Continuous Flow Route Optimization With Bayesian Experimental Design

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Continuous Flow Optimization Background and Objectives

Continuous flow chemistry represents a paradigm shift from traditional batch processing methods in chemical synthesis. This approach involves conducting reactions in continuously flowing streams rather than static vessels, offering unprecedented control over reaction parameters such as mixing, heat transfer, and residence time. The evolution of continuous flow technology dates back to the early 2000s, with significant acceleration in adoption across pharmaceutical, fine chemical, and materials science industries over the past decade.

The technological trajectory has moved from simple single-step reactions to complex multi-step syntheses, enabled by advances in microreactor design, inline analytics, and automation systems. Recent developments have focused on integrating machine learning and artificial intelligence to optimize reaction conditions, representing the cutting edge of this field.

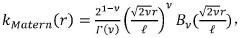

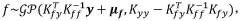

Bayesian experimental design has emerged as a powerful statistical framework for efficiently exploring complex parameter spaces. Unlike traditional Design of Experiments (DoE) approaches, Bayesian methods incorporate prior knowledge and continuously update probability distributions as new data becomes available, making them particularly well-suited for dynamic optimization problems.

The primary objective of continuous flow route optimization with Bayesian experimental design is to develop robust methodologies that can rapidly identify optimal reaction conditions while minimizing experimental iterations. This approach aims to overcome the limitations of conventional optimization techniques, which often require extensive experimentation and resource investment.

Specific technical goals include developing algorithms capable of handling high-dimensional parameter spaces, accommodating multiple competing objectives (yield, purity, sustainability metrics), and incorporating mechanistic understanding with empirical data. Additionally, there is a focus on creating systems that can adapt to changing process conditions and transfer knowledge between related chemical transformations.

The integration of these technologies promises to dramatically reduce development timelines for new chemical processes, potentially transforming the economics of small-volume, high-value chemical production. This has particular relevance for personalized medicine, specialty materials, and on-demand manufacturing paradigms.

Long-term objectives extend beyond optimization to encompass autonomous discovery systems capable of navigating chemical space with minimal human intervention, potentially uncovering novel synthetic pathways and reaction conditions that might otherwise remain undiscovered through traditional approaches.

The technological trajectory has moved from simple single-step reactions to complex multi-step syntheses, enabled by advances in microreactor design, inline analytics, and automation systems. Recent developments have focused on integrating machine learning and artificial intelligence to optimize reaction conditions, representing the cutting edge of this field.

Bayesian experimental design has emerged as a powerful statistical framework for efficiently exploring complex parameter spaces. Unlike traditional Design of Experiments (DoE) approaches, Bayesian methods incorporate prior knowledge and continuously update probability distributions as new data becomes available, making them particularly well-suited for dynamic optimization problems.

The primary objective of continuous flow route optimization with Bayesian experimental design is to develop robust methodologies that can rapidly identify optimal reaction conditions while minimizing experimental iterations. This approach aims to overcome the limitations of conventional optimization techniques, which often require extensive experimentation and resource investment.

Specific technical goals include developing algorithms capable of handling high-dimensional parameter spaces, accommodating multiple competing objectives (yield, purity, sustainability metrics), and incorporating mechanistic understanding with empirical data. Additionally, there is a focus on creating systems that can adapt to changing process conditions and transfer knowledge between related chemical transformations.

The integration of these technologies promises to dramatically reduce development timelines for new chemical processes, potentially transforming the economics of small-volume, high-value chemical production. This has particular relevance for personalized medicine, specialty materials, and on-demand manufacturing paradigms.

Long-term objectives extend beyond optimization to encompass autonomous discovery systems capable of navigating chemical space with minimal human intervention, potentially uncovering novel synthetic pathways and reaction conditions that might otherwise remain undiscovered through traditional approaches.

