Microreactor Material Choices For Corrosive Or Abrasive Chemistries

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microreactor Materials Background and Objectives

Microreactors represent a significant advancement in chemical processing technology, evolving from traditional batch reactors to continuous flow systems with enhanced efficiency and control. The development trajectory of microreactor technology began in the late 1990s with pioneering work in microfluidics, gradually expanding into industrial applications over the past two decades. This evolution has been driven by demands for process intensification, improved safety, and reduced environmental impact across chemical manufacturing sectors.

The materials used in microreactor construction have similarly evolved, initially dominated by glass and silicon substrates borrowed from microelectronics fabrication. As applications diversified into more aggressive chemical environments, material selection became increasingly critical to operational success and longevity. Today's material considerations must balance chemical compatibility, thermal stability, mechanical properties, and economic feasibility.

Current technological trends point toward multi-material microreactor designs that strategically employ different materials in various reactor zones based on specific chemical and physical requirements. This approach represents a departure from earlier single-material designs and acknowledges the complex demands placed on modern microreactor systems.

The primary objective in microreactor material selection for corrosive or abrasive chemistries is to identify substrate materials that maintain structural and functional integrity while resisting degradation under challenging process conditions. This includes resistance to chemical attack from acids, bases, oxidizing agents, and organic solvents, as well as mechanical durability against particulate abrasion and erosion.

Secondary objectives include optimizing heat transfer characteristics, ensuring manufacturing scalability, and maintaining economic viability. The ideal material solution must balance these sometimes competing requirements while enabling precise control over reaction parameters and product quality.

Long-term technological goals in this field include the development of novel composite materials specifically engineered for microreactor applications, advancement of surface modification techniques to enhance chemical resistance, and creation of standardized testing protocols for material performance under various chemical conditions. Additionally, there is growing interest in materials that enable in-situ monitoring capabilities through optical transparency or integrated sensor compatibility.

As industrial adoption of microreactor technology accelerates across pharmaceutical, fine chemical, and specialty materials sectors, the demand for advanced material solutions continues to grow. This creates both technical challenges and significant opportunities for innovation in materials science and chemical engineering disciplines.

The materials used in microreactor construction have similarly evolved, initially dominated by glass and silicon substrates borrowed from microelectronics fabrication. As applications diversified into more aggressive chemical environments, material selection became increasingly critical to operational success and longevity. Today's material considerations must balance chemical compatibility, thermal stability, mechanical properties, and economic feasibility.

Current technological trends point toward multi-material microreactor designs that strategically employ different materials in various reactor zones based on specific chemical and physical requirements. This approach represents a departure from earlier single-material designs and acknowledges the complex demands placed on modern microreactor systems.

The primary objective in microreactor material selection for corrosive or abrasive chemistries is to identify substrate materials that maintain structural and functional integrity while resisting degradation under challenging process conditions. This includes resistance to chemical attack from acids, bases, oxidizing agents, and organic solvents, as well as mechanical durability against particulate abrasion and erosion.

Secondary objectives include optimizing heat transfer characteristics, ensuring manufacturing scalability, and maintaining economic viability. The ideal material solution must balance these sometimes competing requirements while enabling precise control over reaction parameters and product quality.

Long-term technological goals in this field include the development of novel composite materials specifically engineered for microreactor applications, advancement of surface modification techniques to enhance chemical resistance, and creation of standardized testing protocols for material performance under various chemical conditions. Additionally, there is growing interest in materials that enable in-situ monitoring capabilities through optical transparency or integrated sensor compatibility.

As industrial adoption of microreactor technology accelerates across pharmaceutical, fine chemical, and specialty materials sectors, the demand for advanced material solutions continues to grow. This creates both technical challenges and significant opportunities for innovation in materials science and chemical engineering disciplines.

