Wash-Out And Fouling Management In Continuous Reactors

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Continuous Reactor Fouling Background and Objectives

Continuous reactors have become a cornerstone of modern industrial chemical processing, offering significant advantages in efficiency, product consistency, and operational economics compared to batch processes. However, these systems face persistent challenges related to fouling and wash-out phenomena that can severely impact performance and reliability. Fouling, characterized by the unwanted accumulation of materials on reactor surfaces, represents one of the most significant operational challenges in continuous processing across multiple industries.

The evolution of continuous reactor technology dates back to the early 20th century, with significant advancements occurring post-World War II as industrial chemical production scaled dramatically. Throughout this development, fouling management has remained a persistent challenge, evolving from simple mechanical cleaning approaches to sophisticated prevention strategies incorporating advanced materials science and process engineering principles.

Current industrial applications of continuous reactors span diverse sectors including petrochemicals, pharmaceuticals, food processing, and specialty chemicals. Each sector experiences unique fouling mechanisms related to their specific process conditions, catalysts, and feedstocks. The economic impact of fouling is substantial, with estimates suggesting that fouling-related issues account for 0.25-0.30% of the gross domestic product in industrialized countries, translating to billions of dollars annually in maintenance costs, production losses, and energy inefficiencies.

Wash-out phenomena, characterized by the unintended removal of catalysts, microorganisms, or other active components from the reactor system, presents a complementary challenge that often requires contradictory solutions to fouling management. This creates a complex optimization problem for process engineers seeking to maintain stable, efficient operations.

The technical objectives for addressing these challenges include developing comprehensive understanding of fouling mechanisms across different reactor types and process conditions, creating predictive models for fouling behavior, designing innovative surface materials and coatings with anti-fouling properties, implementing advanced real-time monitoring systems, and establishing optimized cleaning protocols that minimize production disruptions.

Recent technological advances in materials science, computational fluid dynamics, and sensor technology have opened new avenues for addressing these challenges. The integration of these technologies promises more effective management strategies that could significantly reduce the economic and operational burdens associated with fouling and wash-out phenomena in continuous reactors.

This technical exploration aims to comprehensively examine the current understanding of fouling mechanisms, evaluate existing management strategies, identify emerging technologies with potential applications in this domain, and outline promising research directions that could lead to transformative solutions for these persistent challenges.

The evolution of continuous reactor technology dates back to the early 20th century, with significant advancements occurring post-World War II as industrial chemical production scaled dramatically. Throughout this development, fouling management has remained a persistent challenge, evolving from simple mechanical cleaning approaches to sophisticated prevention strategies incorporating advanced materials science and process engineering principles.

Current industrial applications of continuous reactors span diverse sectors including petrochemicals, pharmaceuticals, food processing, and specialty chemicals. Each sector experiences unique fouling mechanisms related to their specific process conditions, catalysts, and feedstocks. The economic impact of fouling is substantial, with estimates suggesting that fouling-related issues account for 0.25-0.30% of the gross domestic product in industrialized countries, translating to billions of dollars annually in maintenance costs, production losses, and energy inefficiencies.

Wash-out phenomena, characterized by the unintended removal of catalysts, microorganisms, or other active components from the reactor system, presents a complementary challenge that often requires contradictory solutions to fouling management. This creates a complex optimization problem for process engineers seeking to maintain stable, efficient operations.

The technical objectives for addressing these challenges include developing comprehensive understanding of fouling mechanisms across different reactor types and process conditions, creating predictive models for fouling behavior, designing innovative surface materials and coatings with anti-fouling properties, implementing advanced real-time monitoring systems, and establishing optimized cleaning protocols that minimize production disruptions.

Recent technological advances in materials science, computational fluid dynamics, and sensor technology have opened new avenues for addressing these challenges. The integration of these technologies promises more effective management strategies that could significantly reduce the economic and operational burdens associated with fouling and wash-out phenomena in continuous reactors.

This technical exploration aims to comprehensively examine the current understanding of fouling mechanisms, evaluate existing management strategies, identify emerging technologies with potential applications in this domain, and outline promising research directions that could lead to transformative solutions for these persistent challenges.

