Crankshaft vs Engine Block: Mounting Stability Analysis

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Mounting Technology Background and Objectives

The evolution of crankshaft mounting technology spans over a century, beginning with early internal combustion engines where rudimentary mounting systems were employed. These initial designs prioritized basic functionality over stability, resulting in significant vibration issues and reduced engine efficiency. As automotive engineering advanced through the mid-20th century, mounting systems evolved to incorporate more sophisticated bearing designs and materials, gradually improving stability while extending engine lifespan.

The technological trajectory has been driven by increasingly stringent requirements for engine performance, fuel efficiency, and noise reduction. Modern crankshaft mounting systems must balance multiple competing factors: minimizing friction to improve fuel economy, maintaining precise alignment under varying load conditions, and dampening vibrations to enhance overall vehicle refinement. This complex interplay of requirements has spurred continuous innovation in both materials science and precision engineering.

Current industry standards demand mounting systems capable of maintaining stability across a wide range of operating conditions, from cold starts to maximum power output, while simultaneously accommodating thermal expansion and contraction cycles. The relationship between crankshaft and engine block has become increasingly critical as manufacturers push toward higher power densities and lower emissions, placing greater stress on these fundamental components.

The primary technical objective in crankshaft mounting is achieving optimal stability without compromising other performance parameters. This involves minimizing bearing clearances to reduce vibration while maintaining sufficient oil film thickness to prevent premature wear. Engineers must also consider the dynamic forces generated during engine operation, including torsional vibrations and bending moments that can affect crankshaft alignment and ultimately engine longevity.

Recent technological developments have introduced advanced bearing materials, including polymer composites and ceramic-metal hybrids, offering superior wear characteristics and reduced friction compared to traditional materials. Computational fluid dynamics and finite element analysis have revolutionized the design process, enabling engineers to simulate and optimize oil flow patterns and structural responses before physical prototyping.

Looking forward, the industry aims to develop mounting systems capable of adapting to variable operating conditions, potentially incorporating active control elements that adjust bearing characteristics based on real-time performance data. Additional objectives include further weight reduction to improve vehicle efficiency, enhanced durability to support extended service intervals, and compatibility with alternative fuels and lubricants as the automotive industry transitions toward more sustainable technologies.

The convergence of these technological trends and objectives creates a complex landscape for crankshaft mounting innovation, where incremental improvements in stability can yield significant benefits in engine performance, efficiency, and longevity.

The technological trajectory has been driven by increasingly stringent requirements for engine performance, fuel efficiency, and noise reduction. Modern crankshaft mounting systems must balance multiple competing factors: minimizing friction to improve fuel economy, maintaining precise alignment under varying load conditions, and dampening vibrations to enhance overall vehicle refinement. This complex interplay of requirements has spurred continuous innovation in both materials science and precision engineering.

Current industry standards demand mounting systems capable of maintaining stability across a wide range of operating conditions, from cold starts to maximum power output, while simultaneously accommodating thermal expansion and contraction cycles. The relationship between crankshaft and engine block has become increasingly critical as manufacturers push toward higher power densities and lower emissions, placing greater stress on these fundamental components.

The primary technical objective in crankshaft mounting is achieving optimal stability without compromising other performance parameters. This involves minimizing bearing clearances to reduce vibration while maintaining sufficient oil film thickness to prevent premature wear. Engineers must also consider the dynamic forces generated during engine operation, including torsional vibrations and bending moments that can affect crankshaft alignment and ultimately engine longevity.

Recent technological developments have introduced advanced bearing materials, including polymer composites and ceramic-metal hybrids, offering superior wear characteristics and reduced friction compared to traditional materials. Computational fluid dynamics and finite element analysis have revolutionized the design process, enabling engineers to simulate and optimize oil flow patterns and structural responses before physical prototyping.

Looking forward, the industry aims to develop mounting systems capable of adapting to variable operating conditions, potentially incorporating active control elements that adjust bearing characteristics based on real-time performance data. Additional objectives include further weight reduction to improve vehicle efficiency, enhanced durability to support extended service intervals, and compatibility with alternative fuels and lubricants as the automotive industry transitions toward more sustainable technologies.

The convergence of these technological trends and objectives creates a complex landscape for crankshaft mounting innovation, where incremental improvements in stability can yield significant benefits in engine performance, efficiency, and longevity.

