Crankshaft vs Alternator: Rotation Speed Impact

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft-Alternator Speed Relationship Background

The relationship between crankshaft and alternator rotation speeds represents a fundamental aspect of automotive powertrain design that has evolved significantly since the early days of internal combustion engines. Historically, alternators replaced generators in vehicles during the 1960s, offering improved efficiency and the ability to produce current at lower engine speeds—a critical advancement for increasingly power-hungry vehicles.

The crankshaft serves as the primary rotational output of the engine, converting the linear motion of pistons into rotational energy. This rotation is then transferred through a belt and pulley system to drive various accessories, including the alternator. The speed relationship between these components is not 1:1 but rather determined by pulley diameter ratios, typically designed to allow the alternator to spin at 2-3 times the crankshaft speed.

This speed multiplication is essential because alternators require sufficient rotational velocity to generate adequate electrical current. Most modern alternators achieve optimal efficiency at speeds between 2,000-10,000 RPM, while engine crankshafts typically operate in a much lower range of 800-6,000 RPM during normal driving conditions.

The evolution of this relationship has been driven by increasing electrical demands in vehicles. Early automobiles with minimal electrical requirements could function with simpler generator systems and direct 1:1 ratios. Modern vehicles, however, contain sophisticated electronics, climate control systems, and entertainment features that demand robust electrical generation even at idle speeds.

Engineering challenges in this domain include balancing the need for sufficient electrical output at low engine speeds while preventing over-speed conditions at high engine RPMs. This has led to innovations such as variable pulley ratios, smart alternator control modules, and more recently, decoupled electrical generation systems in hybrid vehicles.

The physical constraints of belt-driven systems also present limitations, including belt wear, tensioning requirements, and efficiency losses through mechanical transmission. These factors have contributed to ongoing research into alternative power generation methods, including integrated starter-generators and fully electric power systems that eliminate traditional mechanical linkages.

Understanding this speed relationship is crucial for diagnosing electrical system issues, as insufficient alternator speed relative to electrical demand can lead to battery discharge, while excessive speeds can cause premature component failure and reduced efficiency.

The crankshaft serves as the primary rotational output of the engine, converting the linear motion of pistons into rotational energy. This rotation is then transferred through a belt and pulley system to drive various accessories, including the alternator. The speed relationship between these components is not 1:1 but rather determined by pulley diameter ratios, typically designed to allow the alternator to spin at 2-3 times the crankshaft speed.

This speed multiplication is essential because alternators require sufficient rotational velocity to generate adequate electrical current. Most modern alternators achieve optimal efficiency at speeds between 2,000-10,000 RPM, while engine crankshafts typically operate in a much lower range of 800-6,000 RPM during normal driving conditions.

The evolution of this relationship has been driven by increasing electrical demands in vehicles. Early automobiles with minimal electrical requirements could function with simpler generator systems and direct 1:1 ratios. Modern vehicles, however, contain sophisticated electronics, climate control systems, and entertainment features that demand robust electrical generation even at idle speeds.

Engineering challenges in this domain include balancing the need for sufficient electrical output at low engine speeds while preventing over-speed conditions at high engine RPMs. This has led to innovations such as variable pulley ratios, smart alternator control modules, and more recently, decoupled electrical generation systems in hybrid vehicles.

The physical constraints of belt-driven systems also present limitations, including belt wear, tensioning requirements, and efficiency losses through mechanical transmission. These factors have contributed to ongoing research into alternative power generation methods, including integrated starter-generators and fully electric power systems that eliminate traditional mechanical linkages.

Understanding this speed relationship is crucial for diagnosing electrical system issues, as insufficient alternator speed relative to electrical demand can lead to battery discharge, while excessive speeds can cause premature component failure and reduced efficiency.

Market Demand Analysis for Efficient Power Generation

The global power generation market is experiencing a significant shift towards more efficient and sustainable solutions, creating a robust demand for advanced technologies that optimize the relationship between crankshafts and alternators. Current market analysis indicates that the power generation equipment sector is projected to reach $145 billion by 2027, with efficiency improvements being a primary driver of growth.

Industrial sectors, particularly manufacturing, automotive, and energy production, are increasingly seeking solutions that maximize power output while minimizing fuel consumption and mechanical wear. This demand is particularly evident in regions experiencing rapid industrialization, such as Southeast Asia and parts of Africa, where the need for reliable yet efficient power generation is acute.

