Model Predictive Control For Stable Operation Of Continuous Microreactors

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

MPC Technology Background and Objectives

Model Predictive Control (MPC) has emerged as a pivotal technology in the field of process control since its inception in the late 1970s. Initially developed for oil refinery applications, MPC has evolved significantly over the past four decades, transitioning from basic linear models to sophisticated nonlinear and hybrid systems capable of handling complex process dynamics. This evolution has been driven by advancements in computational capabilities, optimization algorithms, and control theory.

In the context of continuous microreactors, MPC represents a transformative approach to process control. Microreactors, characterized by their small dimensions (typically channel diameters of 10-500 micrometers), offer numerous advantages including enhanced heat and mass transfer, improved safety profiles, and potential for process intensification. However, these systems also present unique control challenges due to their fast dynamics, sensitivity to disturbances, and complex fluid behavior at microscale.

The technological trajectory of MPC for microreactors has been shaped by parallel developments in miniaturization technologies, microfluidics, and real-time sensing capabilities. Early implementations focused primarily on temperature control, while contemporary systems address multivariable control problems including flow rates, pressure gradients, and chemical composition in real-time. This progression reflects the increasing sophistication of both the control algorithms and the underlying hardware infrastructure.

The primary objective of implementing MPC for continuous microreactors is to achieve robust operational stability while maximizing process efficiency and product quality. Specifically, MPC aims to maintain precise control over critical process parameters despite inherent uncertainties, external disturbances, and potential system nonlinearities. This includes ensuring consistent residence time distributions, preventing clogging or fouling, and maintaining optimal reaction conditions throughout extended operation periods.

Secondary objectives include minimizing energy consumption, reducing waste generation, enabling rapid process reconfiguration, and facilitating seamless scale-up from laboratory to production environments. These goals align with broader industry trends toward sustainable manufacturing practices and flexible production systems capable of responding to market demands with agility.

The technological horizon for MPC in microreactor applications points toward increasing integration with artificial intelligence, machine learning techniques for adaptive model refinement, and edge computing architectures that enable distributed control strategies. Research efforts are increasingly focused on developing control systems capable of handling the complexities of multiphase flows, heterogeneous catalysis, and highly exothermic reactions within microchannels, pushing the boundaries of what can be achieved in continuous-flow chemistry.

In the context of continuous microreactors, MPC represents a transformative approach to process control. Microreactors, characterized by their small dimensions (typically channel diameters of 10-500 micrometers), offer numerous advantages including enhanced heat and mass transfer, improved safety profiles, and potential for process intensification. However, these systems also present unique control challenges due to their fast dynamics, sensitivity to disturbances, and complex fluid behavior at microscale.

The technological trajectory of MPC for microreactors has been shaped by parallel developments in miniaturization technologies, microfluidics, and real-time sensing capabilities. Early implementations focused primarily on temperature control, while contemporary systems address multivariable control problems including flow rates, pressure gradients, and chemical composition in real-time. This progression reflects the increasing sophistication of both the control algorithms and the underlying hardware infrastructure.

The primary objective of implementing MPC for continuous microreactors is to achieve robust operational stability while maximizing process efficiency and product quality. Specifically, MPC aims to maintain precise control over critical process parameters despite inherent uncertainties, external disturbances, and potential system nonlinearities. This includes ensuring consistent residence time distributions, preventing clogging or fouling, and maintaining optimal reaction conditions throughout extended operation periods.

Secondary objectives include minimizing energy consumption, reducing waste generation, enabling rapid process reconfiguration, and facilitating seamless scale-up from laboratory to production environments. These goals align with broader industry trends toward sustainable manufacturing practices and flexible production systems capable of responding to market demands with agility.

The technological horizon for MPC in microreactor applications points toward increasing integration with artificial intelligence, machine learning techniques for adaptive model refinement, and edge computing architectures that enable distributed control strategies. Research efforts are increasingly focused on developing control systems capable of handling the complexities of multiphase flows, heterogeneous catalysis, and highly exothermic reactions within microchannels, pushing the boundaries of what can be achieved in continuous-flow chemistry.

Market Demand for Continuous Microreactor Control

The continuous microreactor market has witnessed substantial growth in recent years, driven by increasing demand for more efficient, sustainable, and precise chemical manufacturing processes. The global market for continuous flow chemistry, which includes microreactors, was valued at approximately $62 billion in 2022 and is projected to reach $95 billion by 2028, representing a compound annual growth rate of 7.4% during the forecast period.

