Turbo vs. supercharger in LM7 engine which is superior?

AUG 13, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LM7 Forced Induction Background and Objectives

The LM7 engine, a member of the GM Gen III small-block V8 family, has been a popular choice for performance enthusiasts since its introduction in 1999. As the automotive industry continues to evolve, the demand for increased power and efficiency has led to a growing interest in forced induction systems for the LM7 engine. This technical research report aims to explore the comparison between turbochargers and superchargers in enhancing LM7 engine performance.

Forced induction systems have been utilized in automotive applications for decades, with both turbochargers and superchargers offering distinct advantages in boosting engine output. The LM7 engine, with its robust design and 5.3-liter displacement, provides an excellent platform for forced induction modifications. Understanding the historical context and technological advancements in forced induction systems is crucial for evaluating their potential impact on LM7 engine performance.

The primary objective of this research is to conduct a comprehensive analysis of turbochargers and superchargers when applied to the LM7 engine. This includes examining the technical principles behind each forced induction method, their integration challenges, and the resulting performance characteristics. By comparing these two technologies, we aim to identify the most suitable forced induction solution for LM7 engine applications across various performance criteria.

Key areas of focus in this study include power output, torque delivery, throttle response, fuel efficiency, and overall drivability. Additionally, we will consider factors such as installation complexity, maintenance requirements, and long-term reliability. This holistic approach will provide valuable insights for both enthusiasts and engineers seeking to optimize LM7 engine performance through forced induction.

As the automotive industry continues to push the boundaries of engine efficiency and power density, forced induction systems play an increasingly critical role. The findings of this research will not only benefit LM7 engine applications but also contribute to the broader understanding of forced induction technologies in modern engine design. By exploring the latest advancements in turbocharger and supercharger technologies, we aim to identify potential areas for future innovation and development in the field of forced induction for V8 engines.

Forced induction systems have been utilized in automotive applications for decades, with both turbochargers and superchargers offering distinct advantages in boosting engine output. The LM7 engine, with its robust design and 5.3-liter displacement, provides an excellent platform for forced induction modifications. Understanding the historical context and technological advancements in forced induction systems is crucial for evaluating their potential impact on LM7 engine performance.

The primary objective of this research is to conduct a comprehensive analysis of turbochargers and superchargers when applied to the LM7 engine. This includes examining the technical principles behind each forced induction method, their integration challenges, and the resulting performance characteristics. By comparing these two technologies, we aim to identify the most suitable forced induction solution for LM7 engine applications across various performance criteria.

Key areas of focus in this study include power output, torque delivery, throttle response, fuel efficiency, and overall drivability. Additionally, we will consider factors such as installation complexity, maintenance requirements, and long-term reliability. This holistic approach will provide valuable insights for both enthusiasts and engineers seeking to optimize LM7 engine performance through forced induction.

As the automotive industry continues to push the boundaries of engine efficiency and power density, forced induction systems play an increasingly critical role. The findings of this research will not only benefit LM7 engine applications but also contribute to the broader understanding of forced induction technologies in modern engine design. By exploring the latest advancements in turbocharger and supercharger technologies, we aim to identify potential areas for future innovation and development in the field of forced induction for V8 engines.

Market Analysis for LM7 Performance Upgrades

The market for LM7 engine performance upgrades has shown significant growth in recent years, driven by enthusiasts seeking to enhance the power and efficiency of their vehicles. The LM7, a 5.3L V8 engine commonly found in GM trucks and SUVs, has become a popular platform for modifications due to its robust design and potential for substantial power gains.

Turbochargers and superchargers represent two primary forced induction options for LM7 performance upgrades. The market for these upgrades is characterized by a mix of aftermarket manufacturers, specialized tuning shops, and OEM-style replacement parts. Turbocharger kits for the LM7 have seen increased demand, particularly among drag racing and high-performance street applications. These systems offer significant power gains, often in the range of 100-200 horsepower, depending on supporting modifications and tuning.