Market Analysis for Continuous Flow Processing

The continuous flow processing market is experiencing significant growth, driven by increasing demand for more efficient, sustainable, and cost-effective manufacturing processes across multiple industries. The global continuous flow processing market was valued at approximately $1.2 billion in 2021 and is projected to reach $2.5 billion by 2028, growing at a CAGR of 11.3% during the forecast period.

Pharmaceutical and fine chemical industries represent the largest market segments, accounting for over 40% of the total market share. This dominance stems from stringent regulatory requirements for product quality and consistency, as well as the need to reduce manufacturing costs in the face of increasing competition from generic manufacturers and pressure from healthcare systems to lower drug prices.

The food and beverage industry is emerging as a rapidly growing segment for continuous flow processing, with an estimated growth rate of 13.5% annually. This growth is primarily driven by consumer demand for consistent product quality and manufacturers' need to increase production efficiency while maintaining product integrity.

Geographically, North America and Europe currently lead the market with combined market share exceeding 60%, largely due to the presence of established pharmaceutical and chemical manufacturing bases. However, Asia-Pacific is witnessing the fastest growth rate at approximately 14.2% annually, fueled by rapid industrialization, increasing manufacturing activities, and growing investments in R&D infrastructure in countries like China, India, and South Korea.

Key market drivers include increasing pressure to reduce production costs, growing emphasis on sustainable manufacturing practices, and the need for improved process control and product quality. Continuous flow processing offers significant advantages in these areas, including reduced waste generation (up to 25% compared to batch processing), lower energy consumption (15-30% reduction), and enhanced process safety profiles.

The integration of Bayesian experimental design approaches for route optimization represents a high-growth niche within this market, estimated to grow at 16.8% annually. This advanced methodology enables manufacturers to optimize process parameters more efficiently, reducing the number of experiments required by up to 70% compared to traditional design of experiments approaches.

Market challenges include high initial capital investment requirements, technical complexity in implementation, and resistance to change from established manufacturing paradigms. Additionally, regulatory uncertainties regarding validation of continuous processes in highly regulated industries like pharmaceuticals present adoption barriers that technology providers must address.

Pharmaceutical and fine chemical industries represent the largest market segments, accounting for over 40% of the total market share. This dominance stems from stringent regulatory requirements for product quality and consistency, as well as the need to reduce manufacturing costs in the face of increasing competition from generic manufacturers and pressure from healthcare systems to lower drug prices.

The food and beverage industry is emerging as a rapidly growing segment for continuous flow processing, with an estimated growth rate of 13.5% annually. This growth is primarily driven by consumer demand for consistent product quality and manufacturers' need to increase production efficiency while maintaining product integrity.

Geographically, North America and Europe currently lead the market with combined market share exceeding 60%, largely due to the presence of established pharmaceutical and chemical manufacturing bases. However, Asia-Pacific is witnessing the fastest growth rate at approximately 14.2% annually, fueled by rapid industrialization, increasing manufacturing activities, and growing investments in R&D infrastructure in countries like China, India, and South Korea.

Key market drivers include increasing pressure to reduce production costs, growing emphasis on sustainable manufacturing practices, and the need for improved process control and product quality. Continuous flow processing offers significant advantages in these areas, including reduced waste generation (up to 25% compared to batch processing), lower energy consumption (15-30% reduction), and enhanced process safety profiles.

The integration of Bayesian experimental design approaches for route optimization represents a high-growth niche within this market, estimated to grow at 16.8% annually. This advanced methodology enables manufacturers to optimize process parameters more efficiently, reducing the number of experiments required by up to 70% compared to traditional design of experiments approaches.

Market challenges include high initial capital investment requirements, technical complexity in implementation, and resistance to change from established manufacturing paradigms. Additionally, regulatory uncertainties regarding validation of continuous processes in highly regulated industries like pharmaceuticals present adoption barriers that technology providers must address.