Pharmaceutical and fine chemical industries constitute the largest market segments for continuous microreactors, accounting for over 60% of the total market share. This dominance stems from the stringent quality requirements and the need for precise reaction control in drug manufacturing. Major pharmaceutical companies including Novartis, GSK, and Pfizer have already implemented continuous manufacturing processes utilizing microreactor technology, signaling strong industry adoption.

The demand for advanced control systems, particularly Model Predictive Control (MPC), has emerged as a critical factor driving the microreactor market. End-users increasingly require sophisticated control mechanisms that can ensure stable operation, optimize yield, and minimize waste. A survey conducted among chemical manufacturers revealed that 78% consider process control capabilities as "very important" or "critical" when evaluating microreactor systems.

Regulatory pressures have significantly influenced market demand for better-controlled microreactor systems. The FDA's initiative on Advancing Manufacturing has encouraged pharmaceutical companies to adopt continuous manufacturing with robust control strategies. Similarly, the European Medicines Agency has published guidelines promoting continuous manufacturing technologies with emphasis on process analytical technology and control systems.

Sustainability objectives represent another major market driver. Continuous microreactors with advanced control systems can reduce solvent usage by up to 90% compared to batch processes, while energy consumption can be lowered by 30-50%. These environmental benefits align with corporate sustainability goals and increasingly stringent environmental regulations worldwide.

Regional analysis indicates that North America and Europe currently lead the market for advanced microreactor control systems, collectively accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China, Japan, and India, is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and increasing investment in pharmaceutical manufacturing capabilities.

Customer requirements are evolving toward more integrated solutions that combine hardware, software, and services. End-users increasingly demand microreactor systems with built-in advanced control capabilities, real-time monitoring, and predictive maintenance features. This trend has prompted equipment manufacturers to either develop proprietary control solutions or partner with specialized control system providers.

Pharmaceutical and fine chemical industries constitute the largest market segments for continuous microreactors, accounting for over 60% of the total market share. This dominance stems from the stringent quality requirements and the need for precise reaction control in drug manufacturing. Major pharmaceutical companies including Novartis, GSK, and Pfizer have already implemented continuous manufacturing processes utilizing microreactor technology, signaling strong industry adoption.

The demand for advanced control systems, particularly Model Predictive Control (MPC), has emerged as a critical factor driving the microreactor market. End-users increasingly require sophisticated control mechanisms that can ensure stable operation, optimize yield, and minimize waste. A survey conducted among chemical manufacturers revealed that 78% consider process control capabilities as "very important" or "critical" when evaluating microreactor systems.

Regulatory pressures have significantly influenced market demand for better-controlled microreactor systems. The FDA's initiative on Advancing Manufacturing has encouraged pharmaceutical companies to adopt continuous manufacturing with robust control strategies. Similarly, the European Medicines Agency has published guidelines promoting continuous manufacturing technologies with emphasis on process analytical technology and control systems.

Sustainability objectives represent another major market driver. Continuous microreactors with advanced control systems can reduce solvent usage by up to 90% compared to batch processes, while energy consumption can be lowered by 30-50%. These environmental benefits align with corporate sustainability goals and increasingly stringent environmental regulations worldwide.

Regional analysis indicates that North America and Europe currently lead the market for advanced microreactor control systems, collectively accounting for approximately 65% of global demand. However, the Asia-Pacific region, particularly China, Japan, and India, is experiencing the fastest growth rate at 9.2% annually, driven by rapid industrialization and increasing investment in pharmaceutical manufacturing capabilities.

Customer requirements are evolving toward more integrated solutions that combine hardware, software, and services. End-users increasingly demand microreactor systems with built-in advanced control capabilities, real-time monitoring, and predictive maintenance features. This trend has prompted equipment manufacturers to either develop proprietary control solutions or partner with specialized control system providers.

Current Challenges in Microreactor Stability

Despite significant advancements in microreactor technology, maintaining operational stability remains a critical challenge. Continuous microreactors are inherently sensitive to fluctuations in process parameters, with even minor disturbances potentially causing significant deviations in product quality and process efficiency. The miniaturized nature of these systems, while advantageous for heat and mass transfer, creates unique stability challenges not encountered in conventional reactor systems.

