Environmental And Safety Benefits Of Continuous Flow For Hazardous Steps

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Continuous Flow Technology Background and Objectives

Continuous flow technology represents a paradigm shift in chemical processing, evolving from traditional batch manufacturing to a more efficient, controlled, and sustainable approach. This technology emerged in the early 2000s as a response to increasing demands for safer and more environmentally friendly chemical processes, particularly when handling hazardous materials. The evolution of continuous flow systems has been driven by advancements in microreactor technology, process intensification strategies, and real-time monitoring capabilities.

The historical development of continuous flow technology can be traced through several key phases. Initially, it was primarily adopted in petrochemical industries for large-scale operations. Subsequently, pharmaceutical and fine chemical sectors began implementing this technology to address specific challenges related to hazardous reactions. The most recent phase has seen integration with digital technologies, enabling unprecedented levels of process control and optimization.

Current technological trends in continuous flow processing include miniaturization of equipment, development of modular and reconfigurable systems, and integration with artificial intelligence for predictive process control. These advancements are collectively pushing the boundaries of what can be achieved in terms of reaction efficiency, safety, and environmental impact.

The primary objective of implementing continuous flow technology for hazardous steps is to minimize risks associated with handling dangerous chemicals while maximizing process efficiency. By containing hazardous reactions within enclosed, controlled environments, continuous flow systems significantly reduce operator exposure to toxic substances and minimize the potential for catastrophic incidents.

Environmental objectives include substantial reduction in waste generation, decreased solvent usage, and lower energy consumption compared to traditional batch processes. The precise control afforded by continuous flow enables optimization of reaction parameters, leading to higher yields and fewer byproducts. This translates directly to reduced environmental footprint across the chemical manufacturing landscape.

Technical goals focus on developing robust, scalable continuous flow systems capable of handling diverse reaction types under varying conditions. This includes addressing challenges related to solid handling, multiphase reactions, and process scale-up. Additionally, there is significant emphasis on creating flexible platforms that can be rapidly reconfigured to accommodate different chemical processes.

Long-term objectives extend beyond immediate safety and environmental benefits to encompass broader sustainability goals. These include developing closed-loop systems that minimize resource consumption, implementing renewable energy sources to power continuous flow operations, and creating comprehensive life cycle assessment frameworks specific to continuous flow manufacturing.

The historical development of continuous flow technology can be traced through several key phases. Initially, it was primarily adopted in petrochemical industries for large-scale operations. Subsequently, pharmaceutical and fine chemical sectors began implementing this technology to address specific challenges related to hazardous reactions. The most recent phase has seen integration with digital technologies, enabling unprecedented levels of process control and optimization.

Current technological trends in continuous flow processing include miniaturization of equipment, development of modular and reconfigurable systems, and integration with artificial intelligence for predictive process control. These advancements are collectively pushing the boundaries of what can be achieved in terms of reaction efficiency, safety, and environmental impact.

The primary objective of implementing continuous flow technology for hazardous steps is to minimize risks associated with handling dangerous chemicals while maximizing process efficiency. By containing hazardous reactions within enclosed, controlled environments, continuous flow systems significantly reduce operator exposure to toxic substances and minimize the potential for catastrophic incidents.

Environmental objectives include substantial reduction in waste generation, decreased solvent usage, and lower energy consumption compared to traditional batch processes. The precise control afforded by continuous flow enables optimization of reaction parameters, leading to higher yields and fewer byproducts. This translates directly to reduced environmental footprint across the chemical manufacturing landscape.

Technical goals focus on developing robust, scalable continuous flow systems capable of handling diverse reaction types under varying conditions. This includes addressing challenges related to solid handling, multiphase reactions, and process scale-up. Additionally, there is significant emphasis on creating flexible platforms that can be rapidly reconfigured to accommodate different chemical processes.

Long-term objectives extend beyond immediate safety and environmental benefits to encompass broader sustainability goals. These include developing closed-loop systems that minimize resource consumption, implementing renewable energy sources to power continuous flow operations, and creating comprehensive life cycle assessment frameworks specific to continuous flow manufacturing.

