Comparing V8 Engines with Other Engine Types

JUL 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V8 Engine Evolution

The V8 engine, a type of internal combustion engine with eight cylinders arranged in a V configuration, has undergone significant evolution since its inception. This evolution has been driven by the constant pursuit of improved performance, fuel efficiency, and environmental sustainability in the automotive industry.

In the early days of V8 engines, they were primarily used in high-performance and luxury vehicles due to their power output and smooth operation. The initial designs focused on maximizing horsepower and torque, often at the expense of fuel efficiency. These early V8s were characterized by large displacements and relatively simple valve trains.

As environmental concerns grew and fuel prices increased, the evolution of V8 engines shifted towards improving efficiency without sacrificing performance. This led to the development of technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. These advancements allowed V8 engines to deliver power when needed while conserving fuel during less demanding driving conditions.

The introduction of turbocharging and supercharging technologies marked another significant milestone in V8 engine evolution. These forced induction systems enabled manufacturers to extract more power from smaller displacement engines, a concept known as "downsizing." This trend allowed V8 engines to maintain their performance characteristics while reducing overall engine size and weight.

In recent years, the focus has shifted towards hybridization and electrification. Many modern V8 engines are now part of hybrid powertrains, combining the traditional internal combustion engine with electric motors. This approach not only improves fuel efficiency but also enhances performance through instant torque delivery from electric motors.

Advanced materials and manufacturing techniques have also played a crucial role in V8 engine evolution. The use of lightweight alloys, improved casting methods, and precision machining has resulted in engines that are more compact, lighter, and capable of higher operating temperatures and pressures.

The integration of sophisticated engine management systems and electronic controls has further refined V8 engine performance. These systems optimize fuel delivery, ignition timing, and other parameters in real-time, ensuring optimal efficiency and power output across various operating conditions.

As emissions regulations become increasingly stringent, V8 engine evolution has also focused on reducing harmful exhaust emissions. Technologies such as advanced catalytic converters, particulate filters, and exhaust gas recirculation systems have been developed to meet these challenges while maintaining the distinctive character of V8 engines.

In the early days of V8 engines, they were primarily used in high-performance and luxury vehicles due to their power output and smooth operation. The initial designs focused on maximizing horsepower and torque, often at the expense of fuel efficiency. These early V8s were characterized by large displacements and relatively simple valve trains.

As environmental concerns grew and fuel prices increased, the evolution of V8 engines shifted towards improving efficiency without sacrificing performance. This led to the development of technologies such as variable valve timing, direct fuel injection, and cylinder deactivation. These advancements allowed V8 engines to deliver power when needed while conserving fuel during less demanding driving conditions.

The introduction of turbocharging and supercharging technologies marked another significant milestone in V8 engine evolution. These forced induction systems enabled manufacturers to extract more power from smaller displacement engines, a concept known as "downsizing." This trend allowed V8 engines to maintain their performance characteristics while reducing overall engine size and weight.

In recent years, the focus has shifted towards hybridization and electrification. Many modern V8 engines are now part of hybrid powertrains, combining the traditional internal combustion engine with electric motors. This approach not only improves fuel efficiency but also enhances performance through instant torque delivery from electric motors.

Advanced materials and manufacturing techniques have also played a crucial role in V8 engine evolution. The use of lightweight alloys, improved casting methods, and precision machining has resulted in engines that are more compact, lighter, and capable of higher operating temperatures and pressures.

The integration of sophisticated engine management systems and electronic controls has further refined V8 engine performance. These systems optimize fuel delivery, ignition timing, and other parameters in real-time, ensuring optimal efficiency and power output across various operating conditions.

As emissions regulations become increasingly stringent, V8 engine evolution has also focused on reducing harmful exhaust emissions. Technologies such as advanced catalytic converters, particulate filters, and exhaust gas recirculation systems have been developed to meet these challenges while maintaining the distinctive character of V8 engines.

