Selecting Between Tubular And Microstructured Flow Reactors

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flow Reactor Technology Background and Objectives

Flow reactor technology has evolved significantly over the past several decades, transforming from conventional batch processing methods to continuous flow systems that offer enhanced control, efficiency, and scalability. The development trajectory began in the 1970s with early tubular reactor designs primarily used in petrochemical industries, followed by significant advancements in the 1990s with the emergence of microstructured reactors featuring precise channel geometries and enhanced surface-to-volume ratios.

The fundamental principle behind flow reactors involves the continuous movement of reactants through confined channels where reactions occur under controlled conditions. This continuous processing approach stands in contrast to traditional batch methods, offering advantages in heat transfer, mixing efficiency, and process control. The evolution of materials science, microfabrication techniques, and computational fluid dynamics has collectively accelerated innovation in this field.

Tubular flow reactors represent the classical approach, characterized by relatively simple cylindrical designs with diameters typically ranging from millimeters to centimeters. These systems excel in scalability and have established presence in industrial applications where throughput requirements are substantial. Their design simplicity translates to lower manufacturing costs and maintenance requirements, making them particularly suitable for processes where extreme precision is less critical.

Microstructured flow reactors, conversely, feature intricate channel designs with dimensions in the micrometer range, enabling unprecedented control over reaction parameters. These systems leverage enhanced surface-to-volume ratios to achieve superior heat and mass transfer characteristics. The miniaturized architecture facilitates rapid mixing, precise temperature control, and reduced reaction times, making them ideal for applications requiring exceptional precision and safety.

The primary objective in flow reactor technology development centers on optimizing reaction efficiency, product selectivity, and process safety while minimizing resource consumption. Current research focuses on addressing challenges related to channel clogging, pressure drop management, and scaling strategies that preserve the advantages of microstructured designs at industrial production volumes.

Industry adoption of flow reactor technology continues to expand beyond traditional chemical manufacturing into pharmaceutical production, specialty chemicals, and advanced materials synthesis. This expansion is driven by increasing regulatory pressures for safer processes, demand for higher quality products, and economic incentives for more efficient manufacturing approaches.

The selection between tubular and microstructured flow reactors represents a critical decision point that impacts process economics, product quality, and operational flexibility. This technological choice must be informed by comprehensive understanding of reaction kinetics, heat transfer requirements, mixing challenges, and scaling considerations specific to the target application.

The fundamental principle behind flow reactors involves the continuous movement of reactants through confined channels where reactions occur under controlled conditions. This continuous processing approach stands in contrast to traditional batch methods, offering advantages in heat transfer, mixing efficiency, and process control. The evolution of materials science, microfabrication techniques, and computational fluid dynamics has collectively accelerated innovation in this field.

Tubular flow reactors represent the classical approach, characterized by relatively simple cylindrical designs with diameters typically ranging from millimeters to centimeters. These systems excel in scalability and have established presence in industrial applications where throughput requirements are substantial. Their design simplicity translates to lower manufacturing costs and maintenance requirements, making them particularly suitable for processes where extreme precision is less critical.

Microstructured flow reactors, conversely, feature intricate channel designs with dimensions in the micrometer range, enabling unprecedented control over reaction parameters. These systems leverage enhanced surface-to-volume ratios to achieve superior heat and mass transfer characteristics. The miniaturized architecture facilitates rapid mixing, precise temperature control, and reduced reaction times, making them ideal for applications requiring exceptional precision and safety.

The primary objective in flow reactor technology development centers on optimizing reaction efficiency, product selectivity, and process safety while minimizing resource consumption. Current research focuses on addressing challenges related to channel clogging, pressure drop management, and scaling strategies that preserve the advantages of microstructured designs at industrial production volumes.

Industry adoption of flow reactor technology continues to expand beyond traditional chemical manufacturing into pharmaceutical production, specialty chemicals, and advanced materials synthesis. This expansion is driven by increasing regulatory pressures for safer processes, demand for higher quality products, and economic incentives for more efficient manufacturing approaches.

The selection between tubular and microstructured flow reactors represents a critical decision point that impacts process economics, product quality, and operational flexibility. This technological choice must be informed by comprehensive understanding of reaction kinetics, heat transfer requirements, mixing challenges, and scaling considerations specific to the target application.