Market Analysis for Fouling Management Solutions

The global market for fouling management solutions in continuous reactors is experiencing robust growth, driven primarily by increasing industrialization and stringent environmental regulations. The market size was valued at approximately $6.2 billion in 2022 and is projected to reach $9.8 billion by 2028, representing a compound annual growth rate (CAGR) of 7.9%. This growth trajectory is particularly pronounced in regions with high industrial activity, such as North America, Europe, and Asia-Pacific.

Chemical processing industries constitute the largest end-user segment, accounting for nearly 38% of the total market share. This is followed by oil and gas (27%), pharmaceuticals (15%), food and beverage (12%), and other industries (8%). The dominance of the chemical sector is attributed to the critical nature of continuous reactors in their production processes and the severe economic implications of fouling-related downtime.

From a solutions perspective, the market can be segmented into mechanical cleaning systems (32%), chemical treatments (28%), ultrasonic technologies (18%), thermal methods (14%), and emerging technologies (8%). Mechanical cleaning solutions currently dominate due to their reliability and established track record, but chemical treatments are gaining traction due to their effectiveness in preventing fouling formation at the molecular level.

Geographically, North America leads the market with a 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, primarily due to rapid industrialization in countries like China and India, coupled with increasing awareness about operational efficiency and sustainability.

Key market drivers include the rising cost of energy, which makes efficient reactor operation imperative; increasing complexity of industrial processes requiring sophisticated fouling management; and growing environmental concerns leading to stricter regulations on waste discharge and emissions. Additionally, the trend toward continuous manufacturing in pharmaceuticals and specialty chemicals is creating new demand for advanced fouling prevention solutions.

Market restraints include high initial investment costs for advanced fouling management systems, technical challenges in implementing solutions for complex reactor designs, and the conservative approach of many industries toward adopting new technologies. Despite these challenges, the market presents significant opportunities, particularly in developing regions and in the integration of digital technologies for predictive fouling management.

Chemical processing industries constitute the largest end-user segment, accounting for nearly 38% of the total market share. This is followed by oil and gas (27%), pharmaceuticals (15%), food and beverage (12%), and other industries (8%). The dominance of the chemical sector is attributed to the critical nature of continuous reactors in their production processes and the severe economic implications of fouling-related downtime.

From a solutions perspective, the market can be segmented into mechanical cleaning systems (32%), chemical treatments (28%), ultrasonic technologies (18%), thermal methods (14%), and emerging technologies (8%). Mechanical cleaning solutions currently dominate due to their reliability and established track record, but chemical treatments are gaining traction due to their effectiveness in preventing fouling formation at the molecular level.

Geographically, North America leads the market with a 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to witness the highest growth rate over the forecast period, primarily due to rapid industrialization in countries like China and India, coupled with increasing awareness about operational efficiency and sustainability.

Key market drivers include the rising cost of energy, which makes efficient reactor operation imperative; increasing complexity of industrial processes requiring sophisticated fouling management; and growing environmental concerns leading to stricter regulations on waste discharge and emissions. Additionally, the trend toward continuous manufacturing in pharmaceuticals and specialty chemicals is creating new demand for advanced fouling prevention solutions.

Market restraints include high initial investment costs for advanced fouling management systems, technical challenges in implementing solutions for complex reactor designs, and the conservative approach of many industries toward adopting new technologies. Despite these challenges, the market presents significant opportunities, particularly in developing regions and in the integration of digital technologies for predictive fouling management.

Wash-Out Challenges in Continuous Processing

Wash-out phenomenon represents one of the most significant operational challenges in continuous processing systems, particularly in bioreactors and chemical processing units. This challenge manifests as the unintended removal or displacement of active microorganisms, catalysts, or reactants from the reaction vessel before the desired conversion or transformation is completed. The fundamental mechanism behind wash-out involves the relationship between the hydraulic retention time (HRT) and the growth rate of microorganisms or the kinetics of the reaction process.

In continuous stirred-tank reactors (CSTRs), wash-out typically occurs when the dilution rate exceeds the maximum specific growth rate of the microorganisms. This critical threshold, often referred to as the "critical dilution rate," represents a key operational parameter that must be carefully managed. When exceeded, the system experiences a rapid decline in biomass concentration, leading to process failure and significant productivity losses.

