Process Intensification: High-Throughput Microreactor Screening Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactor technology has evolved significantly over the past three decades, transforming from laboratory curiosities to powerful tools for chemical process intensification. The initial development in the 1990s focused primarily on proof-of-concept demonstrations, with rudimentary channel designs etched in glass or silicon substrates. These early microreactors exhibited enhanced heat and mass transfer capabilities but lacked standardization and scalability.

The early 2000s marked a pivotal transition as researchers began to systematically explore the fundamental advantages of microreactors: superior surface-to-volume ratios, enhanced mixing efficiency, and precise reaction control. This period saw the emergence of more sophisticated fabrication techniques, including 3D printing, laser ablation, and advanced lithography methods, enabling more complex microreactor architectures with integrated sensors and control systems.

By the 2010s, microreactor technology had matured significantly with the introduction of modular designs, allowing for parallelization and numbering-up approaches to increase throughput. The integration of advanced materials such as ceramics, specialty alloys, and catalytic coatings expanded the application range to include high-temperature and high-pressure reactions previously considered unsuitable for microscale processing.

The current technological landscape features intelligent microreactor systems with real-time monitoring capabilities, automated sampling, and data-driven optimization. Machine learning algorithms are increasingly employed to predict reaction outcomes and optimize process parameters, significantly accelerating the screening process for new chemical transformations and catalytic systems.

The primary objective of high-throughput microreactor screening techniques is to dramatically accelerate the discovery and optimization of chemical processes while minimizing resource consumption. This approach aims to replace traditional batch experimentation with continuous-flow methodologies that offer superior control over reaction parameters and generate more reliable, reproducible data.

Secondary objectives include the development of standardized protocols for microreactor-based screening that can be widely adopted across academia and industry, facilitating knowledge transfer and technology implementation. Additionally, there is a growing emphasis on creating integrated platforms that combine reaction screening with in-line analytics and automated data processing to enable true high-throughput experimentation.

Looking forward, the field is moving toward fully autonomous microreactor systems capable of self-optimization through closed-loop feedback mechanisms. The ultimate goal is to establish microreactor technology as the standard methodology for chemical process development, enabling rapid translation from laboratory discovery to industrial implementation with minimal scale-up challenges.

The early 2000s marked a pivotal transition as researchers began to systematically explore the fundamental advantages of microreactors: superior surface-to-volume ratios, enhanced mixing efficiency, and precise reaction control. This period saw the emergence of more sophisticated fabrication techniques, including 3D printing, laser ablation, and advanced lithography methods, enabling more complex microreactor architectures with integrated sensors and control systems.

By the 2010s, microreactor technology had matured significantly with the introduction of modular designs, allowing for parallelization and numbering-up approaches to increase throughput. The integration of advanced materials such as ceramics, specialty alloys, and catalytic coatings expanded the application range to include high-temperature and high-pressure reactions previously considered unsuitable for microscale processing.

The current technological landscape features intelligent microreactor systems with real-time monitoring capabilities, automated sampling, and data-driven optimization. Machine learning algorithms are increasingly employed to predict reaction outcomes and optimize process parameters, significantly accelerating the screening process for new chemical transformations and catalytic systems.

The primary objective of high-throughput microreactor screening techniques is to dramatically accelerate the discovery and optimization of chemical processes while minimizing resource consumption. This approach aims to replace traditional batch experimentation with continuous-flow methodologies that offer superior control over reaction parameters and generate more reliable, reproducible data.

Secondary objectives include the development of standardized protocols for microreactor-based screening that can be widely adopted across academia and industry, facilitating knowledge transfer and technology implementation. Additionally, there is a growing emphasis on creating integrated platforms that combine reaction screening with in-line analytics and automated data processing to enable true high-throughput experimentation.

Looking forward, the field is moving toward fully autonomous microreactor systems capable of self-optimization through closed-loop feedback mechanisms. The ultimate goal is to establish microreactor technology as the standard methodology for chemical process development, enabling rapid translation from laboratory discovery to industrial implementation with minimal scale-up challenges.

Market Demand for High-Throughput Screening Solutions

The global market for high-throughput screening (HTS) solutions in microreactor technology has experienced significant growth over the past decade, driven primarily by the pharmaceutical, fine chemical, and specialty chemical industries. This growth reflects the increasing demand for more efficient, cost-effective, and environmentally friendly chemical processes.

