining traction due to recent advances in heat-resistant polymers suitable for high-temperature flue gas environments.

Customer requirements are evolving toward integrated solutions that address multiple pollutants simultaneously. End-users increasingly demand membrane systems that can handle particulate matter, SOx, NOx, and mercury in a single installation, driving innovation in multi-functional membrane designs. Additionally, there is growing interest in membranes that can capture carbon dioxide, anticipating future carbon emission regulations.

Market barriers include high initial capital costs, technical challenges related to membrane fouling in coal flue gas environments, and competition from alternative technologies such as electrostatic precipitators and wet scrubbers. However, the long-term operational cost advantages of membrane systems, including reduced maintenance and higher removal efficiencies, are gradually overcoming these barriers.

The competitive landscape features both established industrial filtration companies expanding into coal applications and specialized membrane technology providers developing coal-specific solutions. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this sector to major industrial players seeking comprehensive environmental technology portfolios.

Asia-Pacific represents the largest market segment, accounting for over 45% of global demand, with China and India leading consumption due to their heavy coal dependency and growing environmental concerns. North America and Europe follow with market shares of 22% and 18% respectively, where the focus has shifted toward upgrading existing infrastructure rather than new installations.

Demand patterns show a clear bifurcation between developed and developing markets. In mature economies, the emphasis is on high-efficiency membrane solutions that can achieve ultra-low emission standards, while emerging economies prioritize cost-effective solutions that balance regulatory compliance with economic feasibility. This dichotomy creates distinct market segments with different price sensitivities and performance requirements.

The membrane technology segment specifically has been growing at 7.3% annually, outpacing conventional filtration methods. This accelerated growth reflects the superior performance of membrane solutions in removing fine particulates, sulfur compounds, and mercury from flue gas streams. Ceramic and polymer-based membranes dominate the market, with the latter gaining traction due to recent advances in heat-resistant polymers suitable for high-temperature flue gas environments.

Customer requirements are evolving toward integrated solutions that address multiple pollutants simultaneously. End-users increasingly demand membrane systems that can handle particulate matter, SOx, NOx, and mercury in a single installation, driving innovation in multi-functional membrane designs. Additionally, there is growing interest in membranes that can capture carbon dioxide, anticipating future carbon emission regulations.

Market barriers include high initial capital costs, technical challenges related to membrane fouling in coal flue gas environments, and competition from alternative technologies such as electrostatic precipitators and wet scrubbers. However, the long-term operational cost advantages of membrane systems, including reduced maintenance and higher removal efficiencies, are gradually overcoming these barriers.

The competitive landscape features both established industrial filtration companies expanding into coal applications and specialized membrane technology providers developing coal-specific solutions. Recent market consolidation through mergers and acquisitions indicates the strategic importance of this sector to major industrial players seeking comprehensive environmental technology portfolios.

Current Membrane Technologies and Technical Barriers

Membrane technologies for carbon capture from coal flue gases have evolved significantly over the past decades. Currently, several membrane types dominate the field, each with distinct advantages and limitations. Polymeric membranes, particularly those based on polyimides, polysulfones, and cellulose acetate, represent the most commercially mature technology due to their relatively low cost and ease of manufacturing. These membranes typically operate through solution-diffusion mechanisms, where CO2 dissolves into the membrane material and diffuses through it more rapidly than other flue gas components.

Inorganic membranes, including zeolites, ceramics, and metal-organic frameworks (MOFs), offer superior thermal and chemical stability compared to polymeric alternatives. Zeolite membranes, with their well-defined pore structures, can achieve high selectivity through molecular sieving effects. MOF membranes have garnered significant attention due to their tunable pore sizes and functionalities, potentially allowing for optimized CO2 separation performance.

Mixed matrix membranes (MMMs) combine polymeric matrices with inorganic fillers to leverage the processability of polymers and the superior separation properties of inorganic materials. Recent developments in MMMs have shown promising results in laboratory settings, with CO2 permeabilities exceeding 1000 Barrers while maintaining CO2/N2 selectivity above 30.