For enzymatic and catalytic processes, wash-out manifests differently but with equally detrimental effects. Soluble enzymes or homogeneous catalysts can be carried out with the effluent stream, necessitating continuous replenishment and increasing operational costs. This phenomenon is particularly problematic in pharmaceutical manufacturing, where high-value catalysts can represent a substantial portion of production costs.

The severity of wash-out challenges varies significantly across different reactor configurations. Plug flow reactors (PFRs) exhibit different wash-out dynamics compared to CSTRs, while membrane reactors and immobilized cell systems have been developed specifically to mitigate these issues. The selection of appropriate reactor design must therefore consider the specific kinetics of the target process and the characteristics of the biological or chemical agents involved.

Environmental factors significantly influence wash-out susceptibility. Temperature fluctuations, pH shifts, and the presence of inhibitory compounds can stress microbial communities, reducing their growth rates and lowering the critical dilution rate threshold. This creates a complex operational challenge where multiple parameters must be simultaneously monitored and controlled to maintain stable performance.

Modern continuous manufacturing faces additional wash-out challenges when implementing process intensification strategies. Higher throughput targets often push systems closer to their operational limits, increasing the risk of wash-out events. This is particularly evident in the biopharmaceutical sector, where continuous processing adoption has highlighted the need for robust control strategies to prevent biomass loss during extended campaigns.

The economic implications of wash-out extend beyond immediate productivity losses. Recovery from wash-out events often requires system restart, reseeding of microorganisms, or catalyst replacement, resulting in significant downtime and associated costs. Developing effective strategies to predict, prevent, and rapidly respond to wash-out conditions therefore represents a critical aspect of continuous processing optimization.

In continuous stirred-tank reactors (CSTRs), wash-out typically occurs when the dilution rate exceeds the maximum specific growth rate of the microorganisms. This critical threshold, often referred to as the "critical dilution rate," represents a key operational parameter that must be carefully managed. When exceeded, the system experiences a rapid decline in biomass concentration, leading to process failure and significant productivity losses.

For enzymatic and catalytic processes, wash-out manifests differently but with equally detrimental effects. Soluble enzymes or homogeneous catalysts can be carried out with the effluent stream, necessitating continuous replenishment and increasing operational costs. This phenomenon is particularly problematic in pharmaceutical manufacturing, where high-value catalysts can represent a substantial portion of production costs.

The severity of wash-out challenges varies significantly across different reactor configurations. Plug flow reactors (PFRs) exhibit different wash-out dynamics compared to CSTRs, while membrane reactors and immobilized cell systems have been developed specifically to mitigate these issues. The selection of appropriate reactor design must therefore consider the specific kinetics of the target process and the characteristics of the biological or chemical agents involved.

Environmental factors significantly influence wash-out susceptibility. Temperature fluctuations, pH shifts, and the presence of inhibitory compounds can stress microbial communities, reducing their growth rates and lowering the critical dilution rate threshold. This creates a complex operational challenge where multiple parameters must be simultaneously monitored and controlled to maintain stable performance.

Modern continuous manufacturing faces additional wash-out challenges when implementing process intensification strategies. Higher throughput targets often push systems closer to their operational limits, increasing the risk of wash-out events. This is particularly evident in the biopharmaceutical sector, where continuous processing adoption has highlighted the need for robust control strategies to prevent biomass loss during extended campaigns.

The economic implications of wash-out extend beyond immediate productivity losses. Recovery from wash-out events often requires system restart, reseeding of microorganisms, or catalyst replacement, resulting in significant downtime and associated costs. Developing effective strategies to predict, prevent, and rapidly respond to wash-out conditions therefore represents a critical aspect of continuous processing optimization.

Current Wash-Out and Anti-Fouling Strategies

01 Prevention of fouling in continuous reactors

Various methods and systems are employed to prevent fouling in continuous reactors. These include specialized coatings, surface treatments, and design modifications that reduce the adhesion of materials to reactor walls. Continuous monitoring systems can detect early signs of fouling, allowing for timely intervention. Additionally, controlled flow patterns and optimized reactor geometry can minimize dead zones where fouling typically begins.- Anti-fouling mechanisms for continuous reactors: Various mechanisms can be implemented in continuous reactors to prevent fouling, including specialized coatings, surface treatments, and design features that minimize deposit formation. These mechanisms create surfaces that resist adhesion of particulates and reaction byproducts, thereby maintaining optimal flow conditions and heat transfer efficiency. Some designs incorporate self-cleaning surfaces or materials with specific properties that prevent the accumulation of unwanted deposits during continuous operation.