Market Demand Analysis

The market demand for V8 engines has been steadily evolving in recent years, driven by a complex interplay of factors including environmental regulations, consumer preferences, and technological advancements. While V8 engines have long been associated with high-performance vehicles and luxury automobiles, their market share has been facing challenges due to increasing emphasis on fuel efficiency and reduced emissions.

In the automotive sector, there has been a noticeable shift towards smaller, more efficient engines, including turbocharged four-cylinder and six-cylinder options. This trend is particularly evident in markets with stringent emissions regulations, such as Europe and parts of Asia. However, the demand for V8 engines remains strong in certain segments, particularly in North America, where large trucks and SUVs continue to be popular.

The performance car market still shows a significant appetite for V8 engines, especially in high-end sports cars and muscle cars. Manufacturers like Ferrari, Lamborghini, and Chevrolet continue to offer V8 options in their flagship models, catering to enthusiasts who value the distinctive sound and power delivery characteristics of these engines.

In the commercial vehicle sector, V8 engines maintain a strong presence in heavy-duty trucks and specialized vehicles where high torque output is crucial. This segment values the reliability and power density that V8 configurations can provide, especially for long-haul transportation and construction applications.

The marine industry also represents a notable market for V8 engines, particularly in high-performance boats and larger vessels. The combination of power and durability offered by V8 engines makes them well-suited for marine applications, where reliability under demanding conditions is paramount.

Despite these pockets of demand, the overall market trend is moving towards alternative powertrains. Electric vehicles (EVs) and hybrid systems are gaining market share rapidly, driven by advancements in battery technology and increasing consumer acceptance. This shift is particularly pronounced in the passenger car segment, where many manufacturers are phasing out V8 options in favor of electrified powertrains.

The luxury car market, traditionally a stronghold for V8 engines, is also witnessing a gradual transition. While V8s are still offered in many high-end models, there is an increasing focus on plug-in hybrid and fully electric options, even among brands known for their V8 heritage.

Looking ahead, the market demand for V8 engines is likely to become more niche-focused. While they may continue to play a role in specific applications where their characteristics are highly valued, their overall market share is expected to decline as alternative technologies become more prevalent and regulatory pressures increase.

In the automotive sector, there has been a noticeable shift towards smaller, more efficient engines, including turbocharged four-cylinder and six-cylinder options. This trend is particularly evident in markets with stringent emissions regulations, such as Europe and parts of Asia. However, the demand for V8 engines remains strong in certain segments, particularly in North America, where large trucks and SUVs continue to be popular.

The performance car market still shows a significant appetite for V8 engines, especially in high-end sports cars and muscle cars. Manufacturers like Ferrari, Lamborghini, and Chevrolet continue to offer V8 options in their flagship models, catering to enthusiasts who value the distinctive sound and power delivery characteristics of these engines.

In the commercial vehicle sector, V8 engines maintain a strong presence in heavy-duty trucks and specialized vehicles where high torque output is crucial. This segment values the reliability and power density that V8 configurations can provide, especially for long-haul transportation and construction applications.

The marine industry also represents a notable market for V8 engines, particularly in high-performance boats and larger vessels. The combination of power and durability offered by V8 engines makes them well-suited for marine applications, where reliability under demanding conditions is paramount.

Despite these pockets of demand, the overall market trend is moving towards alternative powertrains. Electric vehicles (EVs) and hybrid systems are gaining market share rapidly, driven by advancements in battery technology and increasing consumer acceptance. This shift is particularly pronounced in the passenger car segment, where many manufacturers are phasing out V8 options in favor of electrified powertrains.

The luxury car market, traditionally a stronghold for V8 engines, is also witnessing a gradual transition. While V8s are still offered in many high-end models, there is an increasing focus on plug-in hybrid and fully electric options, even among brands known for their V8 heritage.

Looking ahead, the market demand for V8 engines is likely to become more niche-focused. While they may continue to play a role in specific applications where their characteristics are highly valued, their overall market share is expected to decline as alternative technologies become more prevalent and regulatory pressures increase.

