Numbering-Up Versus Scale-Up: Economic Case Studies For Microreactors

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Technology Evolution and Objectives

Microreactor technology has evolved significantly over the past three decades, transitioning from laboratory curiosities to commercially viable processing units. The initial development phase in the 1990s focused primarily on proof-of-concept demonstrations, with pioneering work conducted at Massachusetts Institute of Technology and ETH Zurich establishing fundamental principles of microscale chemical processing.

The early 2000s marked a critical transition period characterized by increased industrial interest and the emergence of specialized microreactor manufacturers. Companies like Corning, Ehrfeld Mikrotechnik, and Lonza began developing standardized microreactor platforms, while academic research expanded to address practical implementation challenges such as mixing efficiency, heat transfer optimization, and materials compatibility.

By the 2010s, microreactor technology had matured significantly with the introduction of modular, plug-and-play systems that facilitated easier adoption across various industries. This period saw the first large-scale industrial implementations, particularly in pharmaceutical manufacturing where benefits of enhanced process control and safety became economically compelling.

Current technological objectives center on addressing the fundamental scaling challenge that defines the field: the "numbering-up versus scale-up" paradigm. Traditional chemical engineering has relied on scale-up methodologies where laboratory processes are redesigned for larger vessels. Microreactors, however, follow a fundamentally different approach through "numbering-up" – replicating identical small-scale units to achieve higher throughput while maintaining microscale advantages.

The primary technical objectives driving current research include developing more efficient parallelization strategies that minimize flow distribution issues across multiple channels, creating advanced control systems capable of managing complex networks of microreactors, and designing more robust interconnection technologies to ensure reliable operation of numbered-up systems.

Economic objectives focus on reducing manufacturing costs of microreactor units, optimizing energy efficiency at system level rather than individual reactor level, and developing comprehensive economic models that accurately capture the unique capital and operational expenditure profiles of numbered-up systems compared to conventional scale-up approaches.

Long-term technological goals include achieving seamless integration with continuous downstream processing, developing self-optimizing microreactor networks utilizing machine learning algorithms, and creating standardized interfaces that allow interoperability between components from different manufacturers – ultimately establishing microreactor technology as a mainstream production methodology across chemical, pharmaceutical, and specialty materials industries.

The early 2000s marked a critical transition period characterized by increased industrial interest and the emergence of specialized microreactor manufacturers. Companies like Corning, Ehrfeld Mikrotechnik, and Lonza began developing standardized microreactor platforms, while academic research expanded to address practical implementation challenges such as mixing efficiency, heat transfer optimization, and materials compatibility.

By the 2010s, microreactor technology had matured significantly with the introduction of modular, plug-and-play systems that facilitated easier adoption across various industries. This period saw the first large-scale industrial implementations, particularly in pharmaceutical manufacturing where benefits of enhanced process control and safety became economically compelling.

Current technological objectives center on addressing the fundamental scaling challenge that defines the field: the "numbering-up versus scale-up" paradigm. Traditional chemical engineering has relied on scale-up methodologies where laboratory processes are redesigned for larger vessels. Microreactors, however, follow a fundamentally different approach through "numbering-up" – replicating identical small-scale units to achieve higher throughput while maintaining microscale advantages.

The primary technical objectives driving current research include developing more efficient parallelization strategies that minimize flow distribution issues across multiple channels, creating advanced control systems capable of managing complex networks of microreactors, and designing more robust interconnection technologies to ensure reliable operation of numbered-up systems.

Economic objectives focus on reducing manufacturing costs of microreactor units, optimizing energy efficiency at system level rather than individual reactor level, and developing comprehensive economic models that accurately capture the unique capital and operational expenditure profiles of numbered-up systems compared to conventional scale-up approaches.

Long-term technological goals include achieving seamless integration with continuous downstream processing, developing self-optimizing microreactor networks utilizing machine learning algorithms, and creating standardized interfaces that allow interoperability between components from different manufacturers – ultimately establishing microreactor technology as a mainstream production methodology across chemical, pharmaceutical, and specialty materials industries.

Market Analysis for Microreactor Implementation

The microreactor market is experiencing significant growth, driven by increasing demand for decentralized chemical processing solutions across multiple industries. Current market valuations indicate the global microreactor technology market is expanding at a compound annual growth rate of approximately 19% through 2028, with particularly strong adoption in pharmaceutical manufacturing, fine chemicals, and specialty materials sectors.