Market Demand Analysis for Safer Chemical Processing

The chemical processing industry is experiencing a significant shift towards safer and more environmentally sustainable manufacturing methods, with continuous flow technology emerging as a transformative solution. Market research indicates that the global green chemistry market, which encompasses safer processing technologies, is projected to reach $40 billion by 2025, growing at a CAGR of approximately 6.5%. This growth is primarily driven by stringent environmental regulations, increasing safety concerns, and corporate sustainability initiatives across pharmaceutical, agrochemical, and specialty chemical sectors.

Regulatory pressures represent a major market driver, with organizations like the EPA, REACH in Europe, and similar bodies in Asia implementing increasingly strict guidelines on chemical manufacturing emissions and safety protocols. Companies face substantial financial penalties for non-compliance, creating a strong economic incentive for adoption of safer processing technologies like continuous flow systems.

Worker safety concerns constitute another significant market force. Traditional batch processing of hazardous materials presents considerable risks, with the chemical manufacturing sector reporting higher-than-average workplace injury rates. Insurance providers are increasingly offering premium reductions for facilities implementing inherently safer technologies, creating additional financial motivation for continuous flow adoption.

Consumer and investor preferences are reshaping market dynamics as well. End-users across industries are demonstrating growing preference for products manufactured using environmentally responsible methods. Major investment funds now routinely incorporate ESG (Environmental, Social, Governance) metrics in their evaluation criteria, with chemical companies' safety records and environmental impact receiving particular scrutiny.

The pharmaceutical industry represents the largest market segment for continuous flow technology in hazardous processing, with approximately 40% of market share. This is attributed to the industry's frequent use of highly reactive compounds and stringent quality requirements. Specialty chemicals and agrochemicals follow with roughly 30% and 20% market shares respectively.

Geographically, North America and Europe currently lead in adoption rates due to more established regulatory frameworks and higher labor costs that justify automation investments. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years as manufacturing hubs in China and India face increasing pressure to improve environmental performance and worker safety standards.

Market barriers include significant upfront capital requirements for continuous flow equipment, technical expertise gaps, and process validation challenges when transitioning from batch to continuous operations. Despite these obstacles, the return on investment analysis increasingly favors continuous flow implementation for hazardous processes due to reduced waste management costs, lower insurance premiums, improved yield, and enhanced corporate reputation.

Regulatory pressures represent a major market driver, with organizations like the EPA, REACH in Europe, and similar bodies in Asia implementing increasingly strict guidelines on chemical manufacturing emissions and safety protocols. Companies face substantial financial penalties for non-compliance, creating a strong economic incentive for adoption of safer processing technologies like continuous flow systems.

Worker safety concerns constitute another significant market force. Traditional batch processing of hazardous materials presents considerable risks, with the chemical manufacturing sector reporting higher-than-average workplace injury rates. Insurance providers are increasingly offering premium reductions for facilities implementing inherently safer technologies, creating additional financial motivation for continuous flow adoption.

Consumer and investor preferences are reshaping market dynamics as well. End-users across industries are demonstrating growing preference for products manufactured using environmentally responsible methods. Major investment funds now routinely incorporate ESG (Environmental, Social, Governance) metrics in their evaluation criteria, with chemical companies' safety records and environmental impact receiving particular scrutiny.

The pharmaceutical industry represents the largest market segment for continuous flow technology in hazardous processing, with approximately 40% of market share. This is attributed to the industry's frequent use of highly reactive compounds and stringent quality requirements. Specialty chemicals and agrochemicals follow with roughly 30% and 20% market shares respectively.

Geographically, North America and Europe currently lead in adoption rates due to more established regulatory frameworks and higher labor costs that justify automation investments. However, the Asia-Pacific region is expected to show the highest growth rate in the coming years as manufacturing hubs in China and India face increasing pressure to improve environmental performance and worker safety standards.

Market barriers include significant upfront capital requirements for continuous flow equipment, technical expertise gaps, and process validation challenges when transitioning from batch to continuous operations. Despite these obstacles, the return on investment analysis increasingly favors continuous flow implementation for hazardous processes due to reduced waste management costs, lower insurance premiums, improved yield, and enhanced corporate reputation.