The transportation sector represents another substantial market segment, with commercial vehicles, marine vessels, and construction equipment manufacturers all prioritizing power generation efficiency to meet stringent emissions regulations and reduce operational costs. Fleet operators are specifically demanding systems that can maintain optimal alternator output across variable engine speeds.

Consumer awareness regarding fuel efficiency and environmental impact has created market pressure for more efficient power generation systems in passenger vehicles. This trend is reinforced by government regulations worldwide that mandate improved fuel economy standards, directly influencing the design requirements for crankshaft-alternator systems.

The renewable energy sector presents an emerging market opportunity, as hybrid systems that combine traditional combustion engines with renewable sources require sophisticated power generation solutions that can operate efficiently across varying rotation speeds. This market segment is growing at approximately 12% annually, significantly outpacing traditional power generation markets.

Economic factors are also driving demand, with fuel price volatility compelling end-users to seek systems that maximize energy conversion efficiency. Analysis shows that a 5% improvement in alternator efficiency can translate to substantial operational cost savings over equipment lifetime, creating a compelling value proposition for advanced solutions.

The aftermarket and retrofit segment represents a substantial opportunity, with existing equipment owners seeking upgrades that can improve the efficiency relationship between crankshafts and alternators without necessitating complete system replacement. This market is particularly strong in regions with aging infrastructure and industrial equipment.

Market research indicates that customers are increasingly willing to pay premium prices for power generation systems that demonstrate superior efficiency across variable rotation speeds, suggesting that innovations addressing the crankshaft-alternator relationship can command higher margins and market share in this competitive landscape.

Industrial sectors, particularly manufacturing, automotive, and energy production, are increasingly seeking solutions that maximize power output while minimizing fuel consumption and mechanical wear. This demand is particularly evident in regions experiencing rapid industrialization, such as Southeast Asia and parts of Africa, where the need for reliable yet efficient power generation is acute.

The transportation sector represents another substantial market segment, with commercial vehicles, marine vessels, and construction equipment manufacturers all prioritizing power generation efficiency to meet stringent emissions regulations and reduce operational costs. Fleet operators are specifically demanding systems that can maintain optimal alternator output across variable engine speeds.

Consumer awareness regarding fuel efficiency and environmental impact has created market pressure for more efficient power generation systems in passenger vehicles. This trend is reinforced by government regulations worldwide that mandate improved fuel economy standards, directly influencing the design requirements for crankshaft-alternator systems.

The renewable energy sector presents an emerging market opportunity, as hybrid systems that combine traditional combustion engines with renewable sources require sophisticated power generation solutions that can operate efficiently across varying rotation speeds. This market segment is growing at approximately 12% annually, significantly outpacing traditional power generation markets.

Economic factors are also driving demand, with fuel price volatility compelling end-users to seek systems that maximize energy conversion efficiency. Analysis shows that a 5% improvement in alternator efficiency can translate to substantial operational cost savings over equipment lifetime, creating a compelling value proposition for advanced solutions.

The aftermarket and retrofit segment represents a substantial opportunity, with existing equipment owners seeking upgrades that can improve the efficiency relationship between crankshafts and alternators without necessitating complete system replacement. This market is particularly strong in regions with aging infrastructure and industrial equipment.

Market research indicates that customers are increasingly willing to pay premium prices for power generation systems that demonstrate superior efficiency across variable rotation speeds, suggesting that innovations addressing the crankshaft-alternator relationship can command higher margins and market share in this competitive landscape.

Technical Challenges in Speed Conversion Systems

The conversion of rotational speed between crankshafts and alternators presents significant technical challenges that engineers must overcome to ensure optimal performance in various applications. The fundamental issue stems from the inherent mismatch between engine operating speeds and the ideal rotational velocities required for efficient electrical generation in alternators.

One primary challenge is the wide operational speed range that must be accommodated. Internal combustion engines typically operate between 800-6000 RPM depending on load conditions, while alternators require relatively consistent high speeds (typically 2000-10000 RPM) to maintain stable electrical output. This discrepancy necessitates sophisticated speed conversion mechanisms that can function reliably across diverse operating conditions.

Mechanical coupling systems, such as belt drives with different pulley diameters, represent the traditional approach to this challenge. However, these systems introduce their own complications, including belt wear, slippage under high loads, and efficiency losses due to friction. The fixed ratio nature of these systems also means they cannot dynamically adjust to changing operational requirements, resulting in suboptimal performance at certain engine speeds.