In the pharmaceutical sector, the need for rapid drug discovery and development has created substantial demand for microreactor screening technologies. With the average cost of bringing a new drug to market exceeding $2.6 billion and development timelines stretching to 10-15 years, pharmaceutical companies are actively seeking technologies that can accelerate screening processes while reducing material consumption. High-throughput microreactor screening offers the potential to evaluate thousands of reaction conditions using minimal reagents, addressing this critical industry need.

The fine chemicals industry represents another significant market segment, with manufacturers increasingly adopting microreactor technology to optimize reaction parameters and improve product quality. Market research indicates that this sector is expected to grow at a compound annual growth rate of 5.7% through 2028, with process intensification technologies being a key driver of this expansion.

Environmental regulations and sustainability initiatives are further propelling market demand. As governments worldwide implement stricter emissions standards and waste reduction requirements, chemical manufacturers are turning to microreactor technologies that offer improved energy efficiency, reduced waste generation, and enhanced safety profiles. The European Union's Green Deal and similar initiatives in North America and Asia have created regulatory frameworks that indirectly boost demand for more sustainable processing technologies.

Academic and research institutions constitute another significant market segment, with increasing research funding directed toward process intensification technologies. This trend is particularly evident in countries with strong chemical and pharmaceutical industries, such as Germany, Switzerland, the United States, Japan, and increasingly China.

Regional analysis reveals that North America currently holds the largest market share for high-throughput microreactor screening technologies, followed closely by Europe. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization, increasing R&D investments, and the expansion of pharmaceutical and chemical manufacturing capabilities in countries like China, India, and South Korea.

Customer feedback indicates that key purchasing factors include throughput capacity, automation capabilities, data integration options, and return on investment metrics. End-users increasingly demand systems that can be seamlessly integrated with existing workflows and analytical platforms, highlighting the importance of interoperability in market adoption.

In the pharmaceutical sector, the need for rapid drug discovery and development has created substantial demand for microreactor screening technologies. With the average cost of bringing a new drug to market exceeding $2.6 billion and development timelines stretching to 10-15 years, pharmaceutical companies are actively seeking technologies that can accelerate screening processes while reducing material consumption. High-throughput microreactor screening offers the potential to evaluate thousands of reaction conditions using minimal reagents, addressing this critical industry need.

The fine chemicals industry represents another significant market segment, with manufacturers increasingly adopting microreactor technology to optimize reaction parameters and improve product quality. Market research indicates that this sector is expected to grow at a compound annual growth rate of 5.7% through 2028, with process intensification technologies being a key driver of this expansion.

Environmental regulations and sustainability initiatives are further propelling market demand. As governments worldwide implement stricter emissions standards and waste reduction requirements, chemical manufacturers are turning to microreactor technologies that offer improved energy efficiency, reduced waste generation, and enhanced safety profiles. The European Union's Green Deal and similar initiatives in North America and Asia have created regulatory frameworks that indirectly boost demand for more sustainable processing technologies.

Academic and research institutions constitute another significant market segment, with increasing research funding directed toward process intensification technologies. This trend is particularly evident in countries with strong chemical and pharmaceutical industries, such as Germany, Switzerland, the United States, Japan, and increasingly China.

Regional analysis reveals that North America currently holds the largest market share for high-throughput microreactor screening technologies, followed closely by Europe. However, the Asia-Pacific region is experiencing the fastest growth rate, driven by rapid industrialization, increasing R&D investments, and the expansion of pharmaceutical and chemical manufacturing capabilities in countries like China, India, and South Korea.

Customer feedback indicates that key purchasing factors include throughput capacity, automation capabilities, data integration options, and return on investment metrics. End-users increasingly demand systems that can be seamlessly integrated with existing workflows and analytical platforms, highlighting the importance of interoperability in market adoption.

Current Microreactor Screening Challenges

Despite significant advancements in microreactor technology, high-throughput screening techniques face several critical challenges that impede their widespread industrial adoption. The miniaturization that makes microreactors advantageous also creates substantial difficulties in process monitoring and control. Current sensing technologies struggle to provide accurate, real-time data at the microscale without disrupting the flow dynamics or chemical reactions being studied.