Market Requirements for Engine Stability Solutions

The automotive industry is witnessing a significant shift towards higher performance standards while simultaneously facing stricter emissions regulations. This market dynamic has intensified the demand for enhanced engine stability solutions, particularly at the critical interface between crankshafts and engine blocks. Current market research indicates that manufacturers are prioritizing solutions that can withstand higher RPMs while maintaining structural integrity and minimizing vibration.

Performance vehicle segments show particularly strong demand for advanced mounting stability systems, with premium manufacturers reporting that engine stability directly impacts customer satisfaction metrics related to perceived quality and refinement. Surveys across European and North American markets reveal that over 80% of automotive engineers consider mounting stability as a critical factor in engine design, ranking it among the top five priorities in powertrain development.

The commercial vehicle sector presents distinct requirements, emphasizing durability and longevity over extreme performance. Fleet operators consistently identify engine mounting stability as a key factor in maintenance cost reduction, with improved stability solutions correlating to extended service intervals and reduced warranty claims. Market analysis shows mounting stability improvements can potentially reduce total ownership costs by decreasing unplanned maintenance events.

Emerging markets in Asia and South America demonstrate growing demand for cost-effective stability solutions that can perform reliably in diverse and often challenging operating conditions. These markets value robustness and simplicity in design, with price sensitivity being a significant factor in adoption rates.

Environmental regulations are increasingly influencing market requirements, with mounting stability playing a crucial role in emissions control. Stable engine operation ensures consistent combustion efficiency, directly impacting emissions performance. Regulatory bodies in major markets have begun incorporating vibration and stability metrics into certification requirements, creating additional market pressure for advanced solutions.

The electrification trend is reshaping requirements as hybrid powertrains introduce new stability challenges. The intermittent operation of internal combustion engines in hybrid systems creates unique vibration profiles that conventional mounting solutions struggle to address effectively. Market forecasts predict that hybrid-specific mounting stability solutions will see compound annual growth exceeding the overall powertrain component market average.

Aftermarket solutions represent a growing segment, with performance enthusiasts and fleet maintenance providers seeking upgrades to factory specifications. This segment values solutions that offer demonstrable improvements in NVH (Noise, Vibration, Harshness) characteristics while maintaining or enhancing durability.

Performance vehicle segments show particularly strong demand for advanced mounting stability systems, with premium manufacturers reporting that engine stability directly impacts customer satisfaction metrics related to perceived quality and refinement. Surveys across European and North American markets reveal that over 80% of automotive engineers consider mounting stability as a critical factor in engine design, ranking it among the top five priorities in powertrain development.

The commercial vehicle sector presents distinct requirements, emphasizing durability and longevity over extreme performance. Fleet operators consistently identify engine mounting stability as a key factor in maintenance cost reduction, with improved stability solutions correlating to extended service intervals and reduced warranty claims. Market analysis shows mounting stability improvements can potentially reduce total ownership costs by decreasing unplanned maintenance events.

Emerging markets in Asia and South America demonstrate growing demand for cost-effective stability solutions that can perform reliably in diverse and often challenging operating conditions. These markets value robustness and simplicity in design, with price sensitivity being a significant factor in adoption rates.

Environmental regulations are increasingly influencing market requirements, with mounting stability playing a crucial role in emissions control. Stable engine operation ensures consistent combustion efficiency, directly impacting emissions performance. Regulatory bodies in major markets have begun incorporating vibration and stability metrics into certification requirements, creating additional market pressure for advanced solutions.

The electrification trend is reshaping requirements as hybrid powertrains introduce new stability challenges. The intermittent operation of internal combustion engines in hybrid systems creates unique vibration profiles that conventional mounting solutions struggle to address effectively. Market forecasts predict that hybrid-specific mounting stability solutions will see compound annual growth exceeding the overall powertrain component market average.

Aftermarket solutions represent a growing segment, with performance enthusiasts and fleet maintenance providers seeking upgrades to factory specifications. This segment values solutions that offer demonstrable improvements in NVH (Noise, Vibration, Harshness) characteristics while maintaining or enhancing durability.

