Crankshaft vs Camshaft Synchronization: Power Sync Efficiency

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Synchronization Background and Objectives

The evolution of internal combustion engines has been marked by continuous refinement in synchronization mechanisms between crankshafts and camshafts. Dating back to the early 20th century, this critical relationship has undergone significant transformation from simple mechanical linkages to sophisticated electronically controlled systems. The fundamental purpose of this synchronization remains unchanged: ensuring precise timing between the engine's rotating assembly and valve operation to optimize combustion efficiency.

Traditional synchronization methods relied on timing chains, belts, or gear systems that maintained fixed relationships between crankshaft and camshaft rotation. These systems, while effective, offered limited flexibility in adapting to varying engine operating conditions. The technological trajectory has progressively moved toward more dynamic synchronization solutions that can adjust timing parameters in real-time based on engine load, speed, and environmental factors.

Current market demands for improved fuel efficiency, reduced emissions, and enhanced performance have accelerated innovation in this domain. The industry has witnessed a paradigm shift from fixed mechanical timing to variable valve timing (VVT) systems, which represent a significant milestone in the evolution of crankshaft-camshaft synchronization technology. These advancements have enabled engines to optimize power delivery while simultaneously reducing fuel consumption and emissions.

The primary technical objective in this field is to achieve perfect synchronization efficiency that maximizes power transfer from combustion to mechanical output while minimizing energy losses. This involves precise control of valve events relative to piston position throughout the entire operating range of the engine. Secondary objectives include improving system durability, reducing maintenance requirements, and decreasing manufacturing complexity and costs.

Recent technological developments have introduced electronic camshaft phasing, camless valve actuation systems, and integrated powertrain control architectures that coordinate multiple engine subsystems. These innovations represent attempts to overcome the inherent limitations of mechanical synchronization methods and move toward fully adaptive engine timing control.

The convergence of mechanical engineering principles with electronic control systems has created new possibilities for optimizing the crankshaft-camshaft relationship. As automotive manufacturers face increasingly stringent efficiency and emissions standards, the importance of advanced synchronization technologies continues to grow. The industry is now exploring predictive algorithms and machine learning approaches to further refine timing strategies based on anticipated driving conditions and historical performance data.

This technical investigation aims to comprehensively analyze the evolution, current state, and future directions of crankshaft-camshaft synchronization technologies, with particular emphasis on efficiency improvements in power transfer and overall engine performance optimization.

Traditional synchronization methods relied on timing chains, belts, or gear systems that maintained fixed relationships between crankshaft and camshaft rotation. These systems, while effective, offered limited flexibility in adapting to varying engine operating conditions. The technological trajectory has progressively moved toward more dynamic synchronization solutions that can adjust timing parameters in real-time based on engine load, speed, and environmental factors.

Current market demands for improved fuel efficiency, reduced emissions, and enhanced performance have accelerated innovation in this domain. The industry has witnessed a paradigm shift from fixed mechanical timing to variable valve timing (VVT) systems, which represent a significant milestone in the evolution of crankshaft-camshaft synchronization technology. These advancements have enabled engines to optimize power delivery while simultaneously reducing fuel consumption and emissions.

The primary technical objective in this field is to achieve perfect synchronization efficiency that maximizes power transfer from combustion to mechanical output while minimizing energy losses. This involves precise control of valve events relative to piston position throughout the entire operating range of the engine. Secondary objectives include improving system durability, reducing maintenance requirements, and decreasing manufacturing complexity and costs.

Recent technological developments have introduced electronic camshaft phasing, camless valve actuation systems, and integrated powertrain control architectures that coordinate multiple engine subsystems. These innovations represent attempts to overcome the inherent limitations of mechanical synchronization methods and move toward fully adaptive engine timing control.

The convergence of mechanical engineering principles with electronic control systems has created new possibilities for optimizing the crankshaft-camshaft relationship. As automotive manufacturers face increasingly stringent efficiency and emissions standards, the importance of advanced synchronization technologies continues to grow. The industry is now exploring predictive algorithms and machine learning approaches to further refine timing strategies based on anticipated driving conditions and historical performance data.

This technical investigation aims to comprehensively analyze the evolution, current state, and future directions of crankshaft-camshaft synchronization technologies, with particular emphasis on efficiency improvements in power transfer and overall engine performance optimization.