Supercharger kits, while less common for the LM7, have carved out a niche market among enthusiasts seeking instant throttle response and linear power delivery. The market for supercharger upgrades is smaller but stable, appealing to drivers who prioritize drivability and low-end torque over maximum horsepower figures.

The overall market size for LM7 forced induction upgrades has been steadily expanding, with annual growth rates estimated in the high single digits. This growth is fueled by the large existing fleet of LM7-equipped vehicles and the engine's reputation for reliability and tunability. Online retail channels and specialized performance shops have played a crucial role in market expansion, providing easier access to parts and installation services.

Pricing trends indicate a wide range of options, from budget-friendly turbo kits starting around $3,000 to high-end, custom-built forced induction systems exceeding $10,000. The supercharger market typically commands a premium, with most kits priced between $5,000 and $8,000, reflecting the complexity of integration with the LM7 platform.

Consumer preferences in the LM7 upgrade market show a clear bias towards turbocharger systems, driven by their superior power potential and the growing popularity of turbo builds in the performance community. However, superchargers maintain a loyal following among users who value their unique power delivery characteristics and easier installation process.

Looking ahead, the market for LM7 performance upgrades is expected to continue its growth trajectory, with emerging trends pointing towards more efficient turbocharger designs, hybrid turbo-supercharger systems, and increased integration of electronic boost control and engine management solutions. These advancements are likely to further expand the market, attracting both hardcore enthusiasts and casual performance seekers to the world of forced induction LM7 upgrades.

Turbochargers and superchargers represent two primary forced induction options for LM7 performance upgrades. The market for these upgrades is characterized by a mix of aftermarket manufacturers, specialized tuning shops, and OEM-style replacement parts. Turbocharger kits for the LM7 have seen increased demand, particularly among drag racing and high-performance street applications. These systems offer significant power gains, often in the range of 100-200 horsepower, depending on supporting modifications and tuning.

Supercharger kits, while less common for the LM7, have carved out a niche market among enthusiasts seeking instant throttle response and linear power delivery. The market for supercharger upgrades is smaller but stable, appealing to drivers who prioritize drivability and low-end torque over maximum horsepower figures.

The overall market size for LM7 forced induction upgrades has been steadily expanding, with annual growth rates estimated in the high single digits. This growth is fueled by the large existing fleet of LM7-equipped vehicles and the engine's reputation for reliability and tunability. Online retail channels and specialized performance shops have played a crucial role in market expansion, providing easier access to parts and installation services.

Pricing trends indicate a wide range of options, from budget-friendly turbo kits starting around $3,000 to high-end, custom-built forced induction systems exceeding $10,000. The supercharger market typically commands a premium, with most kits priced between $5,000 and $8,000, reflecting the complexity of integration with the LM7 platform.

Consumer preferences in the LM7 upgrade market show a clear bias towards turbocharger systems, driven by their superior power potential and the growing popularity of turbo builds in the performance community. However, superchargers maintain a loyal following among users who value their unique power delivery characteristics and easier installation process.

Looking ahead, the market for LM7 performance upgrades is expected to continue its growth trajectory, with emerging trends pointing towards more efficient turbocharger designs, hybrid turbo-supercharger systems, and increased integration of electronic boost control and engine management solutions. These advancements are likely to further expand the market, attracting both hardcore enthusiasts and casual performance seekers to the world of forced induction LM7 upgrades.

Turbocharger vs Supercharger Technical Challenges

The comparison of turbochargers and superchargers in LM7 engine performance presents several technical challenges that engineers must address. One of the primary difficulties lies in the integration of these forced induction systems with the existing LM7 engine architecture. The LM7, being a naturally aspirated engine by design, requires significant modifications to accommodate either a turbocharger or a supercharger effectively.

For turbochargers, the main challenge is managing exhaust gas flow and heat. The LM7's stock exhaust manifolds are not optimized for turbocharging, necessitating custom exhaust manifolds or headers to efficiently direct exhaust gases to the turbine. Additionally, the increased exhaust temperatures can lead to thermal management issues, requiring upgraded cooling systems and heat-resistant materials.

