Crankshaft vs Heat Exchanger: Efficiency Enhancement

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft and Heat Exchanger Technology Background

The evolution of mechanical systems has been marked by continuous innovation aimed at enhancing efficiency and performance. Crankshafts and heat exchangers represent two fundamental yet distinct components in mechanical engineering, each with its own historical trajectory and technological significance. The crankshaft, dating back to the Han Dynasty in China (around 2nd century BCE), evolved significantly during the Industrial Revolution when it became integral to steam engines and later internal combustion engines. This component translates linear motion into rotational motion, forming the backbone of modern engine technology.

Heat exchangers, meanwhile, emerged as critical components during the early 20th century with the advancement of industrial processes requiring efficient thermal management. Their development accelerated during World War II when aerospace and nuclear applications demanded more sophisticated heat transfer solutions. The fundamental principle of transferring thermal energy between two or more fluids at different temperatures has remained unchanged, though implementation methodologies have evolved dramatically.

The technological convergence of these components represents a fascinating area of study. While traditionally viewed as separate systems, modern engineering approaches increasingly recognize the potential synergies between crankshaft design and heat exchange efficiency. The thermal energy generated through crankshaft operation has historically been considered waste energy, but contemporary approaches seek to capture and utilize this thermal output through integrated heat exchange systems.

Current technological trends indicate a shift toward holistic system design where mechanical energy conversion (via crankshafts) and thermal energy management (via heat exchangers) are considered as interconnected rather than isolated processes. This paradigm shift is driven by increasing demands for energy efficiency, reduced emissions, and sustainable operation across industrial applications.

The advancement of materials science has significantly impacted both technologies. Modern crankshafts utilize high-strength alloys that can withstand extreme mechanical stress while maintaining optimal thermal properties. Similarly, heat exchanger technology has benefited from the development of advanced materials with superior thermal conductivity and corrosion resistance, enabling more compact and efficient designs.

Computational modeling and simulation have revolutionized the design process for both components. Finite element analysis and computational fluid dynamics now allow engineers to optimize crankshaft geometry for mechanical efficiency while simultaneously modeling heat transfer characteristics. This integrated approach to design represents a significant departure from traditional methodologies that treated mechanical and thermal systems as separate engineering challenges.

The technological goal in this field is to develop integrated systems that maximize overall efficiency by optimizing the relationship between mechanical energy conversion and thermal energy management. This objective aligns with broader industry trends toward energy conservation, emissions reduction, and sustainable engineering practices.

Heat exchangers, meanwhile, emerged as critical components during the early 20th century with the advancement of industrial processes requiring efficient thermal management. Their development accelerated during World War II when aerospace and nuclear applications demanded more sophisticated heat transfer solutions. The fundamental principle of transferring thermal energy between two or more fluids at different temperatures has remained unchanged, though implementation methodologies have evolved dramatically.

The technological convergence of these components represents a fascinating area of study. While traditionally viewed as separate systems, modern engineering approaches increasingly recognize the potential synergies between crankshaft design and heat exchange efficiency. The thermal energy generated through crankshaft operation has historically been considered waste energy, but contemporary approaches seek to capture and utilize this thermal output through integrated heat exchange systems.

Current technological trends indicate a shift toward holistic system design where mechanical energy conversion (via crankshafts) and thermal energy management (via heat exchangers) are considered as interconnected rather than isolated processes. This paradigm shift is driven by increasing demands for energy efficiency, reduced emissions, and sustainable operation across industrial applications.

The advancement of materials science has significantly impacted both technologies. Modern crankshafts utilize high-strength alloys that can withstand extreme mechanical stress while maintaining optimal thermal properties. Similarly, heat exchanger technology has benefited from the development of advanced materials with superior thermal conductivity and corrosion resistance, enabling more compact and efficient designs.

Computational modeling and simulation have revolutionized the design process for both components. Finite element analysis and computational fluid dynamics now allow engineers to optimize crankshaft geometry for mechanical efficiency while simultaneously modeling heat transfer characteristics. This integrated approach to design represents a significant departure from traditional methodologies that treated mechanical and thermal systems as separate engineering challenges.

The technological goal in this field is to develop integrated systems that maximize overall efficiency by optimizing the relationship between mechanical energy conversion and thermal energy management. This objective aligns with broader industry trends toward energy conservation, emissions reduction, and sustainable engineering practices.

Market Demand Analysis for Efficiency Enhancement

The global market for efficiency enhancement technologies in mechanical systems has witnessed substantial growth in recent years, driven by increasing energy costs, stringent environmental regulations, and the pursuit of operational cost reduction. The comparison between crankshaft mechanisms and heat exchangers represents a critical area of interest for industries seeking to optimize energy utilization and system performance.

Energy efficiency has become a paramount concern across industrial sectors, with the International Energy Agency reporting that industrial processes consume approximately 37% of global energy. This significant consumption creates a robust demand for technologies that can improve efficiency, particularly in power generation, automotive, manufacturing, and HVAC systems where both crankshaft mechanisms and heat exchangers are extensively utilized.