- Wash-out prevention systems in continuous flow processes: Systems designed to prevent wash-out in continuous reactors focus on maintaining proper residence time and preventing the unintended removal of catalysts or microorganisms. These systems may include specialized retention mechanisms, baffles, or flow regulators that ensure solid components remain within the reaction zone while allowing products to flow out. Advanced control systems monitor flow rates and adjust parameters to prevent wash-out conditions, particularly important in biological or catalytic processes where maintaining biomass or catalyst concentration is critical.

- Cleaning and maintenance solutions for continuous reactors: Effective cleaning and maintenance solutions for continuous reactors include in-situ cleaning systems, specialized cleaning agents, and mechanical cleaning mechanisms. These solutions allow for periodic or continuous removal of deposits without requiring reactor shutdown. Some designs incorporate clean-in-place (CIP) systems that can circulate cleaning solutions through the reactor during brief operational pauses. Advanced approaches may include ultrasonic cleaning, pulsed flow techniques, or specialized scraping mechanisms that remove fouling while the reactor remains in operation.

- Monitoring and control systems for fouling prevention: Advanced monitoring and control systems help prevent fouling in continuous reactors by detecting early signs of deposit formation and automatically adjusting operating conditions. These systems may use sensors to monitor parameters such as pressure drop, heat transfer efficiency, or flow characteristics that indicate fouling development. Integrated control algorithms can then modify temperature, flow rate, or introduce cleaning cycles to mitigate fouling before it significantly impacts reactor performance. Real-time monitoring enables predictive maintenance and optimization of cleaning schedules.

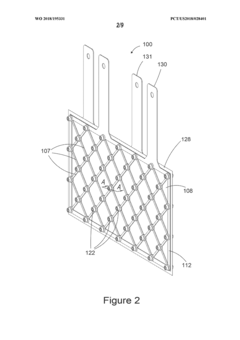

- Novel reactor designs to minimize fouling and wash-out: Innovative reactor designs specifically address fouling and wash-out challenges through geometric configurations that promote turbulent flow, reduce dead zones, and enhance mixing. These designs may include specialized flow distributors, structured packing, or novel geometries that minimize areas prone to deposit accumulation. Some approaches incorporate fluidized bed principles or oscillating flow patterns to keep particles suspended and surfaces clean. Materials selection plays a crucial role, with certain surfaces engineered to minimize adhesion of potential foulants while maintaining chemical compatibility with process fluids.

02 Cleaning systems for continuous reactors

Integrated cleaning systems are essential for maintaining continuous reactor performance. These systems include automated wash cycles, mechanical scrapers, and high-pressure spray nozzles that can operate without interrupting the production process. Some advanced designs incorporate ultrasonic or vibrational cleaning mechanisms to dislodge deposits. Chemical cleaning solutions specifically formulated for different types of fouling materials can be periodically introduced to dissolve accumulated deposits.Expand Specific Solutions03 Wash-out prevention techniques

To prevent wash-out in continuous reactors, various retention mechanisms are implemented. These include baffles, structured packing, and specialized flow distributors that help maintain catalyst or microorganism populations within the reactor. Some designs incorporate membrane filtration systems or settling zones to recover and recycle washed-out materials. Advanced control systems can adjust flow rates in response to detected wash-out conditions, maintaining optimal reactor performance.Expand Specific Solutions04 Monitoring and control systems for fouling detection

Sophisticated monitoring systems are employed to detect and manage fouling in continuous reactors. These include pressure differential sensors, heat transfer efficiency monitors, and inline spectroscopic techniques that can identify early signs of fouling. Some advanced systems use machine learning algorithms to predict fouling events before they become critical. Real-time data analysis allows for automated adjustments to operating conditions, extending run times between cleaning cycles.Expand Specific Solutions05 Material selection and surface modifications