Market segmentation reveals distinct adoption patterns across industries. The pharmaceutical sector represents the largest market share, accounting for nearly 40% of current microreactor implementations, primarily due to stringent quality requirements and the high-value nature of pharmaceutical products. Fine chemicals follow at approximately 30%, with petrochemicals, agrochemicals, and academic research comprising the remaining market segments.

Regional analysis shows Europe leading microreactor adoption with approximately 38% market share, followed by North America at 32% and Asia-Pacific at 25%. The European dominance stems from stringent environmental regulations and strong government support for green chemistry initiatives. However, the Asia-Pacific region demonstrates the fastest growth rate, driven by rapid industrialization in China and India.

Economic drivers for microreactor adoption include significant reductions in capital expenditure when implementing numbering-up strategies versus traditional scale-up approaches. Case studies across multiple industries demonstrate 30-45% lower initial investment requirements for equivalent production capacity. Additionally, operational expenditure advantages include energy savings of 20-35% and reduced waste generation by 40-60% compared to batch processing.

Market barriers persist despite these advantages. High initial technology investment, knowledge gaps in process intensification, regulatory uncertainties for novel production methods, and organizational resistance to changing established manufacturing paradigms all impede faster market penetration. The pharmaceutical industry faces particular challenges with regulatory approval pathways for continuous manufacturing processes.

Future market projections indicate accelerating adoption as technology costs decrease and successful implementation case studies proliferate. The numbering-up approach is gaining particular traction in modular manufacturing facilities, where production capacity can be incrementally adjusted to match market demand. This flexibility represents a significant competitive advantage in volatile markets with uncertain demand forecasts.

Emerging application areas showing promising growth include biopharmaceuticals, renewable energy catalyst production, and advanced materials manufacturing. These sectors value the precise reaction control, reduced environmental footprint, and enhanced safety profiles that microreactor technology offers compared to conventional batch processing methods.

Market segmentation reveals distinct adoption patterns across industries. The pharmaceutical sector represents the largest market share, accounting for nearly 40% of current microreactor implementations, primarily due to stringent quality requirements and the high-value nature of pharmaceutical products. Fine chemicals follow at approximately 30%, with petrochemicals, agrochemicals, and academic research comprising the remaining market segments.

Regional analysis shows Europe leading microreactor adoption with approximately 38% market share, followed by North America at 32% and Asia-Pacific at 25%. The European dominance stems from stringent environmental regulations and strong government support for green chemistry initiatives. However, the Asia-Pacific region demonstrates the fastest growth rate, driven by rapid industrialization in China and India.

Economic drivers for microreactor adoption include significant reductions in capital expenditure when implementing numbering-up strategies versus traditional scale-up approaches. Case studies across multiple industries demonstrate 30-45% lower initial investment requirements for equivalent production capacity. Additionally, operational expenditure advantages include energy savings of 20-35% and reduced waste generation by 40-60% compared to batch processing.

Market barriers persist despite these advantages. High initial technology investment, knowledge gaps in process intensification, regulatory uncertainties for novel production methods, and organizational resistance to changing established manufacturing paradigms all impede faster market penetration. The pharmaceutical industry faces particular challenges with regulatory approval pathways for continuous manufacturing processes.

Future market projections indicate accelerating adoption as technology costs decrease and successful implementation case studies proliferate. The numbering-up approach is gaining particular traction in modular manufacturing facilities, where production capacity can be incrementally adjusted to match market demand. This flexibility represents a significant competitive advantage in volatile markets with uncertain demand forecasts.

Emerging application areas showing promising growth include biopharmaceuticals, renewable energy catalyst production, and advanced materials manufacturing. These sectors value the precise reaction control, reduced environmental footprint, and enhanced safety profiles that microreactor technology offers compared to conventional batch processing methods.

Current Challenges in Microreactor Scaling Approaches

Despite the promising advantages of microreactors in chemical processing, significant challenges persist in scaling approaches, particularly when comparing numbering-up versus traditional scale-up methodologies. The fundamental challenge lies in the economic viability of these approaches across different production scales and applications.