Sample handling represents another major obstacle, particularly for multiphase systems involving solids. Microchannels are prone to clogging when processing particulate matter, limiting screening capabilities for heterogeneous catalysis and crystallization processes. Even with sophisticated anti-fouling designs, long-term reliability remains problematic for continuous operation screening protocols.

Data management presents a growing challenge as screening throughput increases. Modern microreactor arrays can generate terabytes of process data daily, overwhelming traditional analysis frameworks. The integration of machine learning algorithms shows promise but requires standardized data formats and robust analytical pipelines that are still under development across the industry.

Scalability concerns persist between screening results and production implementation. Parameters optimized in microreactors often require significant adjustment when scaled to production volumes due to differences in mixing characteristics, heat transfer, and residence time distributions. This translation gap reduces confidence in screening outcomes and necessitates additional validation steps.

Material compatibility issues further complicate screening efforts. Advanced reaction conditions involving corrosive chemicals, high temperatures, or high pressures demand specialized microreactor materials that may alter reaction kinetics compared to production-scale equipment. The cost of fabricating screening arrays from exotic materials (silicon carbide, specialized alloys, etc.) remains prohibitively expensive for many applications.

Parallelization, while theoretically straightforward, introduces practical challenges in ensuring uniform conditions across multiple reaction channels. Variations in pressure drop, flow distribution, and temperature profiles can introduce systematic errors in screening results. Current flow distribution systems struggle to maintain consistency beyond 50-100 parallel channels without complex compensation mechanisms.

Integration with upstream and downstream processes represents another significant hurdle. High-throughput screening generates numerous potential product streams that must be rapidly analyzed, separated, and either stored or discarded. The analytical bottleneck often limits true screening throughput, with detection technologies lagging behind reaction throughput capabilities.

Sample handling represents another major obstacle, particularly for multiphase systems involving solids. Microchannels are prone to clogging when processing particulate matter, limiting screening capabilities for heterogeneous catalysis and crystallization processes. Even with sophisticated anti-fouling designs, long-term reliability remains problematic for continuous operation screening protocols.

Data management presents a growing challenge as screening throughput increases. Modern microreactor arrays can generate terabytes of process data daily, overwhelming traditional analysis frameworks. The integration of machine learning algorithms shows promise but requires standardized data formats and robust analytical pipelines that are still under development across the industry.

Scalability concerns persist between screening results and production implementation. Parameters optimized in microreactors often require significant adjustment when scaled to production volumes due to differences in mixing characteristics, heat transfer, and residence time distributions. This translation gap reduces confidence in screening outcomes and necessitates additional validation steps.

Material compatibility issues further complicate screening efforts. Advanced reaction conditions involving corrosive chemicals, high temperatures, or high pressures demand specialized microreactor materials that may alter reaction kinetics compared to production-scale equipment. The cost of fabricating screening arrays from exotic materials (silicon carbide, specialized alloys, etc.) remains prohibitively expensive for many applications.

Parallelization, while theoretically straightforward, introduces practical challenges in ensuring uniform conditions across multiple reaction channels. Variations in pressure drop, flow distribution, and temperature profiles can introduce systematic errors in screening results. Current flow distribution systems struggle to maintain consistency beyond 50-100 parallel channels without complex compensation mechanisms.

Integration with upstream and downstream processes represents another significant hurdle. High-throughput screening generates numerous potential product streams that must be rapidly analyzed, separated, and either stored or discarded. The analytical bottleneck often limits true screening throughput, with detection technologies lagging behind reaction throughput capabilities.

Current High-Throughput Screening Methodologies

01 Microfluidic devices for high-throughput screening

Microfluidic devices are utilized for high-throughput screening in microreactors, allowing for parallel processing of multiple samples simultaneously. These devices incorporate channels, chambers, and valves to control fluid flow and enable rapid analysis of chemical and biological reactions. The miniaturized format reduces reagent consumption while increasing experimental throughput, making them ideal for screening catalysts, reaction conditions, and biomolecular interactions.- Microfluidic systems for high-throughput screening: Microfluidic systems enable high-throughput screening by allowing for the parallel processing of multiple reactions in miniaturized channels. These systems incorporate various components such as pumps, valves, and sensors to control and monitor the flow of reagents. The small dimensions of microfluidic channels reduce reagent consumption and reaction times, making them ideal for screening large libraries of compounds or reaction conditions efficiently.