Market Demand Analysis for Corrosion-Resistant Microreactors

The global market for corrosion-resistant microreactors is experiencing significant growth, driven primarily by increasing demand in pharmaceutical, fine chemical, and specialty chemical industries. Current market estimates value this segment at approximately $2.3 billion, with projections indicating a compound annual growth rate of 9.7% through 2028, substantially outpacing the broader chemical equipment market.

Pharmaceutical companies represent the largest market segment, accounting for nearly 38% of demand. This is attributed to the industry's shift toward continuous manufacturing processes and the need to handle increasingly complex and corrosive active pharmaceutical ingredients. The ability to precisely control reaction parameters while maintaining material integrity has become a critical requirement for drug development and production.

The specialty chemicals sector follows closely at 31% market share, with particular emphasis on applications involving fluorination reactions, strong acids, and oxidizing environments. These processes typically involve highly corrosive media that rapidly degrade conventional reactor materials, creating substantial replacement costs and production inefficiencies that advanced corrosion-resistant microreactors can address.

Geographically, North America and Europe currently dominate the market with a combined 65% share, though Asia-Pacific regions—particularly China, Japan, and South Korea—are demonstrating the fastest growth rates as their chemical and pharmaceutical manufacturing capabilities expand. This regional shift is expected to continue as these economies invest heavily in advanced manufacturing technologies.

A key market driver is the increasing regulatory pressure across industries to improve process safety and reduce environmental impact. Corrosion-resistant microreactors offer significant advantages in containing hazardous materials and minimizing waste generation through more efficient reactions, directly addressing these regulatory concerns.

Customer surveys indicate that end-users prioritize three key performance attributes: chemical compatibility across a wide pH range (cited by 87% of respondents), operational longevity under extreme conditions (82%), and the ability to maintain consistent performance without contaminating sensitive products (79%). These requirements are pushing material innovation beyond traditional options like stainless steel and glass.

The market is also witnessing a shift toward customized solutions, with 64% of new installations featuring application-specific material selections rather than general-purpose designs. This trend reflects the growing sophistication of end-users who increasingly understand the critical relationship between material selection and process economics in corrosive applications.

Price sensitivity varies significantly by application, with pharmaceutical applications demonstrating the highest willingness to pay premium prices for advanced materials that ensure product purity and regulatory compliance. In contrast, bulk chemical applications remain more cost-conscious, creating distinct market segments with different value propositions.

Pharmaceutical companies represent the largest market segment, accounting for nearly 38% of demand. This is attributed to the industry's shift toward continuous manufacturing processes and the need to handle increasingly complex and corrosive active pharmaceutical ingredients. The ability to precisely control reaction parameters while maintaining material integrity has become a critical requirement for drug development and production.

The specialty chemicals sector follows closely at 31% market share, with particular emphasis on applications involving fluorination reactions, strong acids, and oxidizing environments. These processes typically involve highly corrosive media that rapidly degrade conventional reactor materials, creating substantial replacement costs and production inefficiencies that advanced corrosion-resistant microreactors can address.

Geographically, North America and Europe currently dominate the market with a combined 65% share, though Asia-Pacific regions—particularly China, Japan, and South Korea—are demonstrating the fastest growth rates as their chemical and pharmaceutical manufacturing capabilities expand. This regional shift is expected to continue as these economies invest heavily in advanced manufacturing technologies.

A key market driver is the increasing regulatory pressure across industries to improve process safety and reduce environmental impact. Corrosion-resistant microreactors offer significant advantages in containing hazardous materials and minimizing waste generation through more efficient reactions, directly addressing these regulatory concerns.

Customer surveys indicate that end-users prioritize three key performance attributes: chemical compatibility across a wide pH range (cited by 87% of respondents), operational longevity under extreme conditions (82%), and the ability to maintain consistent performance without contaminating sensitive products (79%). These requirements are pushing material innovation beyond traditional options like stainless steel and glass.

The market is also witnessing a shift toward customized solutions, with 64% of new installations featuring application-specific material selections rather than general-purpose designs. This trend reflects the growing sophistication of end-users who increasingly understand the critical relationship between material selection and process economics in corrosive applications.

