Material Compatibility And Sealing Challenges In Microreactor Systems

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Materials Evolution and Objectives

Microreactor technology has evolved significantly over the past three decades, transitioning from laboratory curiosities to commercially viable systems. The initial development phase in the 1990s focused primarily on silicon-based microreactors, leveraging established semiconductor fabrication techniques. These early systems demonstrated the concept but suffered from severe material limitations, particularly when exposed to corrosive chemicals or high temperatures.

The early 2000s marked a shift toward more robust materials, with stainless steel and various metal alloys becoming predominant in microreactor construction. This period saw significant improvements in thermal management capabilities and chemical compatibility, enabling broader industrial applications. However, these systems still faced challenges with sealing integrity at high pressures and temperatures, limiting their operational parameters.

By the 2010s, advanced ceramic materials and specialized metal alloys emerged as preferred materials for demanding applications. Silicon carbide, alumina, and specialized glass-ceramic composites offered superior chemical resistance and thermal stability. Concurrently, manufacturing techniques evolved from traditional machining to more sophisticated approaches including 3D printing of metals and ceramics, enabling more complex internal geometries and integrated functionalities.

The current generation of microreactors increasingly incorporates composite material systems that strategically combine different materials to optimize performance characteristics. These hybrid approaches allow engineers to address the competing demands of chemical compatibility, thermal management, and mechanical integrity. For instance, fluoropolymer linings provide chemical resistance while metal substrates ensure structural integrity and heat transfer.

Looking forward, the technical objectives for microreactor materials development center around several key challenges. First is the development of materials capable of withstanding extreme operating conditions, including highly corrosive environments, temperatures exceeding 1000°C, and pressures above 300 bar. Second is the creation of advanced sealing technologies that maintain integrity across thermal cycles and chemical exposure without contaminating reaction products.

Additional objectives include the development of materials with enhanced catalytic properties, potentially through surface functionalization or embedded catalytic structures. There is also significant interest in materials that enable real-time monitoring capabilities through integrated sensors or optically transparent sections. Finally, cost reduction remains a critical goal, as current high-performance materials often carry prohibitive costs that limit widespread commercial adoption.

The evolution trajectory suggests future microreactor systems will likely incorporate increasingly specialized materials tailored to specific reaction chemistries, with a growing emphasis on sustainability and recyclability as additional design considerations.

The early 2000s marked a shift toward more robust materials, with stainless steel and various metal alloys becoming predominant in microreactor construction. This period saw significant improvements in thermal management capabilities and chemical compatibility, enabling broader industrial applications. However, these systems still faced challenges with sealing integrity at high pressures and temperatures, limiting their operational parameters.

By the 2010s, advanced ceramic materials and specialized metal alloys emerged as preferred materials for demanding applications. Silicon carbide, alumina, and specialized glass-ceramic composites offered superior chemical resistance and thermal stability. Concurrently, manufacturing techniques evolved from traditional machining to more sophisticated approaches including 3D printing of metals and ceramics, enabling more complex internal geometries and integrated functionalities.

The current generation of microreactors increasingly incorporates composite material systems that strategically combine different materials to optimize performance characteristics. These hybrid approaches allow engineers to address the competing demands of chemical compatibility, thermal management, and mechanical integrity. For instance, fluoropolymer linings provide chemical resistance while metal substrates ensure structural integrity and heat transfer.

Looking forward, the technical objectives for microreactor materials development center around several key challenges. First is the development of materials capable of withstanding extreme operating conditions, including highly corrosive environments, temperatures exceeding 1000°C, and pressures above 300 bar. Second is the creation of advanced sealing technologies that maintain integrity across thermal cycles and chemical exposure without contaminating reaction products.

Additional objectives include the development of materials with enhanced catalytic properties, potentially through surface functionalization or embedded catalytic structures. There is also significant interest in materials that enable real-time monitoring capabilities through integrated sensors or optically transparent sections. Finally, cost reduction remains a critical goal, as current high-performance materials often carry prohibitive costs that limit widespread commercial adoption.

The evolution trajectory suggests future microreactor systems will likely incorporate increasingly specialized materials tailored to specific reaction chemistries, with a growing emphasis on sustainability and recyclability as additional design considerations.