Market Demand for Efficient Power Synchronization Systems

The automotive industry is witnessing a significant shift towards more efficient power synchronization systems, driven by stringent emission regulations, fuel economy standards, and consumer demand for better performance. The market for advanced crankshaft and camshaft synchronization technologies has expanded considerably, with global automotive powertrain market valued at approximately $68.5 billion in 2023 and projected to grow at a CAGR of 5.8% through 2030.

Engine efficiency optimization has become a critical focus area for manufacturers, with synchronization systems playing a pivotal role in achieving performance targets. Market research indicates that OEMs are willing to invest 15-20% more in advanced synchronization technologies that can deliver 3-5% improvements in fuel efficiency or power output. This represents a substantial market opportunity for innovative solutions in the power sync domain.

The aftermarket segment for performance enhancement components, including upgraded camshaft and crankshaft synchronization systems, has shown robust growth at 7.2% annually, reflecting consumer interest in vehicle performance optimization. Performance enthusiasts and racing applications constitute a specialized but lucrative market segment with higher tolerance for premium pricing on advanced synchronization solutions.

Commercial vehicle manufacturers are increasingly demanding more durable and precise synchronization systems that can withstand higher loads and provide longer service intervals. This sector values reliability and total cost of ownership over initial acquisition costs, creating opportunities for premium synchronization technologies that can demonstrate superior longevity and performance stability.

Emerging markets, particularly in Asia-Pacific and Latin America, show accelerating demand for cost-effective yet reliable synchronization systems as vehicle production volumes increase. These markets are expected to account for over 40% of global demand growth in the next five years, presenting significant expansion opportunities for manufacturers who can adapt their technologies to meet regional price sensitivities.

Electric and hybrid vehicle integration presents a new frontier for synchronization technology applications. While traditional combustion engines remain dominant, the transition period featuring hybrid powertrains requires specialized synchronization solutions that can optimize the interaction between conventional and electric power sources. Market analysis suggests this hybrid segment will grow at 12.4% annually through 2028.

Industry surveys indicate that 78% of automotive engineers consider advanced synchronization systems essential for meeting future emission standards without compromising vehicle performance. This technical necessity is creating sustained demand for innovations in timing precision, reduced friction, and adaptive control mechanisms in power synchronization systems.

Engine efficiency optimization has become a critical focus area for manufacturers, with synchronization systems playing a pivotal role in achieving performance targets. Market research indicates that OEMs are willing to invest 15-20% more in advanced synchronization technologies that can deliver 3-5% improvements in fuel efficiency or power output. This represents a substantial market opportunity for innovative solutions in the power sync domain.

The aftermarket segment for performance enhancement components, including upgraded camshaft and crankshaft synchronization systems, has shown robust growth at 7.2% annually, reflecting consumer interest in vehicle performance optimization. Performance enthusiasts and racing applications constitute a specialized but lucrative market segment with higher tolerance for premium pricing on advanced synchronization solutions.

Commercial vehicle manufacturers are increasingly demanding more durable and precise synchronization systems that can withstand higher loads and provide longer service intervals. This sector values reliability and total cost of ownership over initial acquisition costs, creating opportunities for premium synchronization technologies that can demonstrate superior longevity and performance stability.

Emerging markets, particularly in Asia-Pacific and Latin America, show accelerating demand for cost-effective yet reliable synchronization systems as vehicle production volumes increase. These markets are expected to account for over 40% of global demand growth in the next five years, presenting significant expansion opportunities for manufacturers who can adapt their technologies to meet regional price sensitivities.

Electric and hybrid vehicle integration presents a new frontier for synchronization technology applications. While traditional combustion engines remain dominant, the transition period featuring hybrid powertrains requires specialized synchronization solutions that can optimize the interaction between conventional and electric power sources. Market analysis suggests this hybrid segment will grow at 12.4% annually through 2028.

Industry surveys indicate that 78% of automotive engineers consider advanced synchronization systems essential for meeting future emission standards without compromising vehicle performance. This technical necessity is creating sustained demand for innovations in timing precision, reduced friction, and adaptive control mechanisms in power synchronization systems.

