System Integration: Pumps, Heat Exchangers And CIPs For Continuous Lines

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Continuous Processing System Integration Background and Objectives

Continuous processing systems represent a paradigm shift in manufacturing, particularly in industries such as pharmaceuticals, food and beverage, and chemicals. Unlike batch processing, continuous processing enables uninterrupted production flow, offering significant advantages in efficiency, consistency, and scalability. The integration of pumps, heat exchangers, and Clean-in-Place (CIP) systems forms the backbone of these continuous production lines, ensuring seamless operation and product quality.

The evolution of continuous processing technology dates back to the early 20th century, with significant advancements occurring in the post-World War II industrial boom. However, the sophisticated integration of critical components like pumps, heat exchangers, and CIP systems has accelerated dramatically in the past two decades, driven by increasing demands for production efficiency and regulatory compliance, particularly in highly regulated industries.

Current technological trends indicate a move toward more intelligent, automated, and flexible continuous processing systems. The integration of Industry 4.0 principles, including IoT sensors, real-time monitoring, and predictive maintenance capabilities, is reshaping how these systems operate and interact. This evolution is further propelled by the growing emphasis on sustainability, energy efficiency, and reduced environmental footprint in manufacturing operations.

The primary objective of modern continuous processing system integration is to achieve seamless coordination between pumps, heat exchangers, and CIP systems to maintain consistent product quality while maximizing operational efficiency. This involves addressing several key challenges, including precise flow control, thermal management, and maintaining sterility throughout the production process without interruption.

Additionally, regulatory requirements, particularly in pharmaceutical and food processing, necessitate validation protocols that can demonstrate consistent quality and safety in continuous operations. This has spurred innovation in process analytical technology (PAT) and real-time quality assurance methods integrated directly into continuous processing lines.

From a technical perspective, the integration challenge extends beyond mere mechanical compatibility to encompass sophisticated control systems that can manage the interdependencies between different components. For instance, pump operations must synchronize perfectly with heat exchanger performance to maintain critical process parameters, while CIP systems must effectively clean all components without disrupting production schedules.

The ultimate goal of this technical exploration is to identify optimal integration strategies that balance performance, reliability, maintainability, and compliance requirements. By understanding the complex interplay between these critical components, manufacturers can design continuous processing systems that not only meet current production demands but also adapt to future technological advancements and changing market requirements.

The evolution of continuous processing technology dates back to the early 20th century, with significant advancements occurring in the post-World War II industrial boom. However, the sophisticated integration of critical components like pumps, heat exchangers, and CIP systems has accelerated dramatically in the past two decades, driven by increasing demands for production efficiency and regulatory compliance, particularly in highly regulated industries.

Current technological trends indicate a move toward more intelligent, automated, and flexible continuous processing systems. The integration of Industry 4.0 principles, including IoT sensors, real-time monitoring, and predictive maintenance capabilities, is reshaping how these systems operate and interact. This evolution is further propelled by the growing emphasis on sustainability, energy efficiency, and reduced environmental footprint in manufacturing operations.

The primary objective of modern continuous processing system integration is to achieve seamless coordination between pumps, heat exchangers, and CIP systems to maintain consistent product quality while maximizing operational efficiency. This involves addressing several key challenges, including precise flow control, thermal management, and maintaining sterility throughout the production process without interruption.

Additionally, regulatory requirements, particularly in pharmaceutical and food processing, necessitate validation protocols that can demonstrate consistent quality and safety in continuous operations. This has spurred innovation in process analytical technology (PAT) and real-time quality assurance methods integrated directly into continuous processing lines.

From a technical perspective, the integration challenge extends beyond mere mechanical compatibility to encompass sophisticated control systems that can manage the interdependencies between different components. For instance, pump operations must synchronize perfectly with heat exchanger performance to maintain critical process parameters, while CIP systems must effectively clean all components without disrupting production schedules.

The ultimate goal of this technical exploration is to identify optimal integration strategies that balance performance, reliability, maintainability, and compliance requirements. By understanding the complex interplay between these critical components, manufacturers can design continuous processing systems that not only meet current production demands but also adapt to future technological advancements and changing market requirements.