- Integrated analysis and detection methods in microreactors: Integrated analysis and detection methods in microreactors combine reaction screening with real-time monitoring capabilities. These techniques incorporate spectroscopic methods, electrochemical sensors, or optical detection systems directly into the microreactor platform. This integration allows for immediate data collection and analysis, reducing the time between experimentation and results interpretation, which is crucial for high-throughput applications.

- Parallel processing microreactor arrays: Parallel processing microreactor arrays consist of multiple identical reaction chambers operating simultaneously under controlled conditions. These arrays can be designed with varying reaction parameters across chambers to screen multiple conditions in a single experiment. Advanced systems incorporate automated sample handling and distribution systems to ensure precise delivery of reagents to each microreactor in the array, maximizing experimental throughput and reproducibility.

- Automated control and monitoring systems for microreactors: Automated control and monitoring systems for microreactors utilize software and hardware integration to manage complex screening protocols without manual intervention. These systems can adjust reaction parameters in real-time based on feedback from integrated sensors, allowing for adaptive experimentation. The automation extends to sample preparation, reaction execution, data collection, and analysis, significantly increasing throughput while maintaining experimental precision.

- Novel microreactor designs for specific screening applications: Novel microreactor designs are tailored for specific screening applications such as catalyst testing, enzymatic reactions, or pharmaceutical compound synthesis. These specialized designs incorporate features like gradient generators, mixing zones, or temperature control elements optimized for particular reaction types. Some designs also include compartmentalization strategies to prevent cross-contamination between samples, which is essential when screening large libraries of compounds in high-throughput formats.

02 Integrated sensing and detection systems

Advanced sensing and detection systems are integrated into microreactors to enable real-time monitoring and analysis of reactions during high-throughput screening. These systems may include optical sensors, spectroscopic techniques, electrochemical detectors, and imaging technologies that provide immediate feedback on reaction progress and outcomes. The integration of these detection methods allows for automated data collection and analysis, significantly enhancing the efficiency of screening processes.Expand Specific Solutions03 Parallel reaction optimization techniques

Parallel reaction optimization techniques involve the simultaneous execution of multiple reactions under varying conditions within microreactor arrays. This approach enables rapid identification of optimal reaction parameters such as temperature, pressure, catalyst loading, and reagent concentrations. By conducting numerous experiments in parallel, researchers can efficiently explore large parameter spaces and accelerate the discovery and development of new chemical processes and materials.Expand Specific Solutions04 Automated sample handling and processing systems

Automated systems for sample handling and processing are essential components of high-throughput microreactor screening platforms. These systems include robotic liquid handling, automated sample preparation, and programmable reaction control mechanisms that minimize human intervention and error. The automation of these processes ensures consistency across experiments, increases reproducibility, and allows for continuous operation, thereby maximizing screening efficiency and throughput.Expand Specific Solutions05 Data analysis and machine learning integration

Advanced data analysis methods and machine learning algorithms are increasingly integrated into high-throughput microreactor screening workflows. These computational approaches help process and interpret the large volumes of data generated during screening campaigns, identify patterns, and predict optimal reaction conditions. Machine learning models can guide experimental design, accelerate the optimization process, and enable the discovery of non-obvious relationships between reaction parameters and outcomes.Expand Specific Solutions

Leading Companies in Process Intensification

Process Intensification through high-throughput microreactor screening techniques is currently in a growth phase, with the market expanding rapidly due to increasing demand for efficient chemical processes. The global market size is estimated to reach $2.5 billion by 2025, driven by pharmaceutical, chemical, and energy sectors seeking cost-effective solutions. Technologically, the field is approaching maturity with companies like ExxonMobil Technology & Engineering and LG Chem leading industrial applications, while Corning and Agilent Technologies provide advanced microreactor platforms. Academic institutions such as The Scripps Research Institute and Zhejiang University are pushing boundaries in fundamental research. Pharmaceutical players including Astex Therapeutics and Merck Serono are leveraging these technologies for drug discovery, indicating cross-industry adoption and commercialization potential.