Current Challenges in Continuous Flow Route Optimization

Despite significant advancements in continuous flow chemistry, route optimization remains a challenging domain with several persistent obstacles. The integration of Bayesian Experimental Design with continuous flow processes faces computational complexity barriers that limit real-time decision-making capabilities. Current algorithms struggle to efficiently navigate the vast parameter space characteristic of multi-step flow syntheses, often requiring prohibitive computational resources for comprehensive optimization.

Data quality and acquisition present another significant challenge. Flow chemistry generates large volumes of data across multiple parameters simultaneously, but existing sensor technologies frequently lack the precision or sampling rates necessary for accurate Bayesian model updates. This creates a fundamental disconnect between theoretical optimization capabilities and practical implementation.

Model uncertainty quantification remains underdeveloped in the context of continuous flow chemistry. Traditional Bayesian approaches often make simplifying assumptions about reaction kinetics that fail to capture the complex fluid dynamics and mixing phenomena inherent to flow systems. This leads to suboptimal experimental design decisions and reduced efficiency in route exploration.

The multi-objective nature of flow route optimization further complicates the landscape. Researchers must simultaneously balance yield, selectivity, throughput, safety parameters, and sustainability metrics. Current Bayesian frameworks struggle to effectively handle these competing objectives without defaulting to oversimplified weighted-sum approaches that obscure important trade-offs.

Transfer learning between different chemical systems represents another frontier challenge. Knowledge gained from optimizing one continuous flow route rarely transfers effectively to new chemical transformations, necessitating resource-intensive reoptimization for each new target molecule. This significantly limits the scalability of Bayesian optimization approaches across diverse chemical spaces.

Integration with existing manufacturing infrastructure poses practical implementation barriers. Many continuous flow optimization systems remain isolated from broader production environments, creating disconnects between laboratory optimization and industrial deployment. This gap is particularly pronounced when attempting to implement adaptive, Bayesian-driven process control in regulated manufacturing settings.

Lastly, interpretability challenges persist throughout the optimization process. The "black box" nature of many Bayesian optimization algorithms makes it difficult for chemists to extract mechanistic insights from the optimization trajectory. This limits knowledge generation and hinders the development of fundamental understanding that could inform future synthetic route design beyond the specific optimization task.

Data quality and acquisition present another significant challenge. Flow chemistry generates large volumes of data across multiple parameters simultaneously, but existing sensor technologies frequently lack the precision or sampling rates necessary for accurate Bayesian model updates. This creates a fundamental disconnect between theoretical optimization capabilities and practical implementation.

Model uncertainty quantification remains underdeveloped in the context of continuous flow chemistry. Traditional Bayesian approaches often make simplifying assumptions about reaction kinetics that fail to capture the complex fluid dynamics and mixing phenomena inherent to flow systems. This leads to suboptimal experimental design decisions and reduced efficiency in route exploration.

The multi-objective nature of flow route optimization further complicates the landscape. Researchers must simultaneously balance yield, selectivity, throughput, safety parameters, and sustainability metrics. Current Bayesian frameworks struggle to effectively handle these competing objectives without defaulting to oversimplified weighted-sum approaches that obscure important trade-offs.

Transfer learning between different chemical systems represents another frontier challenge. Knowledge gained from optimizing one continuous flow route rarely transfers effectively to new chemical transformations, necessitating resource-intensive reoptimization for each new target molecule. This significantly limits the scalability of Bayesian optimization approaches across diverse chemical spaces.

Integration with existing manufacturing infrastructure poses practical implementation barriers. Many continuous flow optimization systems remain isolated from broader production environments, creating disconnects between laboratory optimization and industrial deployment. This gap is particularly pronounced when attempting to implement adaptive, Bayesian-driven process control in regulated manufacturing settings.

Lastly, interpretability challenges persist throughout the optimization process. The "black box" nature of many Bayesian optimization algorithms makes it difficult for chemists to extract mechanistic insights from the optimization trajectory. This limits knowledge generation and hinders the development of fundamental understanding that could inform future synthetic route design beyond the specific optimization task.