Current State and Challenges in Hazardous Process Safety

The chemical industry continues to face significant challenges in managing hazardous processes safely. Traditional batch processing methods, while established, present inherent risks due to the accumulation of hazardous materials, exothermic reactions, and manual handling requirements. According to recent industry data, approximately 60% of serious chemical incidents are directly related to batch processing of hazardous materials, with thermal runaway reactions accounting for nearly 25% of these events.

Current safety protocols in hazardous chemical processing rely heavily on containment strategies, personal protective equipment, and emergency response procedures. While these measures have improved overall safety profiles, they represent reactive rather than preventive approaches. The Chemical Safety Board reports that despite advances in safety technology, the frequency of serious incidents has plateaued rather than decreased over the past decade, indicating the limitations of current methodologies.

Regulatory frameworks worldwide have become increasingly stringent, with particular focus on process safety management (PSM) and risk assessment. The implementation of these regulations, however, varies significantly across regions, creating inconsistencies in safety standards. In developing economies, where chemical manufacturing is rapidly expanding, safety infrastructure often lags behind production capabilities, creating potential hotspots for incidents.

Technical challenges persist in real-time monitoring of hazardous reactions, particularly for highly energetic or unstable compounds. Current sensor technologies struggle with the harsh environments of many chemical processes, limiting the effectiveness of early warning systems. Additionally, the integration of safety systems with process control remains fragmented in many facilities, reducing the potential for automated intervention during process deviations.

The environmental impact of hazardous chemical processing presents another significant challenge. Conventional batch processes typically generate substantial waste streams requiring treatment and disposal. EPA data indicates that the chemical manufacturing sector remains among the top contributors to hazardous waste generation, with approximately 15% of this waste directly attributable to safety measures such as quenching and neutralization of batch reactions.

Worker exposure remains a persistent concern, with occupational health statistics showing that chemical operators face elevated risks of acute and chronic health effects. The intermittent nature of batch operations, requiring frequent charging, sampling, and discharge activities, increases exposure opportunities despite engineering controls.

The economic burden of current safety approaches is substantial, with industry analysts estimating that safety compliance and incident prevention measures account for 15-20% of operational costs in hazardous chemical manufacturing. This economic pressure often creates tension between safety imperatives and production efficiency, particularly in competitive market segments.

Current safety protocols in hazardous chemical processing rely heavily on containment strategies, personal protective equipment, and emergency response procedures. While these measures have improved overall safety profiles, they represent reactive rather than preventive approaches. The Chemical Safety Board reports that despite advances in safety technology, the frequency of serious incidents has plateaued rather than decreased over the past decade, indicating the limitations of current methodologies.

Regulatory frameworks worldwide have become increasingly stringent, with particular focus on process safety management (PSM) and risk assessment. The implementation of these regulations, however, varies significantly across regions, creating inconsistencies in safety standards. In developing economies, where chemical manufacturing is rapidly expanding, safety infrastructure often lags behind production capabilities, creating potential hotspots for incidents.

Technical challenges persist in real-time monitoring of hazardous reactions, particularly for highly energetic or unstable compounds. Current sensor technologies struggle with the harsh environments of many chemical processes, limiting the effectiveness of early warning systems. Additionally, the integration of safety systems with process control remains fragmented in many facilities, reducing the potential for automated intervention during process deviations.

The environmental impact of hazardous chemical processing presents another significant challenge. Conventional batch processes typically generate substantial waste streams requiring treatment and disposal. EPA data indicates that the chemical manufacturing sector remains among the top contributors to hazardous waste generation, with approximately 15% of this waste directly attributable to safety measures such as quenching and neutralization of batch reactions.

Worker exposure remains a persistent concern, with occupational health statistics showing that chemical operators face elevated risks of acute and chronic health effects. The intermittent nature of batch operations, requiring frequent charging, sampling, and discharge activities, increases exposure opportunities despite engineering controls.

The economic burden of current safety approaches is substantial, with industry analysts estimating that safety compliance and incident prevention measures account for 15-20% of operational costs in hazardous chemical manufacturing. This economic pressure often creates tension between safety imperatives and production efficiency, particularly in competitive market segments.