Temperature control represents one of the most significant stability challenges. The high surface-to-volume ratio of microreactors results in rapid heat transfer, making them susceptible to thermal runaway scenarios if control systems cannot respond with sufficient speed. This is particularly problematic for highly exothermic reactions where heat generation can quickly exceed heat removal capabilities, leading to potential safety hazards and product degradation.

Flow stability presents another major hurdle. Microchannels are prone to clogging from particulate formation, crystallization, or fouling, which can disrupt flow patterns and create unpredictable pressure drops. These flow disturbances propagate throughout the system, affecting residence time distributions and consequently reaction selectivity and conversion rates. Current flow control mechanisms often lack the precision required for maintaining consistent flow profiles under varying reaction conditions.

Mixing efficiency fluctuations also compromise stability. While microreactors generally offer excellent mixing characteristics, local variations in mixing can occur due to channel geometry imperfections or flow regime transitions. These variations lead to concentration gradients that affect reaction kinetics and product distribution, particularly in multiphase systems where interface quality directly impacts mass transfer rates.

Sensor integration limitations further exacerbate stability challenges. The compact nature of microreactors restricts the implementation of comprehensive sensing arrays, resulting in limited real-time data for process monitoring. This creates significant blind spots in control systems, forcing operators to rely on indirect measurements or delayed offline analysis, which impedes rapid response to developing instabilities.

Conventional control strategies have proven inadequate for addressing these interconnected stability challenges. PID controllers, while widely used, lack the predictive capabilities necessary for anticipating disturbances in microreactor systems. Their reactive nature results in delayed responses to process deviations, often allowing instabilities to amplify before corrective actions are implemented. This limitation becomes particularly problematic for reactions with complex kinetics or those operating near constraint boundaries.

The integration of multiple microreactors into numbering-up configurations introduces additional stability concerns related to flow distribution and thermal management across parallel units. Ensuring uniform conditions across all channels remains technically challenging, with disturbances in one unit potentially cascading throughout the system.

Temperature control represents one of the most significant stability challenges. The high surface-to-volume ratio of microreactors results in rapid heat transfer, making them susceptible to thermal runaway scenarios if control systems cannot respond with sufficient speed. This is particularly problematic for highly exothermic reactions where heat generation can quickly exceed heat removal capabilities, leading to potential safety hazards and product degradation.

Flow stability presents another major hurdle. Microchannels are prone to clogging from particulate formation, crystallization, or fouling, which can disrupt flow patterns and create unpredictable pressure drops. These flow disturbances propagate throughout the system, affecting residence time distributions and consequently reaction selectivity and conversion rates. Current flow control mechanisms often lack the precision required for maintaining consistent flow profiles under varying reaction conditions.

Mixing efficiency fluctuations also compromise stability. While microreactors generally offer excellent mixing characteristics, local variations in mixing can occur due to channel geometry imperfections or flow regime transitions. These variations lead to concentration gradients that affect reaction kinetics and product distribution, particularly in multiphase systems where interface quality directly impacts mass transfer rates.

Sensor integration limitations further exacerbate stability challenges. The compact nature of microreactors restricts the implementation of comprehensive sensing arrays, resulting in limited real-time data for process monitoring. This creates significant blind spots in control systems, forcing operators to rely on indirect measurements or delayed offline analysis, which impedes rapid response to developing instabilities.

Conventional control strategies have proven inadequate for addressing these interconnected stability challenges. PID controllers, while widely used, lack the predictive capabilities necessary for anticipating disturbances in microreactor systems. Their reactive nature results in delayed responses to process deviations, often allowing instabilities to amplify before corrective actions are implemented. This limitation becomes particularly problematic for reactions with complex kinetics or those operating near constraint boundaries.

The integration of multiple microreactors into numbering-up configurations introduces additional stability concerns related to flow distribution and thermal management across parallel units. Ensuring uniform conditions across all channels remains technically challenging, with disturbances in one unit potentially cascading throughout the system.

Existing MPC Solutions for Microreactors

01 Stability enhancement in model predictive control systems

Various techniques are employed to enhance stability in model predictive control (MPC) systems. These include implementing stability constraints, using Lyapunov functions, and incorporating terminal constraints to ensure the controlled system remains within stable operating regions. These methods help prevent oscillations and divergence in control actions, particularly in complex industrial processes where stability is critical for safe and efficient operation.- Stability enhancement in model predictive control systems: Various techniques are employed to enhance stability in model predictive control systems, including robust control algorithms, stability constraints, and optimization methods. These approaches ensure that the controlled process remains stable even under disturbances or model uncertainties. By incorporating stability criteria directly into the control formulation, these systems can maintain reliable operation across varying conditions while optimizing performance objectives.