Current Crankshaft-Camshaft Synchronization Technologies

The synchronization between crankshaft and camshaft represents a critical aspect of internal combustion engine operation, directly influencing power delivery, fuel efficiency, and emissions performance. Current synchronization technologies have evolved significantly over the past decades, moving from purely mechanical systems to sophisticated electromechanical solutions.

Traditional timing belt and chain systems remain the most widely implemented synchronization methods in production vehicles. Timing chains offer superior durability with service intervals often matching engine lifetime, while belts require periodic replacement but operate with reduced noise and weight penalties. Both systems utilize precision-engineered sprockets with specific tooth profiles to maintain accurate timing relationships between the crankshaft and camshaft(s).

Variable Valve Timing (VVT) technologies have revolutionized camshaft-crankshaft synchronization by introducing dynamic phase adjustment capabilities. Hydraulic cam phasers, the most common implementation, utilize engine oil pressure controlled by solenoid valves to rotate the camshaft relative to its drive sprocket, effectively advancing or retarding valve timing. More advanced systems like BMW's VANOS and Toyota's VVT-i can adjust timing across a range of 30-60 degrees of crankshaft rotation.

Electromagnetic actuation systems represent the cutting edge of synchronization technology, eliminating the hydraulic delay inherent in conventional VVT systems. These systems employ electromagnetic actuators to directly control camshaft position relative to the crankshaft, enabling near-instantaneous timing adjustments and greater precision across all engine operating conditions.

Camless valve actuation technologies, though not yet widely commercialized, represent the ultimate evolution in synchronization by eliminating the mechanical camshaft entirely. Systems like Fiat's MultiAir and Koenigsegg's FreeValve utilize electrohydraulic or electromagnetic actuators to directly control valve movement, completely decoupling valve events from crankshaft position while maintaining precise synchronization through electronic control.

Digital timing control systems have become standard across all modern synchronization technologies. Engine control modules continuously monitor crankshaft and camshaft positions through dedicated sensors, typically Hall effect or variable reluctance types, enabling real-time adjustment of synchronization parameters based on operating conditions and driver demands.

Dual Independent Variable Valve Timing (DIVVT) systems extend synchronization control by independently adjusting both intake and exhaust camshafts relative to the crankshaft. This technology enables more precise optimization of valve overlap, significantly improving both low-end torque and high-RPM power while reducing emissions through better exhaust gas management.

The integration of these technologies with advanced engine management systems has enabled unprecedented levels of synchronization precision, allowing engines to dynamically optimize power delivery and efficiency across all operating conditions while meeting increasingly stringent emissions regulations.

Traditional timing belt and chain systems remain the most widely implemented synchronization methods in production vehicles. Timing chains offer superior durability with service intervals often matching engine lifetime, while belts require periodic replacement but operate with reduced noise and weight penalties. Both systems utilize precision-engineered sprockets with specific tooth profiles to maintain accurate timing relationships between the crankshaft and camshaft(s).

Variable Valve Timing (VVT) technologies have revolutionized camshaft-crankshaft synchronization by introducing dynamic phase adjustment capabilities. Hydraulic cam phasers, the most common implementation, utilize engine oil pressure controlled by solenoid valves to rotate the camshaft relative to its drive sprocket, effectively advancing or retarding valve timing. More advanced systems like BMW's VANOS and Toyota's VVT-i can adjust timing across a range of 30-60 degrees of crankshaft rotation.

Electromagnetic actuation systems represent the cutting edge of synchronization technology, eliminating the hydraulic delay inherent in conventional VVT systems. These systems employ electromagnetic actuators to directly control camshaft position relative to the crankshaft, enabling near-instantaneous timing adjustments and greater precision across all engine operating conditions.

Camless valve actuation technologies, though not yet widely commercialized, represent the ultimate evolution in synchronization by eliminating the mechanical camshaft entirely. Systems like Fiat's MultiAir and Koenigsegg's FreeValve utilize electrohydraulic or electromagnetic actuators to directly control valve movement, completely decoupling valve events from crankshaft position while maintaining precise synchronization through electronic control.

Digital timing control systems have become standard across all modern synchronization technologies. Engine control modules continuously monitor crankshaft and camshaft positions through dedicated sensors, typically Hall effect or variable reluctance types, enabling real-time adjustment of synchronization parameters based on operating conditions and driver demands.