Market Analysis for Integrated Continuous Processing Solutions

The continuous processing solutions market is experiencing robust growth, driven by increasing demand for efficient manufacturing systems across pharmaceutical, food and beverage, and chemical industries. The global market for integrated continuous processing systems was valued at approximately $6.2 billion in 2022 and is projected to reach $9.8 billion by 2028, representing a compound annual growth rate of 7.9%. This growth trajectory is particularly pronounced in regions with advanced manufacturing capabilities such as North America, Western Europe, and parts of Asia-Pacific.

Key market drivers include the push for operational efficiency, reduced production footprints, and enhanced product quality consistency. Industries are increasingly recognizing that integrated systems combining pumps, heat exchangers, and Clean-in-Place (CIP) technologies can reduce production time by up to 30% while decreasing energy consumption by 15-25% compared to traditional batch processing methods.

The pharmaceutical sector represents the largest market segment, accounting for approximately 38% of the total market share. This dominance is attributed to stringent regulatory requirements and the need for precise, contamination-free production environments. The food and beverage industry follows closely at 31%, driven by growing consumer demand for consistent product quality and extended shelf life.

Market analysis reveals a significant shift toward modular and flexible continuous processing solutions that can be rapidly reconfigured for different product lines. This trend is particularly evident in mid-sized manufacturing operations seeking to balance capital investment with production versatility. Survey data indicates that 67% of manufacturing decision-makers prioritize integration capabilities when evaluating new processing equipment.

Regional market dynamics show varying adoption rates, with North America leading in terms of technology implementation, followed by Europe and Asia-Pacific. Emerging markets in Latin America and parts of Southeast Asia are showing accelerated growth rates, albeit from smaller base values, as manufacturers in these regions seek to leapfrog older technologies.

Customer demand patterns indicate growing interest in smart integration solutions featuring IoT connectivity, predictive maintenance capabilities, and real-time process monitoring. These advanced features command premium pricing but deliver substantial long-term operational cost savings, with ROI typically realized within 24-36 months of implementation.

Market challenges include high initial capital requirements, technical complexity of system integration, and resistance to workflow changes in established manufacturing environments. These barriers are particularly pronounced in smaller operations where technical expertise and capital resources may be limited.

Key market drivers include the push for operational efficiency, reduced production footprints, and enhanced product quality consistency. Industries are increasingly recognizing that integrated systems combining pumps, heat exchangers, and Clean-in-Place (CIP) technologies can reduce production time by up to 30% while decreasing energy consumption by 15-25% compared to traditional batch processing methods.

The pharmaceutical sector represents the largest market segment, accounting for approximately 38% of the total market share. This dominance is attributed to stringent regulatory requirements and the need for precise, contamination-free production environments. The food and beverage industry follows closely at 31%, driven by growing consumer demand for consistent product quality and extended shelf life.

Market analysis reveals a significant shift toward modular and flexible continuous processing solutions that can be rapidly reconfigured for different product lines. This trend is particularly evident in mid-sized manufacturing operations seeking to balance capital investment with production versatility. Survey data indicates that 67% of manufacturing decision-makers prioritize integration capabilities when evaluating new processing equipment.

Regional market dynamics show varying adoption rates, with North America leading in terms of technology implementation, followed by Europe and Asia-Pacific. Emerging markets in Latin America and parts of Southeast Asia are showing accelerated growth rates, albeit from smaller base values, as manufacturers in these regions seek to leapfrog older technologies.

Customer demand patterns indicate growing interest in smart integration solutions featuring IoT connectivity, predictive maintenance capabilities, and real-time process monitoring. These advanced features command premium pricing but deliver substantial long-term operational cost savings, with ROI typically realized within 24-36 months of implementation.

Market challenges include high initial capital requirements, technical complexity of system integration, and resistance to workflow changes in established manufacturing environments. These barriers are particularly pronounced in smaller operations where technical expertise and capital resources may be limited.

Current Challenges in Pump and Heat Exchanger Integration

The integration of pumps, heat exchangers, and Clean-in-Place (CIP) systems in continuous production lines presents significant technical challenges that impact operational efficiency, product quality, and manufacturing costs. Current integration approaches face several critical obstacles that require innovative solutions to overcome.

Fluid dynamics compatibility remains a primary concern, as mismatched flow rates between pumps and heat exchangers create pressure imbalances throughout the system. These imbalances not only reduce thermal transfer efficiency but also increase energy consumption and mechanical stress on components. Studies indicate that up to 30% of energy losses in integrated systems stem from such incompatibilities.