For numbering-up strategies, maintaining uniform flow distribution across parallel microreactor units presents a substantial technical hurdle. As the number of parallel units increases, ensuring consistent pressure drops and residence times becomes increasingly complex. This challenge is particularly pronounced in gas-liquid and multiphase reactions where flow regimes can vary significantly between channels, leading to product inconsistency.

Manufacturing precision represents another critical challenge. The production of identical microreactor units with consistent channel dimensions, surface properties, and catalyst coatings requires sophisticated fabrication techniques. Even minor variations between units can lead to significant performance discrepancies when operating at industrial scales with hundreds or thousands of parallel units.

Control system complexity increases exponentially with numbering-up approaches. Monitoring and regulating numerous parallel units demands advanced sensor networks and control algorithms. The detection and isolation of malfunctioning units within large arrays remains problematic, potentially compromising overall system reliability and product quality.

For traditional scale-up approaches, maintaining the advantageous heat and mass transfer characteristics of microreactors at larger dimensions constitutes the primary challenge. As channel dimensions increase, the surface-to-volume ratio decreases, diminishing the very benefits that make microreactors attractive. This fundamental limitation often results in reduced reaction efficiency and selectivity at larger scales.

Capital investment considerations present significant economic barriers. While numbering-up preserves process intensification benefits, it typically requires higher initial capital investment compared to conventional scale-up. The economic crossover point where numbering-up becomes more cost-effective than traditional scale-up varies widely depending on reaction characteristics, production volume, and market dynamics.

Operational flexibility also presents challenges for both approaches. Numbering-up offers theoretical advantages in terms of production flexibility, but practical implementation of variable capacity operation in large parallel systems remains difficult. Meanwhile, scaled-up reactors often struggle to maintain performance across varying production rates.

Regulatory and validation hurdles further complicate scaling decisions, particularly in highly regulated industries like pharmaceuticals. The validation pathway for numbered-up systems versus scaled-up systems differs significantly, with regulatory frameworks often better established for conventional scale-up approaches.

For numbering-up strategies, maintaining uniform flow distribution across parallel microreactor units presents a substantial technical hurdle. As the number of parallel units increases, ensuring consistent pressure drops and residence times becomes increasingly complex. This challenge is particularly pronounced in gas-liquid and multiphase reactions where flow regimes can vary significantly between channels, leading to product inconsistency.

Manufacturing precision represents another critical challenge. The production of identical microreactor units with consistent channel dimensions, surface properties, and catalyst coatings requires sophisticated fabrication techniques. Even minor variations between units can lead to significant performance discrepancies when operating at industrial scales with hundreds or thousands of parallel units.

Control system complexity increases exponentially with numbering-up approaches. Monitoring and regulating numerous parallel units demands advanced sensor networks and control algorithms. The detection and isolation of malfunctioning units within large arrays remains problematic, potentially compromising overall system reliability and product quality.

For traditional scale-up approaches, maintaining the advantageous heat and mass transfer characteristics of microreactors at larger dimensions constitutes the primary challenge. As channel dimensions increase, the surface-to-volume ratio decreases, diminishing the very benefits that make microreactors attractive. This fundamental limitation often results in reduced reaction efficiency and selectivity at larger scales.

Capital investment considerations present significant economic barriers. While numbering-up preserves process intensification benefits, it typically requires higher initial capital investment compared to conventional scale-up. The economic crossover point where numbering-up becomes more cost-effective than traditional scale-up varies widely depending on reaction characteristics, production volume, and market dynamics.

Operational flexibility also presents challenges for both approaches. Numbering-up offers theoretical advantages in terms of production flexibility, but practical implementation of variable capacity operation in large parallel systems remains difficult. Meanwhile, scaled-up reactors often struggle to maintain performance across varying production rates.

Regulatory and validation hurdles further complicate scaling decisions, particularly in highly regulated industries like pharmaceuticals. The validation pathway for numbered-up systems versus scaled-up systems differs significantly, with regulatory frameworks often better established for conventional scale-up approaches.

