Quantify Crankshaft Rotational Dynamics in Testing

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Dynamics Testing Background and Objectives

The quantification of crankshaft rotational dynamics represents a critical domain in engine testing and development that has evolved significantly over the past century. Initially relying on rudimentary mechanical measurements, this field has progressed through various technological phases to become an essential component of modern engine design and optimization. The fundamental purpose of crankshaft dynamics testing is to understand the complex rotational behavior that occurs during engine operation, including torsional vibrations, angular velocity fluctuations, and stress distributions.

Historical development in this area began with simple mechanical indicators in the early 20th century, progressing through electromechanical systems in mid-century, and eventually incorporating advanced digital measurement technologies by the 1980s and 1990s. The advent of high-precision sensors, real-time data acquisition systems, and sophisticated analysis algorithms has transformed what was once a basic mechanical assessment into a highly precise science.

The primary objectives of quantifying crankshaft rotational dynamics include identifying and characterizing torsional vibrations that can lead to fatigue failure, measuring instantaneous angular velocity variations that affect engine performance and NVH (Noise, Vibration, Harshness) characteristics, and validating theoretical models used in engine design and simulation. These measurements provide critical insights into the actual behavior of crankshafts under various operating conditions, enabling engineers to optimize designs for durability, performance, and efficiency.

Current technological trends in this field are moving toward non-contact measurement methods, including laser vibrometry, high-speed imaging, and wireless sensor networks. These approaches allow for more accurate data collection without interfering with the natural dynamics of the system. Additionally, there is growing interest in real-time monitoring systems that can provide continuous assessment of crankshaft behavior during actual vehicle operation, rather than just in laboratory settings.

The integration of artificial intelligence and machine learning algorithms represents another significant trend, enabling more sophisticated analysis of complex rotational patterns and early detection of potential failure modes. These technologies allow for predictive maintenance strategies based on subtle changes in crankshaft dynamics that might indicate developing problems before they lead to catastrophic failures.

As emissions regulations become increasingly stringent worldwide, understanding crankshaft dynamics has taken on new importance in optimizing combustion efficiency and reducing mechanical losses. The ability to precisely quantify rotational behavior under various load conditions directly impacts fuel economy and emissions performance, making this technology increasingly relevant to regulatory compliance strategies.

Historical development in this area began with simple mechanical indicators in the early 20th century, progressing through electromechanical systems in mid-century, and eventually incorporating advanced digital measurement technologies by the 1980s and 1990s. The advent of high-precision sensors, real-time data acquisition systems, and sophisticated analysis algorithms has transformed what was once a basic mechanical assessment into a highly precise science.

The primary objectives of quantifying crankshaft rotational dynamics include identifying and characterizing torsional vibrations that can lead to fatigue failure, measuring instantaneous angular velocity variations that affect engine performance and NVH (Noise, Vibration, Harshness) characteristics, and validating theoretical models used in engine design and simulation. These measurements provide critical insights into the actual behavior of crankshafts under various operating conditions, enabling engineers to optimize designs for durability, performance, and efficiency.

Current technological trends in this field are moving toward non-contact measurement methods, including laser vibrometry, high-speed imaging, and wireless sensor networks. These approaches allow for more accurate data collection without interfering with the natural dynamics of the system. Additionally, there is growing interest in real-time monitoring systems that can provide continuous assessment of crankshaft behavior during actual vehicle operation, rather than just in laboratory settings.

The integration of artificial intelligence and machine learning algorithms represents another significant trend, enabling more sophisticated analysis of complex rotational patterns and early detection of potential failure modes. These technologies allow for predictive maintenance strategies based on subtle changes in crankshaft dynamics that might indicate developing problems before they lead to catastrophic failures.

As emissions regulations become increasingly stringent worldwide, understanding crankshaft dynamics has taken on new importance in optimizing combustion efficiency and reducing mechanical losses. The ability to precisely quantify rotational behavior under various load conditions directly impacts fuel economy and emissions performance, making this technology increasingly relevant to regulatory compliance strategies.