Temperature control precision presents another substantial challenge. Modern continuous processing demands increasingly tight temperature tolerances, often within ±0.5°C, which traditional integration methods struggle to maintain consistently. The thermal lag between pump operations and heat exchanger response creates control difficulties, particularly during production transitions or recipe changes.

CIP integration with production equipment introduces complex design constraints. Current systems frequently require compromise between optimal production configuration and effective cleaning accessibility. This results in either reduced production efficiency or inadequate sanitation coverage, with 40% of food processing facilities reporting cleaning-related downtime exceeding planned maintenance windows.

Material compatibility across integrated components presents ongoing challenges. The diverse processing environments—from caustic CIP solutions to various product formulations—demand materials that maintain integrity across temperature ranges and chemical exposures. Current integration approaches often necessitate suboptimal material selections that compromise either durability or performance.

Space utilization efficiency remains problematic in modern manufacturing facilities. Traditional integration approaches require significant floor space for pumps, heat exchangers, and CIP systems, with associated piping and infrastructure. This spatial inefficiency increases capital costs and complicates facility design, particularly in retrofit scenarios where space is limited.

Control system integration presents technical hurdles in harmonizing the operation of pumps, heat exchangers, and CIP systems. Most current implementations utilize separate control architectures with limited communication capabilities, resulting in suboptimal coordination and response to changing process conditions. This fragmentation increases both implementation complexity and ongoing maintenance requirements.

Energy efficiency in integrated systems falls significantly below theoretical optimums. Heat recovery between process and CIP operations remains largely unexploited, with less than 20% of facilities implementing effective energy recapture strategies. The resulting energy waste contributes substantially to operational costs and environmental impact.

Fluid dynamics compatibility remains a primary concern, as mismatched flow rates between pumps and heat exchangers create pressure imbalances throughout the system. These imbalances not only reduce thermal transfer efficiency but also increase energy consumption and mechanical stress on components. Studies indicate that up to 30% of energy losses in integrated systems stem from such incompatibilities.

Temperature control precision presents another substantial challenge. Modern continuous processing demands increasingly tight temperature tolerances, often within ±0.5°C, which traditional integration methods struggle to maintain consistently. The thermal lag between pump operations and heat exchanger response creates control difficulties, particularly during production transitions or recipe changes.

CIP integration with production equipment introduces complex design constraints. Current systems frequently require compromise between optimal production configuration and effective cleaning accessibility. This results in either reduced production efficiency or inadequate sanitation coverage, with 40% of food processing facilities reporting cleaning-related downtime exceeding planned maintenance windows.

Material compatibility across integrated components presents ongoing challenges. The diverse processing environments—from caustic CIP solutions to various product formulations—demand materials that maintain integrity across temperature ranges and chemical exposures. Current integration approaches often necessitate suboptimal material selections that compromise either durability or performance.

Space utilization efficiency remains problematic in modern manufacturing facilities. Traditional integration approaches require significant floor space for pumps, heat exchangers, and CIP systems, with associated piping and infrastructure. This spatial inefficiency increases capital costs and complicates facility design, particularly in retrofit scenarios where space is limited.

Control system integration presents technical hurdles in harmonizing the operation of pumps, heat exchangers, and CIP systems. Most current implementations utilize separate control architectures with limited communication capabilities, resulting in suboptimal coordination and response to changing process conditions. This fragmentation increases both implementation complexity and ongoing maintenance requirements.

Energy efficiency in integrated systems falls significantly below theoretical optimums. Heat recovery between process and CIP operations remains largely unexploited, with less than 20% of facilities implementing effective energy recapture strategies. The resulting energy waste contributes substantially to operational costs and environmental impact.