Market Analysis for Advanced Microreactor Systems

The global microreactor systems market is experiencing significant growth, projected to reach $2.1 billion by 2028, with a compound annual growth rate of 8.7% from 2023. This expansion is primarily driven by increasing demand for decentralized energy solutions, particularly in remote locations and for specialized applications such as space exploration, military operations, and disaster response scenarios.

Advanced microreactor systems are gaining traction across multiple industries, with the energy sector representing the largest market share at approximately 45%. Chemical processing follows at 28%, pharmaceuticals at 15%, and other applications including food processing and academic research comprising the remaining 12%. The market distribution reflects the versatility of microreactor technology in addressing diverse industrial needs.

Geographically, North America currently leads the market with 38% share, followed by Europe at 32%, Asia-Pacific at 24%, and the rest of the world at 6%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% annually, driven by rapid industrialization in China and India, coupled with increasing investments in advanced manufacturing technologies.

Material compatibility and sealing challenges represent critical factors influencing market adoption. End-users consistently cite these technical hurdles as significant barriers, with 67% of potential adopters expressing concerns about long-term material degradation and 58% highlighting sealing reliability as a major consideration in purchasing decisions.

The competitive landscape features both established industrial equipment manufacturers and specialized technology startups. Major players include Thermo Fisher Scientific, Corning Incorporated, Chemtrix BV, and Little Engine Ventures, collectively holding approximately 65% of the market share. These companies are increasingly focusing on developing advanced materials and sealing solutions to address current limitations.

Customer segmentation reveals distinct market needs: large-scale industrial users prioritize operational reliability and compatibility with existing systems, while research institutions and specialty chemical producers emphasize flexibility and customization options. This segmentation is driving product differentiation strategies among manufacturers, with premium pricing models for solutions that effectively address material compatibility challenges.

Market forecasts indicate that innovations addressing material compatibility and sealing challenges could unlock an additional $500 million in market value by 2030, particularly in high-temperature and corrosive environment applications where current technologies face significant limitations.

Advanced microreactor systems are gaining traction across multiple industries, with the energy sector representing the largest market share at approximately 45%. Chemical processing follows at 28%, pharmaceuticals at 15%, and other applications including food processing and academic research comprising the remaining 12%. The market distribution reflects the versatility of microreactor technology in addressing diverse industrial needs.

Geographically, North America currently leads the market with 38% share, followed by Europe at 32%, Asia-Pacific at 24%, and the rest of the world at 6%. However, the Asia-Pacific region is expected to witness the fastest growth rate of 10.2% annually, driven by rapid industrialization in China and India, coupled with increasing investments in advanced manufacturing technologies.

Material compatibility and sealing challenges represent critical factors influencing market adoption. End-users consistently cite these technical hurdles as significant barriers, with 67% of potential adopters expressing concerns about long-term material degradation and 58% highlighting sealing reliability as a major consideration in purchasing decisions.

The competitive landscape features both established industrial equipment manufacturers and specialized technology startups. Major players include Thermo Fisher Scientific, Corning Incorporated, Chemtrix BV, and Little Engine Ventures, collectively holding approximately 65% of the market share. These companies are increasingly focusing on developing advanced materials and sealing solutions to address current limitations.

Customer segmentation reveals distinct market needs: large-scale industrial users prioritize operational reliability and compatibility with existing systems, while research institutions and specialty chemical producers emphasize flexibility and customization options. This segmentation is driving product differentiation strategies among manufacturers, with premium pricing models for solutions that effectively address material compatibility challenges.

Market forecasts indicate that innovations addressing material compatibility and sealing challenges could unlock an additional $500 million in market value by 2030, particularly in high-temperature and corrosive environment applications where current technologies face significant limitations.

Current Challenges in Material Compatibility and Sealing

Microreactor systems face significant material compatibility and sealing challenges that impede their widespread industrial adoption. The harsh operating conditions, including high temperatures (often exceeding 800°C), extreme pressure differentials, and exposure to corrosive chemicals, create a demanding environment for materials and sealing mechanisms. These conditions accelerate material degradation processes such as oxidation, carburization, and metal dusting, particularly in high-temperature applications involving hydrocarbons.