- Application of MPC in industrial processes: Model predictive control is widely implemented in various industrial processes to maintain stable operation while optimizing efficiency. These applications include chemical processing, manufacturing, energy systems, and other complex industrial environments. MPC algorithms in these contexts are designed to handle multiple variables, constraints, and objectives simultaneously while ensuring process stability and product quality under varying operational conditions.

- Advanced MPC algorithms for dynamic systems: Advanced model predictive control algorithms are developed specifically for dynamic systems requiring stable operation. These algorithms incorporate techniques such as state estimation, adaptive modeling, and recursive optimization to handle time-varying parameters and system dynamics. By continuously updating the prediction model and control strategy, these approaches maintain stability while responding effectively to changing conditions and requirements.

- Integration of MPC with other control strategies: Model predictive control is often integrated with other control strategies to enhance stability and performance. These hybrid approaches combine MPC with techniques such as fuzzy logic, neural networks, or traditional PID control to leverage the strengths of each method. The integration allows for robust operation across different operating regimes, improved disturbance rejection, and enhanced stability during transitions between operating points.

- Real-time optimization and constraint handling in MPC: Real-time optimization and effective constraint handling are crucial aspects of stable MPC operation. These systems employ efficient computational methods to solve complex optimization problems within strict time constraints while respecting operational limitations. By incorporating both hard and soft constraints, these approaches ensure that control actions remain within safe operating boundaries while maximizing performance objectives and maintaining process stability.

02 Adaptive and robust MPC for uncertain systems

Adaptive and robust model predictive control strategies are designed to maintain stable operation in the presence of uncertainties, disturbances, and model mismatches. These approaches dynamically adjust control parameters based on real-time system behavior, incorporate uncertainty bounds in the prediction model, and use robust optimization techniques to ensure stability across a range of operating conditions.Expand Specific Solutions03 MPC for engine and turbine control applications

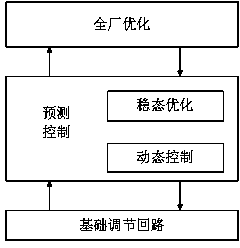

Model predictive control is specifically applied to engine and turbine systems to maintain stable operation while optimizing performance. These implementations account for the unique dynamics of combustion processes, flow characteristics, and thermal behaviors. The control strategies balance efficiency, emissions reduction, and operational stability while respecting physical constraints of the machinery.Expand Specific Solutions04 Distributed and hierarchical MPC architectures

Distributed and hierarchical model predictive control architectures are designed for complex, large-scale systems where centralized control is impractical. These approaches divide the control problem into interconnected subsystems, with coordination mechanisms to ensure overall system stability. Communication protocols between control nodes and optimization of the hierarchical structure are key elements for maintaining stable operation across the entire system.Expand Specific Solutions05 Real-time implementation and computational efficiency for stable MPC

Techniques for real-time implementation and computational efficiency are crucial for stable model predictive control operation in practical applications. These include fast solving algorithms, warm-starting optimization, explicit MPC formulations, and hardware acceleration. By reducing computational delay and ensuring timely control updates, these methods prevent instability that could arise from delayed control actions in dynamic systems.Expand Specific Solutions

Key Industry Players and Research Groups

The microreactor control technology landscape is evolving rapidly, with academic institutions leading research and development. Universities like Zhejiang, Tsinghua, and Southeast University dominate the field, while industrial players such as State Grid Corp. of China, Rolls-Royce, and OMRON are beginning to implement these technologies. The market is in early growth phase, with estimated value of $2-3 billion and projected 15% annual growth. Technical maturity varies significantly - academic research is advanced in theoretical modeling, but commercial implementation remains limited. Companies like Praxair, Weichai Power, and NARI Technology are developing proprietary control systems, indicating increasing industry recognition of microreactor technology's potential for process intensification and energy efficiency.