Superchargers, while easier to integrate mechanically, present their own set of challenges. The belt-driven nature of most superchargers for the LM7 puts additional stress on the engine's accessory drive system. This often requires upgrading the belt, tensioner, and potentially the crankshaft pulley to handle the increased load. Furthermore, the parasitic power loss from driving the supercharger can be significant, affecting overall engine efficiency.

Both systems face challenges in terms of air intake design. The increased airflow demands necessitate larger, more efficient air filtration systems and often require modifications to the engine bay to accommodate larger intake piping. Intercooling becomes crucial for both turbochargers and superchargers to manage charge air temperatures, but finding space for an efficient intercooler system in the LM7's engine bay can be problematic.

Fuel system upgrades are another common challenge. The increased air volume from forced induction requires a corresponding increase in fuel delivery. This often means upgrading fuel injectors, fuel pumps, and potentially the fuel rail to ensure adequate fuel supply under high boost conditions. Calibrating the fuel system to work harmoniously with the forced induction setup is a complex task that requires extensive tuning.

Engine management presents a significant technical hurdle. The stock ECU of the LM7 is not designed to handle forced induction, necessitating either a complete ECU replacement or significant reprogramming. Tuning the engine management system to optimize performance while maintaining reliability is a delicate balance, requiring expertise in both hardware and software aspects of engine control.

Lastly, durability concerns arise with both turbocharging and supercharging. The increased cylinder pressures and temperatures can stress engine components beyond their original design parameters. This often leads to the need for strengthened internal components such as forged pistons, stronger connecting rods, and upgraded head gaskets to ensure long-term reliability under forced induction.

For turbochargers, the main challenge is managing exhaust gas flow and heat. The LM7's stock exhaust manifolds are not optimized for turbocharging, necessitating custom exhaust manifolds or headers to efficiently direct exhaust gases to the turbine. Additionally, the increased exhaust temperatures can lead to thermal management issues, requiring upgraded cooling systems and heat-resistant materials.

Superchargers, while easier to integrate mechanically, present their own set of challenges. The belt-driven nature of most superchargers for the LM7 puts additional stress on the engine's accessory drive system. This often requires upgrading the belt, tensioner, and potentially the crankshaft pulley to handle the increased load. Furthermore, the parasitic power loss from driving the supercharger can be significant, affecting overall engine efficiency.

Both systems face challenges in terms of air intake design. The increased airflow demands necessitate larger, more efficient air filtration systems and often require modifications to the engine bay to accommodate larger intake piping. Intercooling becomes crucial for both turbochargers and superchargers to manage charge air temperatures, but finding space for an efficient intercooler system in the LM7's engine bay can be problematic.

Fuel system upgrades are another common challenge. The increased air volume from forced induction requires a corresponding increase in fuel delivery. This often means upgrading fuel injectors, fuel pumps, and potentially the fuel rail to ensure adequate fuel supply under high boost conditions. Calibrating the fuel system to work harmoniously with the forced induction setup is a complex task that requires extensive tuning.

Engine management presents a significant technical hurdle. The stock ECU of the LM7 is not designed to handle forced induction, necessitating either a complete ECU replacement or significant reprogramming. Tuning the engine management system to optimize performance while maintaining reliability is a delicate balance, requiring expertise in both hardware and software aspects of engine control.

Lastly, durability concerns arise with both turbocharging and supercharging. The increased cylinder pressures and temperatures can stress engine components beyond their original design parameters. This often leads to the need for strengthened internal components such as forged pistons, stronger connecting rods, and upgraded head gaskets to ensure long-term reliability under forced induction.