The choice of construction materials and surface treatments significantly impacts fouling behavior in continuous reactors. Non-stick coatings, polished surfaces, and specialized alloys can reduce deposit formation. Some innovative approaches include micro-patterned surfaces that minimize contact area for potential foulants. Hydrophobic or hydrophilic surface modifications can be selected based on the nature of the process fluids to reduce adhesion of unwanted materials.Expand Specific Solutions

Leading Companies in Reactor Cleaning Technology

The continuous reactor wash-out and fouling management technology landscape is currently in a growth phase, with an estimated market size of $3-5 billion annually and expanding at 7-9% CAGR. The competitive field features established petrochemical leaders like ExxonMobil Chemical Patents and Saudi Basic Industries Corp. developing proprietary solutions, while specialized water treatment companies including Ecolab USA, Evoqua Water Technologies, and Kurita Water Industries focus on chemical treatment approaches. Technology maturity varies significantly across applications, with petroleum giants (China Petroleum & Chemical Corp., Shell) possessing advanced fouling prevention systems, while newer entrants like SilcoTek and Axnano are introducing innovative surface modification and nanotechnology solutions that show promising results but remain in early commercial deployment stages.

Ecolab USA, Inc.

Technical Solution: Ecolab has pioneered a comprehensive approach to fouling management in continuous reactors through their 3D TRASAR™ technology platform. This system combines continuous monitoring, automated chemical dosing, and predictive analytics to prevent fouling before it impacts operational efficiency. Their solution utilizes specialized polymers and dispersants that target specific fouling mechanisms, including mineral scale, biological growth, and particulate deposition. Ecolab's technology incorporates real-time monitoring of key parameters such as heat transfer efficiency, pressure drop, and water chemistry to detect early signs of fouling. Their approach includes customized cleaning protocols based on reactor design and process conditions, with automated chemical delivery systems that adjust treatment levels based on changing operational parameters and influent quality variations.

Strengths: Industry-leading water treatment expertise; digital monitoring capabilities that provide actionable insights; global service network for implementation and support. Weaknesses: Higher initial implementation costs compared to conventional treatments; requires integration with existing control systems which may present compatibility challenges in older facilities.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed the SMART-Clean technology platform for managing fouling in continuous reactors across their extensive refining and petrochemical operations. Their approach combines online monitoring systems with proprietary anti-fouling additives specifically designed for high-temperature, high-pressure environments. Sinopec's technology utilizes acoustic and electrical resistance monitoring to detect early fouling formation in critical reactor zones. Their system incorporates specialized flow distribution devices that minimize dead zones where fouling typically initiates. Sinopec has also developed novel surface modification techniques for reactor internals that reduce foulant adhesion while maintaining catalytic activity. Their approach includes automated cleaning sequences that can be implemented during operation, utilizing controlled chemical injection and flow manipulation to dislodge deposits without requiring complete shutdown.

Strengths: Extensive implementation experience across large-scale petrochemical facilities; cost-effective solutions developed for various reactor types; strong integration with process control systems. Weaknesses: Less published research compared to Western competitors; some technologies may have limited availability outside China; documentation and technical support may have language barriers for international implementation.

Key Patents in Continuous Reactor Maintenance

Washing method, addition polymerization method, prepolymerization method, prepolymerized catalytic component for addition polymerization, and method for producing addition polymer using the same

PatentWO2013047891A2

Innovation

- A method involving the use of specific compounds and a hydrocarbon solvent to wash the reactor walls, followed by addition polymerization with a transition metal catalyst system, preventing fouling and maintaining reactor efficiency.

Electrochemical cell for wastewater treatment with improved electrical protection

PatentWO2018195331A1

Innovation

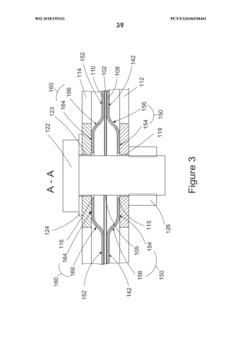

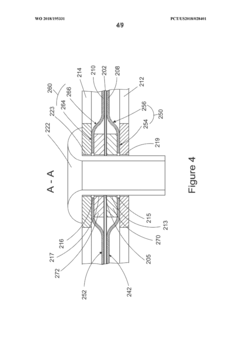

- The electrochemical cell design incorporates a solid polymer electrolyte membrane with anode and cathode catalyst layers, open pore meshes, and compression frames with embossed surfaces and fasteners made of conductive materials, ensuring uniform compression and preventing electrical shorting, allowing for efficient pollutant degradation with reduced energy consumption.