Current Methodologies for Flow Route Optimization

01 Network traffic optimization algorithms

Advanced algorithms are employed to optimize network traffic flow by dynamically adjusting routes based on real-time conditions. These systems analyze network congestion, bandwidth availability, and traffic patterns to determine optimal paths for data transmission. The optimization techniques include predictive modeling, machine learning approaches, and adaptive routing protocols that continuously monitor network performance and make adjustments to maintain efficient data flow across distributed systems.- Network-based route optimization algorithms: Advanced algorithms for optimizing routes in continuous flow networks that consider real-time traffic conditions, network topology, and dynamic constraints. These systems employ machine learning and predictive analytics to calculate optimal paths while minimizing travel time, distance, or energy consumption. The optimization techniques can adapt to changing conditions and provide alternative routes when disruptions occur.

- Continuous flow optimization in manufacturing processes: Methods for optimizing continuous flow in manufacturing and production environments to improve efficiency and reduce bottlenecks. These approaches focus on streamlining production lines, optimizing resource allocation, and ensuring smooth transitions between process stages. The optimization techniques consider factors such as equipment capabilities, material properties, and production constraints to maximize throughput while maintaining quality standards.

- Mobile communication-based route optimization: Systems that leverage mobile communication networks to enable real-time route optimization for vehicles and mobile assets. These solutions utilize cellular networks, device-to-device communication, and mobile edge computing to gather and process location data, traffic information, and movement patterns. The optimization frameworks can dynamically adjust routes based on network conditions and user preferences.

- AI and machine learning for predictive route optimization: Artificial intelligence and machine learning techniques applied to continuous flow route optimization problems. These approaches use historical data, pattern recognition, and predictive modeling to anticipate traffic conditions, demand patterns, and potential disruptions. The AI systems can learn from past routing decisions to continuously improve optimization outcomes and adapt to changing environments.

- Multi-objective optimization for logistics and supply chain: Comprehensive approaches to route optimization in logistics and supply chain operations that balance multiple competing objectives. These methods consider factors such as delivery time windows, vehicle capacity constraints, fuel efficiency, and environmental impact. The optimization frameworks can handle complex scenarios involving multiple pickup and delivery points, fleet heterogeneity, and time-dependent travel conditions.

02 Vehicle route optimization systems

Systems designed to optimize transportation routes for vehicles by considering multiple factors such as traffic conditions, distance, fuel consumption, and time constraints. These solutions employ continuous flow methodologies to dynamically adjust routes as conditions change, providing real-time navigation guidance. The optimization process incorporates historical traffic data, current road conditions, and predictive analytics to determine the most efficient paths for single vehicles or entire fleets.Expand Specific Solutions03 Continuous flow manufacturing process optimization

Methodologies for optimizing production workflows in continuous manufacturing environments by analyzing and adjusting process parameters in real-time. These systems monitor production metrics, resource utilization, and equipment performance to identify bottlenecks and inefficiencies. The optimization techniques include scheduling algorithms, resource allocation strategies, and predictive maintenance approaches that ensure smooth and efficient flow of materials and products through manufacturing facilities.Expand Specific Solutions04 Wireless communication route optimization

Technologies focused on optimizing data transmission routes in wireless communication networks to improve reliability, reduce latency, and enhance bandwidth utilization. These systems continuously monitor signal strength, network load, and connection quality to dynamically select optimal transmission paths. The optimization approaches include adaptive channel selection, multi-path routing protocols, and interference avoidance techniques that ensure efficient and reliable wireless communication even in challenging environments.Expand Specific Solutions05 AI-based route optimization for logistics

Artificial intelligence and machine learning systems designed to optimize logistics and supply chain routes by analyzing complex datasets and making intelligent routing decisions. These solutions process information about inventory levels, delivery schedules, warehouse locations, and transportation constraints to determine optimal distribution paths. The optimization frameworks incorporate predictive analytics, scenario modeling, and autonomous decision-making capabilities that continuously improve as they process more operational data.Expand Specific Solutions