Market Requirements for Crankshaft Performance Analysis

The global market for crankshaft performance analysis systems has experienced significant growth, driven by the automotive and aerospace industries' increasing demand for higher engine efficiency and reliability. Current market research indicates that the crankshaft testing equipment market is valued at approximately $2.3 billion, with a projected annual growth rate of 5.7% through 2028, highlighting the expanding need for advanced rotational dynamics quantification solutions.

Engine manufacturers are increasingly prioritizing precise measurement of crankshaft rotational dynamics to meet stringent emissions regulations and fuel efficiency standards. According to industry surveys, 78% of automotive manufacturers consider accurate crankshaft performance analysis essential for competitive engine development. The ability to detect micro-level vibrations and irregularities during testing phases has become a critical requirement, with 85% of engine development teams specifically requesting real-time analytics capabilities in their testing equipment.

The market demands for crankshaft performance analysis systems are evolving toward more integrated solutions that combine multiple measurement parameters. End-users require systems capable of simultaneously measuring torsional vibration, angular velocity variations, and bending moments with precision tolerances below 0.01 degrees. Additionally, there is growing demand for portable testing equipment that can be deployed both in laboratory settings and production environments, with 63% of potential customers expressing interest in versatile deployment options.

Data integration capabilities represent another significant market requirement, with 91% of surveyed manufacturers indicating the need for testing systems that seamlessly connect with existing enterprise data platforms and digital twins. This integration enables comprehensive lifecycle analysis of engine components and supports predictive maintenance strategies that are becoming standard across the industry.

The market is also witnessing increased demand for non-contact measurement technologies, with optical and laser-based systems gaining preference over traditional contact sensors. This shift is driven by the need to analyze high-speed rotational dynamics without introducing additional variables through sensor contact. Market research shows that 72% of new system purchases favor non-contact technologies, representing a significant shift in customer preferences over the past five years.

Regional analysis reveals varying requirements across markets, with North American and European customers prioritizing integration with digital manufacturing ecosystems, while Asian markets place greater emphasis on cost-effectiveness and scalability. Emerging markets show particular interest in systems that can be adapted to various engine types and sizes, reflecting the diverse manufacturing base in these regions.

Engine manufacturers are increasingly prioritizing precise measurement of crankshaft rotational dynamics to meet stringent emissions regulations and fuel efficiency standards. According to industry surveys, 78% of automotive manufacturers consider accurate crankshaft performance analysis essential for competitive engine development. The ability to detect micro-level vibrations and irregularities during testing phases has become a critical requirement, with 85% of engine development teams specifically requesting real-time analytics capabilities in their testing equipment.

The market demands for crankshaft performance analysis systems are evolving toward more integrated solutions that combine multiple measurement parameters. End-users require systems capable of simultaneously measuring torsional vibration, angular velocity variations, and bending moments with precision tolerances below 0.01 degrees. Additionally, there is growing demand for portable testing equipment that can be deployed both in laboratory settings and production environments, with 63% of potential customers expressing interest in versatile deployment options.

Data integration capabilities represent another significant market requirement, with 91% of surveyed manufacturers indicating the need for testing systems that seamlessly connect with existing enterprise data platforms and digital twins. This integration enables comprehensive lifecycle analysis of engine components and supports predictive maintenance strategies that are becoming standard across the industry.

The market is also witnessing increased demand for non-contact measurement technologies, with optical and laser-based systems gaining preference over traditional contact sensors. This shift is driven by the need to analyze high-speed rotational dynamics without introducing additional variables through sensor contact. Market research shows that 72% of new system purchases favor non-contact technologies, representing a significant shift in customer preferences over the past five years.

Regional analysis reveals varying requirements across markets, with North American and European customers prioritizing integration with digital manufacturing ecosystems, while Asian markets place greater emphasis on cost-effectiveness and scalability. Emerging markets show particular interest in systems that can be adapted to various engine types and sizes, reflecting the diverse manufacturing base in these regions.