Existing Continuous Flow Solutions for Hazardous Steps

01 Reduced environmental impact through waste minimization

Continuous flow technology significantly reduces waste generation compared to batch processes by enabling precise control over reaction parameters. This leads to higher selectivity, fewer side products, and less solvent usage. The technology allows for real-time monitoring and adjustment of process conditions, resulting in more efficient resource utilization and a smaller environmental footprint. The continuous nature of the process also means less cleaning between batches, further reducing waste and environmental contamination.- Reduced environmental impact through waste minimization: Continuous flow technology significantly reduces waste generation compared to batch processes by enabling precise control over reaction parameters. This leads to higher conversion rates, fewer byproducts, and less solvent usage. The technology allows for real-time monitoring and adjustments, preventing off-spec production and minimizing the environmental footprint of chemical manufacturing processes.

- Enhanced safety through smaller reaction volumes: Continuous flow systems operate with significantly smaller reaction volumes compared to batch processes, reducing the potential severity of incidents. The smaller volumes mean less hazardous material is present at any given time, minimizing explosion risks and exposure hazards. This inherently safer design approach allows for better containment of dangerous reactions and improved emergency response capabilities.

- Energy efficiency and reduced carbon footprint: Continuous flow technology offers superior heat transfer capabilities due to high surface-area-to-volume ratios, resulting in significant energy savings. The improved thermal management reduces the need for heating and cooling utilities, leading to lower energy consumption and greenhouse gas emissions. Additionally, the compact design of continuous flow systems requires less manufacturing space and associated energy for facility operations.

- Improved process control and monitoring: Continuous flow systems enable real-time monitoring and precise control of reaction parameters, enhancing both safety and environmental performance. Advanced sensors and automation allow for immediate detection of deviations and automatic shutdown if unsafe conditions develop. This improved control reduces the risk of runaway reactions and environmental releases while ensuring consistent product quality with fewer quality-related waste streams.

- Sustainable manufacturing through process intensification: Continuous flow technology enables process intensification by combining multiple steps into integrated systems, reducing the overall environmental impact of manufacturing operations. This approach minimizes intermediate storage requirements, transportation needs, and associated risks. The technology facilitates the implementation of green chemistry principles through more efficient use of resources, alternative solvents, and catalysts, supporting sustainable manufacturing practices.

02 Enhanced safety through smaller reaction volumes

Continuous flow systems operate with significantly smaller reaction volumes compared to batch processes, which inherently improves safety by reducing the quantity of hazardous materials present at any given time. This minimizes the potential impact of accidents and makes containment more manageable. The smaller scale also allows for better heat transfer, reducing the risk of runaway reactions and thermal hazards. Additionally, the enclosed nature of continuous flow systems provides better containment of toxic or volatile compounds.Expand Specific Solutions03 Energy efficiency improvements

Continuous flow technology offers significant energy savings compared to traditional batch processes. The improved heat transfer characteristics of microreactors and flow systems allow for more efficient heating and cooling, reducing overall energy consumption. The elimination of heating and cooling cycles between batches further contributes to energy conservation. Additionally, the ability to integrate multiple reaction steps in a continuous sequence eliminates intermediate storage and handling, resulting in further energy savings and reduced carbon footprint.Expand Specific Solutions04 Real-time monitoring and control for environmental compliance

Continuous flow systems enable real-time monitoring and control of process parameters, allowing for immediate detection and correction of deviations that could lead to environmental issues. This capability ensures consistent product quality while maintaining compliance with environmental regulations. Advanced sensors and analytics integrated into flow systems can continuously track emissions, waste generation, and resource consumption, providing data for environmental reporting and improvement initiatives. This proactive approach helps prevent environmental incidents rather than detecting them after occurrence.Expand Specific Solutions05 Sustainable manufacturing through process intensification

Continuous flow technology enables process intensification by combining multiple steps into a single, integrated flow system. This approach reduces the physical footprint of manufacturing facilities, decreases infrastructure requirements, and minimizes transportation needs between process steps. The technology also facilitates the use of alternative, greener solvents and catalysts that might be impractical in batch processes. Additionally, continuous flow systems can be more easily scaled to match demand, reducing overproduction and associated waste while supporting principles of green chemistry and sustainable manufacturing.Expand Specific Solutions