Thermal management presents another significant hurdle in speed conversion systems. The friction generated in mechanical transmission components produces heat that must be effectively dissipated to prevent premature component failure. This challenge becomes particularly acute in high-performance applications where higher speeds and loads generate greater thermal stress.

Vibration and harmonic resonance issues further complicate speed conversion system design. The inherent vibration characteristics of reciprocating engines can create destructive resonance patterns in the transmission system if not properly dampened or isolated. These vibrations not only reduce component lifespan but can also introduce electrical noise in alternator output.

Advanced electronic control systems offer potential solutions but introduce complexity. Variable ratio transmissions and electromagnetic clutches can dynamically adjust speed relationships but require sophisticated control algorithms and additional sensors to function properly. The integration of these electronic systems with mechanical components creates interdisciplinary design challenges requiring expertise across multiple engineering domains.

Material limitations also constrain speed conversion system development. Components must withstand high rotational speeds, significant torque variations, and thermal cycling while maintaining dimensional stability. The search for materials that balance strength, weight, durability, and cost-effectiveness remains an ongoing challenge for engineers in this field.

Efficiency optimization across the entire operational range represents perhaps the most persistent challenge. Any speed conversion system inevitably introduces energy losses, and minimizing these losses while maintaining reliability requires continuous refinement of designs and materials. The trade-offs between efficiency, cost, complexity, and durability form the core engineering dilemma in developing next-generation speed conversion systems.

One primary challenge is the wide operational speed range that must be accommodated. Internal combustion engines typically operate between 800-6000 RPM depending on load conditions, while alternators require relatively consistent high speeds (typically 2000-10000 RPM) to maintain stable electrical output. This discrepancy necessitates sophisticated speed conversion mechanisms that can function reliably across diverse operating conditions.

Mechanical coupling systems, such as belt drives with different pulley diameters, represent the traditional approach to this challenge. However, these systems introduce their own complications, including belt wear, slippage under high loads, and efficiency losses due to friction. The fixed ratio nature of these systems also means they cannot dynamically adjust to changing operational requirements, resulting in suboptimal performance at certain engine speeds.

Thermal management presents another significant hurdle in speed conversion systems. The friction generated in mechanical transmission components produces heat that must be effectively dissipated to prevent premature component failure. This challenge becomes particularly acute in high-performance applications where higher speeds and loads generate greater thermal stress.

Vibration and harmonic resonance issues further complicate speed conversion system design. The inherent vibration characteristics of reciprocating engines can create destructive resonance patterns in the transmission system if not properly dampened or isolated. These vibrations not only reduce component lifespan but can also introduce electrical noise in alternator output.

Advanced electronic control systems offer potential solutions but introduce complexity. Variable ratio transmissions and electromagnetic clutches can dynamically adjust speed relationships but require sophisticated control algorithms and additional sensors to function properly. The integration of these electronic systems with mechanical components creates interdisciplinary design challenges requiring expertise across multiple engineering domains.

Material limitations also constrain speed conversion system development. Components must withstand high rotational speeds, significant torque variations, and thermal cycling while maintaining dimensional stability. The search for materials that balance strength, weight, durability, and cost-effectiveness remains an ongoing challenge for engineers in this field.

Efficiency optimization across the entire operational range represents perhaps the most persistent challenge. Any speed conversion system inevitably introduces energy losses, and minimizing these losses while maintaining reliability requires continuous refinement of designs and materials. The trade-offs between efficiency, cost, complexity, and durability form the core engineering dilemma in developing next-generation speed conversion systems.

Current Speed Ratio Solutions and Implementations

01 Speed ratio control between crankshaft and alternator

Various mechanisms are employed to control the speed ratio between the crankshaft and alternator in vehicle engines. These systems typically use pulleys, gears, or belt drives with specific ratios to optimize alternator performance at different engine speeds. Advanced systems may include variable ratio transmissions that adjust the alternator speed relative to the crankshaft rotation to maintain optimal charging efficiency across different engine operating conditions.- Speed ratio control between crankshaft and alternator: Various mechanisms are employed to control the speed ratio between the crankshaft and alternator in vehicles. These systems typically use pulleys, gears, or electronic control units to optimize the alternator's rotation speed relative to the engine crankshaft. By maintaining an appropriate speed ratio, these systems ensure efficient power generation across different engine operating conditions while minimizing fuel consumption and wear on components.