Current Turbocharger and Supercharger Solutions for LM7

01 Engine control and optimization

Advanced control systems and algorithms are used to optimize LM7 engine performance. These systems monitor various parameters and adjust engine settings in real-time to improve efficiency, power output, and fuel economy. Techniques include adaptive learning, predictive modeling, and intelligent control strategies.- Engine control and optimization: Various methods and systems for controlling and optimizing LM7 engine performance, including electronic control units, fuel injection strategies, and adaptive learning algorithms to improve efficiency and power output.

- Performance monitoring and diagnostics: Advanced monitoring systems and diagnostic tools for evaluating LM7 engine performance, including real-time data analysis, fault detection, and predictive maintenance capabilities to ensure optimal operation.

- Emissions reduction and environmental compliance: Innovative technologies and strategies for reducing emissions from LM7 engines while maintaining performance, including exhaust gas recirculation systems, catalytic converters, and advanced combustion control techniques.

- Turbocharging and forced induction: Implementation of turbocharging and other forced induction systems to enhance LM7 engine performance, including variable geometry turbochargers, intercoolers, and boost control mechanisms for improved power and efficiency.

- Fuel efficiency improvements: Techniques and technologies for enhancing fuel efficiency in LM7 engines, including advanced fuel injection systems, combustion chamber design optimizations, and friction reduction strategies to maximize performance and economy.

02 Fuel injection and combustion improvements

Enhancements to the fuel injection system and combustion process contribute to improved LM7 engine performance. This includes precise fuel metering, optimized injection timing, and advanced combustion chamber designs. These improvements result in better fuel atomization, more complete combustion, and increased power output.Expand Specific Solutions03 Turbocharging and forced induction

Implementation of turbocharging or other forced induction methods significantly boosts LM7 engine performance. These systems increase air intake, allowing for more fuel to be burned and resulting in higher power output. Advanced turbocharger designs and control strategies optimize boost pressure across different operating conditions.Expand Specific Solutions04 Engine diagnostics and performance monitoring

Sophisticated diagnostic systems and performance monitoring tools are employed to maintain optimal LM7 engine performance. These systems use sensors and data analysis to detect issues, predict maintenance needs, and provide real-time performance feedback. This enables proactive maintenance and performance tuning.Expand Specific Solutions05 Materials and design optimization

Advanced materials and optimized component designs enhance LM7 engine performance. This includes the use of lightweight alloys, improved piston and cylinder designs, and optimized cooling systems. These advancements reduce friction, improve heat dissipation, and increase overall engine efficiency and durability.Expand Specific Solutions

Key Manufacturers in Forced Induction Industry

The competition landscape for turbochargers vs. superchargers in LM7 engine performance is characterized by a mature market with established players and ongoing innovation. Major automotive companies like Ford, BorgWarner, and Eaton dominate the field, leveraging their extensive R&D capabilities and manufacturing expertise. The market size is substantial, driven by the automotive industry's continuous pursuit of improved engine efficiency and performance. Technological advancements are focused on enhancing power output, fuel efficiency, and emissions reduction. Specialized firms like SuperTurbo Technologies and Bostic Motors are also contributing to the sector's development, offering niche solutions and custom applications for specific engine types.

Ford Global Technologies LLC

Technical Solution: While Ford does not directly manufacture the LM7 engine, their EcoBoost technology provides insights into advanced turbocharging solutions applicable to V8 engines like the LM7. Ford's approach involves using smaller, twin turbochargers for improved responsiveness and reduced lag. Their latest generation of turbochargers features low-inertia turbine wheels and electronically actuated wastegates for precise boost control[8]. Ford has also developed an innovative anti-lag system that keeps the turbochargers spooled up during gear changes, maintaining boost pressure and improving overall performance[9]. These technologies could potentially be adapted for use in LM7 engine applications to enhance performance and efficiency.

Strengths: Advanced boost control systems, reduced turbo lag, and potential for improved fuel efficiency. Weaknesses: May require significant modifications to the LM7 engine architecture for implementation.

BorgWarner, Inc.