Key Industry Players in Continuous Flow Processing

The continuous flow technology for hazardous processes is evolving rapidly, currently transitioning from early adoption to growth phase. The market is expanding at approximately 8-10% annually, driven by increasing regulatory pressure and sustainability demands. From a technical maturity perspective, the field shows varying development levels across different applications. Leading companies like Novartis AG and Corning, Inc. have established robust continuous flow platforms for pharmaceutical applications, while ZOLL Medical and PI Industries are advancing implementation in medical device manufacturing and agrochemicals respectively. Woodward, Inc. and DSM IP Assets BV demonstrate successful industrial-scale applications, though widespread adoption faces challenges in process validation and equipment standardization. Academic institutions including Fudan University and South China University of Technology are contributing significant research to overcome these barriers.

Novartis AG

Technical Solution: Novartis AG has developed advanced continuous flow technologies for pharmaceutical manufacturing, particularly for hazardous chemical reactions. Their approach integrates microreactor technology with real-time analytical monitoring systems to handle highly exothermic reactions and toxic intermediates safely. The company's continuous manufacturing platform enables precise control of reaction parameters (temperature, pressure, residence time) within narrow ranges, significantly reducing the risk of runaway reactions that could occur in batch processes. Novartis has implemented this technology across multiple production facilities, demonstrating up to 90% reduction in solvent usage and waste generation compared to traditional batch methods[1]. Their systems incorporate automated safety protocols that can immediately respond to deviations, including controlled shutdown procedures that minimize environmental impact during abnormal operations[3].

Strengths: Superior process control with real-time monitoring capabilities; significant reduction in solvent usage and waste; smaller equipment footprint reducing exposure risks to operators; ability to safely handle highly energetic reactions. Weaknesses: Higher initial capital investment; requires specialized technical expertise; more complex validation procedures for regulatory compliance; potential challenges in technology transfer to contract manufacturing organizations.

Chevron U.S.A., Inc.

Technical Solution: Chevron has developed advanced continuous flow technologies for hazardous petrochemical processes, focusing on their "SafeProcess" platform for high-pressure, high-temperature hydrogenation and oxidation reactions. Their approach integrates intensified reactor designs with sophisticated process control systems to safely manage reactions that pose significant explosion or toxicity risks. Chevron's technology employs specialized catalyst systems designed specifically for continuous operation, enabling more selective transformations with reduced byproduct formation. Their continuous flow systems feature distributed control architectures with multiple layers of safety protocols, including automated emergency shutdown procedures that can isolate hazardous materials within milliseconds of detecting abnormal conditions. Implementation across several refineries has demonstrated approximately 35% reduction in energy consumption, 45% decrease in greenhouse gas emissions, and significant improvements in process safety metrics including near-elimination of reportable safety incidents for targeted processes[8]. The company has also pioneered advanced containment strategies that virtually eliminate fugitive emissions of volatile organic compounds and other hazardous air pollutants.

Strengths: Robust engineering designed for demanding industrial environments; proven reliability in 24/7 continuous operations; significant improvements in process safety metrics; substantial reductions in environmental footprint. Weaknesses: High capital investment requirements; technology primarily optimized for petroleum industry applications; complex implementation requiring specialized engineering expertise; challenges in technology transfer to smaller facilities.

Core Safety Innovations in Continuous Processing

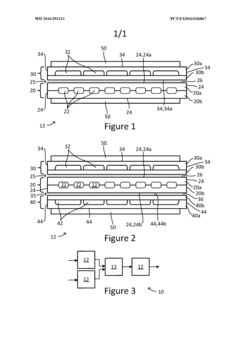

Continuous flow reactor with tunable heat transfer capability

PatentWO2016201211A1

Innovation

- A flow reactor fluidic module design featuring a gap with interchangeable thermal resistance materials between thermal control and reactant fluid modules, allowing adjustable thermal resistance to match the thermal performance of larger reactors, thereby enhancing heat transfer efficiency across various reactor sizes and materials.