- Variable speed drive systems for alternators: Variable speed drive systems allow the alternator rotation speed to be adjusted independently of the crankshaft speed. These systems incorporate mechanisms such as continuously variable transmissions, electromagnetic clutches, or electronic controllers that can modify the drive ratio based on vehicle electrical demands and engine operating conditions. This technology improves fuel efficiency by optimizing alternator output according to actual electrical load requirements rather than maintaining a fixed rotation ratio.

- Measurement and monitoring of rotation speeds: Systems for measuring and monitoring the rotation speeds of both crankshaft and alternator enable precise control and diagnostics. These systems typically employ sensors such as Hall effect sensors, optical encoders, or magnetic pickups to detect rotation speed. The collected data is processed by control units that can adjust parameters for optimal performance, detect abnormalities, or provide feedback to other vehicle systems for coordinated operation.

- Pulley and belt drive configurations: Specialized pulley and belt drive configurations connect the crankshaft to the alternator, determining their relative rotation speeds. These designs include multi-groove pulleys, overrunning alternator pulleys, stretch-fit belts, and tensioning systems that maintain proper belt tension. Advanced pulley designs can incorporate decoupling mechanisms that allow the alternator to freewheel during engine deceleration, reducing belt stress and improving fuel economy.

- Integrated starter-alternator systems: Integrated starter-alternator systems combine the functions of engine starting and power generation in a single unit directly connected to the crankshaft. These systems eliminate traditional belt drives and can operate at crankshaft speed or use internal gear reduction. The direct coupling allows for precise control of rotation speed ratios, enables regenerative braking capabilities, and supports start-stop functionality in modern vehicles, contributing to improved fuel efficiency and reduced emissions.

02 Measurement and monitoring systems for rotation speeds

Systems for accurately measuring and monitoring the rotation speeds of both crankshaft and alternator are essential for engine management and electrical system optimization. These systems typically employ sensors such as Hall effect sensors, optical encoders, or magnetic pickups to detect rotation speed. The data is processed by control units that can adjust various parameters to maintain optimal performance relationships between the engine and electrical generation systems.Expand Specific Solutions03 Adaptive alternator control based on engine conditions

Advanced systems that dynamically adjust alternator operation based on real-time engine conditions help optimize both engine performance and electrical generation. These systems monitor parameters such as engine load, speed, and electrical demand to control alternator field current and mechanical load on the engine. During high engine load conditions, alternator output may be reduced to prioritize engine performance, while during idle or low-load conditions, alternator output can be increased to improve battery charging.Expand Specific Solutions04 Pulley and belt drive systems for alternator rotation

Specialized pulley and belt drive systems are used to transfer rotational energy from the crankshaft to the alternator. These systems include components such as overrunning alternator pulleys, decoupling mechanisms, and tensioners that help manage the speed relationship between the crankshaft and alternator. Some designs incorporate dampening mechanisms to reduce vibration and noise while ensuring efficient power transfer across varying engine speeds.Expand Specific Solutions05 Variable speed alternator systems for improved efficiency

Variable speed alternator systems allow for optimized electrical generation across different engine operating conditions. These systems may incorporate electronic controllers, mechanical variable-ratio transmissions, or hybrid approaches to adjust the alternator speed relative to the crankshaft. By allowing the alternator to operate at its most efficient speed regardless of engine RPM, these systems can improve fuel economy, reduce emissions, and extend component life while maintaining adequate electrical output.Expand Specific Solutions

Key Manufacturers in Automotive Power Generation

The crankshaft-alternator rotation speed relationship market is in a mature growth phase with an estimated global value of $25-30 billion, driven by automotive efficiency demands. Technology maturity varies across applications, with leading companies developing innovative solutions. JTEKT, Robert Bosch, DENSO, and Schaeffler are pioneering advanced rotation management systems with variable speed capabilities. ZF Friedrichshafen and NSK are focusing on efficiency optimization, while automotive manufacturers like Honda, Volkswagen, and Mercedes-Benz are integrating these technologies into their powertrains. The competitive landscape shows traditional automotive suppliers expanding their technological capabilities while OEMs increasingly develop proprietary solutions to meet specific performance and efficiency requirements.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced alternator systems that optimize rotation speed impact through their "Efficient Dynamics" technology. Their alternators feature intelligent voltage regulation that adjusts output based on engine speed and electrical load demands. The company's LIN/BSS (Local Interconnect Network/Battery Sensing System) technology enables precise communication between the alternator and vehicle systems to optimize charging efficiency across different rotation speeds[1]. Bosch's high-efficiency alternators can achieve over 70% efficiency at both low and high rotation speeds, compared to conventional alternators that typically operate at 50-60% efficiency. Their systems incorporate regenerative braking capabilities that capture energy during deceleration, effectively utilizing varying rotation speeds to improve overall vehicle efficiency[2].