Current Challenges in Rotational Dynamics Measurement

Despite significant advancements in crankshaft rotational dynamics measurement technologies, several persistent challenges continue to impede accurate quantification in testing environments. One of the primary obstacles remains the precise measurement of high-frequency vibrations during operation. Current sensor technologies often struggle to capture micro-oscillations that occur at frequencies above 10 kHz, particularly in high-performance engines where these vibrations can significantly impact overall system performance and durability.

Signal noise contamination presents another substantial challenge, especially in industrial testing environments where electromagnetic interference from nearby machinery can distort measurement readings. Even with advanced filtering algorithms, distinguishing between actual crankshaft behavior and environmental noise requires sophisticated signal processing techniques that may introduce their own artifacts into the data.

Temperature variation during testing introduces significant measurement drift in many sensor systems. As engine components heat up during operation, thermal expansion affects both the crankshaft itself and the measurement apparatus, creating discrepancies that can exceed 0.05 degrees in rotational measurement—a critical margin in precision applications such as Formula 1 racing engines or aerospace systems.

Real-time data acquisition and processing limitations continue to constrain comprehensive dynamic analysis. Current systems typically face a trade-off between sampling rate and data resolution, with many commercial solutions unable to simultaneously provide high-frequency sampling (>100 kHz) and high-resolution measurements (< 0.01 degrees) without specialized hardware configurations that significantly increase testing costs.

The integration of multiple measurement parameters remains problematic. Comprehensive crankshaft dynamics analysis requires simultaneous monitoring of angular position, velocity, acceleration, torsional vibration, and axial movement—parameters that traditionally require different sensor types with varying response characteristics, creating synchronization challenges during data integration.

Calibration drift over extended testing periods introduces another layer of complexity. Long-duration tests, essential for fatigue and durability assessment, often suffer from gradual sensor drift that can accumulate to significant measurement errors if not properly compensated for through advanced calibration protocols.

Non-linear behavior quantification presents perhaps the most sophisticated challenge. Modern lightweight crankshafts exhibit complex non-linear responses under varying loads, particularly during transient operations. Current mathematical models struggle to fully characterize these behaviors, leading to discrepancies between predicted and actual performance in extreme operating conditions.

Signal noise contamination presents another substantial challenge, especially in industrial testing environments where electromagnetic interference from nearby machinery can distort measurement readings. Even with advanced filtering algorithms, distinguishing between actual crankshaft behavior and environmental noise requires sophisticated signal processing techniques that may introduce their own artifacts into the data.

Temperature variation during testing introduces significant measurement drift in many sensor systems. As engine components heat up during operation, thermal expansion affects both the crankshaft itself and the measurement apparatus, creating discrepancies that can exceed 0.05 degrees in rotational measurement—a critical margin in precision applications such as Formula 1 racing engines or aerospace systems.

Real-time data acquisition and processing limitations continue to constrain comprehensive dynamic analysis. Current systems typically face a trade-off between sampling rate and data resolution, with many commercial solutions unable to simultaneously provide high-frequency sampling (>100 kHz) and high-resolution measurements (< 0.01 degrees) without specialized hardware configurations that significantly increase testing costs.

The integration of multiple measurement parameters remains problematic. Comprehensive crankshaft dynamics analysis requires simultaneous monitoring of angular position, velocity, acceleration, torsional vibration, and axial movement—parameters that traditionally require different sensor types with varying response characteristics, creating synchronization challenges during data integration.

Calibration drift over extended testing periods introduces another layer of complexity. Long-duration tests, essential for fatigue and durability assessment, often suffer from gradual sensor drift that can accumulate to significant measurement errors if not properly compensated for through advanced calibration protocols.

Non-linear behavior quantification presents perhaps the most sophisticated challenge. Modern lightweight crankshafts exhibit complex non-linear responses under varying loads, particularly during transient operations. Current mathematical models struggle to fully characterize these behaviors, leading to discrepancies between predicted and actual performance in extreme operating conditions.