The miniaturized nature of microreactors exacerbates these challenges, as the high surface-to-volume ratio intensifies material-fluid interactions. This characteristic, while beneficial for heat and mass transfer, increases the susceptibility to corrosion and fouling. Furthermore, the microscale dimensions leave minimal tolerance for material expansion, contraction, or deformation, which can compromise sealing integrity and lead to system failure.

Sealing technologies face particular difficulties in microreactor systems. Traditional sealing methods often prove inadequate due to the microscale geometries and the need for perfect interfacial contact between components. Metal-to-metal seals, gaskets, and O-rings frequently fail under the thermal cycling and chemical exposure typical in microreactor operations. The differential thermal expansion between dissimilar materials used in construction creates additional stress at sealing interfaces, leading to leakage pathways.

Material selection presents another significant challenge. While stainless steel remains common in many applications, it suffers from limited temperature resistance and susceptibility to certain corrosive environments. Advanced ceramics offer superior temperature and corrosion resistance but introduce manufacturing complexities and brittleness concerns. Specialized alloys like Hastelloy and Inconel provide improved performance but at substantially higher costs, limiting economic viability for large-scale deployment.

The integration of heterogeneous materials within a single microreactor system compounds these challenges. Joining dissimilar materials—such as metals to ceramics or polymers to metals—creates weak points vulnerable to thermal and mechanical stress. Current bonding technologies, including diffusion bonding and brazing, often require high temperatures that can alter material properties or introduce residual stresses that compromise long-term reliability.

Manufacturing precision represents another critical challenge. The microscale features of microreactors demand extremely tight tolerances, often at the micron level. Achieving and maintaining such precision across multiple production units while ensuring consistent sealing performance remains difficult with current manufacturing technologies. Surface roughness and microscopic defects that would be inconsequential in conventional reactors can create significant leakage paths in microreactor systems.

The miniaturized nature of microreactors exacerbates these challenges, as the high surface-to-volume ratio intensifies material-fluid interactions. This characteristic, while beneficial for heat and mass transfer, increases the susceptibility to corrosion and fouling. Furthermore, the microscale dimensions leave minimal tolerance for material expansion, contraction, or deformation, which can compromise sealing integrity and lead to system failure.

Sealing technologies face particular difficulties in microreactor systems. Traditional sealing methods often prove inadequate due to the microscale geometries and the need for perfect interfacial contact between components. Metal-to-metal seals, gaskets, and O-rings frequently fail under the thermal cycling and chemical exposure typical in microreactor operations. The differential thermal expansion between dissimilar materials used in construction creates additional stress at sealing interfaces, leading to leakage pathways.

Material selection presents another significant challenge. While stainless steel remains common in many applications, it suffers from limited temperature resistance and susceptibility to certain corrosive environments. Advanced ceramics offer superior temperature and corrosion resistance but introduce manufacturing complexities and brittleness concerns. Specialized alloys like Hastelloy and Inconel provide improved performance but at substantially higher costs, limiting economic viability for large-scale deployment.

The integration of heterogeneous materials within a single microreactor system compounds these challenges. Joining dissimilar materials—such as metals to ceramics or polymers to metals—creates weak points vulnerable to thermal and mechanical stress. Current bonding technologies, including diffusion bonding and brazing, often require high temperatures that can alter material properties or introduce residual stresses that compromise long-term reliability.

Manufacturing precision represents another critical challenge. The microscale features of microreactors demand extremely tight tolerances, often at the micron level. Achieving and maintaining such precision across multiple production units while ensuring consistent sealing performance remains difficult with current manufacturing technologies. Surface roughness and microscopic defects that would be inconsequential in conventional reactors can create significant leakage paths in microreactor systems.

Existing Material and Sealing Solutions for Microreactors

01 Material selection for chemical compatibility in microreactors

The selection of appropriate materials for microreactor systems is crucial to ensure compatibility with various chemicals and reactions. Materials must resist corrosion, degradation, and contamination when exposed to different reagents, solvents, and reaction conditions. Common materials include stainless steel, glass, ceramics, and specialized polymers like PTFE or PEEK. The choice depends on factors such as chemical resistance, temperature stability, and pressure requirements to maintain system integrity during operation.- Material selection for chemical compatibility in microreactors: The selection of appropriate materials for microreactor systems is crucial to ensure compatibility with various chemicals and reactions. Materials must resist corrosion, degradation, and contamination when exposed to different reagents, solvents, and reaction conditions. Common materials include stainless steel, glass, ceramics, and specific polymers like PTFE or PEEK that offer excellent chemical resistance. The proper material selection enhances the longevity and reliability of microreactor systems while maintaining the integrity of the chemical processes.