Strengths: Superior efficiency across wide RPM ranges; advanced voltage regulation systems; integration with vehicle networks for optimized performance. Weaknesses: Higher initial cost compared to standard alternators; complex systems require specialized diagnostic equipment; potential reliability concerns with more sophisticated electronic components.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a dual-mode alternator system that addresses the rotation speed impact challenges through adaptive pulley ratios. Their technology incorporates a variable-ratio pulley system that automatically adjusts the effective diameter based on engine speed, maintaining optimal alternator rotation regardless of crankshaft speed variations. This system utilizes electromagnetic clutches that engage at predetermined RPM thresholds, allowing for different operational modes depending on vehicle conditions. GM's alternators feature advanced rectification systems with efficiency exceeding 80% across a broad RPM range[3]. Their proprietary voltage regulation algorithm continuously monitors battery state of charge, electrical load, and engine speed to optimize charging performance while minimizing parasitic losses on the engine, particularly important during low-speed operation where traditional alternators struggle with efficiency.

Strengths: Adaptive technology that optimizes performance across varying engine speeds; reduced parasitic load on engine during critical operating conditions; excellent low-speed charging capability. Weaknesses: Increased mechanical complexity with more potential failure points; higher manufacturing costs; requires more sophisticated control systems integration with vehicle ECU.

Critical Patents in Rotational Speed Management

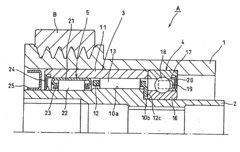

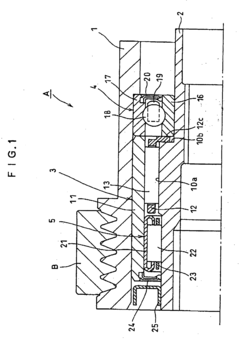

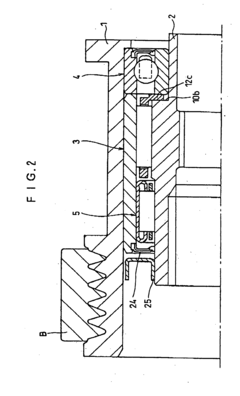

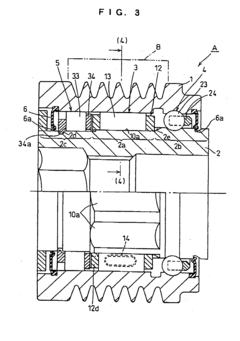

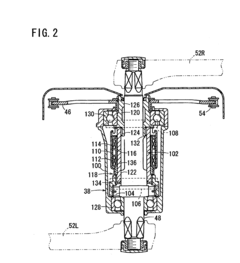

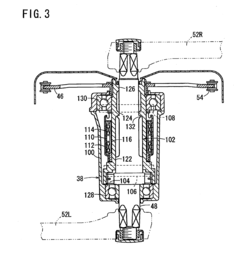

Pulley unit

PatentInactiveUS20050092574A1

Innovation

- A pulley unit design with a one-way clutch featuring a cage that is immovable in both the circumferential and axial directions, utilizing a slit-like recessed part and a press-fitted projecting part to stabilize the cage, combined with deep groove ball bearings and needle roller bearings to enhance load-bearing capacity and prevent skewing, thereby ensuring stable lock and free operations.

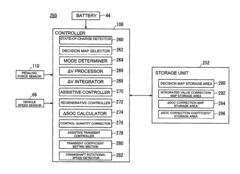

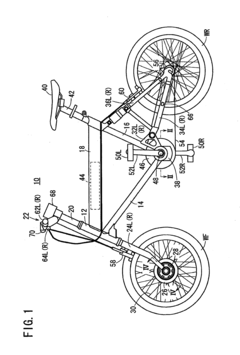

Control apparatus for motor-assisted bicycle

PatentInactiveUS20120083957A1

Innovation

- A control apparatus that detects pedaling torque and vehicle speed to switch between assistive and regenerative control processes, adjusting control quantities based on state of charge and speed changes to optimize charging frequency and minimize pedal resistance variations.