Despite these advances, significant technical barriers persist in membrane technology for coal flue gas applications. The harsh operating conditions present a major challenge, as membranes must withstand temperatures ranging from 40-80°C and resist degradation from acidic components like SOx and NOx. Most current membranes suffer performance losses when exposed to these conditions for extended periods.

The "trade-off" relationship between permeability and selectivity remains a fundamental limitation. As membranes become more permeable to CO2, they typically become less selective, and vice versa. This relationship, known as the Robeson upper bound, has constrained membrane performance improvements despite decades of research.

Membrane fouling and plasticization represent additional barriers to long-term operation. Particulate matter in flue gas can accumulate on membrane surfaces, reducing flux over time. Meanwhile, high CO2 partial pressures can cause polymer chain mobility increases (plasticization), leading to decreased selectivity and mechanical stability.

Scale-up challenges further complicate commercial implementation. Laboratory-scale membranes often show promising performance that deteriorates when manufactured at industrial scales. The development of cost-effective, large-area membrane modules with adequate mechanical support structures remains an engineering challenge that has limited widespread adoption.

Inorganic membranes, including zeolites, ceramics, and metal-organic frameworks (MOFs), offer superior thermal and chemical stability compared to polymeric alternatives. Zeolite membranes, with their well-defined pore structures, can achieve high selectivity through molecular sieving effects. MOF membranes have garnered significant attention due to their tunable pore sizes and functionalities, potentially allowing for optimized CO2 separation performance.

Mixed matrix membranes (MMMs) combine polymeric matrices with inorganic fillers to leverage the processability of polymers and the superior separation properties of inorganic materials. Recent developments in MMMs have shown promising results in laboratory settings, with CO2 permeabilities exceeding 1000 Barrers while maintaining CO2/N2 selectivity above 30.

Despite these advances, significant technical barriers persist in membrane technology for coal flue gas applications. The harsh operating conditions present a major challenge, as membranes must withstand temperatures ranging from 40-80°C and resist degradation from acidic components like SOx and NOx. Most current membranes suffer performance losses when exposed to these conditions for extended periods.

The "trade-off" relationship between permeability and selectivity remains a fundamental limitation. As membranes become more permeable to CO2, they typically become less selective, and vice versa. This relationship, known as the Robeson upper bound, has constrained membrane performance improvements despite decades of research.

Membrane fouling and plasticization represent additional barriers to long-term operation. Particulate matter in flue gas can accumulate on membrane surfaces, reducing flux over time. Meanwhile, high CO2 partial pressures can cause polymer chain mobility increases (plasticization), leading to decreased selectivity and mechanical stability.

Scale-up challenges further complicate commercial implementation. Laboratory-scale membranes often show promising performance that deteriorates when manufactured at industrial scales. The development of cost-effective, large-area membrane modules with adequate mechanical support structures remains an engineering challenge that has limited widespread adoption.

Comparative Testing Methodologies for Membrane Performance

01 Membrane filtration and separation technologies

Membrane technologies are used for filtration and separation processes in various applications. These membranes can be designed with specific pore sizes and materials to selectively filter particles, molecules, or ions. The technology is applied in water treatment, chemical processing, and biological separations, offering advantages such as energy efficiency and reduced chemical usage compared to traditional separation methods.- Filtration and separation membranes: Membranes designed for filtration and separation processes are widely used in various industries. These membranes can be engineered with specific pore sizes and structures to selectively separate components based on size, charge, or other properties. They are commonly employed in water treatment, gas separation, and purification processes. Advanced filtration membranes can be made from polymeric materials, ceramics, or composite structures to enhance performance and durability.

- Biological and biomedical membranes: Membranes for biological and biomedical applications are specifically designed to interact with biological systems. These include membranes for cell culture, tissue engineering, drug delivery, and biosensors. Such membranes often require biocompatibility and may incorporate features that promote cell adhesion, growth, or specific biological responses. Some biological membranes are designed to mimic natural cellular membranes for research or diagnostic purposes.

- Membrane manufacturing and fabrication techniques: Various techniques are employed in the manufacturing and fabrication of membranes with specific properties. These include phase inversion, electrospinning, track-etching, and interfacial polymerization. The manufacturing process significantly influences membrane characteristics such as porosity, mechanical strength, and chemical resistance. Advanced fabrication methods allow for precise control over membrane structure at the micro and nano scales, enabling tailored performance for specific applications.