- Sealing technologies for microfluidic connections: Effective sealing technologies are essential for preventing leaks in microreactor systems, especially at connection points between different components. Various sealing methods include compression fittings, O-rings, gaskets, and specialized bonding techniques. These sealing solutions must maintain integrity under varying pressure and temperature conditions while being compatible with the fluids flowing through the system. Advanced sealing technologies also consider ease of assembly, maintenance, and the ability to withstand repeated thermal cycling without compromising the seal integrity.

- Temperature and pressure resistance in microreactor systems: Microreactor systems often operate under extreme temperature and pressure conditions, requiring materials and sealing solutions that can withstand these demanding environments. The selection of materials with appropriate thermal expansion coefficients helps prevent leakage during temperature fluctuations. High-pressure applications necessitate reinforced designs and specialized sealing mechanisms to maintain system integrity. The ability to withstand thermal cycling and pressure variations without degradation or deformation is critical for ensuring long-term reliability and safety in microreactor operations.

- Integration of sensors and monitoring systems: Modern microreactor systems incorporate various sensors and monitoring technologies to ensure optimal performance and detect potential issues with material compatibility or sealing. These sensors can monitor parameters such as pressure, temperature, flow rate, and chemical composition in real-time. Integration of these monitoring systems requires careful consideration of material compatibility and sealing at sensor interfaces. Advanced systems may include automated shutdown mechanisms that activate when seal failures or material incompatibilities are detected, preventing potential hazards and protecting valuable equipment and processes.

- Modular design approaches for flexibility and maintenance: Modular design approaches in microreactor systems allow for greater flexibility in configuration while addressing material compatibility and sealing challenges. These designs feature standardized connection interfaces that simplify assembly and maintenance while ensuring reliable seals. Modular components can be individually replaced when worn or damaged, reducing downtime and maintenance costs. This approach also enables the selection of specific materials for different modules based on their particular chemical exposure, optimizing overall system performance and longevity while maintaining effective sealing throughout the system.

02 Sealing technologies for microfluidic connections

Effective sealing technologies are essential for preventing leaks in microreactor systems, especially at connection points between different components. Various sealing methods include compression fittings, O-rings, gaskets, and specialized bonding techniques. These sealing solutions must maintain integrity under varying pressure and temperature conditions while being compatible with the fluids flowing through the system. Advanced sealing technologies also consider ease of assembly, disassembly, and maintenance requirements.Expand Specific Solutions03 Temperature and pressure resistance in microreactor systems

Microreactor systems often operate under extreme temperature and pressure conditions, requiring materials and sealing solutions that can withstand these demanding environments. The selection of materials with appropriate thermal expansion coefficients is crucial to prevent leakage or structural failure during temperature fluctuations. High-pressure applications may require specialized reinforced materials and precision-engineered sealing mechanisms to maintain system integrity and prevent catastrophic failures during operation.Expand Specific Solutions04 Integration of sensors and monitoring systems

Modern microreactor systems incorporate various sensors and monitoring devices to ensure optimal performance and detect potential issues related to material compatibility and sealing. These sensors can monitor parameters such as pressure, temperature, flow rate, and chemical composition in real-time. Integration of these monitoring systems requires careful consideration of material interfaces and sealing points to prevent introducing new potential failure points while maintaining the ability to collect accurate data for process control and safety monitoring.Expand Specific Solutions05 Modular design approaches for microreactor systems

Modular design approaches for microreactor systems allow for flexibility in configuration while addressing material compatibility and sealing challenges. These designs feature standardized connection interfaces, interchangeable components, and unified sealing methodologies that simplify assembly and maintenance. Modular approaches enable the selection of specific materials for different sections of the reactor system based on local requirements, while maintaining reliable connections between modules. This strategy enhances system adaptability for various applications while minimizing compatibility and sealing issues.Expand Specific Solutions