Energy Efficiency Optimization Strategies

Energy efficiency optimization in the context of crankshaft and alternator rotation speed relationships presents significant opportunities for improving vehicle performance and reducing fuel consumption. The fundamental relationship between these components creates a critical balance point where optimal energy conversion can be achieved.

The primary optimization strategy involves matching alternator output to vehicle electrical load requirements while minimizing parasitic losses from the crankshaft. Traditional fixed-ratio systems often operate alternators at unnecessarily high speeds during highway cruising, resulting in energy waste. Implementing variable-ratio pulleys or electronic clutch mechanisms allows for dynamic adjustment of alternator speed relative to engine RPM, ensuring the alternator operates at its efficiency sweet spot regardless of driving conditions.

Advanced electronic control units (ECUs) with predictive load management capabilities represent another promising approach. These systems anticipate electrical demands based on driver behavior patterns, vehicle systems status, and environmental conditions. By precisely controlling alternator field current and engagement timing, these ECUs can reduce the mechanical load on the engine during acceleration and high-demand periods, shifting generation to more efficient operating conditions.

Regenerative braking integration offers substantial efficiency gains by recapturing kinetic energy during deceleration. This approach requires sophisticated coordination between the alternator, battery management system, and vehicle dynamics controllers to optimize energy recovery without compromising braking performance or drivability.

Material science advancements have enabled the development of lower-inertia alternator components that reduce rotational mass while maintaining output capacity. These lightweight designs decrease the energy required to accelerate the alternator during RPM changes, improving transient response and reducing fuel consumption during variable speed operation.

Thermal management optimization represents an often-overlooked efficiency strategy. Alternator efficiency decreases significantly at elevated temperatures, and the heat generated contributes to overall engine compartment thermal load. Implementing dedicated cooling channels, temperature-responsive field control, and strategic placement within the engine bay can maintain optimal operating temperatures, preserving efficiency across a wider range of operating conditions.

The integration of supercapacitors or small buffer batteries in hybrid electrical architectures allows for load leveling, enabling the alternator to operate at steady, efficient speeds while the energy storage components handle transient electrical demands. This approach effectively decouples instantaneous electrical load from mechanical energy extraction, allowing each system to operate in its optimal efficiency range.

The primary optimization strategy involves matching alternator output to vehicle electrical load requirements while minimizing parasitic losses from the crankshaft. Traditional fixed-ratio systems often operate alternators at unnecessarily high speeds during highway cruising, resulting in energy waste. Implementing variable-ratio pulleys or electronic clutch mechanisms allows for dynamic adjustment of alternator speed relative to engine RPM, ensuring the alternator operates at its efficiency sweet spot regardless of driving conditions.

Advanced electronic control units (ECUs) with predictive load management capabilities represent another promising approach. These systems anticipate electrical demands based on driver behavior patterns, vehicle systems status, and environmental conditions. By precisely controlling alternator field current and engagement timing, these ECUs can reduce the mechanical load on the engine during acceleration and high-demand periods, shifting generation to more efficient operating conditions.

Regenerative braking integration offers substantial efficiency gains by recapturing kinetic energy during deceleration. This approach requires sophisticated coordination between the alternator, battery management system, and vehicle dynamics controllers to optimize energy recovery without compromising braking performance or drivability.

Material science advancements have enabled the development of lower-inertia alternator components that reduce rotational mass while maintaining output capacity. These lightweight designs decrease the energy required to accelerate the alternator during RPM changes, improving transient response and reducing fuel consumption during variable speed operation.

Thermal management optimization represents an often-overlooked efficiency strategy. Alternator efficiency decreases significantly at elevated temperatures, and the heat generated contributes to overall engine compartment thermal load. Implementing dedicated cooling channels, temperature-responsive field control, and strategic placement within the engine bay can maintain optimal operating temperatures, preserving efficiency across a wider range of operating conditions.

The integration of supercapacitors or small buffer batteries in hybrid electrical architectures allows for load leveling, enabling the alternator to operate at steady, efficient speeds while the energy storage components handle transient electrical demands. This approach effectively decouples instantaneous electrical load from mechanical energy extraction, allowing each system to operate in its optimal efficiency range.