Dual Independent Variable Valve Timing (DIVVT) systems extend synchronization control by independently adjusting both intake and exhaust camshafts relative to the crankshaft. This technology enables more precise optimization of valve overlap, significantly improving both low-end torque and high-RPM power while reducing emissions through better exhaust gas management.

The integration of these technologies with advanced engine management systems has enabled unprecedented levels of synchronization precision, allowing engines to dynamically optimize power delivery and efficiency across all operating conditions while meeting increasingly stringent emissions regulations.

Contemporary Crankshaft-Camshaft Timing Solutions

01 Sensor-based synchronization systems

Advanced sensor systems are used to monitor and synchronize the positions of crankshafts and camshafts in internal combustion engines. These sensors detect the rotational positions of both shafts and provide real-time data to the engine control unit. The control unit then adjusts the timing to maintain optimal synchronization, which improves power output and fuel efficiency. These systems often use hall effect sensors, optical sensors, or magnetic sensors to achieve precise timing control.- Sensor-based synchronization systems: Advanced sensor systems are used to monitor and synchronize crankshaft and camshaft positions in real-time. These systems employ various types of sensors including magnetic, optical, and Hall effect sensors to precisely detect shaft positions and rotational speeds. The data from these sensors is processed by engine control units to optimize timing, which improves power output and fuel efficiency. These synchronization systems can adapt to changing engine conditions and compensate for mechanical wear over time.

- Variable valve timing mechanisms: Variable valve timing (VVT) mechanisms allow for dynamic adjustment of the camshaft position relative to the crankshaft. These systems can advance or retard valve timing based on engine load, speed, and other operating conditions. By optimizing the valve events for different engine speeds and loads, VVT systems improve power output, torque characteristics, and fuel efficiency. Advanced VVT systems may include hydraulic actuators, electronic solenoids, or mechanical phase shifters to achieve precise control over the camshaft-crankshaft relationship.

- Electronic control algorithms for timing optimization: Sophisticated control algorithms are implemented in engine management systems to optimize the synchronization between crankshaft and camshaft. These algorithms process inputs from multiple sensors and adjust timing parameters to maximize efficiency across various operating conditions. The control systems can implement predictive models and adaptive learning to fine-tune engine performance. Some advanced systems incorporate real-time feedback loops that continuously adjust timing to maintain optimal power and efficiency even as engine conditions change.

- Mechanical synchronization devices: Various mechanical devices are used to maintain proper synchronization between crankshaft and camshaft, including timing chains, belts, and gears. These components are designed with specific materials and geometries to minimize friction, reduce noise, and extend service life while maintaining precise timing relationships. Advanced designs incorporate tensioners and dampeners to compensate for chain stretch or belt wear over time. Some systems use dual-chain arrangements or hybrid systems combining different mechanical elements to optimize both durability and timing precision.

- Energy recovery and efficiency enhancement systems: Innovative systems capture and utilize energy during the synchronization process to improve overall engine efficiency. These include regenerative mechanisms that harvest energy from camshaft movement, electromagnetic coupling systems that reduce mechanical losses, and integrated start-stop technologies that maintain synchronization during engine restart events. Some advanced designs incorporate variable inertia flywheels or dual-mass flywheels that optimize energy storage and release during the engine cycle. These systems contribute to reduced fuel consumption and lower emissions while maintaining or improving engine performance.

02 Variable valve timing mechanisms

Variable valve timing mechanisms allow for dynamic adjustment of the camshaft position relative to the crankshaft. These systems can advance or retard valve timing based on engine operating conditions to optimize power, efficiency, and emissions. The mechanisms typically use hydraulic or electric actuators to rotate the camshaft slightly in relation to its drive sprocket or gear. This technology enables engines to achieve better performance across a wider range of operating conditions by optimizing the valve timing for different engine speeds and loads.Expand Specific Solutions03 Electronic control strategies for timing optimization

Advanced electronic control strategies are implemented to optimize the synchronization between crankshaft and camshaft for maximum power and efficiency. These strategies involve complex algorithms that consider multiple engine parameters such as load, speed, temperature, and driver demand. The control systems can make real-time adjustments to timing based on these inputs, ensuring optimal combustion conditions. Some systems also incorporate adaptive learning capabilities to adjust for wear and aging of engine components over time.Expand Specific Solutions04 Mechanical synchronization devices