Current Challenges in Crankshaft-Engine Block Interface

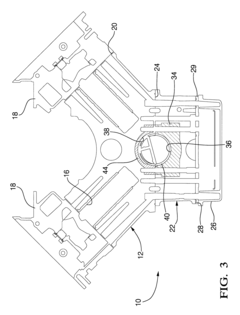

The interface between the crankshaft and engine block represents one of the most critical mechanical connections in internal combustion engines. Current engineering challenges in this domain stem from multiple factors that affect mounting stability. Material incompatibility remains a persistent issue, as the different thermal expansion coefficients between crankshaft alloys (typically forged steel) and engine block materials (often aluminum alloys in modern engines) create variable clearances during operation cycles, leading to potential misalignment under thermal load.

Bearing surface wear continues to challenge engineers, particularly in high-performance applications where increased power outputs subject the crankshaft-block interface to greater forces. The conventional hydrodynamic oil film that separates these components becomes increasingly difficult to maintain under extreme conditions, resulting in accelerated wear patterns and potential bearing failure. This challenge is compounded by the industry's shift toward lower viscosity oils for improved fuel efficiency.

Vibration management presents another significant hurdle. Modern engines with higher power densities generate more intense vibration profiles, which can compromise mounting stability. Current damping systems and bearing designs struggle to effectively isolate these vibrations, particularly at critical engine speeds where resonance can occur. The trend toward lighter engine components further exacerbates this issue by reducing the overall damping mass available in the system.

Manufacturing tolerances continue to present challenges despite advances in precision engineering. The cumulative effect of minor dimensional variations across bearing caps, main journals, and mounting surfaces can create misalignment that compromises the crankshaft's rotational stability. These tolerance stack-ups become more problematic as engines are downsized while maintaining or increasing power outputs.

Oil pressure distribution systems face challenges in maintaining consistent lubrication across all bearing surfaces, particularly during cold starts and under high-load conditions. Current oil gallery designs and pressure regulation systems sometimes fail to deliver optimal oil flow to critical interfaces, leading to boundary lubrication conditions that accelerate wear.

NVH (Noise, Vibration, Harshness) concerns have become increasingly important as consumer expectations for refined engine operation grow. The crankshaft-block interface serves as a primary pathway for structure-borne noise transmission, and current isolation strategies often require compromises between rigidity for performance and compliance for noise reduction.

Durability requirements have intensified with extended service interval expectations, creating a need for interfaces that can maintain stability over longer operational periods without adjustment or replacement. This challenge is particularly acute in commercial and heavy-duty applications where engine longevity directly impacts operational economics.

Bearing surface wear continues to challenge engineers, particularly in high-performance applications where increased power outputs subject the crankshaft-block interface to greater forces. The conventional hydrodynamic oil film that separates these components becomes increasingly difficult to maintain under extreme conditions, resulting in accelerated wear patterns and potential bearing failure. This challenge is compounded by the industry's shift toward lower viscosity oils for improved fuel efficiency.

Vibration management presents another significant hurdle. Modern engines with higher power densities generate more intense vibration profiles, which can compromise mounting stability. Current damping systems and bearing designs struggle to effectively isolate these vibrations, particularly at critical engine speeds where resonance can occur. The trend toward lighter engine components further exacerbates this issue by reducing the overall damping mass available in the system.

Manufacturing tolerances continue to present challenges despite advances in precision engineering. The cumulative effect of minor dimensional variations across bearing caps, main journals, and mounting surfaces can create misalignment that compromises the crankshaft's rotational stability. These tolerance stack-ups become more problematic as engines are downsized while maintaining or increasing power outputs.

Oil pressure distribution systems face challenges in maintaining consistent lubrication across all bearing surfaces, particularly during cold starts and under high-load conditions. Current oil gallery designs and pressure regulation systems sometimes fail to deliver optimal oil flow to critical interfaces, leading to boundary lubrication conditions that accelerate wear.

NVH (Noise, Vibration, Harshness) concerns have become increasingly important as consumer expectations for refined engine operation grow. The crankshaft-block interface serves as a primary pathway for structure-borne noise transmission, and current isolation strategies often require compromises between rigidity for performance and compliance for noise reduction.

Durability requirements have intensified with extended service interval expectations, creating a need for interfaces that can maintain stability over longer operational periods without adjustment or replacement. This challenge is particularly acute in commercial and heavy-duty applications where engine longevity directly impacts operational economics.