- Gas separation and permeable membranes: Membranes designed specifically for gas separation applications utilize differences in gas permeability to achieve selective separation. These membranes can separate gas mixtures based on molecular size, solubility, or diffusivity differences. Applications include carbon capture, hydrogen purification, oxygen enrichment, and natural gas processing. The performance of gas separation membranes is typically characterized by permeability and selectivity parameters, which determine their efficiency in specific separation tasks.

- Membrane modification and functionalization: Modification and functionalization of membrane surfaces enhance their performance for specific applications. Techniques include chemical grafting, plasma treatment, layer-by-layer deposition, and incorporation of nanoparticles. These modifications can improve properties such as fouling resistance, selectivity, chemical stability, or introduce specific functional groups. Surface-modified membranes often exhibit superior performance compared to their unmodified counterparts, particularly in challenging separation environments or specialized applications.

02 Polymer-based membrane materials and fabrication

Polymer materials are widely used in membrane fabrication due to their versatility and tunable properties. Various techniques are employed to create polymer membranes with controlled porosity, thickness, and surface characteristics. These include phase inversion, electrospinning, and surface modification methods. The choice of polymer and fabrication technique significantly impacts membrane performance characteristics such as permeability, selectivity, and mechanical strength.Expand Specific Solutions03 Biological and biomedical membrane applications

Membranes play crucial roles in biological and biomedical applications, including biosensors, drug delivery systems, and tissue engineering. These specialized membranes can be designed to interact with biological materials, facilitate controlled release of therapeutic agents, or serve as substrates for cell growth. The integration of biological components with synthetic membrane materials enables advanced diagnostic and therapeutic applications.Expand Specific Solutions04 Gas separation and permeable membranes

Membranes designed for gas separation utilize differences in gas permeability to achieve selective separation of gas mixtures. These membranes are employed in applications such as carbon capture, hydrogen purification, and natural gas processing. The performance of gas separation membranes depends on factors including material composition, membrane thickness, operating conditions, and the specific gases being separated.Expand Specific Solutions05 Membrane characterization and testing methods

Various analytical techniques and testing methods are used to characterize membrane properties and performance. These include permeability measurements, rejection testing, microscopy for structural analysis, and spectroscopic methods for chemical characterization. Standardized testing protocols help evaluate membrane integrity, fouling resistance, and long-term stability under different operating conditions, which is essential for quality control and performance prediction.Expand Specific Solutions

Leading Companies in Membrane Filtration Industry

The membrane technology for coal flue gas treatment is in a growth phase, with increasing market size driven by environmental regulations and energy efficiency demands. The global market is expected to reach significant scale as coal-fired power plants seek emission reduction solutions. Technologically, the field shows moderate maturity with established players like Membrane Technology & Research and NGK Insulators leading commercial applications, while research institutions including China University of Mining & Technology, Shandong University of Science & Technology, and Lawrence Livermore National Security are advancing fundamental innovations. Energy corporations such as PetroChina, Shell, and Korea Electric Power are actively implementing these technologies, creating a competitive landscape balanced between established industrial solutions and emerging research breakthroughs.

Forschungszentrum Jülich GmbH

Technical Solution: Forschungszentrum Jülich has pioneered ceramic-based membrane technology for coal flue gas applications, focusing on mixed ionic-electronic conducting (MIEC) membranes. Their approach utilizes perovskite-type materials (such as Ba0.5Sr0.5Co0.8Fe0.2O3-δ) that can operate at high temperatures (700-900°C) typical in coal combustion environments. These membranes function through an oxygen vacancy transport mechanism, allowing selective permeation of oxygen while blocking other flue gas components. The research center has developed manufacturing techniques for asymmetric membrane structures with thin selective layers (10-50 μm) on porous supports, achieving oxygen permeation rates of 5-10 ml/cm²·min under simulated coal flue gas conditions. Their testing protocols incorporate realistic flue gas compositions including CO2, SOx, NOx, and water vapor to evaluate membrane stability and performance degradation. Recent innovations include protective surface coatings to enhance resistance against sulfur poisoning and particulate contamination, extending membrane operational lifetime to over 3,000 hours in simulated coal flue gas environments.