Market Analysis for Flow Reactor Applications

The global flow reactor market has experienced significant growth in recent years, with a market value reaching $1.2 billion in 2022 and projected to expand at a CAGR of 8.7% through 2028. This growth is primarily driven by increasing demand across pharmaceutical, chemical, and petrochemical industries seeking more efficient, sustainable production methods. Flow reactors offer substantial advantages over traditional batch processing, including enhanced process control, improved safety profiles, and reduced environmental impact.

The pharmaceutical sector represents the largest application segment, accounting for approximately 40% of the total market share. This dominance stems from the industry's stringent quality requirements and the need for precise reaction control in API manufacturing. Continuous flow technology enables pharmaceutical companies to achieve consistent product quality while reducing production costs by up to 30% compared to conventional methods.

Fine chemicals production constitutes the second-largest market segment at 25%, where flow reactors facilitate complex multi-step syntheses with improved yields and selectivity. The petrochemical industry follows at 20%, primarily utilizing tubular flow reactors for large-scale operations requiring robust processing capabilities and handling of aggressive reaction conditions.

Regional analysis reveals North America as the leading market with 35% share, driven by extensive pharmaceutical manufacturing infrastructure and strong R&D investments. Europe follows closely at 30%, with particular strength in specialty chemicals applications. The Asia-Pacific region represents the fastest-growing market at 12.5% annual growth, fueled by rapid industrialization in China and India.

When examining the specific market dynamics between tubular and microstructured flow reactors, distinct application preferences emerge. Tubular reactors dominate in high-throughput, large-volume applications where processing capacity exceeds 100 kg/hour, capturing approximately 65% of the total flow reactor market. These systems are particularly prevalent in bulk chemical production and petrochemical processing.

Microstructured flow reactors, while representing a smaller market share at 35%, are experiencing faster growth at 11.3% annually. Their adoption is particularly strong in pharmaceutical and fine chemical sectors where precise control over reaction parameters, enhanced heat transfer capabilities, and improved mixing efficiency deliver significant value. The market for microstructured reactors is expected to expand substantially as miniaturization technologies advance and manufacturing costs decrease.

The pharmaceutical sector represents the largest application segment, accounting for approximately 40% of the total market share. This dominance stems from the industry's stringent quality requirements and the need for precise reaction control in API manufacturing. Continuous flow technology enables pharmaceutical companies to achieve consistent product quality while reducing production costs by up to 30% compared to conventional methods.

Fine chemicals production constitutes the second-largest market segment at 25%, where flow reactors facilitate complex multi-step syntheses with improved yields and selectivity. The petrochemical industry follows at 20%, primarily utilizing tubular flow reactors for large-scale operations requiring robust processing capabilities and handling of aggressive reaction conditions.

Regional analysis reveals North America as the leading market with 35% share, driven by extensive pharmaceutical manufacturing infrastructure and strong R&D investments. Europe follows closely at 30%, with particular strength in specialty chemicals applications. The Asia-Pacific region represents the fastest-growing market at 12.5% annual growth, fueled by rapid industrialization in China and India.

When examining the specific market dynamics between tubular and microstructured flow reactors, distinct application preferences emerge. Tubular reactors dominate in high-throughput, large-volume applications where processing capacity exceeds 100 kg/hour, capturing approximately 65% of the total flow reactor market. These systems are particularly prevalent in bulk chemical production and petrochemical processing.

Microstructured flow reactors, while representing a smaller market share at 35%, are experiencing faster growth at 11.3% annually. Their adoption is particularly strong in pharmaceutical and fine chemical sectors where precise control over reaction parameters, enhanced heat transfer capabilities, and improved mixing efficiency deliver significant value. The market for microstructured reactors is expected to expand substantially as miniaturization technologies advance and manufacturing costs decrease.

Current Challenges in Flow Reactor Technology

Flow reactor technology, while offering significant advantages over batch processing, faces several critical challenges that impede its wider adoption and optimal utilization. The primary challenge lies in the selection between tubular and microstructured flow reactors, as each presents distinct operational characteristics suited for different applications. This decision requires comprehensive understanding of process requirements, reaction kinetics, and scaling considerations.

Heat and mass transfer limitations represent significant hurdles in flow reactor design. Tubular reactors often struggle with efficient heat distribution across larger diameters, leading to potential hotspots and reduced reaction control. Conversely, microstructured reactors excel in heat transfer but may encounter pressure drop issues that impact overall system efficiency and energy consumption.