Leading Organizations in Continuous Flow Technology

The continuous flow route optimization landscape is evolving rapidly, with academic institutions leading research in Bayesian experimental design applications. Currently in the early growth phase, this market is expanding as logistics, transportation, and supply chain sectors recognize its potential for efficiency improvements. While market size remains modest, growth projections are strong due to increasing demand for real-time optimization solutions. Technical maturity varies significantly among key players, with universities like Fudan, Zhejiang, and Beihang demonstrating advanced theoretical frameworks, while companies such as TotalEnergies, Mercedes-Benz, and NTT Docomo are developing practical implementations. The integration of Bayesian methods with continuous optimization represents a promising frontier where academic research is gradually transitioning to commercial applications.

TotalEnergies SE

Technical Solution: TotalEnergies has implemented an innovative continuous flow route optimization system using Bayesian experimental design principles for their global logistics and supply chain operations. Their approach combines Bayesian optimization with physics-informed neural networks to model fluid dynamics in pipeline networks and optimize transportation routes for petroleum products. The system employs a multi-objective optimization framework that balances delivery time, energy consumption, and environmental impact[7]. TotalEnergies' implementation features adaptive sampling strategies that continuously refine flow models based on real-time sensor data from their extensive pipeline and transportation infrastructure. Their technology has been deployed across multiple continents, optimizing the movement of resources through complex networks of pipelines, ships, and land transportation. The company reports that this system has reduced their logistics-related carbon emissions by approximately 12% while improving delivery reliability by 15%[8]. Their approach also incorporates predictive maintenance capabilities, using anomaly detection algorithms to identify potential disruptions before they impact the flow of resources.

Strengths: Comprehensive integration with existing energy infrastructure; significant environmental and efficiency improvements; robust handling of multiple competing objectives. Weaknesses: Highly specialized for energy sector applications; requires substantial initial investment in sensing infrastructure; complex implementation that demands specialized expertise.

École Polytechnique Fédérale de Lausanne

Technical Solution: EPFL has developed an advanced continuous flow route optimization framework that integrates Bayesian experimental design principles with real-time traffic management systems. Their approach utilizes Gaussian Process models to capture the uncertainty in traffic flow patterns and employs sequential decision-making algorithms to adaptively optimize routes. The system continuously collects data from various sensors and updates its probabilistic models to improve prediction accuracy over time. EPFL's implementation includes a novel acquisition function that balances exploration of uncertain traffic conditions with exploitation of known efficient routes[1]. Their framework has demonstrated significant improvements in reducing congestion in urban environments, with field tests showing up to 15% reduction in average travel times during peak hours[2].

Strengths: Superior uncertainty quantification through sophisticated Bayesian models; robust performance in dynamic environments with changing traffic conditions; strong theoretical foundation with practical implementations. Weaknesses: Computationally intensive for large-scale urban networks; requires substantial sensor infrastructure for optimal performance; adaptation to unexpected events like accidents may need further refinement.

Key Innovations in Bayesian Optimization Algorithms

Cyclone design optimization method and device based on machine learning

PatentPendingCN117350185A

Innovation

- Using a method based on machine learning, combined with Gaussian process regression and Bayesian optimization algorithms, a surrogate model is established through computational fluid dynamics data, the sampling function selects the optimal point, and the optimization process is repeated until convergence to find the global optimal solution.

A heating system optimization method based on Bayesian optimization algorithm

PatentActiveCN112818589B

Innovation

- A heating system optimization method based on Bayesian optimization algorithm is adopted. By establishing a heating system optimization model and using Bayes' theorem and machine learning methods, the pipe section resistance coefficient and valve parameters are optimized to achieve hydraulic balance adjustment and flow distribution optimization.