Engine Tech Landscape

The engine technology landscape has undergone significant evolution over the past century, with various engine types emerging to meet diverse performance and efficiency requirements. V8 engines, characterized by their V-shaped configuration of eight cylinders, have been a prominent player in this landscape, particularly in high-performance and luxury vehicles.

The development of engine technology has been driven by several key factors, including the pursuit of increased power output, improved fuel efficiency, and reduced emissions. These objectives have led to continuous innovations in engine design, materials, and control systems. In recent decades, environmental concerns and stringent regulations have further accelerated the pace of technological advancements in the automotive industry.

V8 engines have maintained their relevance in this evolving landscape due to their ability to deliver high power and torque while offering relatively smooth operation. However, they face increasing competition from alternative engine configurations and propulsion technologies. Inline-four and V6 engines have gained popularity for their balance of performance and efficiency, while turbocharged variants have allowed smaller engines to achieve power outputs previously associated with larger displacements.

Hybrid powertrains have emerged as a significant trend, combining internal combustion engines with electric motors to optimize fuel economy and reduce emissions. This has led to the development of hybrid V8 systems, allowing manufacturers to retain the performance characteristics of V8 engines while addressing efficiency concerns.

Concurrently, the rise of electric vehicles has introduced a paradigm shift in the engine technology landscape. Electric motors offer instant torque, zero direct emissions, and simplified powertrains, challenging the traditional dominance of internal combustion engines, including V8s.

Advanced materials and manufacturing techniques have played a crucial role in enhancing engine performance across all configurations. Lightweight alloys, composite materials, and precision manufacturing have enabled engineers to push the boundaries of engine design, improving power-to-weight ratios and thermal efficiency.

The integration of sophisticated electronic control systems and sensors has revolutionized engine management, allowing for precise control of fuel injection, ignition timing, and valve actuation. These advancements have benefited all engine types, including V8s, by optimizing performance, fuel efficiency, and emissions control.

Looking ahead, the engine technology landscape is likely to continue evolving rapidly. While V8 engines may face challenges in meeting increasingly stringent emissions standards, innovations in areas such as variable compression ratios, advanced turbocharging, and electrification could help extend their viability. The comparison between V8 engines and other engine types will increasingly focus on their ability to meet regulatory requirements while satisfying consumer demands for performance, efficiency, and driving experience.

The development of engine technology has been driven by several key factors, including the pursuit of increased power output, improved fuel efficiency, and reduced emissions. These objectives have led to continuous innovations in engine design, materials, and control systems. In recent decades, environmental concerns and stringent regulations have further accelerated the pace of technological advancements in the automotive industry.

V8 engines have maintained their relevance in this evolving landscape due to their ability to deliver high power and torque while offering relatively smooth operation. However, they face increasing competition from alternative engine configurations and propulsion technologies. Inline-four and V6 engines have gained popularity for their balance of performance and efficiency, while turbocharged variants have allowed smaller engines to achieve power outputs previously associated with larger displacements.

Hybrid powertrains have emerged as a significant trend, combining internal combustion engines with electric motors to optimize fuel economy and reduce emissions. This has led to the development of hybrid V8 systems, allowing manufacturers to retain the performance characteristics of V8 engines while addressing efficiency concerns.

Concurrently, the rise of electric vehicles has introduced a paradigm shift in the engine technology landscape. Electric motors offer instant torque, zero direct emissions, and simplified powertrains, challenging the traditional dominance of internal combustion engines, including V8s.

Advanced materials and manufacturing techniques have played a crucial role in enhancing engine performance across all configurations. Lightweight alloys, composite materials, and precision manufacturing have enabled engineers to push the boundaries of engine design, improving power-to-weight ratios and thermal efficiency.

The integration of sophisticated electronic control systems and sensors has revolutionized engine management, allowing for precise control of fuel injection, ignition timing, and valve actuation. These advancements have benefited all engine types, including V8s, by optimizing performance, fuel efficiency, and emissions control.