Current Methodologies for Quantifying Rotational Dynamics

01 Crankshaft balancing and vibration reduction

Various methods and systems for balancing crankshafts to reduce vibration during rotation. These include counterweights, dynamic balancing techniques, and specialized designs that minimize rotational irregularities. Proper balancing improves engine performance, reduces wear on bearings, and minimizes noise and vibration transmitted to the vehicle structure.- Crankshaft balancing and vibration reduction: Various methods and systems are employed to balance crankshafts and reduce vibrations during rotation. These include counterweights, balance shafts, and specialized damping mechanisms that help minimize torsional vibrations and improve engine smoothness. Proper balancing is crucial for engine performance, durability, and noise reduction, particularly at high rotational speeds where dynamic forces are most significant.

- Torsional vibration damping systems: Specialized damping systems are designed to absorb and mitigate torsional vibrations in crankshafts. These systems include torsional dampers, dual-mass flywheels, and viscous damping mechanisms that help prevent resonance conditions and reduce stress on engine components. By controlling torsional oscillations, these systems improve engine reliability, reduce wear on bearings and other components, and enhance overall powertrain performance.

- Crankshaft rotational speed monitoring and control: Advanced systems for monitoring and controlling crankshaft rotational dynamics include sensors, electronic control units, and feedback mechanisms. These systems provide real-time data on crankshaft position, speed, and acceleration, allowing for precise engine management. Applications include variable valve timing, cylinder deactivation, and adaptive engine control strategies that optimize performance based on operating conditions.

- Crankshaft design optimization for rotational dynamics: Innovative crankshaft designs focus on optimizing rotational dynamics through material selection, geometric configurations, and structural analysis. These designs incorporate features such as hollow sections, variable journal diameters, and optimized counterweight placement to reduce inertial forces while maintaining strength. Advanced manufacturing techniques and materials enable lighter crankshafts with improved rotational characteristics and durability.

- Crankshaft bearing systems for improved rotational performance: Specialized bearing systems are developed to support crankshaft rotation under high loads and speeds. These include hydrodynamic bearings, roller bearings, and hybrid bearing systems that minimize friction and wear while providing adequate support. Advanced lubrication systems ensure proper oil film formation and heat dissipation, which are critical for maintaining optimal rotational dynamics and extending engine life.

02 Crankshaft torsional vibration damping

Technologies focused on damping torsional vibrations in crankshafts during engine operation. These include torsional dampers, dual-mass flywheels, and specialized materials or structures that absorb vibrational energy. These systems help prevent resonance conditions that could lead to crankshaft failure and improve overall engine smoothness and durability.Expand Specific Solutions03 Crankshaft rotational speed measurement and control

Systems for accurately measuring and controlling crankshaft rotational dynamics, including speed sensors, position detectors, and electronic control units. These technologies enable precise engine timing, improved combustion efficiency, and advanced control strategies that optimize performance under varying operating conditions.Expand Specific Solutions04 Crankshaft design optimization for rotational performance

Innovative crankshaft designs that optimize rotational dynamics through geometric modifications, material selection, and manufacturing techniques. These designs focus on weight reduction, strength improvement, and optimized bearing surfaces to enhance rotational performance, fuel efficiency, and engine longevity.Expand Specific Solutions05 Crankshaft-driven auxiliary systems and their impact on dynamics

Analysis and improvement of how auxiliary systems connected to the crankshaft affect overall rotational dynamics. This includes optimized pulley systems, decoupling mechanisms, and variable drive systems that minimize parasitic losses and irregular loading on the crankshaft during operation, resulting in smoother engine performance and improved efficiency.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The crankshaft rotational dynamics testing market is currently in a growth phase, with increasing demand driven by automotive and industrial equipment manufacturers seeking improved engine performance and efficiency. The global market size is estimated to exceed $500 million, expanding at approximately 5-7% annually as emission regulations tighten worldwide. Leading players include established automotive suppliers like Robert Bosch GmbH, ZF Friedrichshafen AG, and Schaeffler Technologies, who possess advanced testing capabilities. Major vehicle manufacturers such as Toyota, Honda, and Renault are investing heavily in this technology. Specialized testing equipment providers like AVL List GmbH have developed sophisticated measurement systems, while academic institutions including Tianjin University and Shanghai Institute of Technology contribute to technological advancement through research partnerships with industry leaders.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive crankshaft dynamics testing platform that combines physical measurements with advanced simulation capabilities. Their system utilizes high-precision optical encoders with resolution capabilities of 3600 pulses per revolution to capture minute variations in rotational behavior. Bosch's technology incorporates strain gauge-based torque measurement systems capable of detecting torsional vibrations across the entire operating range of modern engines. Their testing methodology integrates real-time data acquisition with sophisticated filtering algorithms to isolate crankshaft dynamics from other powertrain influences. The company employs specialized modal analysis techniques to identify critical frequencies and damping characteristics of crankshaft assemblies. Bosch has also developed proprietary software that correlates measured data with finite element models to validate design parameters and predict failure modes under extreme operating conditions[2]. Their testing systems can simultaneously monitor multiple parameters including angular velocity fluctuations, torsional vibration amplitudes, and bearing loads.