Price sensitivity varies significantly by application, with pharmaceutical applications demonstrating the highest willingness to pay premium prices for advanced materials that ensure product purity and regulatory compliance. In contrast, bulk chemical applications remain more cost-conscious, creating distinct market segments with different value propositions.

Current Material Limitations and Technical Challenges

Microreactors operating in corrosive or abrasive chemical environments face significant material limitations that impede their widespread industrial adoption. Traditional materials such as stainless steel (316L), commonly used in chemical processing equipment, demonstrate inadequate resistance when exposed to highly corrosive media like concentrated acids, strong oxidizers, or halogen-containing compounds. These materials experience accelerated degradation, leading to reduced operational lifespans and potential contamination of reaction products.

Glass and quartz microreactors offer excellent chemical resistance to many corrosive substances but suffer from inherent brittleness and poor thermal shock resistance. This fragility significantly limits their application in high-pressure systems or processes requiring rapid temperature changes, creating a substantial barrier for continuous flow chemistry applications that demand robust material performance under varying conditions.

Polymer-based microreactors (PTFE, PEEK, PFA) present another alternative with good chemical compatibility profiles, but they introduce their own set of limitations. These materials typically exhibit lower temperature resistance compared to metals and ceramics, with operational ceilings generally below 300°C. Additionally, polymers often demonstrate poor thermal conductivity, creating challenges for reactions requiring precise temperature control or efficient heat transfer.

Advanced ceramic materials like silicon carbide and aluminum nitride show promising chemical resistance but face manufacturing challenges. The complex microchannel geometries essential for efficient microreactor performance are difficult to achieve in ceramic substrates using conventional fabrication techniques. This manufacturing limitation restricts design flexibility and increases production costs substantially.

Surface modification technologies represent a potential solution pathway but currently face durability issues. Coatings such as diamond-like carbon (DLC), tantalum, or specialized polymers can enhance the chemical resistance of base materials, but their long-term stability remains problematic. Delamination, cracking, and uneven coverage in microchannels with high aspect ratios compromise the effectiveness of these protective layers over extended operational periods.

The integration of composite materials presents another technical challenge. While combining different materials could theoretically provide optimal performance characteristics, the interfaces between dissimilar materials often become vulnerability points. Differential thermal expansion, chemical attack at material boundaries, and bonding failures create reliability concerns that have not been adequately resolved in current microreactor designs.

From a geographical perspective, material technology development shows significant regional variations. European research institutions lead in ceramic microreactor development, while North American companies focus on advanced polymer composites and Asian manufacturers excel in specialized metal alloy formulations. This distributed expertise creates challenges for technology integration and standardization across global supply chains.

Glass and quartz microreactors offer excellent chemical resistance to many corrosive substances but suffer from inherent brittleness and poor thermal shock resistance. This fragility significantly limits their application in high-pressure systems or processes requiring rapid temperature changes, creating a substantial barrier for continuous flow chemistry applications that demand robust material performance under varying conditions.

Polymer-based microreactors (PTFE, PEEK, PFA) present another alternative with good chemical compatibility profiles, but they introduce their own set of limitations. These materials typically exhibit lower temperature resistance compared to metals and ceramics, with operational ceilings generally below 300°C. Additionally, polymers often demonstrate poor thermal conductivity, creating challenges for reactions requiring precise temperature control or efficient heat transfer.

Advanced ceramic materials like silicon carbide and aluminum nitride show promising chemical resistance but face manufacturing challenges. The complex microchannel geometries essential for efficient microreactor performance are difficult to achieve in ceramic substrates using conventional fabrication techniques. This manufacturing limitation restricts design flexibility and increases production costs substantially.

Surface modification technologies represent a potential solution pathway but currently face durability issues. Coatings such as diamond-like carbon (DLC), tantalum, or specialized polymers can enhance the chemical resistance of base materials, but their long-term stability remains problematic. Delamination, cracking, and uneven coverage in microchannels with high aspect ratios compromise the effectiveness of these protective layers over extended operational periods.