The Scripps Research Institute

Technical Solution: The Scripps Research Institute has developed an innovative microfluidic platform specifically designed for high-throughput screening of biocatalytic reactions and pharmaceutical synthesis pathways. Their system utilizes droplet-based microfluidics where each microdroplet functions as an individual nanoliter-scale reactor, enabling millions of parallel reactions to be conducted simultaneously. The technology incorporates fluorescence-activated droplet sorting (FADS) mechanisms that can rapidly analyze and isolate droplets containing successful reactions based on spectroscopic signatures. Scripps' platform features integrated microvalve systems that allow precise control over reagent combinations and reaction timing across thousands of parallel chambers. Their approach employs specialized surface chemistry modifications to prevent biomolecule adsorption and enzyme denaturation at interfaces, maintaining biological activity throughout the screening process. The institute has developed computational tools that integrate reaction modeling with experimental data to predict optimal conditions for biocatalytic transformations, significantly accelerating enzyme engineering and optimization.

Strengths: Exceptional throughput capacity for biological applications; minimal reagent consumption; excellent compatibility with biological systems; sophisticated detection capabilities for complex reactions. Weaknesses: More specialized for biological applications than general chemical processes; requires highly specialized expertise to operate; challenges in scaling up successful reactions to production volumes.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has pioneered an integrated microreactor platform specifically designed for catalyst screening in petrochemical applications. Their system employs parallel microreactor arrays with independent temperature and pressure control for each channel, allowing simultaneous evaluation of multiple catalysts under varying conditions. The technology incorporates advanced microfluidic control systems that precisely regulate reactant ratios and residence times across hundreds of reaction chambers. ExxonMobil's platform features integrated online analytical capabilities, including micro-GC and mass spectrometry systems that provide real-time composition analysis without manual sampling. Their high-throughput screening approach utilizes robotic sample handling and preparation systems that can prepare and load hundreds of catalyst formulations per day. The company has developed proprietary data analytics software that applies machine learning algorithms to rapidly identify optimal catalyst compositions and reaction conditions from the massive datasets generated.

Strengths: Exceptional throughput capacity for catalyst screening; robust design suitable for high-pressure and high-temperature conditions; sophisticated data analytics capabilities; seamless integration with existing refinery processes. Weaknesses: System complexity requires specialized maintenance; high initial investment cost; primarily optimized for gas-phase reactions rather than liquid-phase chemistry.

Key Innovations in Microreactor Design

Microreactor array platform

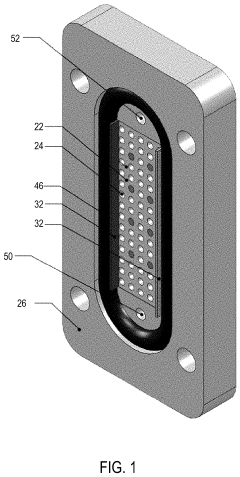

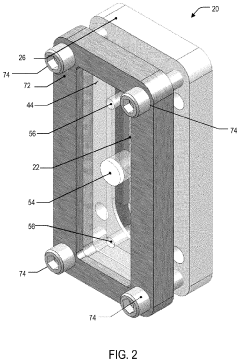

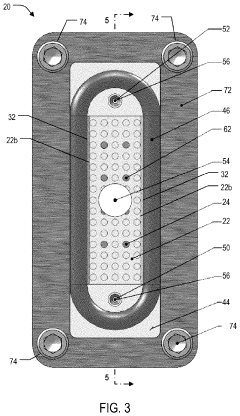

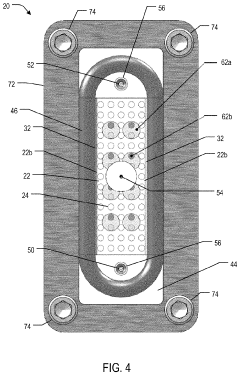

PatentActiveUS20210039091A1

Innovation

- A microreactor array platform is developed, featuring an array of microreactors sealed by a flexible, impervious sealing film with a reagent gap and an injector system for precise filling and sealing, allowing for independent chemical reactions without interference and maintaining reaction conditions.