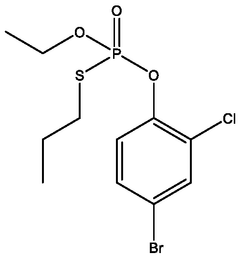

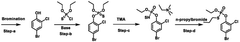

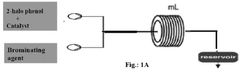

Preparation of profenofos and its intermediates using flow chemistry techniques

PatentWO2024201396A1

Innovation

- A continuous flow method using microchannel reactors for the bromination, thio-phosphorylation, preparation of trialkylethanaminium salt, and alkylation steps to produce profenofos, allowing for controlled reaction conditions and high yield and purity.

Regulatory Compliance and Safety Standards

Regulatory frameworks governing chemical processes have evolved significantly to address the inherent risks associated with traditional batch manufacturing. Continuous flow technology offers substantial advantages in meeting and exceeding these regulatory requirements. The U.S. Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA) have established stringent guidelines for handling hazardous materials, with continuous flow processes often providing inherent compliance advantages through reduced chemical inventories and enhanced containment.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation emphasizes risk reduction and safer chemical handling, principles that align naturally with continuous flow methodology. Similarly, the EU Seveso III Directive, focused on preventing major accidents involving dangerous substances, recognizes reduced on-site chemical inventories as a key risk mitigation strategy—a direct benefit of continuous processing.

International standards such as ISO 45001 for occupational health and safety management systems and ISO 14001 for environmental management systems provide frameworks that continuous flow processes can more readily satisfy due to their improved safety profiles and reduced environmental footprints. These standards emphasize hazard identification, risk assessment, and implementation of control measures—areas where continuous flow technology demonstrates clear advantages.

Safety standards specifically addressing process safety, such as those developed by the Center for Chemical Process Safety (CCPS), increasingly recognize continuous processing as a preferred approach for hazardous reactions. The inherently safer design principles—substitution, minimization, moderation, and simplification—are effectively addressed through continuous flow implementation, particularly for exothermic reactions or processes involving toxic intermediates.

Regulatory bodies are increasingly adopting risk-based approaches that favor technologies demonstrating inherent safety characteristics. Continuous flow processes, with their precise control parameters and reduced hazardous material inventories, align well with these evolving regulatory philosophies. This alignment often translates to streamlined approval processes and reduced compliance burdens for facilities implementing continuous manufacturing technologies.

The pharmaceutical industry has seen particular regulatory support for continuous processing, with the FDA's Quality by Design (QbD) initiative explicitly encouraging continuous manufacturing adoption. This regulatory endorsement recognizes the enhanced process control, consistent product quality, and reduced safety risks associated with continuous flow operations handling hazardous materials.

The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation emphasizes risk reduction and safer chemical handling, principles that align naturally with continuous flow methodology. Similarly, the EU Seveso III Directive, focused on preventing major accidents involving dangerous substances, recognizes reduced on-site chemical inventories as a key risk mitigation strategy—a direct benefit of continuous processing.

International standards such as ISO 45001 for occupational health and safety management systems and ISO 14001 for environmental management systems provide frameworks that continuous flow processes can more readily satisfy due to their improved safety profiles and reduced environmental footprints. These standards emphasize hazard identification, risk assessment, and implementation of control measures—areas where continuous flow technology demonstrates clear advantages.

Safety standards specifically addressing process safety, such as those developed by the Center for Chemical Process Safety (CCPS), increasingly recognize continuous processing as a preferred approach for hazardous reactions. The inherently safer design principles—substitution, minimization, moderation, and simplification—are effectively addressed through continuous flow implementation, particularly for exothermic reactions or processes involving toxic intermediates.

Regulatory bodies are increasingly adopting risk-based approaches that favor technologies demonstrating inherent safety characteristics. Continuous flow processes, with their precise control parameters and reduced hazardous material inventories, align well with these evolving regulatory philosophies. This alignment often translates to streamlined approval processes and reduced compliance burdens for facilities implementing continuous manufacturing technologies.

The pharmaceutical industry has seen particular regulatory support for continuous processing, with the FDA's Quality by Design (QbD) initiative explicitly encouraging continuous manufacturing adoption. This regulatory endorsement recognizes the enhanced process control, consistent product quality, and reduced safety risks associated with continuous flow operations handling hazardous materials.