The integration of composite materials presents another technical challenge. While combining different materials could theoretically provide optimal performance characteristics, the interfaces between dissimilar materials often become vulnerability points. Differential thermal expansion, chemical attack at material boundaries, and bonding failures create reliability concerns that have not been adequately resolved in current microreactor designs.

From a geographical perspective, material technology development shows significant regional variations. European research institutions lead in ceramic microreactor development, while North American companies focus on advanced polymer composites and Asian manufacturers excel in specialized metal alloy formulations. This distributed expertise creates challenges for technology integration and standardization across global supply chains.

Existing Material Solutions for Harsh Chemical Environments

01 Corrosion-resistant metallic alloys for microreactors

Specialized metallic alloys can be used in microreactors to enhance corrosion resistance in harsh chemical environments. These alloys typically contain elements such as chromium, nickel, and molybdenum that form protective oxide layers on the surface. The composition of these alloys can be optimized to withstand specific corrosive media encountered in microreactor applications, including acidic, alkaline, or high-temperature environments.- Ceramic materials for corrosion resistance: Ceramic materials are widely used in microreactors due to their excellent corrosion resistance properties. These materials can withstand harsh chemical environments, high temperatures, and pressure conditions commonly found in microreactor applications. Ceramics such as silicon carbide, alumina, and zirconia offer superior resistance to chemical attack from acids, bases, and other corrosive substances, making them ideal for microreactors handling aggressive chemicals.

- Metal alloys with enhanced corrosion resistance: Specialized metal alloys have been developed specifically for microreactor applications requiring both corrosion and abrasion resistance. These alloys often contain elements such as chromium, nickel, molybdenum, and titanium that form protective oxide layers on the surface. The composition of these alloys is carefully engineered to provide optimal performance in specific chemical environments while maintaining structural integrity under the high-pressure and high-temperature conditions typical in microreactors.

- Polymer-based materials for chemical resistance: Advanced polymers and polymer composites offer excellent chemical resistance for certain microreactor applications. Materials such as fluoropolymers (PTFE, PFA), high-performance thermoplastics, and specially formulated polymer composites can withstand a wide range of chemicals while providing good abrasion resistance. These materials are particularly useful in applications where metal or ceramic materials might be unsuitable due to specific chemical incompatibilities or where lower operating temperatures are acceptable.

- Surface coating and treatment technologies: Various surface coating and treatment technologies have been developed to enhance the corrosion and abrasion resistance of microreactor materials. These include plasma-sprayed coatings, chemical vapor deposition, physical vapor deposition, and sol-gel processes. Such treatments can significantly improve the performance of base materials by creating protective layers that resist chemical attack and mechanical wear while maintaining the thermal and mechanical properties required for microreactor operation.

- Composite and hybrid materials: Composite and hybrid materials combine the advantages of different material classes to achieve superior corrosion and abrasion resistance in microreactors. These may include metal-ceramic composites, ceramic-polymer hybrids, or multilayered structures. By strategically combining materials with complementary properties, these composites can offer enhanced performance in challenging environments while addressing specific operational requirements such as thermal conductivity, mechanical strength, and chemical compatibility.

02 Ceramic and glass materials for corrosion resistance

Ceramic and glass materials offer excellent corrosion resistance for microreactor applications involving aggressive chemicals. Materials such as silicon carbide, alumina, borosilicate glass, and various technical ceramics provide superior resistance to chemical attack compared to metals. These materials can be used either as the primary construction material for the microreactor or as protective coatings on metal substrates to enhance their durability in corrosive environments.Expand Specific Solutions03 Polymer and composite materials for microreactors