Technical Solution: BorgWarner's advanced turbocharger technology for the LM7 engine focuses on enhancing performance while improving fuel efficiency. Their latest designs incorporate variable geometry turbochargers (VGT) that adjust vane positions to optimize airflow across different engine speeds[1]. This allows for better low-end torque and reduced turbo lag. BorgWarner has also developed dual-volute turbochargers specifically for V8 engines like the LM7, which can provide up to 10% improvement in transient response[2]. Their eTurbo™ system, which integrates an electric motor with the turbocharger, can further reduce lag and improve overall engine responsiveness[3].

Strengths: Superior boost control, reduced turbo lag, and improved fuel efficiency. Weaknesses: Higher complexity and cost compared to traditional fixed geometry turbochargers.

Core Innovations in Forced Induction for LM7

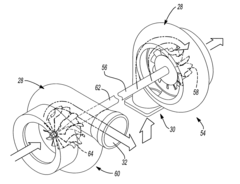

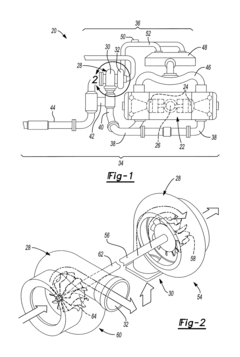

Turbocharger with Electrically Coupled Fully Variable Turbo-Compound Capability and Method of Controlling the Same

PatentActiveUS20160017793A1

Innovation

- A turbocharger apparatus with electrically coupled and fully variable turbo-compound capability, utilizing a planetary gearset to connect a turbine, compressor, and electric machines, allowing for variable rotational speeds and power split, reducing parasitic losses and eliminating torsional vibration transfer, and addressing turbo lag by electrically driving the compressor at low speeds and optimizing power distribution across engine operating ranges.

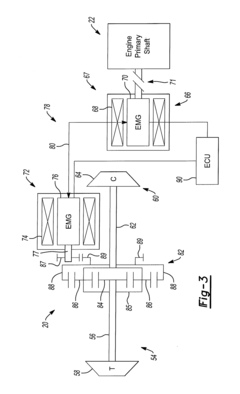

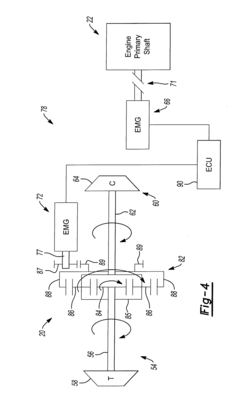

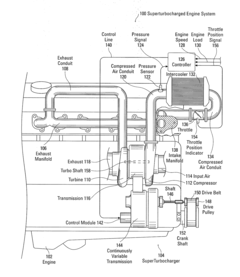

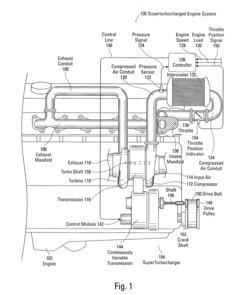

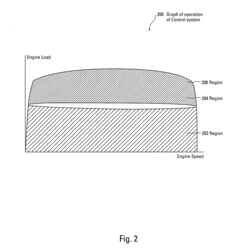

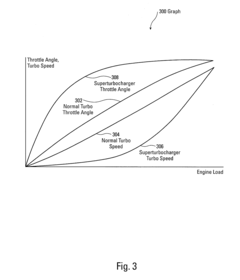

Superturbocharger control systems

PatentActiveUS20120186248A1

Innovation

- A superturbocharged engine control system that utilizes a continuously variable transmission (CVT) to adjust the effective drive ratio based on engine load and throttle position, allowing for efficient turbocharging and turbocompounding, thereby eliminating turbo lag and optimizing energy use.

Emissions Regulations Impact on Forced Induction

Emissions regulations have significantly impacted the development and implementation of forced induction systems in automotive engines, including the LM7 engine. As environmental concerns continue to grow, governments worldwide have implemented increasingly stringent emissions standards, forcing manufacturers to adapt their engine technologies accordingly.