Strengths: Exceptional thermal stability suitable for high-temperature applications; high oxygen selectivity; resistant to thermal cycling; can be integrated directly into high-temperature processes without cooling flue gas. Weaknesses: Manufacturing complexity and associated high costs; brittleness of ceramic materials poses challenges for module design and scaling; sensitivity to certain contaminants like sulfur compounds that can poison active sites.

Membrane Technology & Research, Inc.

Technical Solution: Membrane Technology & Research (MTR) has developed advanced polymeric membranes specifically designed for coal flue gas applications. Their technology utilizes selective polymer materials that can withstand the harsh conditions of flue gas environments while effectively separating CO2 from other components. MTR's approach involves multi-layer composite membranes with a thin selective layer supported by a porous substrate, optimizing both permeability and selectivity. Their Polaris™ membrane system has demonstrated CO2 capture rates exceeding 90% in simulated coal flue gas environments with temperatures ranging from 30-60°C. The membrane modules are designed in spiral-wound configurations that maximize surface area while minimizing pressure drop. MTR has conducted extensive field testing at actual coal-fired power plants, demonstrating membrane stability over extended periods (>5,000 hours) despite the presence of contaminants like SOx and NOx in the flue gas streams.

Strengths: High CO2 selectivity with minimal pressure drop; modular design allows for scalability; lower energy requirements compared to traditional amine scrubbing; resistant to common flue gas contaminants. Weaknesses: Performance can degrade at elevated temperatures; requires pre-treatment of flue gas to remove particulates and certain contaminants; may require compression of flue gas which adds to operational costs.

Key Membrane Patents and Technical Literature Analysis

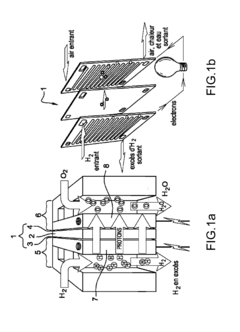

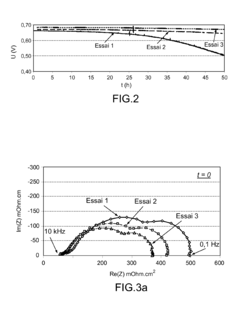

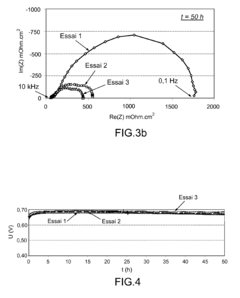

Method for measuring the reproducibility of N individual electrode- / ion-exchange membrane assemblies by introducing a pollutant

PatentInactiveEP2669982A1

Innovation

- A method involving the introduction of a polluting species into the fuel or oxidant streams of MEAs to amplify performance differences, with measurements of electrochemical parameters such as cell voltage and impedance, and comparison of these measurements to evaluate reproducibility, using a device that supplies the polluting agent and measures electrochemical parameters.

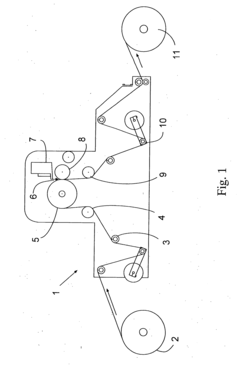

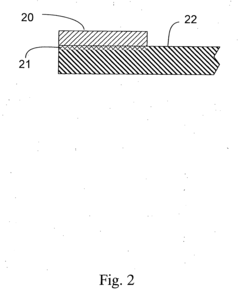

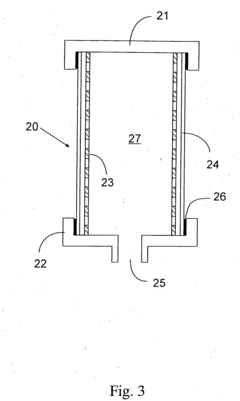

Laminated edge filter structure and method of making

PatentInactiveUS20040200771A1

Innovation

- An extrusion lamination process is used to form a non-porous strip on the edges of the filter membrane, which is then subjected to pressure to create a strong mechanical bond with the potting material, ensuring a solid seal without disrupting the hydrophilic coating, allowing for simultaneous formation of multiple membranes and varying widths.