Advanced polymers and composite materials can be utilized in microreactor construction to provide both corrosion and abrasion resistance. Fluoropolymers like PTFE, PFA, and PEEK offer exceptional chemical resistance across a wide pH range. Polymer-matrix composites reinforced with fibers or particles can enhance mechanical properties while maintaining chemical resistance. These materials are particularly suitable for low to moderate temperature applications where traditional materials might fail due to chemical attack.Expand Specific Solutions04 Surface treatments and coatings for enhanced resistance

Various surface treatments and coating technologies can significantly improve the corrosion and abrasion resistance of microreactor materials. These include plasma-sprayed ceramic coatings, chemical vapor deposition of diamond-like carbon, physical vapor deposition of nitrides or carbides, and sol-gel derived protective layers. Such surface modifications can extend the service life of microreactors by providing a protective barrier between the base material and the corrosive media while maintaining heat transfer properties.Expand Specific Solutions05 Microstructural design for improved durability

The microstructural design of materials used in microreactors can be engineered to enhance both corrosion and abrasion resistance. Techniques such as grain refinement, precipitation hardening, and controlled phase distribution can create materials with superior mechanical properties and chemical stability. Additionally, the incorporation of self-healing mechanisms or sacrificial elements can provide dynamic protection against progressive corrosion damage, extending the operational lifetime of microreactors in demanding environments.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The microreactor materials market for corrosive/abrasive chemistries is in a growth phase, with increasing demand driven by chemical processing efficiency requirements. Key players include Corning, Inc., leveraging their glass expertise; Arkema France and JSR Corp. offering advanced polymer solutions; and H.C. Starck and 3M providing specialized metal and composite materials. The market shows technological diversification with companies like Resonac and Global Graphene Group developing novel nanomaterials. Academic-industry partnerships are emerging between corporations and institutions like Nagaoka University of Technology and Nanjing Tech University, indicating the field is transitioning from research to commercial applications with significant innovation potential in corrosion-resistant microreactor technologies.

Corning, Inc.

Technical Solution: Corning has developed advanced glass and ceramic microreactors specifically designed for corrosive and abrasive chemical applications. Their technology utilizes proprietary glass-ceramic composites that combine the chemical resistance of high-purity glass with the mechanical durability of engineered ceramics. These microreactors feature ultra-smooth internal channels (surface roughness <10nm) created through precision manufacturing processes, minimizing particle generation and preventing catalyst deposition. Corning's Advanced-Flow™ Reactors employ modular designs with fluidically-optimized flow paths that ensure uniform residence time distribution and excellent heat transfer capabilities (>10 kW/m²·K)[1]. The reactors incorporate proprietary connection technologies that maintain seal integrity under extreme pH conditions (0-14) and temperatures up to 300°C. Additionally, Corning has developed specialized coatings that can be applied to reactor surfaces to enhance chemical compatibility with specific aggressive media, including strong oxidizers and fluorinated compounds[3].

Strengths: Superior chemical resistance across a wide pH range; excellent thermal stability and heat transfer properties; precision-engineered flow paths for optimal mixing; modular design allowing scalable production. Weaknesses: Higher initial cost compared to metal alternatives; potential limitations with certain organic solvents; more complex manufacturing process requiring specialized expertise.

Arkema France SA

Technical Solution: Arkema has developed an innovative microreactor material platform specifically targeting highly corrosive and abrasive chemical applications. Their technology centers on advanced PVDF (polyvinylidene fluoride) and PEKK (polyetherketoneketone) polymer blends that have been engineered at the molecular level to enhance chemical resistance while maintaining mechanical integrity. These microreactors feature Arkema's proprietary Kynar® PVDF grades modified with nano-structured additives that create a hierarchical surface morphology, significantly improving abrasion resistance while maintaining excellent chemical compatibility. The internal channels incorporate a gradient composition structure with the highest chemical resistance at the fluid interface, transitioning to enhanced mechanical properties in the structural layers. Arkema's manufacturing process enables precise control of surface properties, including controlled roughness (Ra 0.1-2.0μm) tailored to specific applications, and the ability to introduce functional surface modifications such as superhydrophobicity or catalytic activity[3]. Their latest generation includes integrated sensors based on piezoelectric PVDF films that enable real-time monitoring of flow conditions and early detection of channel fouling or degradation in aggressive chemical environments[6].