Various mechanical devices are used to maintain proper synchronization between crankshaft and camshaft, including timing chains, belts, and gears. These components physically connect the crankshaft to the camshaft, ensuring they rotate at the correct relative speeds. Innovations in these mechanical systems focus on reducing friction, minimizing noise, improving durability, and maintaining precise timing over the life of the engine. Advanced materials and designs help to reduce power losses in the drive system, contributing to overall engine efficiency.Expand Specific Solutions05 Fault detection and correction systems

Systems for detecting and correcting synchronization errors between crankshaft and camshaft are essential for maintaining engine performance and preventing damage. These systems monitor timing relationships and can identify when synchronization is outside acceptable parameters. When faults are detected, the engine control unit can implement corrective actions such as adjusting timing or, in severe cases, limiting engine operation to prevent damage. Some advanced systems can compensate for minor timing errors to maintain optimal performance even when mechanical components begin to wear.Expand Specific Solutions

Leading Manufacturers in Engine Synchronization Technology

The crankshaft-camshaft synchronization technology market is currently in a mature growth phase, with an estimated global market size of $5-7 billion annually. Major automotive OEMs like Volkswagen, BMW, Hyundai, and Ford are competing alongside specialized component manufacturers such as Schaeffler, BorgWarner, ZF Friedrichshafen, and Robert Bosch. The technology landscape shows varying levels of maturity, with traditional mechanical synchronization systems being well-established while electronic and variable timing solutions are still evolving. Tier-1 suppliers like Continental Automotive and Vitesco Technologies are advancing power efficiency optimization through integrated powertrain control systems, while research institutions like Tongji University contribute to fundamental innovation. The competitive dynamics are shifting toward solutions that maximize fuel efficiency while reducing emissions in both conventional and hybrid powertrains.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed an innovative crankshaft-camshaft synchronization system called "UniAir" that utilizes electrohydraulic valve control technology. This system enables fully variable control of valve lift and timing, effectively decoupling camshaft rotation from fixed mechanical constraints. Their solution incorporates high-precision hydraulic actuators that can adjust valve timing in real-time based on engine load conditions. Schaeffler's technology features a unique "soft landing" valve control algorithm that reduces impact forces during valve closing, significantly extending component life while maintaining precise synchronization. The system includes integrated temperature compensation that maintains timing accuracy across extreme operating conditions from cold starts to full operating temperature. Their advanced control software continuously optimizes the phase relationship between crankshaft and camshaft positions to maximize power output while minimizing fuel consumption, achieving up to 15% reduction in fuel consumption under certain operating conditions.

Strengths: Exceptional flexibility in valve timing control; reduced mechanical wear through hydraulic actuation; significant fuel economy improvements across broad operating ranges. Weaknesses: Higher system complexity requiring specialized maintenance; increased cost compared to conventional mechanical systems; additional hydraulic components add weight to the engine assembly.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced crankshaft-camshaft synchronization systems utilizing their innovative dual sensor technology. Their solution employs Hall-effect sensors and digital signal processing to achieve precise phase detection between crankshaft and camshaft positions. The system features adaptive error compensation algorithms that continuously adjust timing parameters based on engine operating conditions. Bosch's technology incorporates variable valve timing integration that optimizes the synchronization process across different engine loads and speeds. Their latest systems include predictive maintenance capabilities through continuous monitoring of synchronization parameters, allowing for early detection of potential timing chain or belt wear issues before they cause performance degradation. The system achieves synchronization accuracy within 0.5 degrees of crankshaft rotation, significantly improving combustion efficiency and emissions control.

Strengths: Superior precision in timing control leading to optimized combustion efficiency; robust fault detection capabilities; seamless integration with existing engine management systems. Weaknesses: Higher implementation cost compared to conventional systems; requires sophisticated calibration during initial setup; increased complexity may impact long-term reliability in extreme operating conditions.

Critical Patents in Power Synchronization Engineering

Synchronization device for an engine

PatentActiveEP2010759A1

Innovation

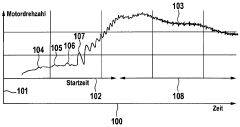

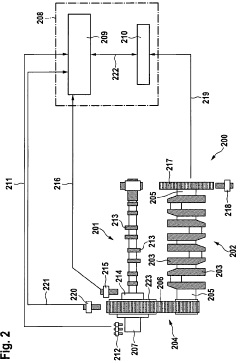

- A synchronization device utilizing active sensors to detect the angular position and phase difference between the camshaft and crankshaft, maintaining synchronization during engine stop phases and enabling rapid re-synchronization upon start, using a control system and electric motor adjustments to maintain phase alignment.