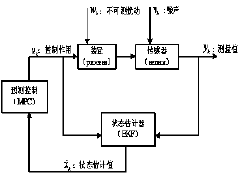

Zhejiang University

Technical Solution: Zhejiang University has developed advanced model predictive control (MPC) frameworks specifically tailored for continuous microreactors. Their approach integrates real-time optimization with robust control strategies to maintain stable operation under process disturbances. The university's research team has implemented a multi-layer control architecture that combines first-principles modeling with data-driven techniques to capture complex reaction kinetics in microreactor environments. Their system employs nonlinear MPC algorithms with state estimation capabilities to handle the fast dynamics characteristic of microreactor systems, achieving control intervals in the millisecond range. The technology incorporates adaptive parameter tuning mechanisms that automatically adjust control parameters based on changing reaction conditions, ensuring optimal performance across varying operational scenarios.

Strengths: Superior handling of the rapid dynamics inherent in microreactor systems; integration of advanced state estimation techniques for dealing with unmeasured variables. Weaknesses: Higher computational requirements compared to conventional control methods; requires detailed process models that may be challenging to develop for complex reaction systems.

Rolls-Royce Plc

Technical Solution: Rolls-Royce has pioneered industrial implementation of model predictive control for continuous microreactors in their manufacturing processes. Their proprietary system incorporates economic objectives directly into the control formulation, creating an economic MPC framework that optimizes both process stability and production efficiency simultaneously. The company has developed specialized hardware-software integration that enables real-time execution of complex MPC algorithms on industrial-grade controllers with response times under 50ms. Their approach features a hierarchical control structure where the MPC layer provides optimal setpoints to lower-level regulatory controllers, creating a robust cascade system. Rolls-Royce's implementation includes comprehensive fault detection and isolation mechanisms that can identify process anomalies and reconfigure the control strategy to maintain safe operation during abnormal conditions.

Strengths: Proven industrial implementation with demonstrated economic benefits; robust fault-tolerance capabilities that ensure continuous operation. Weaknesses: Proprietary system with limited external compatibility; significant initial investment required for implementation.

Core MPC Algorithms for Flow Chemistry

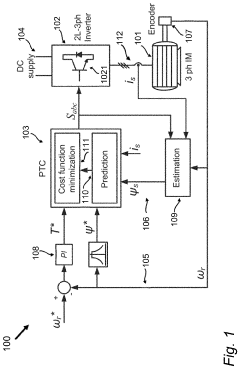

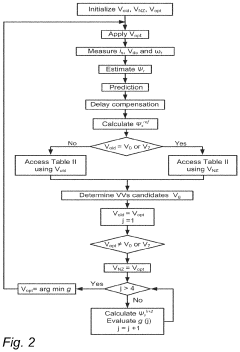

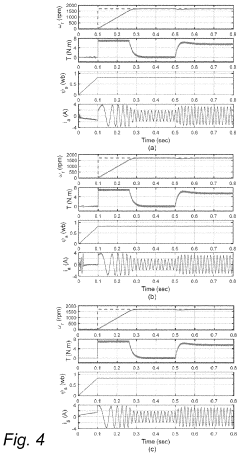

Method for controlling electric drive system and electric drive system

PatentActiveUS20200409320A1

Innovation

- The method involves predefining an initial voltage vector and using a lookup table to select a group of candidate voltage vectors, calculating a cost function based on the deviation between predicted and reference stator flux, and applying the primary voltage vector that minimizes this cost function, thereby reducing computation and eliminating the need for flux weighting factors.

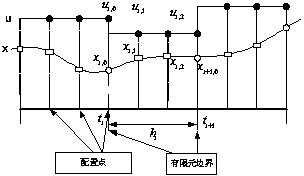

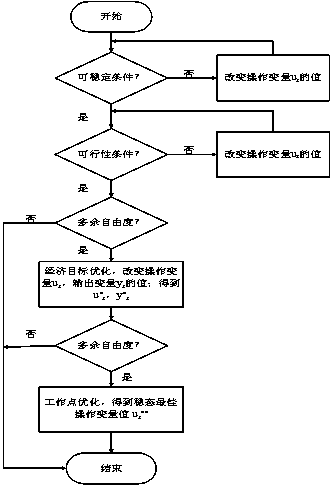

Multi-target hierarchical prediction control method based on continuous stirred tank reactor

PatentInactiveCN104536294A

Innovation

- A multi-objective dual-layer predictive control method based on a nonlinear model is adopted, discretized through the finite element orthogonal configuration method, and combined with steady-state and dynamic optimization objectives to determine the predicted values of input and output variables to ensure system stability, feasibility and Economic benefits, dynamic optimization layer provides optimal control objectives.