Looking ahead, the engine technology landscape is likely to continue evolving rapidly. While V8 engines may face challenges in meeting increasingly stringent emissions standards, innovations in areas such as variable compression ratios, advanced turbocharging, and electrification could help extend their viability. The comparison between V8 engines and other engine types will increasingly focus on their ability to meet regulatory requirements while satisfying consumer demands for performance, efficiency, and driving experience.

Current V8 Solutions

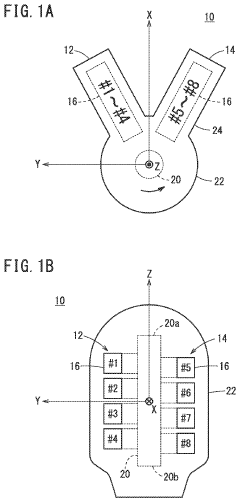

01 V8 Engine Design and Configuration

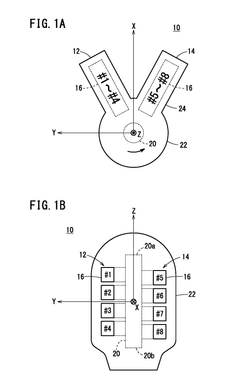

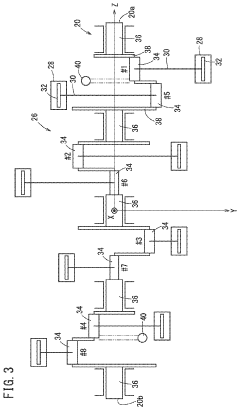

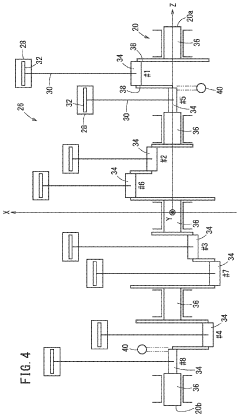

V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design while providing high power output. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.- V8 Engine Design and Configuration: V8 engines are designed with eight cylinders arranged in two banks of four, forming a V-shape. This configuration allows for a compact design, improved power output, and better balance compared to inline engines. Various aspects of V8 engine design, including cylinder arrangement, crankshaft configuration, and valve train systems, are continuously improved to enhance performance and efficiency.

- Fuel Injection and Combustion Systems: Advanced fuel injection and combustion systems are crucial for optimizing V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery, air-fuel mixture formation, and combustion control contribute to increased power output, reduced emissions, and improved fuel efficiency in V8 engines.

- Turbocharging and Supercharging: Forced induction systems, such as turbochargers and superchargers, are frequently used in V8 engines to boost power output and efficiency. These systems compress the intake air, allowing more fuel to be burned and increasing engine power. Advanced turbocharging and supercharging technologies, including variable geometry turbochargers and electric superchargers, are being developed to further enhance V8 engine performance.

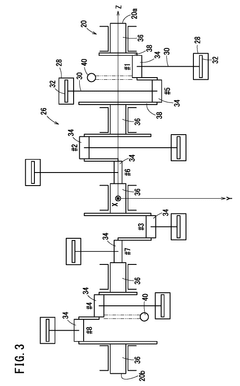

- Engine Management and Control Systems: Sophisticated engine management and control systems are essential for optimizing V8 engine performance, efficiency, and emissions. These systems incorporate advanced sensors, actuators, and electronic control units to monitor and adjust various engine parameters in real-time. Developments in engine control software, adaptive learning algorithms, and integration with vehicle systems contribute to improved V8 engine operation across different driving conditions.

- Materials and Manufacturing Techniques: Advancements in materials science and manufacturing techniques play a crucial role in V8 engine development. Lightweight materials, such as aluminum alloys and composites, are used to reduce engine weight and improve power-to-weight ratios. Innovative manufacturing processes, including 3D printing and advanced casting techniques, enable the production of complex engine components with improved strength, durability, and thermal management properties.