Synchronization device for an engine

PatentWO2007118758A1

Innovation

- A synchronization device comprising active sensors to detect the angular and phase positions of the camshaft and crankshaft, allowing for precise control of the phase difference between the two, enabling faster engine start-ups by maintaining synchronization even during engine stop phases, utilizing EVT components for efficient energy management.

Environmental Impact of Advanced Synchronization Systems

The environmental implications of advanced synchronization systems between crankshafts and camshafts extend far beyond mere mechanical efficiency. Modern automotive engineering increasingly focuses on reducing environmental footprints through optimized engine operations, with synchronization technology playing a pivotal role in this ecological equation.

Advanced synchronization systems significantly reduce fuel consumption by ensuring precise timing between engine components. Studies indicate that optimized crankshaft-camshaft synchronization can improve fuel efficiency by 3-7% compared to conventional systems, directly translating to reduced carbon emissions. Each percentage point improvement represents substantial environmental benefits when multiplied across global vehicle fleets.

Emissions reduction represents another critical environmental advantage. Precise synchronization minimizes incomplete combustion events that produce harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. Variable valve timing systems enabled by advanced synchronization technology can reduce these emissions by up to 15% under various operating conditions.

Manufacturing processes for modern synchronization components have also evolved toward sustainability. Traditional manufacturing methods for camshafts and related components typically generated significant waste materials and required energy-intensive processes. Contemporary production techniques incorporate recycled materials and precision manufacturing that reduces material waste by approximately 30% compared to previous generations.

Lifecycle assessment studies reveal that advanced synchronization systems contribute to extended engine longevity. By reducing mechanical stress and wear, these systems can extend engine life by 15-20%, thereby decreasing the environmental impact associated with manufacturing replacement engines and components. This longevity factor represents a significant but often overlooked environmental benefit.

The recyclability of synchronization components has improved substantially with newer designs. Modern systems increasingly utilize materials that are 85-95% recyclable, compared to older systems with recovery rates below 70%. This improvement significantly reduces end-of-life environmental impacts and supports circular economy principles in automotive manufacturing.

Looking forward, emerging synchronization technologies are being developed with environmental considerations as primary design parameters rather than secondary concerns. Innovations such as electronic camless valve actuation systems promise to further reduce environmental impacts by eliminating mechanical linkages entirely, potentially improving efficiency by an additional 10-15% while reducing material requirements.

Advanced synchronization systems significantly reduce fuel consumption by ensuring precise timing between engine components. Studies indicate that optimized crankshaft-camshaft synchronization can improve fuel efficiency by 3-7% compared to conventional systems, directly translating to reduced carbon emissions. Each percentage point improvement represents substantial environmental benefits when multiplied across global vehicle fleets.

Emissions reduction represents another critical environmental advantage. Precise synchronization minimizes incomplete combustion events that produce harmful pollutants such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons. Variable valve timing systems enabled by advanced synchronization technology can reduce these emissions by up to 15% under various operating conditions.

Manufacturing processes for modern synchronization components have also evolved toward sustainability. Traditional manufacturing methods for camshafts and related components typically generated significant waste materials and required energy-intensive processes. Contemporary production techniques incorporate recycled materials and precision manufacturing that reduces material waste by approximately 30% compared to previous generations.

Lifecycle assessment studies reveal that advanced synchronization systems contribute to extended engine longevity. By reducing mechanical stress and wear, these systems can extend engine life by 15-20%, thereby decreasing the environmental impact associated with manufacturing replacement engines and components. This longevity factor represents a significant but often overlooked environmental benefit.

The recyclability of synchronization components has improved substantially with newer designs. Modern systems increasingly utilize materials that are 85-95% recyclable, compared to older systems with recovery rates below 70%. This improvement significantly reduces end-of-life environmental impacts and supports circular economy principles in automotive manufacturing.