Strengths: Exceptional measurement accuracy; integrated hardware-software solution; extensive automotive industry experience; comprehensive validation capabilities. Weaknesses: Systems typically require significant calibration time; high initial investment costs; limited flexibility for non-standard crankshaft configurations.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed specialized crankshaft rotational dynamics testing technology that focuses on bearing-crankshaft interactions under dynamic loading conditions. Their system employs high-frequency eddy current sensors with sub-micron resolution to measure journal orbit patterns during operation. Schaeffler's approach integrates specialized bearing instrumentation with crankshaft dynamics measurement, providing comprehensive insights into the complete rotating assembly behavior. Their testing methodology incorporates advanced oil film pressure measurement techniques using miniaturized pressure transducers embedded in bearing shells to correlate with rotational dynamics. The company utilizes proprietary algorithms for separating torsional, bending, and axial vibration components from complex measurement signals. Schaeffler's testing platforms can simulate variable loading conditions while maintaining precise measurement of rotational irregularities across operating speeds from idle to maximum rated RPM[5]. Their technology includes specialized instrumentation for measuring damper effectiveness and timing chain/belt dynamics as they relate to crankshaft rotational behavior.

Strengths: Industry-leading expertise in bearing-crankshaft interaction; excellent measurement capabilities for oil film dynamics; comprehensive understanding of friction influences on rotational behavior. Weaknesses: Testing approach more focused on bearing performance than overall crankshaft dynamics; complex setup procedures; requires specialized facilities for full implementation.

Key Technologies in Crankshaft Dynamics Measurement

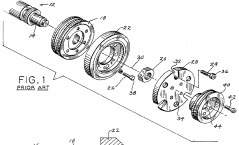

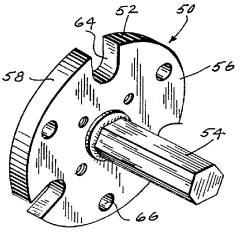

Engine crankshaft indexing method and tool

PatentInactiveUS4922749A

Innovation

- A tool with a disc attachable to the crankshaft pulley and a grippable shank that engages with existing bolts to rotate the crankshaft, allowing precise indexing without removing compression-relieving seals, featuring removable and integrally connected designs for various configurations.

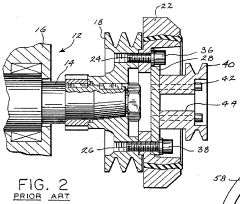

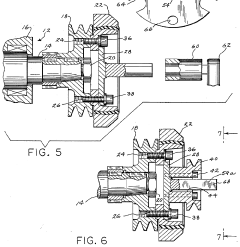

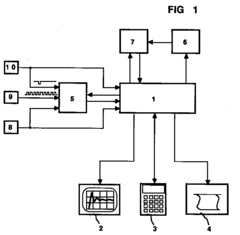

Method for off-bench determining of technical characteristics of combustion engines and their single cylinders, and apparatus making use of this method

PatentInactiveEP0463537A3

Innovation

- A method utilizing the existing angular division of the crankshaft components, such as the starter ring gear, to measure partial rotation times in defined crank angle ranges, allowing for real-time determination of torque, power, and angular acceleration, while synchronizing measurements with the engine's work cycle, using a device with sensors for crank angle reference and logical sequence signals to calculate key figures like maximum torque, nominal power, and mechanical efficiency.