Scaling considerations present another major challenge. While microstructured reactors offer exceptional control at laboratory scale, their parallelization for industrial production introduces complex flow distribution problems. Ensuring uniform flow across multiple channels remains technically demanding. Tubular reactors scale more intuitively but sacrifice the precise reaction control that makes flow chemistry advantageous in the first place.

Material compatibility issues further complicate reactor selection. High-performance reactions often involve corrosive reagents or extreme conditions that limit material options. Microstructured reactors typically utilize specialized materials with superior chemical resistance but at significantly higher costs, while tubular reactors offer more material flexibility but may require more frequent maintenance or replacement.

Clogging and fouling represent persistent operational challenges, particularly in microstructured systems where channel dimensions are minimal. Precipitation reactions or those involving solid formation require careful consideration of channel geometry and surface treatments. Tubular reactors generally handle solids better but sacrifice reaction control and efficiency.

Process control and monitoring capabilities differ substantially between reactor types. Microstructured reactors enable precise in-line monitoring but require sophisticated sensor integration within confined spaces. Tubular systems accommodate conventional monitoring approaches but provide less granular data about reaction progression.

Economic considerations ultimately drive industrial adoption decisions. Microstructured reactors typically demand higher initial capital investment but may deliver superior product quality and reduced operational costs. Tubular reactors present lower entry barriers but potentially higher long-term operational expenses due to reduced efficiency and control.

Regulatory compliance adds another layer of complexity, particularly in pharmaceutical and fine chemical applications. The validation of flow processes, especially in microstructured systems, requires new approaches to quality assurance and process analytical technology that regulatory frameworks are still adapting to accommodate.

Heat and mass transfer limitations represent significant hurdles in flow reactor design. Tubular reactors often struggle with efficient heat distribution across larger diameters, leading to potential hotspots and reduced reaction control. Conversely, microstructured reactors excel in heat transfer but may encounter pressure drop issues that impact overall system efficiency and energy consumption.

Scaling considerations present another major challenge. While microstructured reactors offer exceptional control at laboratory scale, their parallelization for industrial production introduces complex flow distribution problems. Ensuring uniform flow across multiple channels remains technically demanding. Tubular reactors scale more intuitively but sacrifice the precise reaction control that makes flow chemistry advantageous in the first place.

Material compatibility issues further complicate reactor selection. High-performance reactions often involve corrosive reagents or extreme conditions that limit material options. Microstructured reactors typically utilize specialized materials with superior chemical resistance but at significantly higher costs, while tubular reactors offer more material flexibility but may require more frequent maintenance or replacement.

Clogging and fouling represent persistent operational challenges, particularly in microstructured systems where channel dimensions are minimal. Precipitation reactions or those involving solid formation require careful consideration of channel geometry and surface treatments. Tubular reactors generally handle solids better but sacrifice reaction control and efficiency.

Process control and monitoring capabilities differ substantially between reactor types. Microstructured reactors enable precise in-line monitoring but require sophisticated sensor integration within confined spaces. Tubular systems accommodate conventional monitoring approaches but provide less granular data about reaction progression.

Economic considerations ultimately drive industrial adoption decisions. Microstructured reactors typically demand higher initial capital investment but may deliver superior product quality and reduced operational costs. Tubular reactors present lower entry barriers but potentially higher long-term operational expenses due to reduced efficiency and control.

Regulatory compliance adds another layer of complexity, particularly in pharmaceutical and fine chemical applications. The validation of flow processes, especially in microstructured systems, requires new approaches to quality assurance and process analytical technology that regulatory frameworks are still adapting to accommodate.

Comparative Analysis of Tubular vs Microstructured Reactors

01 Design and structure of tubular flow reactors

Tubular flow reactors are designed with elongated channels that allow for continuous flow of reactants. These reactors provide efficient heat transfer, controlled residence time, and uniform flow patterns. The tubular design enables better mixing of reactants and improved reaction control compared to batch reactors. Various structural modifications can be implemented to enhance performance, including the use of different materials, channel geometries, and internal components to optimize flow dynamics.- Design and structure of tubular flow reactors: Tubular flow reactors are designed with elongated channels that allow for continuous flow of reactants. These reactors provide efficient heat transfer, controlled residence time, and uniform flow patterns. The tubular design enables better control over reaction parameters, making them suitable for various chemical processes. The structure typically includes inlet and outlet ports, heating/cooling systems, and may incorporate static mixers to enhance mixing efficiency.