Strengths: Excellent resistance to a wide range of chemicals including strong acids, bases, and oxidizers; good mechanical properties allowing for thin-walled designs; ability to be easily formed into complex geometries; cost-effective manufacturing at scale. Weaknesses: Temperature limitations compared to ceramic options (typically <200°C); potential degradation under certain combinations of high temperature and pressure; limited transparency making visual inspection challenging; potential for stress cracking under certain conditions.

Key Innovations in Anti-Corrosion and Anti-Abrasion Materials

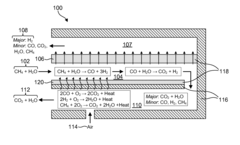

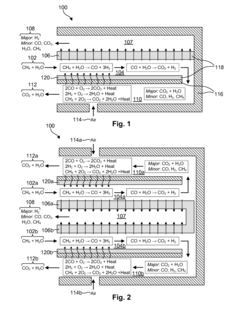

Catalytic Microchannel Reformer

PatentInactiveUS20150174548A1

Innovation

- The use of porous ceramic membranes fabricated from alumina powder and phosphate-containing reagents, such as CERCANAM®, which provide excellent thermal shock resistance and high surface area for efficient hydrogen extraction and catalyst infiltration, allowing for selective hydrogen removal and increased hydrogen yield during hydrocarbon reforming.

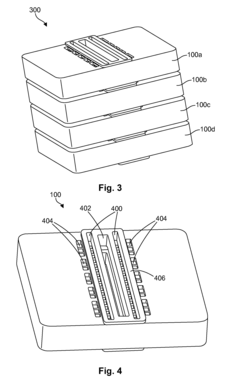

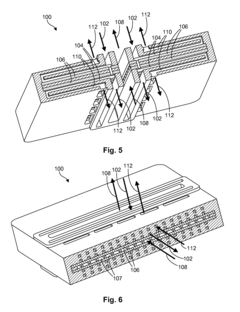

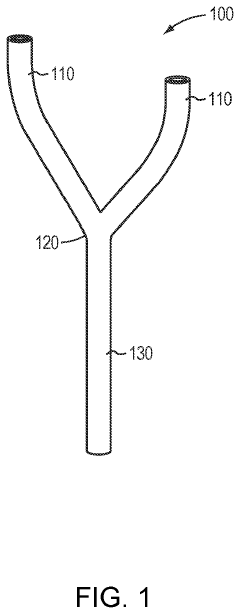

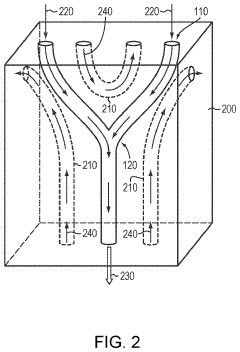

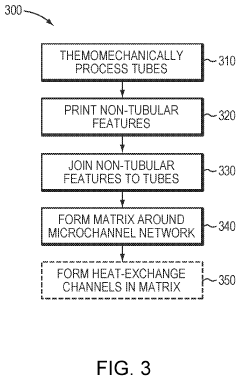

Microreactor systems and methods

PatentActiveUS20220023821A1

Innovation

- The use of hollow corrosion-resistant microchannels surrounded by a thermally conductive matrix material, where the microchannels are formed from refractory metals and the matrix consists of high thermal conductivity materials like aluminum, copper, or silver, allowing for efficient heat transfer without intersecting the microchannel conduits.

Safety Standards and Compliance Requirements

Compliance with safety standards is paramount when selecting materials for microreactors handling corrosive or abrasive chemistries. The regulatory landscape governing these applications spans multiple jurisdictions and industries, with standards varying based on the specific chemicals involved, operating conditions, and intended applications.