Environmental Regulations Impact on Membrane Development

Environmental regulations have become increasingly stringent worldwide, significantly influencing the development trajectory of membrane technologies for coal flue gas applications. The Clean Air Act Amendments in the United States and similar legislation in Europe and Asia have progressively lowered permissible emission limits for sulfur dioxide, nitrogen oxides, particulate matter, and more recently, carbon dioxide and mercury.

These regulatory frameworks have created a dual impact on membrane development. First, they have accelerated research funding and industrial investment in advanced separation technologies, with membranes receiving particular attention due to their potential energy efficiency advantages over traditional absorption processes. The European Union's Industrial Emissions Directive (2010/75/EU) specifically encouraged the adoption of Best Available Techniques (BAT), positioning membrane technology as a promising candidate for meeting these standards.

Second, regulations have directly shaped membrane material requirements and performance benchmarks. Membranes must now demonstrate not only high selectivity for target pollutants but also exceptional durability under the harsh conditions typical of coal flue gases. The U.S. Environmental Protection Agency's Mercury and Air Toxics Standards (MATS) have particularly influenced membrane development toward materials resistant to mercury contamination and capable of functioning in the presence of acid gases.

Regional variations in regulatory approaches have led to differentiated membrane development pathways. China's ultra-low emission standards implemented since 2014 have driven research toward membranes capable of simultaneous multi-pollutant capture, while European regulations emphasizing carbon capture have fostered development of CO2-selective membranes with improved permeability-selectivity trade-offs.

The timeline of regulatory implementation has also shaped testing protocols for membrane evaluation. Phased implementation of stricter limits has created a stepwise approach to membrane performance requirements, with initial focus on SO2 and NOx removal gradually expanding to include CO2 capture capabilities. This regulatory progression has influenced comparative testing methodologies, requiring increasingly complex simulated flue gas compositions to validate membrane performance under realistic conditions.

Looking forward, anticipated regulations on emerging contaminants of concern, such as ultrafine particulates and trace heavy metals, are already influencing the next generation of membrane materials. Developers are increasingly incorporating adaptability to regulatory changes as a design criterion, focusing on modular membrane systems that can be upgraded as requirements evolve.

These regulatory frameworks have created a dual impact on membrane development. First, they have accelerated research funding and industrial investment in advanced separation technologies, with membranes receiving particular attention due to their potential energy efficiency advantages over traditional absorption processes. The European Union's Industrial Emissions Directive (2010/75/EU) specifically encouraged the adoption of Best Available Techniques (BAT), positioning membrane technology as a promising candidate for meeting these standards.

Second, regulations have directly shaped membrane material requirements and performance benchmarks. Membranes must now demonstrate not only high selectivity for target pollutants but also exceptional durability under the harsh conditions typical of coal flue gases. The U.S. Environmental Protection Agency's Mercury and Air Toxics Standards (MATS) have particularly influenced membrane development toward materials resistant to mercury contamination and capable of functioning in the presence of acid gases.

Regional variations in regulatory approaches have led to differentiated membrane development pathways. China's ultra-low emission standards implemented since 2014 have driven research toward membranes capable of simultaneous multi-pollutant capture, while European regulations emphasizing carbon capture have fostered development of CO2-selective membranes with improved permeability-selectivity trade-offs.

The timeline of regulatory implementation has also shaped testing protocols for membrane evaluation. Phased implementation of stricter limits has created a stepwise approach to membrane performance requirements, with initial focus on SO2 and NOx removal gradually expanding to include CO2 capture capabilities. This regulatory progression has influenced comparative testing methodologies, requiring increasingly complex simulated flue gas compositions to validate membrane performance under realistic conditions.

Looking forward, anticipated regulations on emerging contaminants of concern, such as ultrafine particulates and trace heavy metals, are already influencing the next generation of membrane materials. Developers are increasingly incorporating adaptability to regulatory changes as a design criterion, focusing on modular membrane systems that can be upgraded as requirements evolve.