Vibration Analysis and Noise Reduction Techniques

Vibration analysis in crankshaft testing environments represents a critical component for understanding rotational dynamics. The complex mechanical interactions within engine systems generate significant vibration signatures that can provide valuable diagnostic information about crankshaft performance, structural integrity, and potential failure modes. Modern vibration analysis techniques employ sophisticated sensor arrays, including accelerometers, proximity probes, and laser vibrometry systems, to capture multi-dimensional vibration data across various frequency ranges.

Time-domain and frequency-domain analysis methods form the foundation of crankshaft vibration assessment. Fast Fourier Transform (FFT) analysis enables the identification of specific frequency components related to rotational events, while order tracking techniques allow for the isolation of vibration patterns directly linked to crankshaft rotation speed. These methodologies facilitate the detection of torsional vibrations, bending modes, and axial movements that characterize crankshaft behavior under various operating conditions.

Noise reduction in crankshaft testing environments presents unique challenges due to the inherent complexity of signal acquisition in high-interference settings. Advanced signal processing techniques such as wavelet decomposition, empirical mode decomposition, and adaptive filtering have proven effective in separating meaningful vibration signatures from background noise. These approaches enable more precise quantification of rotational dynamics by enhancing signal-to-noise ratios and isolating specific vibration components of interest.

The integration of machine learning algorithms with traditional vibration analysis has revolutionized pattern recognition capabilities in crankshaft testing. Supervised and unsupervised learning models can identify subtle vibration patterns associated with specific mechanical conditions, enabling early detection of developing issues before they manifest as catastrophic failures. Neural networks and support vector machines have demonstrated particular efficacy in classifying vibration signatures associated with various crankshaft defects.

Noise reduction hardware solutions complement analytical approaches through specialized mounting systems, vibration isolation platforms, and acoustic enclosures. These physical interventions minimize environmental interference and transmission path effects, ensuring that measured vibrations accurately reflect actual crankshaft dynamics rather than external influences. The strategic placement of damping materials and the implementation of active noise cancellation technologies further enhance measurement fidelity in testing environments.

Real-time monitoring systems represent the cutting edge of vibration analysis for crankshaft testing, enabling continuous assessment of rotational dynamics during extended operation. These systems incorporate edge computing capabilities to process vibration data instantaneously, providing immediate feedback on developing anomalies and facilitating adaptive testing protocols that respond to changing crankshaft conditions.

Time-domain and frequency-domain analysis methods form the foundation of crankshaft vibration assessment. Fast Fourier Transform (FFT) analysis enables the identification of specific frequency components related to rotational events, while order tracking techniques allow for the isolation of vibration patterns directly linked to crankshaft rotation speed. These methodologies facilitate the detection of torsional vibrations, bending modes, and axial movements that characterize crankshaft behavior under various operating conditions.

Noise reduction in crankshaft testing environments presents unique challenges due to the inherent complexity of signal acquisition in high-interference settings. Advanced signal processing techniques such as wavelet decomposition, empirical mode decomposition, and adaptive filtering have proven effective in separating meaningful vibration signatures from background noise. These approaches enable more precise quantification of rotational dynamics by enhancing signal-to-noise ratios and isolating specific vibration components of interest.

The integration of machine learning algorithms with traditional vibration analysis has revolutionized pattern recognition capabilities in crankshaft testing. Supervised and unsupervised learning models can identify subtle vibration patterns associated with specific mechanical conditions, enabling early detection of developing issues before they manifest as catastrophic failures. Neural networks and support vector machines have demonstrated particular efficacy in classifying vibration signatures associated with various crankshaft defects.

Noise reduction hardware solutions complement analytical approaches through specialized mounting systems, vibration isolation platforms, and acoustic enclosures. These physical interventions minimize environmental interference and transmission path effects, ensuring that measured vibrations accurately reflect actual crankshaft dynamics rather than external influences. The strategic placement of damping materials and the implementation of active noise cancellation technologies further enhance measurement fidelity in testing environments.