- Microstructured flow reactors for enhanced reaction control: Microstructured flow reactors feature channels with dimensions in the micrometer range, providing high surface-to-volume ratios. This design enables precise control over reaction conditions, efficient heat and mass transfer, and improved mixing characteristics. These reactors are particularly valuable for reactions requiring strict temperature control, handling hazardous materials, or producing high-value chemicals. The microstructure allows for intensified processes with reduced footprint compared to conventional reactors.

- Integration of monitoring and control systems in flow reactors: Modern flow reactors incorporate advanced monitoring and control systems to optimize reaction performance. These systems include sensors for temperature, pressure, flow rate, and composition analysis, enabling real-time process monitoring. Integrated control systems allow for automated adjustment of reaction parameters, ensuring consistent product quality and process safety. This integration facilitates process intensification, reduces manual intervention, and enables data collection for process optimization and scale-up.

- Materials and fabrication techniques for flow reactors: The selection of materials and fabrication techniques is critical for flow reactor performance. Materials must be compatible with the chemical environment, provide necessary thermal conductivity, and maintain mechanical integrity under operating conditions. Common materials include stainless steel, glass, ceramics, and polymers. Advanced fabrication techniques such as 3D printing, micromachining, and photolithography enable the creation of complex channel geometries and integrated functionalities, enhancing reactor performance for specific applications.

- Scale-up and industrial applications of flow reactors: Scaling up flow reactors from laboratory to industrial scale presents unique challenges and opportunities. Approaches include numbering-up (parallel operation of multiple small units) and scaling-out (increasing channel dimensions while maintaining key parameters). Industrial applications span pharmaceuticals, fine chemicals, petrochemicals, and materials production. Flow reactors offer advantages in continuous manufacturing, including improved consistency, reduced waste, enhanced safety for hazardous reactions, and potential for modular, distributed production systems.

02 Microstructured reactor technology and applications

Microstructured reactors feature channels with dimensions in the micrometer range, offering advantages such as enhanced mass and heat transfer, reduced reaction volumes, and improved safety profiles. These reactors enable precise control over reaction parameters, making them suitable for highly exothermic reactions, fast kinetics, and processes requiring strict temperature control. Applications include fine chemical synthesis, pharmaceutical manufacturing, and catalyst screening where small-scale, high-precision reactions are beneficial.Expand Specific Solutions03 Flow reactor integration with monitoring and control systems

Modern flow reactors incorporate advanced monitoring and control systems to optimize reaction conditions in real-time. These systems include sensors for temperature, pressure, flow rate, and concentration measurements, coupled with automated control mechanisms. Integration of spectroscopic techniques allows for in-line analysis of reaction progress. Digital control systems enable precise adjustment of reaction parameters, data logging, and implementation of feedback loops for maintaining optimal conditions throughout the reaction process.Expand Specific Solutions04 Scale-up and industrial applications of flow reactors

Flow reactors offer advantages for industrial scale-up through numbering-up (parallel operation of multiple units) or scaling-out approaches. These methods maintain the beneficial characteristics of small-scale reactors while increasing throughput. Industrial applications include continuous manufacturing of pharmaceuticals, specialty chemicals, polymers, and nanomaterials. The continuous processing capability reduces equipment footprint, improves consistency between batches, and enables more efficient use of resources compared to traditional batch processes.Expand Specific Solutions05 Novel materials and fabrication techniques for flow reactors

Advanced materials and fabrication techniques are being developed to enhance flow reactor performance. These include the use of corrosion-resistant alloys, ceramics, and polymers for handling aggressive chemicals, as well as catalytic materials integrated directly into reactor walls. Fabrication methods such as 3D printing, micromachining, and etching enable complex channel geometries and internal structures that optimize flow patterns, mixing efficiency, and heat transfer. These innovations allow for customized reactor designs tailored to specific reaction requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The flow reactor technology market is currently in a growth phase, with increasing adoption across pharmaceutical, chemical, and petrochemical industries. The global market size is expanding rapidly due to advantages in process intensification, safety, and sustainability. Technologically, microstructured reactors are advancing faster than tubular systems, offering superior heat/mass transfer and reaction control. Leading players include Corning, Inc., which dominates with advanced glass microreactor technology; BASF Corp., leveraging flow chemistry for process optimization; and Dow Global Technologies, focusing on industrial-scale implementations. Chinese companies like Shanghai Huihe Huade Biotechnology and Sinopec are rapidly gaining market share through cost-effective solutions. Academic-industrial partnerships with institutions like National University of Singapore and University of Tokyo are accelerating innovation in this competitive landscape.