Environmental Impact of Cleaning Chemicals

The cleaning chemicals used in wash-out processes for continuous reactors present significant environmental concerns that require careful consideration. Traditional cleaning agents often contain harsh chemicals such as strong acids, caustic alkalis, chlorinated solvents, and surfactants that can have detrimental effects on aquatic ecosystems when discharged into water bodies. These chemicals may alter pH levels, deplete oxygen content, and introduce toxic compounds that harm aquatic life and disrupt ecological balance.

Phosphates, commonly found in many industrial cleaning formulations, contribute to eutrophication in water bodies, leading to excessive algal growth and subsequent oxygen depletion. Similarly, chlorinated compounds can form persistent organic pollutants that bioaccumulate in the food chain, posing long-term environmental risks. The volume of wastewater generated during reactor cleaning operations further compounds these environmental challenges, particularly in facilities with frequent cleaning cycles.

Regulatory frameworks worldwide have become increasingly stringent regarding the discharge of cleaning chemicals. The European Union's Water Framework Directive, the U.S. Clean Water Act, and similar regulations in other regions impose strict limits on chemical effluents from industrial processes. Non-compliance can result in substantial penalties, operational restrictions, and reputational damage for manufacturing companies.

The environmental footprint of cleaning operations extends beyond direct aquatic impacts. The production, transportation, and disposal of cleaning chemicals contribute to carbon emissions and resource depletion. Many conventional cleaning agents are derived from non-renewable petroleum resources, raising sustainability concerns throughout their lifecycle.

Recent industry trends show a shift toward greener cleaning alternatives with reduced environmental impact. Biodegradable surfactants, enzyme-based cleaners, and plant-derived solvents are gaining traction as environmentally responsible options. These alternatives typically break down more readily in the environment and produce fewer harmful byproducts. Advanced oxidation processes using hydrogen peroxide or ozone also offer promising cleaning efficacy with potentially lower environmental consequences.

Closed-loop cleaning systems represent another significant advancement in minimizing environmental impact. These systems capture, treat, and recycle cleaning solutions, substantially reducing both water consumption and chemical discharge. While implementation requires initial capital investment, the long-term environmental benefits and potential regulatory compliance advantages make them increasingly attractive options for continuous reactor operations.

Phosphates, commonly found in many industrial cleaning formulations, contribute to eutrophication in water bodies, leading to excessive algal growth and subsequent oxygen depletion. Similarly, chlorinated compounds can form persistent organic pollutants that bioaccumulate in the food chain, posing long-term environmental risks. The volume of wastewater generated during reactor cleaning operations further compounds these environmental challenges, particularly in facilities with frequent cleaning cycles.

Regulatory frameworks worldwide have become increasingly stringent regarding the discharge of cleaning chemicals. The European Union's Water Framework Directive, the U.S. Clean Water Act, and similar regulations in other regions impose strict limits on chemical effluents from industrial processes. Non-compliance can result in substantial penalties, operational restrictions, and reputational damage for manufacturing companies.

The environmental footprint of cleaning operations extends beyond direct aquatic impacts. The production, transportation, and disposal of cleaning chemicals contribute to carbon emissions and resource depletion. Many conventional cleaning agents are derived from non-renewable petroleum resources, raising sustainability concerns throughout their lifecycle.

Recent industry trends show a shift toward greener cleaning alternatives with reduced environmental impact. Biodegradable surfactants, enzyme-based cleaners, and plant-derived solvents are gaining traction as environmentally responsible options. These alternatives typically break down more readily in the environment and produce fewer harmful byproducts. Advanced oxidation processes using hydrogen peroxide or ozone also offer promising cleaning efficacy with potentially lower environmental consequences.

Closed-loop cleaning systems represent another significant advancement in minimizing environmental impact. These systems capture, treat, and recycle cleaning solutions, substantially reducing both water consumption and chemical discharge. While implementation requires initial capital investment, the long-term environmental benefits and potential regulatory compliance advantages make them increasingly attractive options for continuous reactor operations.