02 Fuel Injection and Combustion Systems

Advanced fuel injection and combustion systems are crucial for optimizing V8 engine performance. These systems include direct injection, variable valve timing, and cylinder deactivation technologies. Improvements in fuel delivery and combustion processes aim to increase power output while reducing fuel consumption and emissions.Expand Specific Solutions03 Turbocharging and Supercharging

Forced induction systems, such as turbochargers and superchargers, are frequently used in V8 engines to boost power output. These systems compress the intake air, allowing more fuel to be burned and increasing engine efficiency. Various designs and configurations of turbochargers and superchargers are developed to suit different V8 engine applications.Expand Specific Solutions04 Engine Block and Component Materials

The selection of materials for V8 engine blocks and components is critical for performance and durability. Advanced materials, such as high-strength alloys and composites, are used to reduce weight while maintaining structural integrity. Innovations in manufacturing processes and material science contribute to the development of more efficient and reliable V8 engines.Expand Specific Solutions05 Cooling and Lubrication Systems

Effective cooling and lubrication systems are essential for maintaining optimal V8 engine performance and longevity. Innovations in these areas include advanced coolant formulations, improved oil circulation systems, and more efficient heat exchangers. These developments aim to enhance thermal management and reduce friction within the engine.Expand Specific Solutions

Key Engine Manufacturers

The competition landscape for comparing V8 engines with other engine types is characterized by a mature market with established players and ongoing technological advancements. The global automotive engine market, valued at over $200 billion, is experiencing a shift towards more efficient and environmentally friendly solutions. Major manufacturers like Honda, BMW, Toyota, Ford, and GM are investing heavily in research and development to improve V8 engines and explore alternative technologies. These companies are at various stages of technological maturity, with some focusing on refining traditional V8 designs while others are developing hybrid and electric powertrains. The market is seeing increased competition from emerging players and alternative engine configurations, driving innovation and efficiency improvements across the industry.

Honda Motor Co., Ltd.

Technical Solution: Honda's V8 engine technology focuses on high-performance applications, particularly in their luxury Acura brand and racing divisions. Their V8 engines feature advanced variable valve timing and lift electronic control (VTEC) system, which optimizes valve timing and lift for improved performance and efficiency across a wide range of engine speeds[1]. Honda's V8 engines also incorporate direct fuel injection and cylinder deactivation technologies, allowing for a balance between power and fuel economy[2]. Compared to other engine types, Honda's V8 engines offer a combination of smooth power delivery and relatively compact packaging, making them suitable for high-end vehicles and performance applications[3].

Strengths: High power output, smooth operation, and advanced technologies for improved efficiency. Weaknesses: Higher fuel consumption compared to smaller engines, increased complexity, and higher production costs.

Toyota Motor Corp.

Technical Solution: Toyota's approach to V8 engines emphasizes reliability and durability, particularly in their truck and SUV applications. Their V8 engines feature dual overhead camshafts (DOHC) and variable valve timing with intelligence (VVT-i) for improved performance and efficiency[4]. Toyota has also developed a hybrid V8 system for their Lexus brand, combining a V8 gasoline engine with electric motors for enhanced power and reduced fuel consumption[5]. In comparison to other engine types, Toyota's V8 engines offer a balance of power, torque, and longevity, making them well-suited for heavy-duty applications and luxury vehicles[6].

Strengths: Proven reliability, strong torque output, and adaptability to hybrid systems. Weaknesses: Generally lower fuel efficiency compared to smaller engines and increased weight.