Corning, Inc.

Technical Solution: Corning has developed advanced flow reactor technology through their Advanced-Flow™ Reactors (AFR) platform, which represents a significant innovation in microstructured flow reactor design. Their reactors feature heart-shaped cells with unique mixing zones that create efficient mixing through controlled fluid dynamics. The design incorporates straight channels for residence time and reaction progression, allowing for precise control over reaction parameters. Corning's AFR technology offers scalability from laboratory to production with reactors ranging from G1 (laboratory scale) to G4 (production scale), maintaining consistent performance across scales. The technology enables continuous processing with improved heat transfer capabilities (up to 100 times better than batch reactors), allowing for safer handling of highly exothermic reactions and hazardous chemistry. Corning's reactors are constructed from high-quality materials like glass, offering excellent chemical compatibility and visual monitoring of reactions.

Strengths: Superior heat transfer efficiency, excellent chemical resistance, transparent construction allowing visual monitoring, proven scalability from lab to production, and precise reaction control. Weaknesses: Higher initial capital investment compared to conventional systems, potential for clogging with particulate-forming reactions, and specialized expertise required for implementation and operation.

BASF Corp.

Technical Solution: BASF has pioneered comprehensive flow chemistry solutions through their FlowChemistry program, focusing on both microstructured and tubular flow reactor technologies. Their approach integrates reactor design with process development expertise to optimize chemical manufacturing processes. BASF's microreactor systems feature precision-engineered microchannels (typically 100-1000 μm) that maximize surface-to-volume ratios, enabling exceptional heat transfer coefficients of 10,000-35,000 W/m²K compared to conventional reactors' 2,000-3,000 W/m²K. For larger-scale production, BASF employs advanced tubular reactor designs with enhanced mixing elements and optimized flow patterns. Their technology selection methodology evaluates reaction characteristics (kinetics, exothermicity, phase behavior) against reactor capabilities to determine the optimal solution. BASF has successfully implemented these technologies for hazardous reactions like nitrations, diazotizations, and organometallic chemistry, achieving significant yield improvements and waste reduction across their production portfolio.

Strengths: Comprehensive expertise in both reactor types allowing application-specific optimization, established scale-up methodologies, integration with digital process control systems, and proven implementation across diverse chemical processes. Weaknesses: Complex decision-making framework requiring extensive characterization data, higher implementation costs for specialty applications, and potential challenges with multiphase reactions in certain configurations.

Key Patents and Innovations in Flow Reactor Design

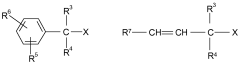

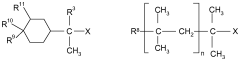

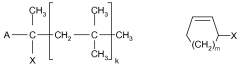

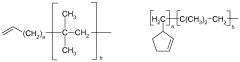

Process and apparatus for continuously polymerizing cationically polymerizable monomers

PatentWO2009133187A1

Innovation

- A process involving the mixing of at least two liquid streams containing cationically polymerizable monomers, initiators, and catalysts in a mixer with microstructures before polymerization in a single reaction zone, allowing for polymerization at higher temperatures while maintaining narrow molecular weight distributions.

Process and apparatus for carrying out (bio)chemical reactions and unit operations in fluid systems

PatentInactiveEP0010571A1

Innovation

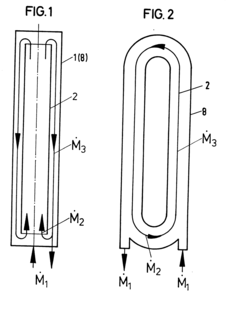

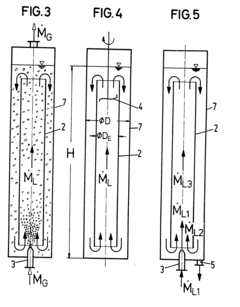

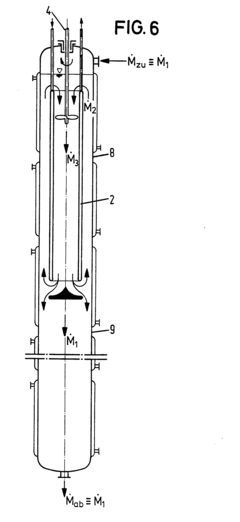

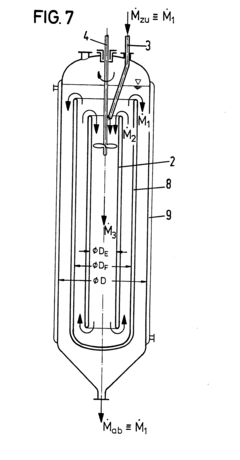

- The combination of loop reactor and tubular reactor characteristics, where the loop reactor provides intensive recirculation and uniform distribution, and the tubular reactor ensures minimal back-mixing, allowing for adjustable circulation times and enhanced cooling surfaces, while the tubular section ensures pipe-like flow characteristics for gas and liquid phases.