The introduction of more rigorous emissions regulations has led to a shift in the design and application of both turbochargers and superchargers. These forced induction systems, while primarily used to enhance engine performance, now play a crucial role in meeting emissions targets. Manufacturers must balance the desire for increased power output with the need to reduce harmful emissions, particularly nitrogen oxides (NOx) and particulate matter.

Turbochargers have gained popularity in recent years due to their ability to improve fuel efficiency and reduce emissions. By utilizing exhaust gases to drive the compressor, turbochargers can provide a significant boost in power without substantially increasing fuel consumption. This characteristic aligns well with emissions regulations that demand lower CO2 output. Additionally, modern turbocharger designs incorporate variable geometry technology, allowing for optimized performance across a broader range of engine speeds and loads, further enhancing emissions control.

Superchargers, while traditionally favored for their instant throttle response and linear power delivery, have faced challenges in meeting stricter emissions standards. The mechanical nature of superchargers, which draw power directly from the engine, can lead to increased fuel consumption and, consequently, higher emissions. However, advancements in supercharger technology, such as electric-assisted variants, are helping to address these concerns and improve overall efficiency.

The impact of emissions regulations on forced induction systems has also led to the development of hybrid solutions. Some manufacturers have begun implementing electric compressors in conjunction with traditional turbochargers or superchargers. These systems can provide instant boost at low engine speeds, reducing turbo lag and improving overall engine efficiency, while still meeting stringent emissions requirements.

Furthermore, the push for cleaner engines has accelerated research into advanced materials and coatings for forced induction components. These innovations aim to reduce friction, improve heat management, and enhance overall system efficiency, all of which contribute to lower emissions and improved performance.

As emissions regulations continue to evolve, the future of forced induction in engines like the LM7 will likely see further integration with electrification and advanced control systems. This ongoing development will be crucial in meeting increasingly stringent environmental standards while still delivering the performance characteristics that consumers demand.

The introduction of more rigorous emissions regulations has led to a shift in the design and application of both turbochargers and superchargers. These forced induction systems, while primarily used to enhance engine performance, now play a crucial role in meeting emissions targets. Manufacturers must balance the desire for increased power output with the need to reduce harmful emissions, particularly nitrogen oxides (NOx) and particulate matter.

Turbochargers have gained popularity in recent years due to their ability to improve fuel efficiency and reduce emissions. By utilizing exhaust gases to drive the compressor, turbochargers can provide a significant boost in power without substantially increasing fuel consumption. This characteristic aligns well with emissions regulations that demand lower CO2 output. Additionally, modern turbocharger designs incorporate variable geometry technology, allowing for optimized performance across a broader range of engine speeds and loads, further enhancing emissions control.

Superchargers, while traditionally favored for their instant throttle response and linear power delivery, have faced challenges in meeting stricter emissions standards. The mechanical nature of superchargers, which draw power directly from the engine, can lead to increased fuel consumption and, consequently, higher emissions. However, advancements in supercharger technology, such as electric-assisted variants, are helping to address these concerns and improve overall efficiency.

The impact of emissions regulations on forced induction systems has also led to the development of hybrid solutions. Some manufacturers have begun implementing electric compressors in conjunction with traditional turbochargers or superchargers. These systems can provide instant boost at low engine speeds, reducing turbo lag and improving overall engine efficiency, while still meeting stringent emissions requirements.

Furthermore, the push for cleaner engines has accelerated research into advanced materials and coatings for forced induction components. These innovations aim to reduce friction, improve heat management, and enhance overall system efficiency, all of which contribute to lower emissions and improved performance.

As emissions regulations continue to evolve, the future of forced induction in engines like the LM7 will likely see further integration with electrification and advanced control systems. This ongoing development will be crucial in meeting increasingly stringent environmental standards while still delivering the performance characteristics that consumers demand.