Leading Companies in Microreactor Materials Industry

The microreactor systems market is currently in a growth phase, characterized by increasing adoption across chemical processing, pharmaceuticals, and energy sectors. The global market size is estimated to reach $2-3 billion by 2025, with a CAGR of approximately 15%. Material compatibility and sealing challenges represent critical technical barriers, with companies at varying stages of technological maturity. Industry leaders like Corning and Kyocera have developed advanced ceramic-based solutions, while ElringKlinger and Battelle Memorial Institute focus on specialized sealing technologies. Research institutions such as CEA and Nanjing Tech University are driving fundamental innovations. Chemical industry giants including Sinopec and thyssenkrupp are integrating microreactor technologies into larger process systems, while materials specialists like Shanghai Hiwave and Merck are developing novel composite materials to address extreme operating conditions.

Corning, Inc.

Technical Solution: Corning has developed advanced glass and ceramic materials specifically engineered for microreactor systems that address material compatibility challenges. Their proprietary glass-ceramic composites offer exceptional chemical resistance across a wide pH range while maintaining structural integrity at high temperatures (up to 600°C). Corning's microreactor technology utilizes photolithography and etching techniques to create precise microchannels with uniform flow distribution. Their patented fusion sealing technology creates hermetic bonds between similar and dissimilar materials without introducing thermal stress points, critical for preventing leakage of potentially hazardous chemicals. Additionally, Corning has pioneered specialized coatings that prevent catalyst poisoning and fouling, extending microreactor operational lifetimes significantly compared to conventional systems.

Strengths: Superior chemical resistance, excellent thermal stability, and precision manufacturing capabilities. Their hermetic sealing technology creates exceptionally reliable bonds. Weaknesses: Higher cost compared to polymer alternatives, limited flexibility in design modifications after fabrication, and potential brittleness issues under mechanical stress.

Battelle Memorial Institute

Technical Solution: Battelle has developed innovative material solutions for microreactor systems focusing on extreme environment applications. Their approach combines advanced ceramic matrix composites (CMCs) with specialized metal alloys to create hybrid structures that withstand both high temperatures (800-1000°C) and corrosive chemical environments. Battelle's proprietary sealing technology utilizes gradient material interfaces that gradually transition between dissimilar materials, minimizing thermal expansion mismatch and preventing crack formation. Their microreactor designs incorporate self-healing materials that can repair minor damage during operation, significantly extending service life. Additionally, Battelle has pioneered non-destructive testing methods specifically for evaluating seal integrity in microreactor systems, allowing for real-time monitoring of potential failure points before catastrophic leakage occurs.

Strengths: Exceptional performance in extreme environments, innovative self-healing material capabilities, and comprehensive testing protocols for quality assurance. Weaknesses: Complex manufacturing processes increase production costs, limited scalability for mass production, and relatively new technology with limited long-term performance data.

Key Innovations in Microreactor Interface Engineering

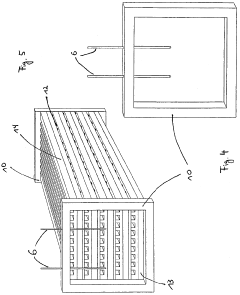

Technical functional element consisting of a stack of layers

PatentInactiveEP1858636A1

Innovation

- A thin-film coating is applied between foils or plates, extending into microstructures, providing a reliable seal and protecting the material from aggressive media, while allowing for the use of inexpensive and easily structured materials, and enabling fine microstructures without complex microstructuring methods.