Scale-up Considerations for Industrial Implementation

Scaling up flow reactors from laboratory to industrial scale presents unique challenges that require careful consideration of both technical and economic factors. When transitioning from tubular to microstructured flow reactors (or vice versa), manufacturers must evaluate multiple parameters including production volume requirements, heat and mass transfer characteristics, and operational flexibility. The numbering-up approach commonly used with microstructured reactors offers advantages in maintaining consistent performance across scales, whereas traditional tubular reactors typically employ dimensional scaling which may introduce performance variations.

For microstructured flow reactors, industrial implementation often involves parallel arrangement of multiple reactor units rather than increasing individual channel dimensions. This preserves the favorable heat and mass transfer characteristics that make these reactors advantageous at smaller scales. However, this approach requires sophisticated flow distribution systems to ensure uniform flow across all channels, adding complexity to the overall system design. Additionally, manufacturers must consider the increased capital expenditure associated with precision-engineered microstructured components when implementing at industrial scale.

Tubular flow reactors, conversely, offer simpler scale-up pathways through increased diameter and length, though this approach may compromise some of the mixing and heat transfer efficiencies observed at smaller scales. The reduced surface-to-volume ratio in larger tubular reactors can lead to temperature gradients and potential hotspots, necessitating additional cooling systems or modified operating conditions. Despite these challenges, tubular reactors often present lower initial investment costs and may be more suitable for processes where extreme mixing efficiency is not critical.

Material selection becomes increasingly important at industrial scale, particularly for microstructured reactors where channel fouling can significantly impact performance. Advanced materials such as specialized stainless steels, ceramics, or coated surfaces may be necessary to prevent corrosion, fouling, or catalytic degradation during extended operation. These material considerations directly impact maintenance schedules and operational costs, which must be factored into the overall economic assessment.

Regulatory compliance and safety considerations also scale differently between reactor types. Microstructured reactors often offer inherent safety advantages due to smaller reaction volumes and improved heat management, potentially simplifying regulatory approval processes. However, their complex internal geometries may present cleaning validation challenges in regulated industries such as pharmaceuticals. Tubular reactors, while potentially presenting greater safety risks due to larger volumes, benefit from established regulatory frameworks and industry familiarity.

For microstructured flow reactors, industrial implementation often involves parallel arrangement of multiple reactor units rather than increasing individual channel dimensions. This preserves the favorable heat and mass transfer characteristics that make these reactors advantageous at smaller scales. However, this approach requires sophisticated flow distribution systems to ensure uniform flow across all channels, adding complexity to the overall system design. Additionally, manufacturers must consider the increased capital expenditure associated with precision-engineered microstructured components when implementing at industrial scale.

Tubular flow reactors, conversely, offer simpler scale-up pathways through increased diameter and length, though this approach may compromise some of the mixing and heat transfer efficiencies observed at smaller scales. The reduced surface-to-volume ratio in larger tubular reactors can lead to temperature gradients and potential hotspots, necessitating additional cooling systems or modified operating conditions. Despite these challenges, tubular reactors often present lower initial investment costs and may be more suitable for processes where extreme mixing efficiency is not critical.

Material selection becomes increasingly important at industrial scale, particularly for microstructured reactors where channel fouling can significantly impact performance. Advanced materials such as specialized stainless steels, ceramics, or coated surfaces may be necessary to prevent corrosion, fouling, or catalytic degradation during extended operation. These material considerations directly impact maintenance schedules and operational costs, which must be factored into the overall economic assessment.

Regulatory compliance and safety considerations also scale differently between reactor types. Microstructured reactors often offer inherent safety advantages due to smaller reaction volumes and improved heat management, potentially simplifying regulatory approval processes. However, their complex internal geometries may present cleaning validation challenges in regulated industries such as pharmaceuticals. Tubular reactors, while potentially presenting greater safety risks due to larger volumes, benefit from established regulatory frameworks and industry familiarity.