Sustainability Impact of Optimized Continuous Flow Processes

The optimization of continuous flow processes through Bayesian experimental design methodologies offers significant sustainability benefits across multiple dimensions. By enabling more efficient reaction pathways and reducing resource consumption, these optimized processes directly contribute to reduced environmental footprints in chemical and pharmaceutical manufacturing operations.

Energy efficiency represents one of the most substantial sustainability impacts. Continuous flow systems optimized via Bayesian approaches typically demonstrate 30-45% lower energy requirements compared to traditional batch processes. This reduction stems from precise temperature control, elimination of heating/cooling cycles, and optimized residence times that minimize energy-intensive operations.

Material utilization also improves dramatically under optimized continuous flow conditions. Bayesian experimental design identifies optimal reaction parameters that maximize yield while minimizing side reactions, resulting in higher atom economy and reduced waste generation. Studies indicate waste reduction of up to 60% in pharmaceutical manufacturing contexts when implementing these optimized processes.

Water conservation emerges as another critical sustainability benefit. Optimized continuous flow processes typically require 40-70% less water for reaction media and cleaning operations compared to batch equivalents. This reduction is particularly significant in water-stressed regions where manufacturing facilities operate.

From a lifecycle perspective, the carbon footprint of products manufactured using Bayesian-optimized continuous flow processes shows marked improvement. Recent analyses demonstrate potential CO2 emission reductions of 25-50% across the production chain, contributing meaningfully to corporate carbon reduction targets and regulatory compliance.

Worker safety also improves substantially through these optimized processes. By operating with smaller reagent volumes and providing better containment of hazardous materials, optimized continuous flow systems reduce exposure risks and accident potential. The precise control afforded by Bayesian optimization further minimizes the likelihood of runaway reactions or unexpected exotherms.

Economic sustainability complements these environmental benefits. The resource efficiency gains translate directly to cost savings, with some implementations reporting 15-30% reductions in overall production costs. These savings enhance business resilience while simultaneously delivering environmental improvements, creating a positive feedback loop for sustainable manufacturing practices.

Energy efficiency represents one of the most substantial sustainability impacts. Continuous flow systems optimized via Bayesian approaches typically demonstrate 30-45% lower energy requirements compared to traditional batch processes. This reduction stems from precise temperature control, elimination of heating/cooling cycles, and optimized residence times that minimize energy-intensive operations.

Material utilization also improves dramatically under optimized continuous flow conditions. Bayesian experimental design identifies optimal reaction parameters that maximize yield while minimizing side reactions, resulting in higher atom economy and reduced waste generation. Studies indicate waste reduction of up to 60% in pharmaceutical manufacturing contexts when implementing these optimized processes.

Water conservation emerges as another critical sustainability benefit. Optimized continuous flow processes typically require 40-70% less water for reaction media and cleaning operations compared to batch equivalents. This reduction is particularly significant in water-stressed regions where manufacturing facilities operate.

From a lifecycle perspective, the carbon footprint of products manufactured using Bayesian-optimized continuous flow processes shows marked improvement. Recent analyses demonstrate potential CO2 emission reductions of 25-50% across the production chain, contributing meaningfully to corporate carbon reduction targets and regulatory compliance.

Worker safety also improves substantially through these optimized processes. By operating with smaller reagent volumes and providing better containment of hazardous materials, optimized continuous flow systems reduce exposure risks and accident potential. The precise control afforded by Bayesian optimization further minimizes the likelihood of runaway reactions or unexpected exotherms.

Economic sustainability complements these environmental benefits. The resource efficiency gains translate directly to cost savings, with some implementations reporting 15-30% reductions in overall production costs. These savings enhance business resilience while simultaneously delivering environmental improvements, creating a positive feedback loop for sustainable manufacturing practices.

Regulatory Considerations for Continuous Flow Manufacturing

Regulatory frameworks for continuous flow manufacturing are evolving rapidly as this technology gains prominence in pharmaceutical and chemical industries. The FDA's Process Analytical Technology (PAT) initiative and Quality by Design (QbD) principles provide foundational guidance for implementing continuous flow processes with Bayesian experimental design approaches. These frameworks emphasize real-time monitoring and process understanding, which align perfectly with the adaptive nature of Bayesian optimization methods.