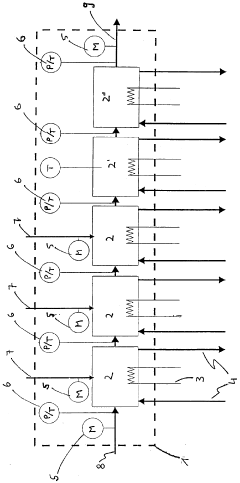

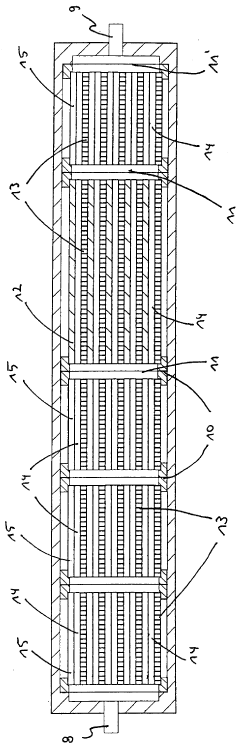

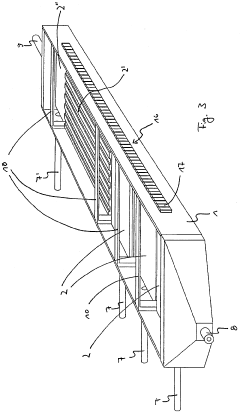

Modular microreaction system

PatentWO2001041916A1

Innovation

- A modular microreaction system with frame elements that are permanently or detachably connected to film stacks, allowing for flexible insertion and removal within a smooth or grid-patterned housing, enabling variable configurations and easy handling, and using materials like metal, silicon, or ceramic for enhanced durability and insulation.

Safety Standards and Compliance Requirements

Microreactor systems operate under stringent safety regulations due to their handling of potentially hazardous materials and high-energy processes. The Nuclear Regulatory Commission (NRC) and Department of Energy (DOE) have established comprehensive frameworks specifically addressing material compatibility and sealing requirements in these systems. These regulations mandate rigorous testing protocols for all sealing components, requiring demonstration of integrity under extreme temperature fluctuations (typically -40°C to 850°C) and radiation exposure levels up to 10^9 Gy for nuclear applications.

ASME Boiler and Pressure Vessel Code Section III provides critical guidelines for pressure boundary components, with Division 5 specifically addressing high-temperature reactor systems. These standards establish minimum requirements for material selection, emphasizing corrosion resistance against process fluids and compatibility with adjacent structural materials. For hydrogen-based microreactors, compliance with ISO/TR 15916 is essential, as it addresses specific sealing challenges related to hydrogen embrittlement and permeation.

Material certification processes have become increasingly stringent, requiring manufacturers to document complete material provenance and processing history. This includes verification of chemical composition, microstructural characteristics, and mechanical properties under simulated operational conditions. The International Atomic Energy Agency (IAEA) Safety Standards Series further mandates regular in-service inspection protocols for sealing components, with replacement intervals determined by material degradation models.

Environmental regulations add another layer of compliance requirements, particularly regarding potential leakage of process fluids. The EPA's Risk Management Program (RMP) and OSHA's Process Safety Management (PSM) standards establish threshold quantities for regulated substances, directly impacting sealing system design and monitoring requirements. These regulations necessitate implementation of continuous monitoring systems capable of detecting micro-leaks before they escalate to safety-critical levels.

Recent regulatory trends show increasing focus on lifecycle assessment of sealing materials, requiring manufacturers to demonstrate end-of-life disposal pathways that minimize environmental impact. The European Union's REACH regulation has particularly influenced global standards by restricting certain high-performance elastomers and fluoropolymers previously common in sealing applications due to their persistent environmental footprint.

Compliance documentation has evolved toward digital material passports that track sealing components from raw material sourcing through manufacturing, installation, maintenance, and eventual decommissioning. This comprehensive approach ensures material traceability while facilitating regulatory inspections and audits throughout the microreactor system's operational lifetime.

ASME Boiler and Pressure Vessel Code Section III provides critical guidelines for pressure boundary components, with Division 5 specifically addressing high-temperature reactor systems. These standards establish minimum requirements for material selection, emphasizing corrosion resistance against process fluids and compatibility with adjacent structural materials. For hydrogen-based microreactors, compliance with ISO/TR 15916 is essential, as it addresses specific sealing challenges related to hydrogen embrittlement and permeation.

Material certification processes have become increasingly stringent, requiring manufacturers to document complete material provenance and processing history. This includes verification of chemical composition, microstructural characteristics, and mechanical properties under simulated operational conditions. The International Atomic Energy Agency (IAEA) Safety Standards Series further mandates regular in-service inspection protocols for sealing components, with replacement intervals determined by material degradation models.

Environmental regulations add another layer of compliance requirements, particularly regarding potential leakage of process fluids. The EPA's Risk Management Program (RMP) and OSHA's Process Safety Management (PSM) standards establish threshold quantities for regulated substances, directly impacting sealing system design and monitoring requirements. These regulations necessitate implementation of continuous monitoring systems capable of detecting micro-leaks before they escalate to safety-critical levels.