Sustainability and Energy Efficiency Aspects

The sustainability and energy efficiency aspects of flow reactors represent critical considerations in modern chemical processing industries. Tubular and microstructured flow reactors offer distinct advantages in terms of environmental impact and energy consumption profiles that must be carefully evaluated during technology selection processes.

Microstructured flow reactors demonstrate superior energy efficiency due to their enhanced heat transfer capabilities. The high surface-to-volume ratio enables precise temperature control with minimal energy input, reducing overall energy consumption by 20-40% compared to conventional batch processes. This characteristic is particularly valuable for exothermic reactions where efficient heat removal prevents runaway conditions and minimizes cooling utility requirements.

Tubular reactors, while generally less energy-efficient on a unit volume basis, offer advantages through economies of scale and continuous operation. Their established technology allows for effective heat integration within broader plant systems, potentially recovering up to 60% of process heat through strategic design. However, their larger thermal mass necessitates higher initial heating requirements and presents challenges in rapid temperature adjustments.

From a sustainability perspective, both reactor types enable significant reductions in solvent usage—a key environmental consideration. Microstructured reactors typically achieve 50-80% solvent reduction through intensified processing, while tubular systems generally realize 30-50% reductions compared to batch alternatives. This directly translates to decreased waste generation and lower environmental footprint across the chemical value chain.

Material efficiency represents another crucial sustainability factor. Microstructured reactors excel in reaction selectivity due to precise mixing and residence time distribution, potentially increasing desired product yield by 5-15% while reducing byproduct formation. This improvement directly reduces raw material consumption and waste treatment requirements, enhancing overall process sustainability.

Operational lifespan and maintenance requirements further differentiate these technologies. Tubular reactors typically demonstrate longer service lives (15-25 years) with lower replacement frequency, reducing embodied carbon impacts from manufacturing replacement equipment. Conversely, microstructured reactors may require more frequent component replacement but offer advantages through modular design that facilitates targeted maintenance rather than complete system overhaul.

Carbon footprint assessments reveal that implementation of either flow technology can reduce greenhouse gas emissions by 15-30% compared to batch processing, primarily through improved energy efficiency, reduced waste generation, and enhanced process intensification. The selection between tubular and microstructured options should therefore consider specific reaction requirements alongside organizational sustainability targets and available infrastructure.

Microstructured flow reactors demonstrate superior energy efficiency due to their enhanced heat transfer capabilities. The high surface-to-volume ratio enables precise temperature control with minimal energy input, reducing overall energy consumption by 20-40% compared to conventional batch processes. This characteristic is particularly valuable for exothermic reactions where efficient heat removal prevents runaway conditions and minimizes cooling utility requirements.

Tubular reactors, while generally less energy-efficient on a unit volume basis, offer advantages through economies of scale and continuous operation. Their established technology allows for effective heat integration within broader plant systems, potentially recovering up to 60% of process heat through strategic design. However, their larger thermal mass necessitates higher initial heating requirements and presents challenges in rapid temperature adjustments.

From a sustainability perspective, both reactor types enable significant reductions in solvent usage—a key environmental consideration. Microstructured reactors typically achieve 50-80% solvent reduction through intensified processing, while tubular systems generally realize 30-50% reductions compared to batch alternatives. This directly translates to decreased waste generation and lower environmental footprint across the chemical value chain.

Material efficiency represents another crucial sustainability factor. Microstructured reactors excel in reaction selectivity due to precise mixing and residence time distribution, potentially increasing desired product yield by 5-15% while reducing byproduct formation. This improvement directly reduces raw material consumption and waste treatment requirements, enhancing overall process sustainability.

Operational lifespan and maintenance requirements further differentiate these technologies. Tubular reactors typically demonstrate longer service lives (15-25 years) with lower replacement frequency, reducing embodied carbon impacts from manufacturing replacement equipment. Conversely, microstructured reactors may require more frequent component replacement but offer advantages through modular design that facilitates targeted maintenance rather than complete system overhaul.

Carbon footprint assessments reveal that implementation of either flow technology can reduce greenhouse gas emissions by 15-30% compared to batch processing, primarily through improved energy efficiency, reduced waste generation, and enhanced process intensification. The selection between tubular and microstructured options should therefore consider specific reaction requirements alongside organizational sustainability targets and available infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!