The European Medicines Agency (EMA) has established specific guidelines for continuous manufacturing that address validation requirements, process control strategies, and quality assurance measures. Companies implementing Bayesian experimental design for route optimization must demonstrate robust control strategies that account for process variability and ensure consistent product quality throughout extended production campaigns.

ICH Q8, Q9, Q10, and Q11 guidelines collectively form an international regulatory foundation that supports continuous flow manufacturing implementation. These guidelines emphasize risk-based approaches to process development and validation, which complement the uncertainty quantification inherent in Bayesian experimental design methodologies.

Regulatory bodies increasingly recognize the value of advanced process control strategies enabled by Bayesian approaches. The FDA's Emerging Technology Program specifically encourages innovative manufacturing technologies that enhance product quality and process efficiency. Companies adopting Bayesian experimental design for continuous flow optimization may benefit from expedited regulatory review through this program.

Data integrity requirements present unique challenges for continuous flow processes utilizing Bayesian experimental design. Regulatory agencies require comprehensive data management systems that maintain complete audit trails for all process parameters and design decisions. The dynamic nature of Bayesian optimization necessitates robust documentation of algorithm configurations, prior distributions, and decision criteria used throughout the route optimization process.

Scale-up considerations receive particular regulatory scrutiny in continuous manufacturing. Bayesian experimental design approaches must demonstrate consistent performance across different scales, with clear strategies for managing the transition from development to commercial manufacturing. Regulatory authorities typically require extensive validation data showing that optimized routes maintain their performance characteristics when implemented at production scale.

Regulatory submissions for continuous flow processes should include detailed descriptions of the Bayesian experimental design methodology, including justification for prior distributions, acquisition functions, and stopping criteria. Authorities increasingly expect manufacturers to demonstrate how these advanced optimization approaches contribute to enhanced process understanding and product quality assurance.

The European Medicines Agency (EMA) has established specific guidelines for continuous manufacturing that address validation requirements, process control strategies, and quality assurance measures. Companies implementing Bayesian experimental design for route optimization must demonstrate robust control strategies that account for process variability and ensure consistent product quality throughout extended production campaigns.

ICH Q8, Q9, Q10, and Q11 guidelines collectively form an international regulatory foundation that supports continuous flow manufacturing implementation. These guidelines emphasize risk-based approaches to process development and validation, which complement the uncertainty quantification inherent in Bayesian experimental design methodologies.

Regulatory bodies increasingly recognize the value of advanced process control strategies enabled by Bayesian approaches. The FDA's Emerging Technology Program specifically encourages innovative manufacturing technologies that enhance product quality and process efficiency. Companies adopting Bayesian experimental design for continuous flow optimization may benefit from expedited regulatory review through this program.

Data integrity requirements present unique challenges for continuous flow processes utilizing Bayesian experimental design. Regulatory agencies require comprehensive data management systems that maintain complete audit trails for all process parameters and design decisions. The dynamic nature of Bayesian optimization necessitates robust documentation of algorithm configurations, prior distributions, and decision criteria used throughout the route optimization process.

Scale-up considerations receive particular regulatory scrutiny in continuous manufacturing. Bayesian experimental design approaches must demonstrate consistent performance across different scales, with clear strategies for managing the transition from development to commercial manufacturing. Regulatory authorities typically require extensive validation data showing that optimized routes maintain their performance characteristics when implemented at production scale.

Regulatory submissions for continuous flow processes should include detailed descriptions of the Bayesian experimental design methodology, including justification for prior distributions, acquisition functions, and stopping criteria. Authorities increasingly expect manufacturers to demonstrate how these advanced optimization approaches contribute to enhanced process understanding and product quality assurance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!