Existing Integration Solutions for Continuous Processing

01 Integrated CIP systems for efficient cleaning

Clean-in-place (CIP) systems integrated with pumps and heat exchangers enable efficient cleaning of processing equipment without disassembly. These systems utilize controlled flow rates, temperatures, and cleaning solutions to remove contaminants from internal surfaces. The integration allows for automated cleaning cycles, reducing downtime and ensuring consistent cleaning results across the entire system. Advanced CIP systems may include sensors for monitoring cleaning effectiveness and optimizing resource usage.- Integrated CIP systems for efficient cleaning: Clean-in-place (CIP) systems integrated with pumps and heat exchangers enable efficient cleaning of processing equipment without disassembly. These systems utilize optimized flow rates, temperatures, and cleaning solutions to remove residues from internal surfaces. The integration allows for automated cleaning cycles, reducing downtime and ensuring consistent cleaning results while minimizing water and chemical usage. Advanced CIP systems incorporate sensors for monitoring cleaning effectiveness and can be programmed for different cleaning protocols based on specific process requirements.

- Heat recovery and energy efficiency in integrated systems: Integrated systems combining pumps, heat exchangers, and CIP equipment can be designed to maximize energy efficiency through heat recovery mechanisms. Waste heat from one process can be captured and reused in another part of the system, reducing overall energy consumption. These systems often incorporate plate heat exchangers or regenerative heat recovery units that transfer thermal energy between process fluids and cleaning solutions. Advanced control systems optimize the timing and flow rates to maximize heat transfer efficiency while maintaining required process temperatures.

- Modular and compact integration solutions: Modular designs for integrating pumps, heat exchangers, and CIP systems allow for flexible installation in limited spaces and easy expansion or modification. These compact solutions combine multiple functions into unified skid-mounted units that can be pre-assembled and tested before installation. The modular approach reduces installation time, simplifies maintenance, and allows for standardization across multiple processing lines. These systems often feature quick-connect fittings and standardized interfaces to facilitate integration with existing plant infrastructure.

- Advanced control systems for integrated operations: Sophisticated control systems enable seamless coordination between pumps, heat exchangers, and CIP operations. These systems utilize programmable logic controllers (PLCs) and human-machine interfaces (HMIs) to automate sequences, monitor performance parameters, and optimize resource usage. The integration of sensors and real-time monitoring allows for predictive maintenance and process optimization. Advanced control algorithms can adjust operating parameters based on changing conditions, ensuring consistent performance while minimizing energy and resource consumption.

- Hygienic design for food and pharmaceutical applications: Specialized integration of pumps, heat exchangers, and CIP systems for food and pharmaceutical applications focuses on hygienic design principles. These systems feature sanitary connections, self-draining configurations, and materials compatible with food and pharmaceutical processing. The integration eliminates dead zones where product could accumulate and ensures complete cleanability of all product-contact surfaces. Hygienic design considerations extend to the selection of appropriate seals, gaskets, and surface finishes to prevent contamination and facilitate validation according to regulatory requirements.

02 Heat recovery and energy efficiency solutions

Integration of heat exchangers with pumping systems allows for efficient energy recovery and utilization. These systems capture waste heat from one process and transfer it to another, reducing overall energy consumption. The integration includes strategic placement of heat exchangers, optimized pump selection for proper flow rates, and control systems that balance thermal requirements across the entire system. Such configurations significantly improve energy efficiency in industrial processes while maintaining required temperature profiles.Expand Specific Solutions03 Modular system design for flexibility and scalability

Modular approaches to integrating pumps, heat exchangers, and CIP systems allow for flexible configuration and easy scalability. These designs feature standardized connection points, interchangeable components, and plug-and-play functionality. The modular architecture enables quick adaptation to changing process requirements, simplified maintenance, and future expansion capabilities. Control systems are designed to recognize and adapt to new modules automatically, reducing commissioning time and engineering complexity.Expand Specific Solutions04 Advanced control systems for integrated operation

Sophisticated control systems enable coordinated operation of pumps, heat exchangers, and CIP systems. These controls manage process parameters such as flow rates, temperatures, pressures, and cleaning cycles to optimize overall system performance. Integration includes automated sequencing, fault detection, predictive maintenance algorithms, and remote monitoring capabilities. The control architecture may incorporate machine learning to continuously improve efficiency and adapt to changing operating conditions.Expand Specific Solutions05 Specialized integration for challenging environments

Custom integration solutions for pumps, heat exchangers, and CIP systems designed for challenging operational environments such as high-temperature processes, corrosive media, or hygienic applications. These specialized systems incorporate materials and designs that withstand extreme conditions while maintaining efficient heat transfer and cleaning capabilities. The integration accounts for thermal expansion, chemical compatibility, and regulatory requirements specific to the application environment, ensuring reliable long-term operation.Expand Specific Solutions