V8 Tech Innovations

V8 engine

PatentWO2021171405A1

Innovation

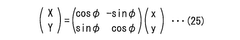

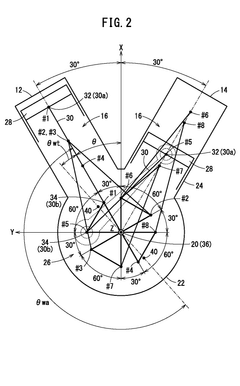

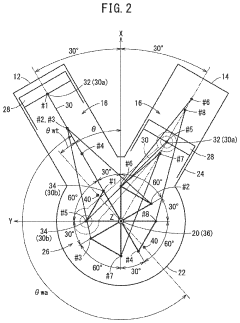

- The engine is configured with a 60° bank angle, where crank pins on one bank are arranged at 90° intervals and offset by 60° from the other bank, allowing for cancellation of the primary inertia couple without additional special parts, and the ignition timing is set to achieve balanced explosions similar to conventional V8 engines.

V8 engine

PatentActiveUS20230109196A1

Innovation

- The V8 engine configuration features crank pins arranged at 90° intervals on one bank and offset by 60° on the other bank, allowing for cancellation of primary inertia couples without additional specialized components by optimizing the arrangement of crank pins and connecting rods.

Emissions Regulations

Emissions regulations have become increasingly stringent worldwide, significantly impacting the automotive industry and engine design. For V8 engines and other engine types, these regulations have driven substantial changes in technology and performance characteristics. The primary focus of emissions regulations is to reduce harmful pollutants such as carbon dioxide (CO2), nitrogen oxides (NOx), particulate matter (PM), and hydrocarbons (HC).

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) set the standards for vehicle emissions. The European Union has its own set of regulations, known as Euro standards, which have progressively tightened since their introduction in 1992. Other countries, including China, Japan, and India, have also implemented similar regulatory frameworks.

These regulations have led to the development and implementation of various technologies across different engine types. For V8 engines, manufacturers have employed strategies such as direct fuel injection, variable valve timing, and cylinder deactivation to improve fuel efficiency and reduce emissions. Other engine types, like four-cylinder and six-cylinder engines, have seen similar advancements, often with the addition of turbocharging to maintain power output while reducing engine size.

Hybrid and electric powertrains have gained prominence as alternatives to traditional internal combustion engines, partly due to their ability to meet stricter emissions standards. This shift has put pressure on V8 engines, which typically consume more fuel and produce higher emissions compared to smaller engine configurations.

The impact of emissions regulations on V8 engines has been particularly pronounced in the performance and luxury vehicle segments. Manufacturers have had to balance the demand for high-performance V8 engines with the need to meet increasingly stringent emissions targets. This has resulted in the development of more efficient V8 designs, as well as the gradual reduction of V8 offerings in some vehicle lineups.

Looking ahead, the trend towards electrification and the potential for zero-emission vehicle mandates in some regions may further challenge the viability of V8 engines in the long term. However, advancements in fuel technology, such as synthetic fuels and hydrogen combustion, may provide new avenues for V8 engines to meet future emissions requirements while maintaining their distinctive performance characteristics.

In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) set the standards for vehicle emissions. The European Union has its own set of regulations, known as Euro standards, which have progressively tightened since their introduction in 1992. Other countries, including China, Japan, and India, have also implemented similar regulatory frameworks.

These regulations have led to the development and implementation of various technologies across different engine types. For V8 engines, manufacturers have employed strategies such as direct fuel injection, variable valve timing, and cylinder deactivation to improve fuel efficiency and reduce emissions. Other engine types, like four-cylinder and six-cylinder engines, have seen similar advancements, often with the addition of turbocharging to maintain power output while reducing engine size.

Hybrid and electric powertrains have gained prominence as alternatives to traditional internal combustion engines, partly due to their ability to meet stricter emissions standards. This shift has put pressure on V8 engines, which typically consume more fuel and produce higher emissions compared to smaller engine configurations.

The impact of emissions regulations on V8 engines has been particularly pronounced in the performance and luxury vehicle segments. Manufacturers have had to balance the demand for high-performance V8 engines with the need to meet increasingly stringent emissions targets. This has resulted in the development of more efficient V8 designs, as well as the gradual reduction of V8 offerings in some vehicle lineups.