Key international standards include ISO 10298 for gas cylinders and chemical compatibility, ASME BPE (Bioprocessing Equipment) standards for pharmaceutical applications, and ASTM D543 for evaluating the resistance of plastics to chemical reagents. For microreactors specifically, ISO 22916 provides guidelines on microprocess engineering vocabulary and apparatus, establishing a framework for safety considerations.

Material selection must adhere to pressure equipment directives such as the European Pressure Equipment Directive (PED 2014/68/EU) and ASME Boiler and Pressure Vessel Code Section VIII, which govern the design and construction of pressure vessels. These standards specify material requirements, testing protocols, and safety factors that must be considered when designing microreactors for high-pressure applications.

Chemical compatibility documentation is essential, with manufacturers required to provide material safety data sheets (MSDS) and compatibility charts. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized hazard communication tools that must be incorporated into material selection processes and documentation.

For pharmaceutical and food applications, additional compliance with FDA regulations (21 CFR Parts 210 and 211) and USP Class VI testing is necessary, particularly for materials that may come into contact with products intended for human consumption. These standards evaluate biocompatibility and leachable/extractable profiles of materials.

Environmental regulations also impact material choices, with restrictions on certain substances under frameworks like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and the Toxic Substances Control Act (TSCA) in the United States. These regulations may limit the use of certain alloys or composites containing restricted substances.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) must be applied during material selection to identify potential failure scenarios related to material degradation. Documentation of these assessments is increasingly required by regulatory bodies as part of the approval process for new chemical processing equipment.

Certification requirements vary by industry and application, with third-party verification often necessary to demonstrate compliance. Organizations such as TÜV, UL, and DNV GL provide certification services specific to materials used in chemical processing equipment, validating that selected materials meet the applicable standards for their intended use in corrosive or abrasive environments.

Key international standards include ISO 10298 for gas cylinders and chemical compatibility, ASME BPE (Bioprocessing Equipment) standards for pharmaceutical applications, and ASTM D543 for evaluating the resistance of plastics to chemical reagents. For microreactors specifically, ISO 22916 provides guidelines on microprocess engineering vocabulary and apparatus, establishing a framework for safety considerations.

Material selection must adhere to pressure equipment directives such as the European Pressure Equipment Directive (PED 2014/68/EU) and ASME Boiler and Pressure Vessel Code Section VIII, which govern the design and construction of pressure vessels. These standards specify material requirements, testing protocols, and safety factors that must be considered when designing microreactors for high-pressure applications.

Chemical compatibility documentation is essential, with manufacturers required to provide material safety data sheets (MSDS) and compatibility charts. The Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized hazard communication tools that must be incorporated into material selection processes and documentation.

For pharmaceutical and food applications, additional compliance with FDA regulations (21 CFR Parts 210 and 211) and USP Class VI testing is necessary, particularly for materials that may come into contact with products intended for human consumption. These standards evaluate biocompatibility and leachable/extractable profiles of materials.

Environmental regulations also impact material choices, with restrictions on certain substances under frameworks like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) in Europe and the Toxic Substances Control Act (TSCA) in the United States. These regulations may limit the use of certain alloys or composites containing restricted substances.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) must be applied during material selection to identify potential failure scenarios related to material degradation. Documentation of these assessments is increasingly required by regulatory bodies as part of the approval process for new chemical processing equipment.

Certification requirements vary by industry and application, with third-party verification often necessary to demonstrate compliance. Organizations such as TÜV, UL, and DNV GL provide certification services specific to materials used in chemical processing equipment, validating that selected materials meet the applicable standards for their intended use in corrosive or abrasive environments.