Cost-Benefit Analysis of Advanced Membrane Systems

The implementation of advanced membrane systems for coal flue gas treatment requires thorough cost-benefit analysis to determine economic viability. Initial capital expenditure for membrane systems typically ranges from $2-5 million for medium-scale power plants, with costs varying based on membrane material selection, system complexity, and installation requirements. Polymeric membranes generally offer lower upfront costs ($80-150/m²) compared to ceramic or metal-organic framework membranes ($200-500/m²), though the latter demonstrate superior durability in harsh flue gas environments.

Operational expenditures must account for membrane replacement cycles, which differ significantly across materials. Testing in simulated coal flue gas environments reveals that conventional polymeric membranes require replacement every 2-3 years, while advanced composite membranes can extend service life to 4-6 years, substantially reducing lifetime costs despite higher initial investment.

Energy consumption represents another critical cost factor. Comparative testing demonstrates that pressure-driven membrane systems consume 0.2-0.4 kWh per ton of CO₂ captured, whereas conventional amine scrubbing technologies require 0.8-1.2 kWh for equivalent performance. This energy differential translates to approximately $500,000-750,000 in annual savings for a 500MW coal power plant.

Regulatory compliance benefits must also factor into the analysis. Advanced membrane systems capable of removing multiple pollutants simultaneously (CO₂, SOx, NOx) can eliminate the need for separate treatment systems, potentially saving $1-2 million in capital costs and $300,000-500,000 in annual operational expenses.

Market opportunities present additional economic advantages. Carbon capture credits, which currently range from $30-70 per ton depending on jurisdiction, can generate significant revenue streams when membrane efficiency exceeds 90% capture rates. Testing indicates that the latest selective membranes can achieve 92-95% capture efficiency under optimized conditions.

Return on investment calculations based on comparative testing suggest that advanced membrane systems typically achieve payback periods of 4-7 years, compared to 8-12 years for conventional scrubbing technologies. This favorable economic profile is further enhanced when accounting for potential carbon tax avoidance, which could range from $40-120 per ton of CO₂ by 2030 according to current policy projections.

Sensitivity analysis reveals that membrane performance degradation rates in actual coal flue gas conditions represent the most significant risk factor affecting long-term economics. Laboratory testing under accelerated aging conditions indicates that membrane selectivity typically decreases by 5-15% annually, necessitating careful monitoring and maintenance protocols to maintain optimal cost-benefit ratios throughout system lifetime.

Operational expenditures must account for membrane replacement cycles, which differ significantly across materials. Testing in simulated coal flue gas environments reveals that conventional polymeric membranes require replacement every 2-3 years, while advanced composite membranes can extend service life to 4-6 years, substantially reducing lifetime costs despite higher initial investment.

Energy consumption represents another critical cost factor. Comparative testing demonstrates that pressure-driven membrane systems consume 0.2-0.4 kWh per ton of CO₂ captured, whereas conventional amine scrubbing technologies require 0.8-1.2 kWh for equivalent performance. This energy differential translates to approximately $500,000-750,000 in annual savings for a 500MW coal power plant.

Regulatory compliance benefits must also factor into the analysis. Advanced membrane systems capable of removing multiple pollutants simultaneously (CO₂, SOx, NOx) can eliminate the need for separate treatment systems, potentially saving $1-2 million in capital costs and $300,000-500,000 in annual operational expenses.

Market opportunities present additional economic advantages. Carbon capture credits, which currently range from $30-70 per ton depending on jurisdiction, can generate significant revenue streams when membrane efficiency exceeds 90% capture rates. Testing indicates that the latest selective membranes can achieve 92-95% capture efficiency under optimized conditions.

Return on investment calculations based on comparative testing suggest that advanced membrane systems typically achieve payback periods of 4-7 years, compared to 8-12 years for conventional scrubbing technologies. This favorable economic profile is further enhanced when accounting for potential carbon tax avoidance, which could range from $40-120 per ton of CO₂ by 2030 according to current policy projections.

Sensitivity analysis reveals that membrane performance degradation rates in actual coal flue gas conditions represent the most significant risk factor affecting long-term economics. Laboratory testing under accelerated aging conditions indicates that membrane selectivity typically decreases by 5-15% annually, necessitating careful monitoring and maintenance protocols to maintain optimal cost-benefit ratios throughout system lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!