Looking ahead, the trend towards electrification and the potential for zero-emission vehicle mandates in some regions may further challenge the viability of V8 engines in the long term. However, advancements in fuel technology, such as synthetic fuels and hydrogen combustion, may provide new avenues for V8 engines to meet future emissions requirements while maintaining their distinctive performance characteristics.

Fuel Efficiency Metrics

Fuel efficiency is a critical metric when comparing V8 engines to other engine types. It measures the amount of fuel consumed per unit of distance traveled or work performed. For V8 engines, fuel efficiency is often expressed in miles per gallon (MPG) or liters per 100 kilometers (L/100km). These metrics allow for direct comparisons between different engine configurations and sizes.

V8 engines, known for their power and performance, have historically been associated with lower fuel efficiency compared to smaller engine types. However, advancements in technology have significantly improved their efficiency in recent years. Modern V8 engines often employ technologies such as variable valve timing, direct fuel injection, and cylinder deactivation to optimize fuel consumption.

When comparing V8 engines to other engine types, it's essential to consider the specific application and driving conditions. In highway driving, V8 engines can achieve competitive fuel efficiency due to their ability to operate at lower RPMs while maintaining higher speeds. However, in city driving with frequent stops and starts, smaller engines typically have an advantage in fuel economy.

Another important metric for comparing fuel efficiency is the brake specific fuel consumption (BSFC), which measures the rate of fuel consumption divided by the power output. This metric is particularly useful for comparing engines of different sizes and configurations, as it provides a normalized measure of efficiency.

The energy density of the fuel used also plays a crucial role in efficiency comparisons. Diesel engines, for instance, often achieve better fuel efficiency than gasoline engines due to the higher energy content of diesel fuel and the higher compression ratios used in diesel engines.

Hybrid and electric powertrains have introduced new metrics for efficiency comparisons. For hybrid vehicles, which may combine a V8 engine with electric motors, metrics such as combined MPG or MPGe (miles per gallon equivalent) are used to account for both fuel and electricity consumption. These metrics allow for a more comprehensive comparison of overall energy efficiency across different powertrain types.

It's important to note that fuel efficiency metrics should be considered alongside other performance parameters, such as power output, torque, and emissions. A holistic approach to engine comparison ensures a balanced assessment of the strengths and weaknesses of V8 engines relative to other engine types across various applications and use cases.

V8 engines, known for their power and performance, have historically been associated with lower fuel efficiency compared to smaller engine types. However, advancements in technology have significantly improved their efficiency in recent years. Modern V8 engines often employ technologies such as variable valve timing, direct fuel injection, and cylinder deactivation to optimize fuel consumption.

When comparing V8 engines to other engine types, it's essential to consider the specific application and driving conditions. In highway driving, V8 engines can achieve competitive fuel efficiency due to their ability to operate at lower RPMs while maintaining higher speeds. However, in city driving with frequent stops and starts, smaller engines typically have an advantage in fuel economy.

Another important metric for comparing fuel efficiency is the brake specific fuel consumption (BSFC), which measures the rate of fuel consumption divided by the power output. This metric is particularly useful for comparing engines of different sizes and configurations, as it provides a normalized measure of efficiency.

The energy density of the fuel used also plays a crucial role in efficiency comparisons. Diesel engines, for instance, often achieve better fuel efficiency than gasoline engines due to the higher energy content of diesel fuel and the higher compression ratios used in diesel engines.

Hybrid and electric powertrains have introduced new metrics for efficiency comparisons. For hybrid vehicles, which may combine a V8 engine with electric motors, metrics such as combined MPG or MPGe (miles per gallon equivalent) are used to account for both fuel and electricity consumption. These metrics allow for a more comprehensive comparison of overall energy efficiency across different powertrain types.

It's important to note that fuel efficiency metrics should be considered alongside other performance parameters, such as power output, torque, and emissions. A holistic approach to engine comparison ensures a balanced assessment of the strengths and weaknesses of V8 engines relative to other engine types across various applications and use cases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!