Comparative Analysis of Numbering-Up vs Scale-Up Strategies

01 Cost reduction through process intensification

Microreactors enable significant cost reduction through process intensification, allowing for more efficient use of resources. The miniaturized design reduces the amount of reagents and catalysts needed, minimizes waste generation, and decreases energy consumption. This intensification leads to lower operational costs and improved economic efficiency compared to conventional batch reactors. Additionally, the continuous flow operation eliminates the need for large reaction vessels and reduces labor costs associated with batch processing.- Cost reduction through process intensification: Microreactors enable significant cost reduction through process intensification, allowing for more efficient chemical reactions in smaller volumes. The enhanced heat and mass transfer capabilities lead to higher yields and selectivity, reducing waste and raw material costs. The compact design also minimizes the need for large infrastructure investments, making production more economical especially for high-value chemicals and pharmaceuticals.

- Energy efficiency improvements: Microreactors demonstrate superior energy efficiency compared to conventional reactors due to their high surface-to-volume ratio, which enables better heat transfer. This results in reduced energy consumption for heating and cooling processes, lower operational costs, and smaller carbon footprint. The precise temperature control also prevents unwanted side reactions, further improving energy utilization and process economics.

- Scalability and modular production advantages: The modular nature of microreactors allows for flexible scaling through numbering-up rather than traditional scale-up, reducing economic risks associated with process development. This approach enables gradual capacity expansion with lower initial capital investment, faster market entry, and the ability to adjust production volumes according to demand fluctuations. The modular design also facilitates distributed manufacturing closer to customers, reducing logistics costs.

- Reduced time-to-market and development costs: Microreactor technology accelerates process development and optimization through rapid experimentation with minimal material consumption. The ability to quickly test and refine reaction parameters reduces R&D timelines and costs, enabling faster commercialization of new products. The seamless transition from lab to production scale with consistent process parameters eliminates costly re-optimization steps typically required in conventional scale-up approaches.

- Operational efficiency and quality improvements: Microreactors offer enhanced operational efficiency through continuous processing, automation, and precise control of reaction parameters. This results in consistent product quality, reduced batch-to-batch variations, and fewer rejected products. The continuous operation minimizes labor requirements and handling steps, while improved safety features reduce the need for extensive containment measures, collectively contributing to lower operational costs and higher economic efficiency.

02 Improved yield and selectivity

Microreactors provide better control over reaction parameters such as temperature, pressure, and mixing, resulting in improved yield and selectivity. The enhanced heat and mass transfer capabilities allow for more precise reaction control, reducing side reactions and increasing product purity. This improvement in yield and selectivity directly translates to economic benefits through higher-quality products, reduced purification costs, and more efficient use of raw materials, ultimately improving the overall economic efficiency of chemical processes.Expand Specific Solutions03 Reduced capital investment and space requirements

The compact nature of microreactors significantly reduces the physical footprint of production facilities, leading to lower capital investment in infrastructure and land. Their modular design allows for flexible scaling by adding parallel units rather than building larger reactors, enabling gradual investment as production demands increase. This approach reduces initial capital expenditure and financial risk compared to traditional large-scale batch processing facilities. The smaller equipment size also results in lower installation costs and reduced maintenance expenses.Expand Specific Solutions04 Faster time-to-market and production flexibility

Microreactors enable rapid process development and optimization due to their small scale and precise control capabilities. This accelerates the transition from laboratory to production, reducing time-to-market for new products. The modular nature of microreactor systems provides production flexibility, allowing manufacturers to quickly adapt to changing market demands or produce multiple products on the same equipment. This agility creates economic advantages through faster return on investment and the ability to capitalize on market opportunities more rapidly than traditional manufacturing methods.Expand Specific Solutions05 Continuous manufacturing and process automation

Microreactors facilitate continuous manufacturing processes that can be highly automated, reducing labor costs and human error. The continuous operation eliminates downtime associated with batch changeovers, increasing overall equipment effectiveness and throughput. Advanced process control systems integrated with microreactors enable real-time monitoring and adjustment, ensuring consistent product quality and reducing quality control costs. This combination of continuous processing and automation significantly improves economic efficiency through higher productivity, reduced labor requirements, and consistent product quality.Expand Specific Solutions

Leading Companies and Research Institutions in Microreactor Technology

Microreactor technology is currently in a transitional phase from early adoption to growth stage, with the global market estimated at $2-3 billion and projected to expand significantly. The technology demonstrates moderate maturity with varying implementation levels across industries. Leading players include Corning, Inc., which has pioneered glass microreactor systems, and Lonza Ltd., which has integrated microreactors into pharmaceutical manufacturing. Academic institutions like Nanjing Tech University and California Institute of Technology are advancing fundamental research, while energy giants Saudi Aramco and SINOPEC are exploring applications in petrochemical processing. Companies like Hitachi and FUJIFILM are developing specialized microreactor equipment, indicating growing industrial interest in scaling this technology for commercial applications beyond laboratory settings.