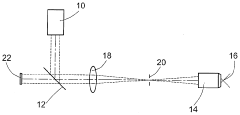

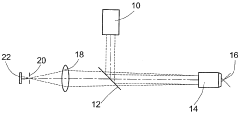

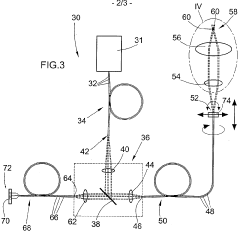

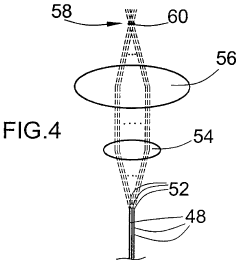

High rate screening method and device for optically detecting samples

PatentWO2001040769A2

Innovation

- The method involves using a multiplicity of optical fibers to distribute excitation and emission radiation, with a beam splitter device separating the paths, allowing for simultaneous focusing of excitation radiation into multiple foci within sample measurement volumes and detection of emission radiation by separate detector areas, thereby enabling high-throughput screening with reduced optical losses and chromatic errors.

Scale-up Considerations for Industrial Implementation

The transition from laboratory-scale microreactor systems to industrial production presents significant engineering challenges that must be addressed systematically. When scaling up high-throughput microreactor screening techniques, maintaining the advantageous characteristics of microreactors—such as enhanced heat and mass transfer, precise residence time control, and improved safety profiles—becomes increasingly complex. Industrial implementation requires careful consideration of several critical factors to ensure successful technology transfer.

Material selection becomes paramount at industrial scale, as materials must withstand prolonged exposure to potentially corrosive reagents while maintaining structural integrity under increased pressure and temperature conditions. Stainless steel, specialized alloys, and advanced polymers are commonly employed, with selection criteria including chemical compatibility, thermal conductivity, and mechanical strength under operating conditions.

Numbering-up versus traditional scale-up represents a fundamental decision point in microreactor technology implementation. Rather than increasing individual reactor dimensions (which would compromise the inherent advantages of microfluidics), industrial applications often employ parallel arrangements of multiple microreactor units. This approach preserves the beneficial transport phenomena while increasing throughput, though it introduces challenges in flow distribution and control systems.

Process control complexity increases exponentially with scale. Industrial microreactor systems require sophisticated monitoring and control architectures to maintain uniform conditions across parallel units. Advanced sensor integration becomes essential, with real-time monitoring of temperature, pressure, flow rates, and potentially reaction progress through spectroscopic methods. These systems must be robust enough for continuous operation while maintaining the precision required for microreactor performance.

Heat management strategies differ significantly between laboratory and industrial scales. While laboratory systems may rely on simple water baths or heating blocks, industrial implementations require more sophisticated approaches such as integrated heat exchangers, specialized heating/cooling zones, or advanced thermal management materials to maintain isothermal conditions across larger systems.

Economic considerations ultimately determine industrial viability. Capital expenditure for microreactor systems typically exceeds that of conventional batch equipment, necessitating clear demonstration of process intensification benefits—including reduced footprint, improved yield, enhanced safety, and potentially reduced downstream processing requirements. Comprehensive techno-economic analysis must account for both direct production costs and indirect benefits such as reduced waste treatment and improved product consistency.

Regulatory compliance presents additional challenges, particularly in pharmaceutical and fine chemical applications. Process validation strategies must be developed to demonstrate consistent performance across parallel microreactor units, with appropriate quality control measures implemented to ensure product uniformity.

Material selection becomes paramount at industrial scale, as materials must withstand prolonged exposure to potentially corrosive reagents while maintaining structural integrity under increased pressure and temperature conditions. Stainless steel, specialized alloys, and advanced polymers are commonly employed, with selection criteria including chemical compatibility, thermal conductivity, and mechanical strength under operating conditions.

Numbering-up versus traditional scale-up represents a fundamental decision point in microreactor technology implementation. Rather than increasing individual reactor dimensions (which would compromise the inherent advantages of microfluidics), industrial applications often employ parallel arrangements of multiple microreactor units. This approach preserves the beneficial transport phenomena while increasing throughput, though it introduces challenges in flow distribution and control systems.

Process control complexity increases exponentially with scale. Industrial microreactor systems require sophisticated monitoring and control architectures to maintain uniform conditions across parallel units. Advanced sensor integration becomes essential, with real-time monitoring of temperature, pressure, flow rates, and potentially reaction progress through spectroscopic methods. These systems must be robust enough for continuous operation while maintaining the precision required for microreactor performance.

Heat management strategies differ significantly between laboratory and industrial scales. While laboratory systems may rely on simple water baths or heating blocks, industrial implementations require more sophisticated approaches such as integrated heat exchangers, specialized heating/cooling zones, or advanced thermal management materials to maintain isothermal conditions across larger systems.