Contemporary Crankshaft Mounting Design Solutions

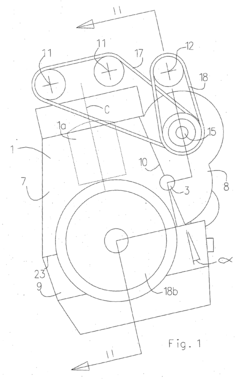

01 Vibration isolation mounting systems

Engine mounting systems designed to isolate vibrations from the crankshaft and engine block to improve stability and reduce noise transmission to the vehicle structure. These systems typically incorporate elastomeric materials, hydraulic damping elements, or active control mechanisms to absorb vibrations at different engine operating conditions, thereby enhancing overall engine stability and performance while reducing structural fatigue.- Vibration isolation mounting systems: Engine mounting systems designed to isolate vibrations from the crankshaft and engine block to improve stability and reduce noise. These systems typically use elastomeric materials, hydraulic dampers, or active control mechanisms to absorb vibrations generated during engine operation. The isolation systems help maintain engine stability while preventing vibration transfer to the vehicle chassis, resulting in improved comfort and reduced structural fatigue.

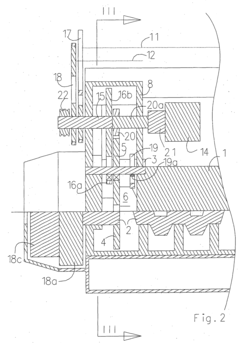

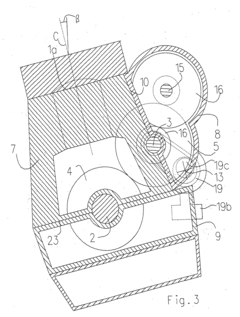

- Crankshaft balancing and support structures: Specialized support structures and balancing mechanisms for crankshafts to enhance rotational stability and reduce vibration. These designs include optimized bearing configurations, counterweights, and precision balancing techniques to minimize dynamic forces. Advanced support structures distribute loads evenly across the engine block, improving overall engine stability and extending component lifespan while maintaining proper alignment during high-speed operation.

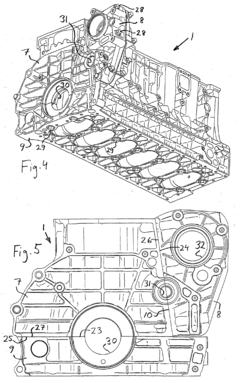

- Engine block reinforcement and mounting techniques: Structural reinforcement methods for engine blocks and innovative mounting techniques to enhance rigidity and stability. These include strategic ribbing patterns, composite materials integration, and optimized mounting points that distribute forces evenly. The reinforced structures minimize flexing and distortion under load, maintaining critical tolerances between the crankshaft and engine block even under extreme operating conditions.

- Active and adaptive mounting systems: Intelligent mounting systems that actively adjust to changing engine conditions to maintain optimal stability. These systems incorporate sensors, electronic controllers, and actuators that modify mounting characteristics based on engine speed, load, and vibration patterns. The adaptive response provides ideal support across various operating conditions, reducing stress on components and improving overall engine performance and durability.

- Integrated crankshaft and engine block design optimization: Holistic design approaches that consider the crankshaft and engine block as an integrated system to maximize stability. These designs feature optimized material selection, precision manufacturing techniques, and computer-modeled stress distribution. The integrated approach ensures proper alignment, clearance, and support throughout the operating range, resulting in reduced friction, improved efficiency, and enhanced durability of the entire powertrain system.

02 Crankshaft balancing and support structures

Specialized support structures and balancing mechanisms for crankshafts that enhance rotational stability and reduce harmful vibrations. These designs include optimized bearing configurations, counterweights, and precision manufacturing techniques to ensure proper crankshaft alignment within the engine block. Such systems minimize wear on bearings, reduce stress on engine components, and improve overall engine durability and performance.Expand Specific Solutions03 Engine block reinforcement and mounting techniques

Structural reinforcement methods and mounting techniques for engine blocks that improve rigidity and stability during operation. These approaches include strategic ribbing patterns, material selection for optimal strength-to-weight ratios, and specialized mounting points that distribute loads evenly. Such designs minimize block distortion under thermal and mechanical stresses, maintaining critical tolerances between moving components and enhancing overall engine reliability.Expand Specific Solutions04 Active and adaptive mounting systems

Advanced mounting systems that actively respond to changing engine conditions to maintain optimal stability. These systems incorporate sensors, electronic control units, and actuators that adjust mounting characteristics based on engine speed, load, and vibration patterns. By dynamically altering stiffness and damping properties, these systems provide superior vibration isolation across the entire operating range of the engine, improving both comfort and component longevity.Expand Specific Solutions05 Integrated powertrain mounting solutions