Industry Leaders in Continuous Processing Equipment

The system integration market for pumps, heat exchangers, and CIPs in continuous lines is currently in a growth phase, with increasing demand driven by automation and efficiency requirements across food, pharmaceutical, and chemical industries. The global market size is estimated to exceed $15 billion, expanding at 5-7% annually. Technologically, the field is moderately mature but evolving rapidly with smart integration capabilities. Leading players include established industrial equipment manufacturers like WILO SE and Johnson Controls, alongside specialized system integrators such as Process Group and Efficient Energy GmbH. Asian manufacturers including Haier Smart Home and Samsung Electronics are gaining market share through cost-effective solutions, while companies like Panasonic and Carrier Corp. differentiate through advanced control systems and energy efficiency innovations.

Carrier Corp.

Technical Solution: Carrier Corporation has developed an integrated system approach for continuous processing lines that optimizes the interaction between pumps, heat exchangers, and CIP systems to maximize energy efficiency and production uptime. Their technology incorporates variable-speed pumping systems that automatically adjust flow rates based on real-time thermal demands, reducing energy consumption by up to 35% compared to conventional fixed-flow systems. Carrier's heat exchanger designs feature enhanced surface geometries that improve heat transfer coefficients while minimizing pressure drops, addressing a critical efficiency factor in continuous operations. Their integrated CIP solutions utilize advanced spray technologies that achieve thorough cleaning with reduced water and chemical consumption, supporting sustainability goals while ensuring sanitary production conditions. Carrier's systems feature a modular architecture that allows for phased implementation and future expansion without disrupting existing operations, providing flexibility for evolving production requirements. The company's integration approach includes comprehensive monitoring systems that track key performance indicators across the entire process line, enabling continuous optimization of operational parameters.

Strengths: Exceptional energy efficiency through intelligent flow control; modular design supports phased implementation and future expansion; comprehensive monitoring enables continuous performance optimization. Weaknesses: Higher initial capital investment compared to non-integrated approaches; requires specialized technical expertise for optimal configuration; system complexity may increase troubleshooting challenges.

WILO SE

Technical Solution: WILO SE has developed advanced pump integration systems for continuous processing lines that utilize intelligent control algorithms to optimize flow rates and pressure based on real-time production demands. Their technology incorporates variable frequency drives (VFDs) that automatically adjust pump performance to match system requirements, reducing energy consumption by up to 30% compared to conventional fixed-speed pumps. WILO's systems feature modular designs that allow for seamless integration with existing production infrastructure while maintaining sanitary conditions required in food and pharmaceutical applications. Their CIP (Clean-In-Place) solutions incorporate high-efficiency pumps specifically designed to deliver precise chemical concentrations and flow rates during cleaning cycles, ensuring consistent cleaning results while minimizing downtime between production runs.

Strengths: Superior energy efficiency through intelligent control systems; modular design allows for easy integration with existing production lines; advanced monitoring capabilities provide real-time performance data. Weaknesses: Higher initial investment compared to conventional systems; requires specialized maintenance personnel; proprietary control systems may limit compatibility with third-party equipment.