Economic considerations ultimately determine industrial viability. Capital expenditure for microreactor systems typically exceeds that of conventional batch equipment, necessitating clear demonstration of process intensification benefits—including reduced footprint, improved yield, enhanced safety, and potentially reduced downstream processing requirements. Comprehensive techno-economic analysis must account for both direct production costs and indirect benefits such as reduced waste treatment and improved product consistency.

Regulatory compliance presents additional challenges, particularly in pharmaceutical and fine chemical applications. Process validation strategies must be developed to demonstrate consistent performance across parallel microreactor units, with appropriate quality control measures implemented to ensure product uniformity.

Sustainability Impact of Microreactor Technologies

Microreactor technologies represent a significant advancement in sustainable chemical processing, offering multiple environmental benefits that align with global sustainability goals. The miniaturization of reaction systems fundamentally changes resource utilization patterns, resulting in substantial reductions in energy consumption compared to conventional batch reactors. This efficiency stems from improved heat and mass transfer capabilities, allowing reactions to operate under more precise conditions with lower energy inputs.

The environmental footprint of chemical processes is further diminished through dramatic reductions in solvent usage, often by 80-90% compared to traditional methods. This decrease directly translates to less waste generation and reduced environmental contamination risks. Additionally, the enhanced control over reaction parameters enables higher selectivity, minimizing the formation of unwanted by-products that would otherwise require energy-intensive separation processes and disposal.

Carbon emissions represent another critical sustainability metric where microreactor technologies demonstrate considerable advantages. Studies indicate potential CO2 emission reductions of 30-50% when implementing microreactor systems at industrial scale, primarily due to improved energy efficiency and process intensification. This contribution to decarbonization efforts positions microreactors as valuable tools in addressing climate change challenges.

From a life cycle assessment perspective, microreactor technologies offer compelling sustainability benefits across multiple impact categories. Their compact size reduces material requirements for manufacturing equipment, while their operational efficiency minimizes resource consumption throughout the product lifecycle. The modular nature of these systems also facilitates easier maintenance and component replacement, extending operational lifespans and reducing waste from equipment disposal.

Water conservation represents another significant sustainability advantage, with microreactor systems typically requiring 40-60% less cooling water than conventional reactors. This reduction is particularly valuable in water-stressed regions where industrial water usage competes with other essential needs.

The implementation of high-throughput microreactor screening techniques further enhances these sustainability benefits by optimizing reaction conditions more efficiently. This approach allows researchers to identify the most environmentally favorable process parameters with minimal material consumption during development phases, creating a multiplier effect on sustainability outcomes when processes are scaled to production levels.

The environmental footprint of chemical processes is further diminished through dramatic reductions in solvent usage, often by 80-90% compared to traditional methods. This decrease directly translates to less waste generation and reduced environmental contamination risks. Additionally, the enhanced control over reaction parameters enables higher selectivity, minimizing the formation of unwanted by-products that would otherwise require energy-intensive separation processes and disposal.

Carbon emissions represent another critical sustainability metric where microreactor technologies demonstrate considerable advantages. Studies indicate potential CO2 emission reductions of 30-50% when implementing microreactor systems at industrial scale, primarily due to improved energy efficiency and process intensification. This contribution to decarbonization efforts positions microreactors as valuable tools in addressing climate change challenges.

From a life cycle assessment perspective, microreactor technologies offer compelling sustainability benefits across multiple impact categories. Their compact size reduces material requirements for manufacturing equipment, while their operational efficiency minimizes resource consumption throughout the product lifecycle. The modular nature of these systems also facilitates easier maintenance and component replacement, extending operational lifespans and reducing waste from equipment disposal.

Water conservation represents another significant sustainability advantage, with microreactor systems typically requiring 40-60% less cooling water than conventional reactors. This reduction is particularly valuable in water-stressed regions where industrial water usage competes with other essential needs.

The implementation of high-throughput microreactor screening techniques further enhances these sustainability benefits by optimizing reaction conditions more efficiently. This approach allows researchers to identify the most environmentally favorable process parameters with minimal material consumption during development phases, creating a multiplier effect on sustainability outcomes when processes are scaled to production levels.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!