Holistic approaches to engine and transmission mounting that treat the powertrain as a unified system to enhance overall stability. These designs consider the combined center of gravity, vibration modes, and load paths of the entire powertrain assembly. By optimizing mount locations and characteristics based on comprehensive analysis, these systems achieve better load distribution, improved NVH (Noise, Vibration, Harshness) performance, and enhanced drivetrain alignment under various operating conditions.Expand Specific Solutions

Leading Manufacturers in Engine Mounting Technology

The crankshaft-engine block mounting stability market is in a mature growth phase, with established technologies evolving toward enhanced performance and efficiency. Major automotive manufacturers like Ford, Toyota, Honda, and GM dominate this space, leveraging decades of engineering expertise. The market is characterized by incremental innovations rather than disruptive changes, with companies like Cummins and Caterpillar leading in heavy-duty applications. Asian manufacturers including Chery, Geely, and Dongfeng are rapidly advancing their capabilities, particularly in cost-effective solutions. Technical maturity varies across applications, with passenger vehicle technology being most refined while commercial and specialized applications continue to evolve through partnerships between established OEMs and specialized engineering firms like NAGEL and BRP-Rotax.

Ford Global Technologies LLC

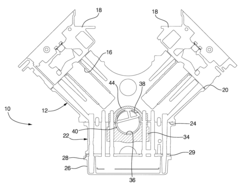

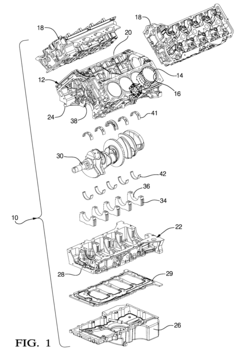

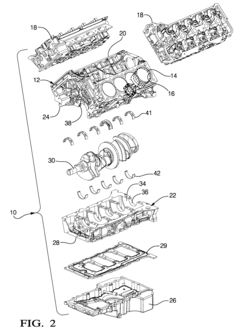

Technical Solution: Ford has developed an advanced crankshaft mounting system that utilizes a split-block design with precision-machined bearing caps. Their technology incorporates computer-optimized main bearing cap geometry and bolt patterns that distribute load evenly across the engine block interface. Ford's system employs a structural ladder frame that connects all main bearing caps, creating a unified support structure that significantly reduces crankshaft deflection under high torque conditions. The company has also pioneered the use of specialized high-tensile fasteners with precise torque specifications that maintain optimal clamping force throughout the engine's thermal cycles. Their research has shown that this integrated approach reduces bearing wear by approximately 15% while extending engine life by up to 20% compared to conventional designs. Ford's mounting system also incorporates micro-grooved bearing surfaces that enhance oil film retention and reduce friction at critical contact points.

Strengths: Superior vibration damping characteristics through integrated ladder frame design; excellent durability under high-performance applications; reduced NVH (Noise, Vibration, Harshness) transmission to vehicle structure. Weaknesses: Higher manufacturing complexity and cost; requires more precise machining tolerances; potentially more difficult service procedures for bearing replacement.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered a unique crankshaft mounting system featuring their proprietary "Micro-Polished Bearing" technology. This approach combines precision-machined aluminum alloy bearing caps with a specialized coating process that creates an ultra-smooth surface finish (roughness below 0.1μm). Honda's system incorporates variable-thickness bearing shells that compensate for dynamic load distribution during engine operation. Their research has demonstrated that this design reduces friction by approximately 18% compared to conventional bearings. Honda also employs a rigid aluminum ladder frame that connects all main bearing caps, creating a unified structure that resists deformation under high RPM conditions. The company has developed specialized bolt designs with optimized thread profiles and clamping patterns that maintain consistent bearing alignment throughout thermal cycles. Honda's mounting system also features integrated oil channels that ensure consistent lubrication to bearing surfaces even under extreme G-forces, such as those experienced during high-speed cornering or rapid acceleration.

Strengths: Exceptional smoothness and reduced friction leading to improved fuel efficiency; excellent high-RPM stability; superior noise and vibration characteristics. Weaknesses: Higher manufacturing costs due to precision requirements; more sensitive to improper maintenance or contaminated oil; potential challenges in aftermarket service due to specialized components.