Real-time monitoring systems represent the cutting edge of vibration analysis for crankshaft testing, enabling continuous assessment of rotational dynamics during extended operation. These systems incorporate edge computing capabilities to process vibration data instantaneously, providing immediate feedback on developing anomalies and facilitating adaptive testing protocols that respond to changing crankshaft conditions.

Industry Standards and Certification Requirements

The crankshaft testing industry operates under a comprehensive framework of standards and certification requirements that ensure consistency, reliability, and safety across automotive and industrial applications. ISO 1940-1 stands as the cornerstone standard for mechanical vibration, specifically addressing balance quality requirements for rotors in a constant state. This standard establishes the permissible residual imbalance values for crankshafts based on their operational speed and application, providing essential guidelines for manufacturers and testing facilities.

ASTM E2375 complements these requirements by detailing the standard practice for ultrasonic testing of wrought products, including crankshafts, offering precise methodologies for detecting internal discontinuities that could compromise rotational integrity. For automotive applications specifically, SAE J1979 outlines the diagnostic test modes for emission-related powertrain components, incorporating crankshaft position sensor testing protocols that directly impact rotational dynamics assessment.

The certification landscape requires testing facilities to maintain ISO/IEC 17025 accreditation, which validates their technical competence in performing specific tests and calibrations for crankshaft rotational dynamics. This accreditation ensures that the measurement uncertainty is properly calculated and reported, a critical factor when quantifying precise rotational characteristics.

Regional regulations introduce additional layers of compliance requirements. In Europe, the Machinery Directive 2006/42/EC mandates essential health and safety requirements for machinery components, including specific provisions for rotating parts like crankshafts. Similarly, in North America, ASME B89.4.10 provides standards for the performance evaluation of coordinate measuring machine systems used in dimensional metrology of crankshafts.

The certification process typically involves three phases: initial qualification testing, which establishes baseline performance metrics; periodic verification testing to ensure continued compliance; and special certification for high-performance or safety-critical applications. Documentation requirements include detailed test procedures, calibration records for all measurement equipment, uncertainty budgets, and traceability to national or international standards.

Emerging trends in standardization include the development of specialized protocols for high-speed crankshafts exceeding 10,000 RPM, integration of digital twin concepts into testing standards, and harmonization of international requirements to facilitate global manufacturing and testing operations. These evolving standards increasingly emphasize real-time monitoring capabilities and predictive analytics as essential components of comprehensive crankshaft rotational dynamics assessment.

ASTM E2375 complements these requirements by detailing the standard practice for ultrasonic testing of wrought products, including crankshafts, offering precise methodologies for detecting internal discontinuities that could compromise rotational integrity. For automotive applications specifically, SAE J1979 outlines the diagnostic test modes for emission-related powertrain components, incorporating crankshaft position sensor testing protocols that directly impact rotational dynamics assessment.

The certification landscape requires testing facilities to maintain ISO/IEC 17025 accreditation, which validates their technical competence in performing specific tests and calibrations for crankshaft rotational dynamics. This accreditation ensures that the measurement uncertainty is properly calculated and reported, a critical factor when quantifying precise rotational characteristics.

Regional regulations introduce additional layers of compliance requirements. In Europe, the Machinery Directive 2006/42/EC mandates essential health and safety requirements for machinery components, including specific provisions for rotating parts like crankshafts. Similarly, in North America, ASME B89.4.10 provides standards for the performance evaluation of coordinate measuring machine systems used in dimensional metrology of crankshafts.

The certification process typically involves three phases: initial qualification testing, which establishes baseline performance metrics; periodic verification testing to ensure continued compliance; and special certification for high-performance or safety-critical applications. Documentation requirements include detailed test procedures, calibration records for all measurement equipment, uncertainty budgets, and traceability to national or international standards.

Emerging trends in standardization include the development of specialized protocols for high-speed crankshafts exceeding 10,000 RPM, integration of digital twin concepts into testing standards, and harmonization of international requirements to facilitate global manufacturing and testing operations. These evolving standards increasingly emphasize real-time monitoring capabilities and predictive analytics as essential components of comprehensive crankshaft rotational dynamics assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!