Cost-Benefit Analysis of Turbochargers vs Superchargers

When comparing turbochargers and superchargers for the LM7 engine, a cost-benefit analysis is crucial for making an informed decision. The initial cost of a turbocharger system is generally higher than that of a supercharger due to its more complex design and additional components such as intercoolers and wastegates. However, turbochargers often provide better long-term fuel efficiency, which can offset the higher upfront cost over time.

Superchargers, while less expensive initially, tend to consume more engine power to operate, potentially reducing overall efficiency. This power consumption can translate to increased fuel costs over the life of the vehicle. However, superchargers offer instant throttle response and consistent power delivery across the RPM range, which some drivers may find more desirable for certain applications.

Maintenance costs should also be considered. Turbochargers, with their high-temperature operation and oil-cooled bearings, may require more frequent maintenance and potential rebuilds. Superchargers, being mechanically driven, generally have lower maintenance requirements but may need belt replacements periodically.

Performance benefits must be weighed against costs. Turbochargers typically offer higher peak power outputs and better high-altitude performance due to their ability to maintain boost pressure regardless of ambient air density. This can be particularly advantageous for the LM7 engine in varied driving conditions. Superchargers, while providing immediate boost, may have limitations in maximum power output compared to turbochargers.

Fuel economy is another critical factor. Turbochargers can improve fuel efficiency by recovering energy from exhaust gases, especially at highway speeds. Superchargers, however, may slightly decrease fuel economy due to their constant mechanical load on the engine.

Installation complexity and associated labor costs differ between the two systems. Superchargers are often easier to install, potentially reducing labor costs. Turbochargers may require more extensive modifications to the exhaust system and engine management, increasing installation expenses.

Resale value of the vehicle should also be considered. A well-installed turbocharger system might add more value to an LM7-equipped vehicle in the performance market, potentially offsetting some of the initial investment.

In conclusion, while turbochargers generally offer better long-term performance and efficiency benefits for the LM7 engine, they come with higher initial and potential maintenance costs. Superchargers provide a more cost-effective short-term solution with simpler installation but may have higher operating costs and lower peak performance. The optimal choice depends on the specific performance goals, budget constraints, and long-term ownership plans for the LM7-powered vehicle.

Superchargers, while less expensive initially, tend to consume more engine power to operate, potentially reducing overall efficiency. This power consumption can translate to increased fuel costs over the life of the vehicle. However, superchargers offer instant throttle response and consistent power delivery across the RPM range, which some drivers may find more desirable for certain applications.

Maintenance costs should also be considered. Turbochargers, with their high-temperature operation and oil-cooled bearings, may require more frequent maintenance and potential rebuilds. Superchargers, being mechanically driven, generally have lower maintenance requirements but may need belt replacements periodically.

Performance benefits must be weighed against costs. Turbochargers typically offer higher peak power outputs and better high-altitude performance due to their ability to maintain boost pressure regardless of ambient air density. This can be particularly advantageous for the LM7 engine in varied driving conditions. Superchargers, while providing immediate boost, may have limitations in maximum power output compared to turbochargers.

Fuel economy is another critical factor. Turbochargers can improve fuel efficiency by recovering energy from exhaust gases, especially at highway speeds. Superchargers, however, may slightly decrease fuel economy due to their constant mechanical load on the engine.

Installation complexity and associated labor costs differ between the two systems. Superchargers are often easier to install, potentially reducing labor costs. Turbochargers may require more extensive modifications to the exhaust system and engine management, increasing installation expenses.

Resale value of the vehicle should also be considered. A well-installed turbocharger system might add more value to an LM7-equipped vehicle in the performance market, potentially offsetting some of the initial investment.

In conclusion, while turbochargers generally offer better long-term performance and efficiency benefits for the LM7 engine, they come with higher initial and potential maintenance costs. Superchargers provide a more cost-effective short-term solution with simpler installation but may have higher operating costs and lower peak performance. The optimal choice depends on the specific performance goals, budget constraints, and long-term ownership plans for the LM7-powered vehicle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!