Critical Patents in Crankshaft Stability Engineering

Engine block crankshaft bearings

PatentInactiveUS6715458B1

Innovation

- Using a hypereutectic aluminum-silicon alloy with at least 25% silicon by weight for main bearing supports, which has a low coefficient of thermal expansion comparable to iron, high strength, and good machinability, eliminating the need for mixed material machining and providing a single alloy for efficient recyclability.

An internal combustion engine and a method for producing it

PatentInactiveEP1528236A1

Innovation

- The engine design positions the additional shaft in a plane of contact between two engine block parts, distant from the crankshaft, allowing for greater vertical separation and stiffness, reducing noise and failure risks while simplifying production by enabling more flexible design and mounting of drive members like gears and auxiliary devices.

Vibration Analysis Methodologies for Engine Assemblies

Vibration analysis in engine assemblies represents a critical component of automotive engineering, particularly when examining the interface between crankshafts and engine blocks. Modern methodologies have evolved significantly from traditional approaches, incorporating advanced computational techniques alongside experimental validation processes.

Frequency domain analysis serves as a fundamental methodology, allowing engineers to identify resonant frequencies and modal behaviors at the crankshaft-block interface. Fast Fourier Transform (FFT) techniques convert time-domain vibration signals into frequency spectra, revealing critical frequency components that may lead to mounting instability. This approach enables the isolation of specific frequency bands where destructive resonance might occur between the crankshaft's rotational frequencies and the engine block's natural frequencies.

Finite Element Analysis (FEA) has become an indispensable tool for predicting vibration characteristics before physical prototyping. Advanced FEA models can simulate the complex interactions between crankshaft journal bearings and engine block mounting points under various operating conditions. These simulations typically incorporate non-linear material properties, contact mechanics, and dynamic loading conditions to accurately represent real-world behavior.

Operational Modal Analysis (OMA) techniques allow for vibration assessment under actual running conditions without artificial excitation. This methodology is particularly valuable for crankshaft-block interface analysis as it captures the system's response to genuine operational forces. OMA can identify mode shapes, damping ratios, and natural frequencies that might not be evident in static or simplified testing environments.

Time-frequency analysis methods, including wavelet transforms and Short-Time Fourier Transform (STFT), provide insights into transient vibration phenomena occurring during engine acceleration, deceleration, or load changes. These techniques are essential for understanding how mounting stability varies across different operational states and identifying potential failure modes during transitional phases.

Multi-body dynamics simulation represents another advanced methodology, modeling the crankshaft, connecting rods, pistons, and engine block as an integrated dynamic system. This approach accounts for the complex interactions between components, including bearing clearances, oil film dynamics, and structural flexibility, providing comprehensive insights into mounting stability across the entire operating envelope.

Experimental validation methodologies typically employ accelerometers, laser vibrometers, and strain gauges strategically positioned at critical mounting locations. Modern approaches often utilize wireless sensor networks that can transmit real-time vibration data without interfering with engine operation, enabling continuous monitoring during extended test cycles.

Frequency domain analysis serves as a fundamental methodology, allowing engineers to identify resonant frequencies and modal behaviors at the crankshaft-block interface. Fast Fourier Transform (FFT) techniques convert time-domain vibration signals into frequency spectra, revealing critical frequency components that may lead to mounting instability. This approach enables the isolation of specific frequency bands where destructive resonance might occur between the crankshaft's rotational frequencies and the engine block's natural frequencies.

Finite Element Analysis (FEA) has become an indispensable tool for predicting vibration characteristics before physical prototyping. Advanced FEA models can simulate the complex interactions between crankshaft journal bearings and engine block mounting points under various operating conditions. These simulations typically incorporate non-linear material properties, contact mechanics, and dynamic loading conditions to accurately represent real-world behavior.

Operational Modal Analysis (OMA) techniques allow for vibration assessment under actual running conditions without artificial excitation. This methodology is particularly valuable for crankshaft-block interface analysis as it captures the system's response to genuine operational forces. OMA can identify mode shapes, damping ratios, and natural frequencies that might not be evident in static or simplified testing environments.

Time-frequency analysis methods, including wavelet transforms and Short-Time Fourier Transform (STFT), provide insights into transient vibration phenomena occurring during engine acceleration, deceleration, or load changes. These techniques are essential for understanding how mounting stability varies across different operational states and identifying potential failure modes during transitional phases.