Corning, Inc.

Technical Solution: Corning has developed the Advanced-Flow™ Reactor (AFR) technology specifically designed for numbering-up approaches in chemical processing. Their system utilizes glass microreactors with superior heat transfer capabilities (10-100 times better than conventional reactors) and modular design that allows parallel operation of multiple reactor units. The AFR technology enables precise control of reaction parameters, with residence times ranging from seconds to minutes, and can handle multiphase reactions including gas-liquid, liquid-liquid, and solid-liquid systems. Corning's approach focuses on maintaining consistent flow distribution across parallel channels, ensuring uniform product quality while increasing production capacity through the addition of identical reactor modules rather than redesigning larger vessels. Their G1, G3, and G4 reactor platforms demonstrate progressive numbering-up capabilities, with the G4 system capable of producing several tons of product per year.

Strengths: Superior heat transfer capabilities allow for better temperature control and safer handling of exothermic reactions; modular design enables flexible capacity scaling without significant re-engineering; excellent chemical resistance of glass materials. Weaknesses: Higher initial capital investment compared to conventional batch reactors; requires specialized expertise for operation; potential for channel clogging with solid-forming reactions.

Lonza Ltd.

Technical Solution: Lonza has developed an advanced microreactor platform specifically designed for pharmaceutical and fine chemical manufacturing that leverages numbering-up principles. Their FlowPlate® technology incorporates multiple parallel microchannels with precise temperature control (±0.5°C) and residence time distribution optimization. Lonza's approach focuses on maintaining consistent quality across scaled production by replicating validated microreactor conditions rather than traditional scale-up. Their system incorporates advanced process analytical technology (PAT) for real-time monitoring and control of critical process parameters. Lonza has demonstrated successful implementation for several pharmaceutical intermediates, achieving production rates of 50-100 kg/day through numbering-up of identical reactor modules. Their economic analysis shows that for high-value, low-volume products, the numbering-up approach reduces capital expenditure by approximately 25-30% compared to batch processing, while also improving yield by 5-15% due to better reaction control and reduced side product formation.

Strengths: Excellent for handling hazardous or highly exothermic reactions safely; enables continuous processing of pharmaceuticals with consistent quality; flexibility to produce multiple products on the same equipment through rapid changeover. Weaknesses: Higher initial investment compared to traditional batch equipment; requires specialized operator training; potential challenges with solids handling in microchannels.

Key Patents and Innovations in Microreactor Scaling

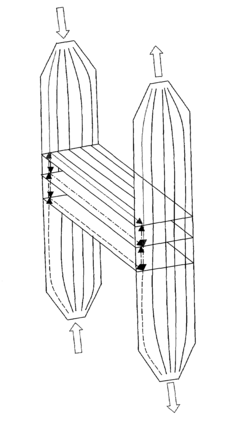

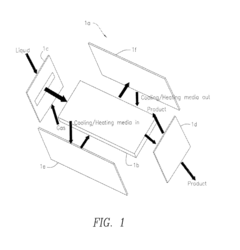

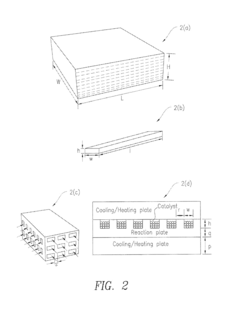

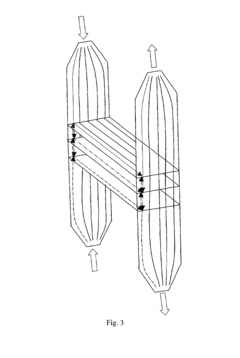

Scalable microreactors and methods for using same

PatentInactiveUS7670567B2

Innovation

- A scalable microreactor design featuring a multilayered reaction block with alternating reactor and heat exchanger plates, coupled with interdigitated distribution channels in the manifolds to ensure uniform flow distribution across the microchannels, minimizing differences in fluid travel distance and enhancing mass and heat transfer rates.