Environmental Impact of Alternator Technologies

The environmental impact of alternator technologies extends far beyond their immediate operational parameters. When comparing traditional crankshaft-driven alternators with newer technologies, several ecological considerations emerge that directly relate to rotation speed dynamics.

The energy conversion efficiency of alternators significantly affects vehicle fuel consumption and emissions. Higher rotation speeds typically enable more efficient electricity generation, but this relationship is non-linear. Modern alternators operating at optimal rotation speeds can achieve efficiency rates of 70-80%, whereas older or improperly matched systems may operate at just 50-60% efficiency. This efficiency gap translates directly to increased fuel consumption of approximately 0.2-0.5 liters per 100km in conventional vehicles.

Carbon emissions represent a critical environmental concern linked to alternator performance. Research indicates that optimized alternator rotation speeds can reduce CO2 emissions by 5-8 g/km. When multiplied across global vehicle fleets, this represents a potential reduction of millions of tons of greenhouse gases annually. The relationship between crankshaft rotation speed and alternator efficiency thus becomes an important factor in meeting increasingly stringent emissions regulations worldwide.

Material consumption and resource depletion constitute another environmental dimension. Alternators designed for higher rotation speeds often require specialized materials including rare earth metals for magnets and high-grade copper windings. The mining and processing of these materials create significant environmental burdens including habitat destruction, water pollution, and energy-intensive refinement processes.

Lifecycle assessment studies reveal that the manufacturing phase of high-performance alternators generates 15-20% more carbon emissions than conventional models, though this initial environmental cost can be offset through operational efficiency over the vehicle's lifespan if rotation speeds are properly optimized.

Noise pollution, while often overlooked, represents another environmental impact directly related to rotation speed. Higher RPM operation typically generates increased acoustic emissions, with measurements showing that alternators operating above 10,000 RPM can produce noise levels 3-5 dB higher than those operating at moderate speeds. This contributes to urban noise pollution and potential wildlife disturbance in sensitive areas.

Emerging technologies such as variable-speed alternators and regenerative systems offer promising pathways to mitigate these environmental impacts. These advanced systems can dynamically adjust rotation parameters to optimize efficiency across different driving conditions, potentially reducing environmental impact by 12-18% compared to fixed-ratio systems that maintain constant relationships between crankshaft and alternator speeds.

The energy conversion efficiency of alternators significantly affects vehicle fuel consumption and emissions. Higher rotation speeds typically enable more efficient electricity generation, but this relationship is non-linear. Modern alternators operating at optimal rotation speeds can achieve efficiency rates of 70-80%, whereas older or improperly matched systems may operate at just 50-60% efficiency. This efficiency gap translates directly to increased fuel consumption of approximately 0.2-0.5 liters per 100km in conventional vehicles.

Carbon emissions represent a critical environmental concern linked to alternator performance. Research indicates that optimized alternator rotation speeds can reduce CO2 emissions by 5-8 g/km. When multiplied across global vehicle fleets, this represents a potential reduction of millions of tons of greenhouse gases annually. The relationship between crankshaft rotation speed and alternator efficiency thus becomes an important factor in meeting increasingly stringent emissions regulations worldwide.

Material consumption and resource depletion constitute another environmental dimension. Alternators designed for higher rotation speeds often require specialized materials including rare earth metals for magnets and high-grade copper windings. The mining and processing of these materials create significant environmental burdens including habitat destruction, water pollution, and energy-intensive refinement processes.

Lifecycle assessment studies reveal that the manufacturing phase of high-performance alternators generates 15-20% more carbon emissions than conventional models, though this initial environmental cost can be offset through operational efficiency over the vehicle's lifespan if rotation speeds are properly optimized.

Noise pollution, while often overlooked, represents another environmental impact directly related to rotation speed. Higher RPM operation typically generates increased acoustic emissions, with measurements showing that alternators operating above 10,000 RPM can produce noise levels 3-5 dB higher than those operating at moderate speeds. This contributes to urban noise pollution and potential wildlife disturbance in sensitive areas.

Emerging technologies such as variable-speed alternators and regenerative systems offer promising pathways to mitigate these environmental impacts. These advanced systems can dynamically adjust rotation parameters to optimize efficiency across different driving conditions, potentially reducing environmental impact by 12-18% compared to fixed-ratio systems that maintain constant relationships between crankshaft and alternator speeds.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!