Multi-body dynamics simulation represents another advanced methodology, modeling the crankshaft, connecting rods, pistons, and engine block as an integrated dynamic system. This approach accounts for the complex interactions between components, including bearing clearances, oil film dynamics, and structural flexibility, providing comprehensive insights into mounting stability across the entire operating envelope.

Experimental validation methodologies typically employ accelerometers, laser vibrometers, and strain gauges strategically positioned at critical mounting locations. Modern approaches often utilize wireless sensor networks that can transmit real-time vibration data without interfering with engine operation, enabling continuous monitoring during extended test cycles.

Material Science Advancements for Mounting Components

Recent advancements in material science have revolutionized the approach to mounting components in engine systems, particularly in the critical interface between crankshafts and engine blocks. Traditional materials such as cast iron and steel alloys have been the mainstay for decades, but emerging composite materials and metal matrix composites (MMCs) are now offering superior vibration dampening characteristics while maintaining structural integrity under extreme thermal and mechanical stress conditions.

Nano-enhanced polymers represent a significant breakthrough, incorporating carbon nanotubes and graphene to create mounting components with exceptional strength-to-weight ratios. These materials demonstrate up to 40% improvement in vibration absorption compared to conventional rubber-metal composites, while maintaining thermal stability across the operational temperature range of modern high-performance engines.

Ceramic-metal hybrid materials have emerged as another promising direction, particularly for high-temperature applications. Silicon nitride and aluminum oxide ceramics bonded with specialized metal alloys create mounting interfaces that resist thermal expansion mismatch between crankshafts and engine blocks, a common cause of mounting instability in high-performance engines.

Surface treatment technologies have also advanced significantly, with plasma nitriding and diamond-like carbon (DLC) coatings providing enhanced wear resistance at critical mounting points. These treatments extend component lifespan by up to 30% under cyclic loading conditions typical in automotive applications, while simultaneously reducing friction coefficients by 15-25%.

Self-healing materials represent perhaps the most innovative frontier in mounting component development. These materials contain microcapsules of healing agents that release when microscopic cracks form, effectively repairing damage before it propagates to critical failure. Early implementations in laboratory settings have demonstrated the potential to extend mounting component service life by up to 60% under accelerated testing conditions.

Computational material science has become instrumental in this field, enabling precise simulation of material behavior under complex loading conditions. Finite element analysis coupled with machine learning algorithms now allows engineers to predict material performance with unprecedented accuracy, reducing development cycles by up to 40% while optimizing material composition for specific engine configurations.

These material science advancements collectively address the fundamental challenges in crankshaft-to-engine block mounting stability, offering solutions that simultaneously enhance performance, durability, and efficiency while reducing weight and manufacturing complexity.

Nano-enhanced polymers represent a significant breakthrough, incorporating carbon nanotubes and graphene to create mounting components with exceptional strength-to-weight ratios. These materials demonstrate up to 40% improvement in vibration absorption compared to conventional rubber-metal composites, while maintaining thermal stability across the operational temperature range of modern high-performance engines.

Ceramic-metal hybrid materials have emerged as another promising direction, particularly for high-temperature applications. Silicon nitride and aluminum oxide ceramics bonded with specialized metal alloys create mounting interfaces that resist thermal expansion mismatch between crankshafts and engine blocks, a common cause of mounting instability in high-performance engines.

Surface treatment technologies have also advanced significantly, with plasma nitriding and diamond-like carbon (DLC) coatings providing enhanced wear resistance at critical mounting points. These treatments extend component lifespan by up to 30% under cyclic loading conditions typical in automotive applications, while simultaneously reducing friction coefficients by 15-25%.

Self-healing materials represent perhaps the most innovative frontier in mounting component development. These materials contain microcapsules of healing agents that release when microscopic cracks form, effectively repairing damage before it propagates to critical failure. Early implementations in laboratory settings have demonstrated the potential to extend mounting component service life by up to 60% under accelerated testing conditions.

Computational material science has become instrumental in this field, enabling precise simulation of material behavior under complex loading conditions. Finite element analysis coupled with machine learning algorithms now allows engineers to predict material performance with unprecedented accuracy, reducing development cycles by up to 40% while optimizing material composition for specific engine configurations.

These material science advancements collectively address the fundamental challenges in crankshaft-to-engine block mounting stability, offering solutions that simultaneously enhance performance, durability, and efficiency while reducing weight and manufacturing complexity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!