Key Technologies in Pump-Heat Exchanger Synchronization

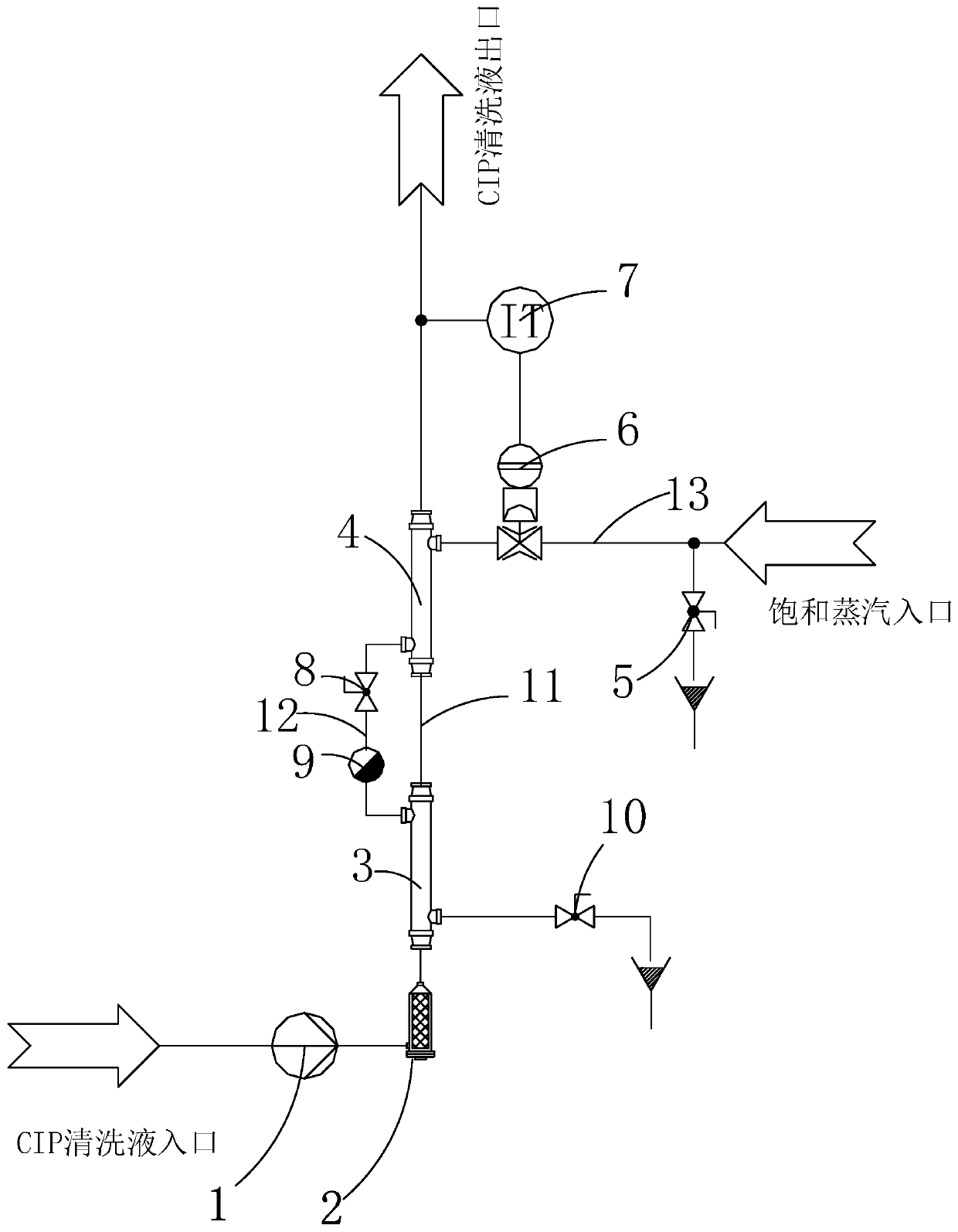

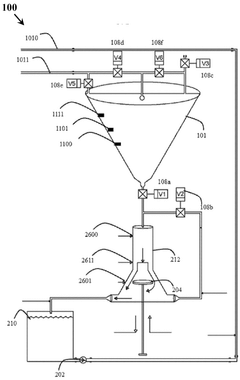

Clean in place (CIP) heat exchange device

PatentActiveCN111185444A

Innovation

- A CIP heat exchange device is designed, including a condensate heat exchanger and a steam heat exchanger. The CIP cleaning fluid is preheated by the thermal energy of the saturated condensate water in the steam heat exchanger, and the cleaning fluid is controlled through a regulating valve and a temperature sensor. temperature to ensure efficient utilization of steam.

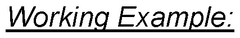

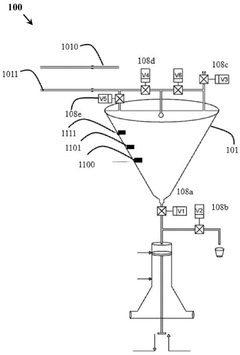

A clean-in-place system for volumetric filling machines and a method thereof

PatentWO2025146569A1

Innovation

- A CIP system for volumetric filling machines featuring a control unit, sensors, adaptive flow mechanism with straight and conical tubes, variable speed pumps, and programmable logic controller (PLC) for real-time monitoring and automated cleaning processes, integrating with the production line to optimize cleaning based on equipment type and contamination levels.