Recent regulatory trends show increasing focus on lifecycle assessment of sealing materials, requiring manufacturers to demonstrate end-of-life disposal pathways that minimize environmental impact. The European Union's REACH regulation has particularly influenced global standards by restricting certain high-performance elastomers and fluoropolymers previously common in sealing applications due to their persistent environmental footprint.

Compliance documentation has evolved toward digital material passports that track sealing components from raw material sourcing through manufacturing, installation, maintenance, and eventual decommissioning. This comprehensive approach ensures material traceability while facilitating regulatory inspections and audits throughout the microreactor system's operational lifetime.

Sustainability Aspects of Microreactor Materials

The sustainability of materials used in microreactor systems represents a critical dimension of their overall environmental impact and long-term viability. Current material selection practices often prioritize performance characteristics like corrosion resistance and thermal stability, while sustainability considerations remain secondary. This paradigm requires shifting toward a more holistic approach that balances technical requirements with environmental responsibility.

Lifecycle assessment (LCA) of microreactor materials reveals significant environmental footprints associated with rare metals and specialized alloys commonly employed in these systems. For instance, platinum-based catalysts and high-nickel alloys require energy-intensive mining and processing operations that generate substantial carbon emissions. The environmental burden extends beyond production to include operational lifespan and end-of-life management.

Material recyclability presents both challenges and opportunities in microreactor design. While certain components like stainless steel housings offer established recycling pathways, composite materials and specialized ceramics often lack economically viable recovery methods. Advanced manufacturing techniques such as additive manufacturing may facilitate more efficient material utilization during production but can complicate separation for recycling due to multi-material integration.

Emerging bio-based and renewable materials show promise for reducing the environmental impact of microreactor systems. Biopolymers derived from agricultural waste streams are being investigated for non-critical components, while bio-inspired catalyst designs aim to replace rare earth elements with more abundant alternatives. These innovations, though currently limited to low-temperature applications, represent important steps toward more sustainable material selection.

Energy efficiency in material processing directly impacts the sustainability profile of microreactor systems. Novel manufacturing approaches like low-temperature sintering and solvent-free coating technologies can significantly reduce the energy requirements for component fabrication. Additionally, designing for material efficiency through topology optimization and strategic material placement minimizes waste generation during manufacturing.

Regulatory frameworks increasingly influence material selection decisions in microreactor development. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations limit the use of certain toxic materials, driving innovation toward safer alternatives. Similar regulatory trends are emerging globally, creating both compliance challenges and opportunities for differentiation through sustainable material choices.

Lifecycle assessment (LCA) of microreactor materials reveals significant environmental footprints associated with rare metals and specialized alloys commonly employed in these systems. For instance, platinum-based catalysts and high-nickel alloys require energy-intensive mining and processing operations that generate substantial carbon emissions. The environmental burden extends beyond production to include operational lifespan and end-of-life management.

Material recyclability presents both challenges and opportunities in microreactor design. While certain components like stainless steel housings offer established recycling pathways, composite materials and specialized ceramics often lack economically viable recovery methods. Advanced manufacturing techniques such as additive manufacturing may facilitate more efficient material utilization during production but can complicate separation for recycling due to multi-material integration.

Emerging bio-based and renewable materials show promise for reducing the environmental impact of microreactor systems. Biopolymers derived from agricultural waste streams are being investigated for non-critical components, while bio-inspired catalyst designs aim to replace rare earth elements with more abundant alternatives. These innovations, though currently limited to low-temperature applications, represent important steps toward more sustainable material selection.

Energy efficiency in material processing directly impacts the sustainability profile of microreactor systems. Novel manufacturing approaches like low-temperature sintering and solvent-free coating technologies can significantly reduce the energy requirements for component fabrication. Additionally, designing for material efficiency through topology optimization and strategic material placement minimizes waste generation during manufacturing.

Regulatory frameworks increasingly influence material selection decisions in microreactor development. The European Union's Restriction of Hazardous Substances (RoHS) directive and Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulations limit the use of certain toxic materials, driving innovation toward safer alternatives. Similar regulatory trends are emerging globally, creating both compliance challenges and opportunities for differentiation through sustainable material choices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!