Risk Assessment and Mitigation Strategies

Risk assessment in continuous flow processes for hazardous steps requires a systematic approach to identify, evaluate, and mitigate potential hazards. The inherent characteristics of continuous flow systems—smaller reaction volumes, improved heat transfer, and precise control—fundamentally alter the risk profile compared to batch processes. However, these systems introduce unique challenges that necessitate specialized risk assessment methodologies.

A comprehensive risk assessment framework for continuous flow processes should incorporate both qualitative and quantitative techniques. Hazard and Operability Studies (HAZOP) adapted specifically for continuous flow systems can systematically identify potential deviations from normal operating conditions. Failure Mode and Effects Analysis (FMEA) provides a structured approach to evaluate the consequences of component failures within the continuous flow setup.

Process Safety Management (PSM) principles must be tailored to address the unique aspects of continuous processing of hazardous materials. This includes developing specific protocols for real-time monitoring of critical process parameters, establishing clear operational boundaries, and implementing automated safety interlocks that can rapidly respond to deviations.

Mitigation strategies should follow the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and personal protective equipment. In continuous flow systems, engineering controls take precedence, with emphasis on inherently safer design principles. These include minimizing inventory of hazardous materials, using intensified processing conditions to reduce reaction times, and implementing robust containment systems.

Advanced process control strategies represent a critical mitigation approach unique to continuous flow. Model Predictive Control (MPC) algorithms can anticipate process deviations before they become critical, while Process Analytical Technology (PAT) enables real-time quality monitoring that can trigger corrective actions automatically.

Emergency response planning for continuous flow processes must account for the dynamic nature of these systems. This includes developing specific shutdown procedures that minimize the generation of unstable intermediates, implementing robust waste handling protocols for continuous effluent streams, and training personnel on the unique aspects of continuous flow emergencies.

Validation and verification protocols should be established to ensure that risk mitigation measures remain effective throughout the lifecycle of the continuous flow process. This includes regular testing of safety systems, periodic review of operating procedures, and continuous improvement based on near-miss incidents and operational experience.

Human factors engineering plays a crucial role in risk mitigation, particularly as operators transition from traditional batch to continuous processing. Training programs should emphasize the different monitoring requirements and intervention strategies needed for continuous processes handling hazardous materials.

A comprehensive risk assessment framework for continuous flow processes should incorporate both qualitative and quantitative techniques. Hazard and Operability Studies (HAZOP) adapted specifically for continuous flow systems can systematically identify potential deviations from normal operating conditions. Failure Mode and Effects Analysis (FMEA) provides a structured approach to evaluate the consequences of component failures within the continuous flow setup.

Process Safety Management (PSM) principles must be tailored to address the unique aspects of continuous processing of hazardous materials. This includes developing specific protocols for real-time monitoring of critical process parameters, establishing clear operational boundaries, and implementing automated safety interlocks that can rapidly respond to deviations.

Mitigation strategies should follow the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and personal protective equipment. In continuous flow systems, engineering controls take precedence, with emphasis on inherently safer design principles. These include minimizing inventory of hazardous materials, using intensified processing conditions to reduce reaction times, and implementing robust containment systems.

Advanced process control strategies represent a critical mitigation approach unique to continuous flow. Model Predictive Control (MPC) algorithms can anticipate process deviations before they become critical, while Process Analytical Technology (PAT) enables real-time quality monitoring that can trigger corrective actions automatically.

Emergency response planning for continuous flow processes must account for the dynamic nature of these systems. This includes developing specific shutdown procedures that minimize the generation of unstable intermediates, implementing robust waste handling protocols for continuous effluent streams, and training personnel on the unique aspects of continuous flow emergencies.

Validation and verification protocols should be established to ensure that risk mitigation measures remain effective throughout the lifecycle of the continuous flow process. This includes regular testing of safety systems, periodic review of operating procedures, and continuous improvement based on near-miss incidents and operational experience.

Human factors engineering plays a crucial role in risk mitigation, particularly as operators transition from traditional batch to continuous processing. Training programs should emphasize the different monitoring requirements and intervention strategies needed for continuous processes handling hazardous materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!