Cost-Benefit Analysis Framework for Scaling Decisions

When evaluating the economic viability of microreactor technologies, a structured cost-benefit analysis framework is essential for making informed scaling decisions. This framework must systematically compare the numbering-up approach (adding parallel microreactor units) against traditional scale-up methods (increasing the size of individual reactors).

The foundation of this framework begins with capital expenditure (CAPEX) assessment, which should account for initial equipment costs, installation expenses, and facility modifications. For numbering-up strategies, the analysis must incorporate potential economies of repetition, where manufacturing multiple identical units may reduce per-unit costs. Conversely, scale-up approaches typically benefit from the conventional economies of scale, though with diminishing returns at larger sizes.

Operational expenditure (OPEX) considerations form the second pillar of the framework, encompassing energy consumption, maintenance requirements, labor costs, and raw material efficiency. Numbering-up often demonstrates advantages in operational flexibility, allowing for selective unit activation based on production demands, which can significantly reduce energy costs during periods of lower throughput.

Risk assessment constitutes the third critical component, quantifying potential financial impacts of system failures, production interruptions, and quality control issues. The distributed nature of numbered-up systems typically offers enhanced reliability through redundancy, whereas scaled-up systems may present higher consequence failures despite lower failure frequency.

Time-to-market factors must be evaluated as the fourth element, including construction timelines, validation periods, and regulatory approval processes. Numbered-up approaches generally enable incremental capacity expansion and faster initial deployment, providing earlier revenue generation opportunities compared to larger scale-up projects.

The framework should incorporate scalability and flexibility metrics as its fifth component, measuring the system's ability to adapt to changing market demands or product specifications. This includes quantifying the costs of capacity adjustments and product changeovers under both scaling approaches.

Finally, a comprehensive net present value (NPV) analysis should integrate all these factors across the projected lifecycle, applying appropriate discount rates to future cash flows and conducting sensitivity analyses on key variables such as market demand fluctuations, raw material costs, and regulatory changes.

This structured framework enables decision-makers to systematically evaluate the economic implications of different scaling strategies for microreactor technologies, leading to more informed investment decisions aligned with both short-term financial constraints and long-term strategic objectives.

The foundation of this framework begins with capital expenditure (CAPEX) assessment, which should account for initial equipment costs, installation expenses, and facility modifications. For numbering-up strategies, the analysis must incorporate potential economies of repetition, where manufacturing multiple identical units may reduce per-unit costs. Conversely, scale-up approaches typically benefit from the conventional economies of scale, though with diminishing returns at larger sizes.

Operational expenditure (OPEX) considerations form the second pillar of the framework, encompassing energy consumption, maintenance requirements, labor costs, and raw material efficiency. Numbering-up often demonstrates advantages in operational flexibility, allowing for selective unit activation based on production demands, which can significantly reduce energy costs during periods of lower throughput.

Risk assessment constitutes the third critical component, quantifying potential financial impacts of system failures, production interruptions, and quality control issues. The distributed nature of numbered-up systems typically offers enhanced reliability through redundancy, whereas scaled-up systems may present higher consequence failures despite lower failure frequency.

Time-to-market factors must be evaluated as the fourth element, including construction timelines, validation periods, and regulatory approval processes. Numbered-up approaches generally enable incremental capacity expansion and faster initial deployment, providing earlier revenue generation opportunities compared to larger scale-up projects.

The framework should incorporate scalability and flexibility metrics as its fifth component, measuring the system's ability to adapt to changing market demands or product specifications. This includes quantifying the costs of capacity adjustments and product changeovers under both scaling approaches.

Finally, a comprehensive net present value (NPV) analysis should integrate all these factors across the projected lifecycle, applying appropriate discount rates to future cash flows and conducting sensitivity analyses on key variables such as market demand fluctuations, raw material costs, and regulatory changes.

This structured framework enables decision-makers to systematically evaluate the economic implications of different scaling strategies for microreactor technologies, leading to more informed investment decisions aligned with both short-term financial constraints and long-term strategic objectives.