Energy Efficiency Considerations in Integrated Systems

Energy efficiency has emerged as a critical consideration in integrated systems for continuous processing lines, particularly those involving pumps, heat exchangers, and Clean-in-Place (CIP) systems. The interconnected nature of these components presents both challenges and opportunities for energy optimization across the entire system rather than individual components in isolation.

Pump systems typically consume 20-25% of industrial electricity globally, with significant potential for efficiency improvements. Integration of variable frequency drives (VFDs) in pumping systems has demonstrated energy savings of 30-50% in continuous processing applications by allowing precise flow control based on actual system demands. Additionally, proper pump sizing and selection based on system curves rather than peak requirements can eliminate energy waste from oversized equipment.

Heat exchangers represent another critical area for energy efficiency considerations. Advanced plate heat exchangers with enhanced surface geometries have shown 15-20% improved thermal efficiency compared to traditional designs. The strategic placement of heat recovery systems between hot and cold process streams can recapture up to 60% of thermal energy that would otherwise be wasted. Furthermore, fouling mitigation strategies integrated into system design can maintain optimal heat transfer efficiency over extended operational periods.

CIP systems present unique energy efficiency challenges in continuous lines due to their intermittent yet essential nature. Optimization approaches include flow sequencing algorithms that reduce cleaning cycle times by 15-25% while maintaining sanitation standards. Integration of spray ball technology with precise pressure control has demonstrated water and energy savings of 30-40% compared to conventional flooding methods. Real-time monitoring systems that adjust cleaning parameters based on actual soil load rather than worst-case scenarios further enhance efficiency.

System-level integration strategies offer the greatest potential for energy optimization. Waste heat recovery between process steps can reduce overall energy consumption by 20-35% in well-designed systems. Intelligent control systems that coordinate pump speeds, heat exchanger operations, and CIP cycles based on production demands have demonstrated energy savings of 15-30% compared to independently controlled components.

The economic implications of energy-efficient integrated systems extend beyond direct utility cost savings. Reduced energy consumption correlates with lower maintenance requirements and extended equipment life, with studies indicating a 15-25% reduction in lifecycle costs for optimized systems. Additionally, the environmental benefits align with increasingly stringent regulatory requirements and corporate sustainability goals, providing both compliance advantages and marketing opportunities.

Pump systems typically consume 20-25% of industrial electricity globally, with significant potential for efficiency improvements. Integration of variable frequency drives (VFDs) in pumping systems has demonstrated energy savings of 30-50% in continuous processing applications by allowing precise flow control based on actual system demands. Additionally, proper pump sizing and selection based on system curves rather than peak requirements can eliminate energy waste from oversized equipment.

Heat exchangers represent another critical area for energy efficiency considerations. Advanced plate heat exchangers with enhanced surface geometries have shown 15-20% improved thermal efficiency compared to traditional designs. The strategic placement of heat recovery systems between hot and cold process streams can recapture up to 60% of thermal energy that would otherwise be wasted. Furthermore, fouling mitigation strategies integrated into system design can maintain optimal heat transfer efficiency over extended operational periods.

CIP systems present unique energy efficiency challenges in continuous lines due to their intermittent yet essential nature. Optimization approaches include flow sequencing algorithms that reduce cleaning cycle times by 15-25% while maintaining sanitation standards. Integration of spray ball technology with precise pressure control has demonstrated water and energy savings of 30-40% compared to conventional flooding methods. Real-time monitoring systems that adjust cleaning parameters based on actual soil load rather than worst-case scenarios further enhance efficiency.

System-level integration strategies offer the greatest potential for energy optimization. Waste heat recovery between process steps can reduce overall energy consumption by 20-35% in well-designed systems. Intelligent control systems that coordinate pump speeds, heat exchanger operations, and CIP cycles based on production demands have demonstrated energy savings of 15-30% compared to independently controlled components.

The economic implications of energy-efficient integrated systems extend beyond direct utility cost savings. Reduced energy consumption correlates with lower maintenance requirements and extended equipment life, with studies indicating a 15-25% reduction in lifecycle costs for optimized systems. Additionally, the environmental benefits align with increasingly stringent regulatory requirements and corporate sustainability goals, providing both compliance advantages and marketing opportunities.