Safety and Risk Management Protocols

Safety and risk management in continuous microreactors utilizing Model Predictive Control (MPC) requires a comprehensive approach due to the inherent hazards associated with chemical processing at microscale. The implementation of robust safety protocols begins with thorough hazard identification specific to microreactor operations, including thermal runaway reactions, pressure fluctuations, and material compatibility issues that may arise during continuous processing.

Risk assessment frameworks tailored for MPC-controlled microreactors must incorporate both deterministic and probabilistic methodologies. These assessments should evaluate the likelihood and consequences of control system failures, sensor malfunctions, and process deviations. The unique characteristics of microreactors, such as high surface-to-volume ratios and rapid heat transfer capabilities, necessitate specialized risk evaluation parameters that differ from conventional batch reactor systems.

Preventive safety measures in MPC-controlled microreactors include the implementation of multi-layered control architectures with redundant safety systems. Critical to these systems is the integration of real-time monitoring with predictive capabilities that can anticipate potential hazardous conditions before they manifest. Advanced fault detection algorithms should be embedded within the MPC framework to identify anomalies in process parameters that may indicate impending safety issues.

Emergency response protocols must be designed specifically for the rapid dynamics of microreactor systems. These protocols should include automated shutdown sequences triggered by predefined safety thresholds, containment strategies for potential releases, and isolation mechanisms to prevent cascade failures across interconnected microreactor units. The MPC system should incorporate safety constraints as hard boundaries within its optimization algorithm to ensure process variables remain within safe operating envelopes regardless of production objectives.

Regulatory compliance represents another crucial aspect of safety management for microreactors. Current regulatory frameworks may require adaptation to address the unique characteristics of continuous microreactor operations. Organizations implementing MPC for microreactors should engage proactively with regulatory bodies to develop appropriate compliance strategies that satisfy both safety requirements and operational flexibility needs.

Training programs for personnel operating MPC-controlled microreactors must emphasize the distinctive safety considerations of these systems. Operators require specialized knowledge regarding the interpretation of MPC-generated control actions, recognition of potential safety-critical scenarios, and appropriate intervention strategies when automated systems require human oversight. Simulation-based training environments can provide valuable experience in managing abnormal situations without risking actual process safety.

Continuous improvement of safety protocols through systematic incident investigation and knowledge sharing represents the final component of comprehensive risk management. Post-incident analyses should feed back into MPC model refinement and safety constraint updates, creating an evolving safety system that adapts to operational experience and emerging risk factors.

Risk assessment frameworks tailored for MPC-controlled microreactors must incorporate both deterministic and probabilistic methodologies. These assessments should evaluate the likelihood and consequences of control system failures, sensor malfunctions, and process deviations. The unique characteristics of microreactors, such as high surface-to-volume ratios and rapid heat transfer capabilities, necessitate specialized risk evaluation parameters that differ from conventional batch reactor systems.

Preventive safety measures in MPC-controlled microreactors include the implementation of multi-layered control architectures with redundant safety systems. Critical to these systems is the integration of real-time monitoring with predictive capabilities that can anticipate potential hazardous conditions before they manifest. Advanced fault detection algorithms should be embedded within the MPC framework to identify anomalies in process parameters that may indicate impending safety issues.

Emergency response protocols must be designed specifically for the rapid dynamics of microreactor systems. These protocols should include automated shutdown sequences triggered by predefined safety thresholds, containment strategies for potential releases, and isolation mechanisms to prevent cascade failures across interconnected microreactor units. The MPC system should incorporate safety constraints as hard boundaries within its optimization algorithm to ensure process variables remain within safe operating envelopes regardless of production objectives.

Regulatory compliance represents another crucial aspect of safety management for microreactors. Current regulatory frameworks may require adaptation to address the unique characteristics of continuous microreactor operations. Organizations implementing MPC for microreactors should engage proactively with regulatory bodies to develop appropriate compliance strategies that satisfy both safety requirements and operational flexibility needs.

Training programs for personnel operating MPC-controlled microreactors must emphasize the distinctive safety considerations of these systems. Operators require specialized knowledge regarding the interpretation of MPC-generated control actions, recognition of potential safety-critical scenarios, and appropriate intervention strategies when automated systems require human oversight. Simulation-based training environments can provide valuable experience in managing abnormal situations without risking actual process safety.