Sustainability and Environmental Impact of Scaling Approaches

The environmental impact of scaling approaches in microreactor technology represents a critical dimension in the evaluation of numbering-up versus traditional scale-up methodologies. Microreactors inherently offer several sustainability advantages that become particularly evident when comparing these scaling strategies.

Numbering-up approaches demonstrate superior resource efficiency by maintaining the optimized reaction conditions of the base unit across multiple parallel systems. This preservation of reaction parameters results in consistently higher yields and significantly reduced waste generation compared to conventional scale-up methods. Studies indicate waste reduction of 30-45% in pharmaceutical manufacturing processes utilizing numbered-up microreactor arrays versus traditional batch reactors scaled to equivalent production capacity.

Energy consumption patterns also differ markedly between the two approaches. Traditional scale-up often requires disproportionately higher energy inputs due to less efficient heat and mass transfer in larger vessels. Conversely, numbered-up microreactor systems maintain the excellent heat transfer characteristics of the base unit, resulting in energy savings typically ranging from 20-35% across various chemical processes, particularly in highly exothermic reactions.

The environmental footprint extends to solvent usage, where microreactors excel through intensified processing. Case studies in fine chemical production demonstrate solvent reduction of up to 60% when utilizing numbered-up microreactor configurations compared to conventional batch processing. This translates directly to reduced environmental impact through decreased volatile organic compound (VOC) emissions and hazardous waste disposal requirements.

Life cycle assessment (LCA) studies comparing the two scaling approaches reveal that numbering-up strategies generally result in lower carbon footprints across the production lifecycle. A comprehensive analysis of pharmaceutical intermediate production showed a 25-40% reduction in greenhouse gas emissions when employing numbered-up microreactor technology versus traditional scale-up methods for equivalent production volumes.

Water consumption represents another significant environmental consideration. The precise reaction control in microreactors typically reduces cooling water requirements by 30-50% compared to scaled-up batch processes. Additionally, the modular nature of numbered-up systems allows for more efficient implementation of water recycling technologies, further enhancing sustainability metrics.

The environmental benefits of numbering-up extend to safety considerations, with reduced risk of catastrophic releases due to smaller inventories of hazardous materials in each processing unit. This inherent safety feature translates to reduced environmental risk profiles and aligns with green chemistry principles emphasizing hazard reduction through process design.

Numbering-up approaches demonstrate superior resource efficiency by maintaining the optimized reaction conditions of the base unit across multiple parallel systems. This preservation of reaction parameters results in consistently higher yields and significantly reduced waste generation compared to conventional scale-up methods. Studies indicate waste reduction of 30-45% in pharmaceutical manufacturing processes utilizing numbered-up microreactor arrays versus traditional batch reactors scaled to equivalent production capacity.

Energy consumption patterns also differ markedly between the two approaches. Traditional scale-up often requires disproportionately higher energy inputs due to less efficient heat and mass transfer in larger vessels. Conversely, numbered-up microreactor systems maintain the excellent heat transfer characteristics of the base unit, resulting in energy savings typically ranging from 20-35% across various chemical processes, particularly in highly exothermic reactions.

The environmental footprint extends to solvent usage, where microreactors excel through intensified processing. Case studies in fine chemical production demonstrate solvent reduction of up to 60% when utilizing numbered-up microreactor configurations compared to conventional batch processing. This translates directly to reduced environmental impact through decreased volatile organic compound (VOC) emissions and hazardous waste disposal requirements.

Life cycle assessment (LCA) studies comparing the two scaling approaches reveal that numbering-up strategies generally result in lower carbon footprints across the production lifecycle. A comprehensive analysis of pharmaceutical intermediate production showed a 25-40% reduction in greenhouse gas emissions when employing numbered-up microreactor technology versus traditional scale-up methods for equivalent production volumes.

Water consumption represents another significant environmental consideration. The precise reaction control in microreactors typically reduces cooling water requirements by 30-50% compared to scaled-up batch processes. Additionally, the modular nature of numbered-up systems allows for more efficient implementation of water recycling technologies, further enhancing sustainability metrics.

The environmental benefits of numbering-up extend to safety considerations, with reduced risk of catastrophic releases due to smaller inventories of hazardous materials in each processing unit. This inherent safety feature translates to reduced environmental risk profiles and aligns with green chemistry principles emphasizing hazard reduction through process design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!