Sanitary Design Standards for Continuous Processing

Sanitary design standards are fundamental to the successful implementation of continuous processing systems in food, beverage, and pharmaceutical industries. These standards ensure that integrated systems comprising pumps, heat exchangers, and Clean-in-Place (CIP) equipment maintain product safety and quality throughout operation.

The 3-A Sanitary Standards and European Hygienic Engineering & Design Group (EHEDG) guidelines provide the foundational framework for sanitary design in continuous processing. These standards emphasize materials of construction, with stainless steel (typically 316L) being predominant due to its corrosion resistance and cleanability. Surface finish requirements typically specify Ra values of 0.8μm or smoother for product contact surfaces to prevent microbial harborage.

Equipment geometry in continuous processing lines must eliminate dead zones and promote self-draining capabilities. For pumps, this means selecting designs that avoid product retention areas, with centrifugal and positive displacement pumps requiring specific considerations for seal arrangements and impeller designs. Heat exchangers must incorporate sanitary plate or tubular designs with appropriate gasket materials that withstand both process conditions and cleaning chemicals.

Connection points between system components represent critical control points in sanitary design. Tri-clamp fittings with appropriate gaskets have become the industry standard, replacing threaded connections that can harbor microorganisms. Valve selection is equally important, with mix-proof valves often preferred in continuous systems to prevent cross-contamination during simultaneous processing and cleaning operations.

CIP systems for continuous lines require specialized design considerations beyond batch processing applications. Flow velocities must achieve the recommended 1.5-2.0 m/s in all product pathways to ensure effective cleaning. Temperature monitoring and control systems must verify that all surfaces reach and maintain the minimum required cleaning temperatures, typically 75-85°C for hot water sanitization phases.

Automation and validation protocols form an essential component of sanitary design implementation. Modern continuous systems incorporate strategically placed temperature, flow, and conductivity sensors to verify cleaning effectiveness. These sensors must themselves meet sanitary design standards and be positioned to avoid creating new harborage points.

Regulatory compliance with FDA, USDA, and international standards requires comprehensive documentation of sanitary design features. This includes material certificates, surface finish verification, and design validation studies that demonstrate cleanability under worst-case scenarios. Manufacturers must maintain detailed records of design decisions that impact product safety and quality.

The 3-A Sanitary Standards and European Hygienic Engineering & Design Group (EHEDG) guidelines provide the foundational framework for sanitary design in continuous processing. These standards emphasize materials of construction, with stainless steel (typically 316L) being predominant due to its corrosion resistance and cleanability. Surface finish requirements typically specify Ra values of 0.8μm or smoother for product contact surfaces to prevent microbial harborage.

Equipment geometry in continuous processing lines must eliminate dead zones and promote self-draining capabilities. For pumps, this means selecting designs that avoid product retention areas, with centrifugal and positive displacement pumps requiring specific considerations for seal arrangements and impeller designs. Heat exchangers must incorporate sanitary plate or tubular designs with appropriate gasket materials that withstand both process conditions and cleaning chemicals.

Connection points between system components represent critical control points in sanitary design. Tri-clamp fittings with appropriate gaskets have become the industry standard, replacing threaded connections that can harbor microorganisms. Valve selection is equally important, with mix-proof valves often preferred in continuous systems to prevent cross-contamination during simultaneous processing and cleaning operations.

CIP systems for continuous lines require specialized design considerations beyond batch processing applications. Flow velocities must achieve the recommended 1.5-2.0 m/s in all product pathways to ensure effective cleaning. Temperature monitoring and control systems must verify that all surfaces reach and maintain the minimum required cleaning temperatures, typically 75-85°C for hot water sanitization phases.

Automation and validation protocols form an essential component of sanitary design implementation. Modern continuous systems incorporate strategically placed temperature, flow, and conductivity sensors to verify cleaning effectiveness. These sensors must themselves meet sanitary design standards and be positioned to avoid creating new harborage points.

Regulatory compliance with FDA, USDA, and international standards requires comprehensive documentation of sanitary design features. This includes material certificates, surface finish verification, and design validation studies that demonstrate cleanability under worst-case scenarios. Manufacturers must maintain detailed records of design decisions that impact product safety and quality.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!