Process Efficiency Optimization Approaches

Process efficiency optimization in continuous reactors facing wash-out and fouling challenges requires systematic approaches that balance operational stability with productivity. The implementation of real-time monitoring systems represents a cornerstone strategy, utilizing advanced sensors to track critical parameters such as temperature, pressure, flow rates, and concentration gradients throughout the reactor system. These monitoring capabilities enable operators to detect early signs of fouling or process instability before they escalate into significant issues.

Adaptive control algorithms have emerged as powerful tools for maintaining optimal reactor performance. These sophisticated systems can automatically adjust operating conditions based on real-time data, implementing preventive measures when wash-out conditions are detected or modifying flow patterns to minimize fouling accumulation. The integration of machine learning techniques further enhances these systems by enabling predictive maintenance scheduling based on historical performance patterns.

Flow optimization techniques represent another critical approach to efficiency enhancement. By carefully engineering flow dynamics within the reactor, operators can create conditions that naturally minimize fouling deposition while maintaining sufficient residence time for desired reactions. This includes the implementation of strategic flow distributors, baffles, or specialized reactor geometries that promote uniform distribution and reduce dead zones where fouling typically initiates.

Periodic cleaning protocols, when properly integrated into production schedules, can significantly extend reactor operational time. Modern approaches include clean-in-place (CIP) systems that allow for cleaning without complete disassembly, reducing downtime substantially. The development of specialized cleaning agents tailored to specific fouling types has further improved the efficiency of these operations, with some formulations capable of dissolving deposits without damaging catalyst surfaces or reactor materials.

Surface modification technologies have revolutionized fouling management by creating reactor surfaces that inherently resist deposit formation. These include hydrophobic coatings that prevent adhesion of water-based foulants, catalytic surfaces that promote self-cleaning reactions, and nano-structured materials that minimize the surface area available for fouling accumulation. Recent advances in material science have yielded coatings with exceptional durability even under harsh reaction conditions.

Process intensification strategies focus on redesigning reaction systems to achieve higher throughput with smaller equipment footprints. Techniques such as microreactor technology, oscillatory flow reactors, and spinning disc reactors create highly controlled environments that inherently resist fouling while maintaining excellent mass transfer characteristics. These innovative designs often operate under conditions that naturally discourage fouling formation while enhancing reaction efficiency.

Adaptive control algorithms have emerged as powerful tools for maintaining optimal reactor performance. These sophisticated systems can automatically adjust operating conditions based on real-time data, implementing preventive measures when wash-out conditions are detected or modifying flow patterns to minimize fouling accumulation. The integration of machine learning techniques further enhances these systems by enabling predictive maintenance scheduling based on historical performance patterns.

Flow optimization techniques represent another critical approach to efficiency enhancement. By carefully engineering flow dynamics within the reactor, operators can create conditions that naturally minimize fouling deposition while maintaining sufficient residence time for desired reactions. This includes the implementation of strategic flow distributors, baffles, or specialized reactor geometries that promote uniform distribution and reduce dead zones where fouling typically initiates.

Periodic cleaning protocols, when properly integrated into production schedules, can significantly extend reactor operational time. Modern approaches include clean-in-place (CIP) systems that allow for cleaning without complete disassembly, reducing downtime substantially. The development of specialized cleaning agents tailored to specific fouling types has further improved the efficiency of these operations, with some formulations capable of dissolving deposits without damaging catalyst surfaces or reactor materials.

Surface modification technologies have revolutionized fouling management by creating reactor surfaces that inherently resist deposit formation. These include hydrophobic coatings that prevent adhesion of water-based foulants, catalytic surfaces that promote self-cleaning reactions, and nano-structured materials that minimize the surface area available for fouling accumulation. Recent advances in material science have yielded coatings with exceptional durability even under harsh reaction conditions.

Process intensification strategies focus on redesigning reaction systems to achieve higher throughput with smaller equipment footprints. Techniques such as microreactor technology, oscillatory flow reactors, and spinning disc reactors create highly controlled environments that inherently resist fouling while maintaining excellent mass transfer characteristics. These innovative designs often operate under conditions that naturally discourage fouling formation while enhancing reaction efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!