Continuous improvement of safety protocols through systematic incident investigation and knowledge sharing represents the final component of comprehensive risk management. Post-incident analyses should feed back into MPC model refinement and safety constraint updates, creating an evolving safety system that adapts to operational experience and emerging risk factors.

Scale-up Considerations for Industrial Implementation

Scaling up Model Predictive Control (MPC) systems from laboratory microreactors to industrial-scale implementation presents several significant challenges that must be addressed systematically. The computational demands increase exponentially with system size, requiring more sophisticated hardware and optimized algorithms to maintain real-time control capabilities. Industrial microreactor arrays may contain hundreds or thousands of parallel channels, necessitating distributed control architectures rather than centralized approaches that work well in laboratory settings.

Hardware considerations become paramount at industrial scale, with robust sensors and actuators needed to withstand harsh manufacturing environments while maintaining the precision required for effective MPC implementation. Sensor placement strategies must be reconsidered, as the optimal configuration for a single microreactor rarely translates directly to large-scale systems. Redundancy in critical measurement points becomes essential to ensure continuous operation despite potential sensor failures.

Communication infrastructure represents another crucial aspect of scale-up, as latency between sensors, controllers, and actuators can significantly impact control performance. Industrial implementations typically require dedicated networks with deterministic response times to support the high-frequency control loops characteristic of MPC systems for microreactors. Standardized communication protocols must be selected to ensure seamless integration with existing industrial control systems.

Economic considerations ultimately drive industrial implementation decisions. The capital expenditure for comprehensive MPC systems across large microreactor arrays must be justified through demonstrable improvements in yield, quality, and operational efficiency. A phased implementation approach often proves most practical, beginning with critical process units before expanding to facility-wide deployment. This allows for validation of economic benefits while minimizing initial investment risks.

Regulatory compliance adds another dimension to scale-up considerations. Industrial MPC implementations for microreactors must adhere to relevant industry standards and validation requirements, particularly in highly regulated sectors such as pharmaceuticals or specialty chemicals. Control system documentation, validation protocols, and change management procedures must be established to satisfy regulatory scrutiny while maintaining operational flexibility.

Training requirements for operational staff increase substantially when transitioning from laboratory to industrial scale. Operators must understand the fundamentals of MPC operation to effectively monitor system performance and respond appropriately to controller recommendations. Maintenance personnel require specialized training to troubleshoot complex control systems without compromising production continuity. This human factor often proves to be one of the most challenging aspects of successful industrial implementation.

Hardware considerations become paramount at industrial scale, with robust sensors and actuators needed to withstand harsh manufacturing environments while maintaining the precision required for effective MPC implementation. Sensor placement strategies must be reconsidered, as the optimal configuration for a single microreactor rarely translates directly to large-scale systems. Redundancy in critical measurement points becomes essential to ensure continuous operation despite potential sensor failures.

Communication infrastructure represents another crucial aspect of scale-up, as latency between sensors, controllers, and actuators can significantly impact control performance. Industrial implementations typically require dedicated networks with deterministic response times to support the high-frequency control loops characteristic of MPC systems for microreactors. Standardized communication protocols must be selected to ensure seamless integration with existing industrial control systems.

Economic considerations ultimately drive industrial implementation decisions. The capital expenditure for comprehensive MPC systems across large microreactor arrays must be justified through demonstrable improvements in yield, quality, and operational efficiency. A phased implementation approach often proves most practical, beginning with critical process units before expanding to facility-wide deployment. This allows for validation of economic benefits while minimizing initial investment risks.

Regulatory compliance adds another dimension to scale-up considerations. Industrial MPC implementations for microreactors must adhere to relevant industry standards and validation requirements, particularly in highly regulated sectors such as pharmaceuticals or specialty chemicals. Control system documentation, validation protocols, and change management procedures must be established to satisfy regulatory scrutiny while maintaining operational flexibility.

Training requirements for operational staff increase substantially when transitioning from laboratory to industrial scale. Operators must understand the fundamentals of MPC operation to effectively monitor system performance and respond appropriately to controller recommendations. Maintenance personnel require specialized training to troubleshoot complex control systems without compromising production continuity. This human factor often proves to be one of the most challenging aspects of successful industrial implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!