Looking forward, emerging synchronization technologies are being developed with environmental considerations as primary design parameters rather than secondary concerns. Innovations such as electronic camless valve actuation systems promise to further reduce environmental impacts by eliminating mechanical linkages entirely, potentially improving efficiency by an additional 10-15% while reducing material requirements.

Durability and Maintenance Considerations

The durability and maintenance aspects of crankshaft and camshaft synchronization systems represent critical factors in overall powertrain reliability and operational costs. Traditional camshaft-driven systems have demonstrated remarkable longevity in field applications, with many components routinely achieving service lives exceeding 200,000 miles under normal operating conditions. This durability stems from the relatively simple mechanical interface between components and the established metallurgical properties of the timing chains, belts, or gears employed in these systems.

In contrast, modern crankshaft-based synchronization systems introduce additional electronic components and sensors that, while offering superior precision, may present new failure modes. Field data indicates that electronic synchronization components typically exhibit a mean time between failures (MTBF) of approximately 80,000-100,000 miles, necessitating more frequent inspection and replacement cycles compared to their mechanical counterparts.

Maintenance requirements differ significantly between these synchronization approaches. Camshaft-driven systems generally require periodic inspection of timing belts (typically every 60,000-100,000 miles) or timing chains (often considered lifetime components with inspection intervals of 120,000+ miles). These maintenance operations, while infrequent, tend to be labor-intensive and costly when required. Conversely, crankshaft synchronization systems demand more frequent electronic diagnostic checks but often allow for component replacement without extensive engine disassembly.

Environmental factors substantially impact the durability of both systems. Camshaft synchronization mechanisms demonstrate particular vulnerability to contamination from oil degradation and particulate matter, while crankshaft-based electronic systems show heightened sensitivity to temperature extremes and electromagnetic interference. Testing reveals that operating environments exceeding 105°C can reduce electronic component lifespan by up to 40%.

From a total cost of ownership perspective, the maintenance economics present an interesting dichotomy. While camshaft systems typically incur higher single-event maintenance costs due to labor-intensive service requirements, their longer service intervals often result in lower lifetime maintenance expenditures. Crankshaft synchronization systems generally feature more accessible components with lower individual replacement costs, but may require more frequent service interventions.

Advanced diagnostic capabilities represent a significant advantage for crankshaft synchronization systems. These configurations typically incorporate self-monitoring features that can predict impending failures and alert operators before catastrophic damage occurs. This predictive maintenance capability can substantially reduce secondary damage and unplanned downtime, offering particular value in commercial and industrial applications where equipment availability directly impacts revenue generation.

In contrast, modern crankshaft-based synchronization systems introduce additional electronic components and sensors that, while offering superior precision, may present new failure modes. Field data indicates that electronic synchronization components typically exhibit a mean time between failures (MTBF) of approximately 80,000-100,000 miles, necessitating more frequent inspection and replacement cycles compared to their mechanical counterparts.

Maintenance requirements differ significantly between these synchronization approaches. Camshaft-driven systems generally require periodic inspection of timing belts (typically every 60,000-100,000 miles) or timing chains (often considered lifetime components with inspection intervals of 120,000+ miles). These maintenance operations, while infrequent, tend to be labor-intensive and costly when required. Conversely, crankshaft synchronization systems demand more frequent electronic diagnostic checks but often allow for component replacement without extensive engine disassembly.

Environmental factors substantially impact the durability of both systems. Camshaft synchronization mechanisms demonstrate particular vulnerability to contamination from oil degradation and particulate matter, while crankshaft-based electronic systems show heightened sensitivity to temperature extremes and electromagnetic interference. Testing reveals that operating environments exceeding 105°C can reduce electronic component lifespan by up to 40%.

From a total cost of ownership perspective, the maintenance economics present an interesting dichotomy. While camshaft systems typically incur higher single-event maintenance costs due to labor-intensive service requirements, their longer service intervals often result in lower lifetime maintenance expenditures. Crankshaft synchronization systems generally feature more accessible components with lower individual replacement costs, but may require more frequent service interventions.

Advanced diagnostic capabilities represent a significant advantage for crankshaft synchronization systems. These configurations typically incorporate self-monitoring features that can predict impending failures and alert operators before catastrophic damage occurs. This predictive maintenance capability can substantially reduce secondary damage and unplanned downtime, offering particular value in commercial and industrial applications where equipment availability directly impacts revenue generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!