Lifecycle Assessment and Sustainability Considerations

The lifecycle assessment of materials used in microreactors for corrosive or abrasive chemistries reveals significant environmental and economic implications across their entire lifespan. When evaluating sustainability considerations, it becomes evident that traditional materials like stainless steel, despite their widespread use, often present substantial environmental burdens due to energy-intensive mining and manufacturing processes. The carbon footprint associated with specialty alloys such as Hastelloy and Inconel is particularly concerning, with production emissions estimated at 7-12 kg CO2 equivalent per kilogram of material.

Advanced ceramics and silicon carbide offer improved sustainability profiles with longer service lives in harsh chemical environments, potentially reducing the frequency of replacement and associated environmental impacts. Life cycle analyses indicate that silicon carbide microreactors, despite higher initial production energy requirements, demonstrate superior sustainability metrics when operational lifespans exceed five years in corrosive applications, resulting in a 30-40% reduction in lifetime environmental impact compared to metallic alternatives.

Material recyclability presents another critical dimension in sustainability assessment. Precious metal-coated reactors, while offering excellent chemical resistance, pose significant end-of-life challenges due to complex recovery processes. Conversely, monolithic ceramic systems, though difficult to recycle in their entirety, contain fewer toxic components requiring special disposal considerations. Recent innovations in modular design approaches have improved end-of-life management, with disassembly-friendly configurations enabling up to 85% material recovery rates.

Water consumption throughout the material lifecycle must also be considered, particularly for manufacturing processes involving extensive washing and treatment steps. Fluoropolymer production, for instance, requires substantial water inputs, with estimates suggesting 200-300 liters per kilogram of finished material. This contrasts with certain glass formulations that may require only 40-60% of this water volume during manufacturing.

Energy efficiency during operational phases represents another sustainability factor, with thermal conductivity properties directly influencing process energy requirements. Materials with superior heat transfer characteristics can reduce energy consumption by 15-25% over reactor lifetimes, offsetting initial embodied energy costs. This becomes particularly relevant when considering the cumulative energy demands of continuous processing operations that may run for thousands of hours annually.

Emerging bio-based and renewable material alternatives are beginning to enter consideration for less demanding microreactor applications. While currently limited in their chemical resistance profiles, these materials offer significantly reduced environmental footprints and may represent promising future directions as their performance characteristics improve through ongoing research and development efforts.

Advanced ceramics and silicon carbide offer improved sustainability profiles with longer service lives in harsh chemical environments, potentially reducing the frequency of replacement and associated environmental impacts. Life cycle analyses indicate that silicon carbide microreactors, despite higher initial production energy requirements, demonstrate superior sustainability metrics when operational lifespans exceed five years in corrosive applications, resulting in a 30-40% reduction in lifetime environmental impact compared to metallic alternatives.

Material recyclability presents another critical dimension in sustainability assessment. Precious metal-coated reactors, while offering excellent chemical resistance, pose significant end-of-life challenges due to complex recovery processes. Conversely, monolithic ceramic systems, though difficult to recycle in their entirety, contain fewer toxic components requiring special disposal considerations. Recent innovations in modular design approaches have improved end-of-life management, with disassembly-friendly configurations enabling up to 85% material recovery rates.

Water consumption throughout the material lifecycle must also be considered, particularly for manufacturing processes involving extensive washing and treatment steps. Fluoropolymer production, for instance, requires substantial water inputs, with estimates suggesting 200-300 liters per kilogram of finished material. This contrasts with certain glass formulations that may require only 40-60% of this water volume during manufacturing.

Energy efficiency during operational phases represents another sustainability factor, with thermal conductivity properties directly influencing process energy requirements. Materials with superior heat transfer characteristics can reduce energy consumption by 15-25% over reactor lifetimes, offsetting initial embodied energy costs. This becomes particularly relevant when considering the cumulative energy demands of continuous processing operations that may run for thousands of hours annually.

Emerging bio-based and renewable material alternatives are beginning to enter consideration for less demanding microreactor applications. While currently limited in their chemical resistance profiles, these materials offer significantly reduced environmental footprints and may represent promising future directions as their performance characteristics improve through ongoing research and development efforts.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!