The automotive industry presents one of the largest markets for efficiency enhancement technologies. With over 80 million vehicles produced annually worldwide, manufacturers are under pressure to improve fuel efficiency and reduce emissions. Enhanced crankshaft designs that minimize friction losses and optimize power transfer can deliver fuel economy improvements of 2-5%, representing substantial savings across vehicle fleets and meeting increasingly stringent regulatory requirements.

Similarly, the industrial heat exchange market has been expanding at a compound annual growth rate of 6.8%, reaching a valuation exceeding $16 billion. This growth is fueled by the need for more efficient thermal management systems across power generation, chemical processing, and refrigeration industries. Advanced heat exchanger designs that minimize pressure drops and maximize heat transfer coefficients can reduce energy consumption by up to 30% compared to conventional designs.

The marine and shipping industry has also emerged as a significant market for efficiency enhancement technologies. With the International Maritime Organization mandating a 40% reduction in carbon intensity by 2030, ship operators are actively seeking solutions to improve propulsion efficiency through advanced crankshaft designs and waste heat recovery systems utilizing sophisticated heat exchangers.

Geographically, the demand for efficiency enhancement technologies shows distinct patterns. Mature markets in North America and Europe focus on retrofitting existing systems with more efficient components, while rapidly industrializing economies in Asia-Pacific, particularly China and India, incorporate these technologies into new installations. This regional variation creates diverse market opportunities for technology providers specializing in both crankshaft optimization and heat exchanger efficiency.

The market is further stimulated by the growing trend toward electrification and hybridization across multiple industries. This transition creates demand for systems that can efficiently convert between mechanical, thermal, and electrical energy domains, positioning advanced crankshaft mechanisms and heat exchangers as critical components in the energy conversion chain.

Energy efficiency has become a paramount concern across industrial sectors, with the International Energy Agency reporting that industrial processes consume approximately 37% of global energy. This significant consumption creates a robust demand for technologies that can improve efficiency, particularly in power generation, automotive, manufacturing, and HVAC systems where both crankshaft mechanisms and heat exchangers are extensively utilized.

The automotive industry presents one of the largest markets for efficiency enhancement technologies. With over 80 million vehicles produced annually worldwide, manufacturers are under pressure to improve fuel efficiency and reduce emissions. Enhanced crankshaft designs that minimize friction losses and optimize power transfer can deliver fuel economy improvements of 2-5%, representing substantial savings across vehicle fleets and meeting increasingly stringent regulatory requirements.

Similarly, the industrial heat exchange market has been expanding at a compound annual growth rate of 6.8%, reaching a valuation exceeding $16 billion. This growth is fueled by the need for more efficient thermal management systems across power generation, chemical processing, and refrigeration industries. Advanced heat exchanger designs that minimize pressure drops and maximize heat transfer coefficients can reduce energy consumption by up to 30% compared to conventional designs.

The marine and shipping industry has also emerged as a significant market for efficiency enhancement technologies. With the International Maritime Organization mandating a 40% reduction in carbon intensity by 2030, ship operators are actively seeking solutions to improve propulsion efficiency through advanced crankshaft designs and waste heat recovery systems utilizing sophisticated heat exchangers.

Geographically, the demand for efficiency enhancement technologies shows distinct patterns. Mature markets in North America and Europe focus on retrofitting existing systems with more efficient components, while rapidly industrializing economies in Asia-Pacific, particularly China and India, incorporate these technologies into new installations. This regional variation creates diverse market opportunities for technology providers specializing in both crankshaft optimization and heat exchanger efficiency.

The market is further stimulated by the growing trend toward electrification and hybridization across multiple industries. This transition creates demand for systems that can efficiently convert between mechanical, thermal, and electrical energy domains, positioning advanced crankshaft mechanisms and heat exchangers as critical components in the energy conversion chain.

Technical Challenges in Thermal-Mechanical Systems

The integration of crankshaft and heat exchanger systems presents significant technical challenges that require innovative solutions to enhance overall efficiency. Current thermal-mechanical systems face limitations in energy transfer, material compatibility, and operational stability under varying conditions. The primary challenge lies in the thermal gradient management between the mechanical components of crankshafts and the fluid dynamics within heat exchangers, creating a complex interplay that affects system performance.

Material science constraints represent a critical obstacle in this domain. Traditional materials used in crankshaft manufacturing, such as forged steel and nodular cast iron, exhibit different thermal expansion properties compared to heat exchanger materials like copper, aluminum, or specialized alloys. These discrepancies create stress points at interface junctions, leading to potential mechanical failures under thermal cycling conditions and reducing system longevity.

Fluid dynamics optimization presents another significant challenge. The integration of heat exchangers with crankshaft systems requires precise control of fluid flow patterns to maximize heat transfer efficiency while minimizing pressure drops. Current computational fluid dynamics (CFD) models struggle to accurately predict behavior in complex geometries where mechanical motion and thermal transfer occur simultaneously, resulting in suboptimal designs that fail to achieve theoretical efficiency limits.

Energy recovery mechanisms remain underdeveloped in existing systems. While waste heat represents a substantial energy source, current technologies capture only 20-30% of available thermal energy from crankshaft operations. The challenge involves developing more effective thermal interfaces and working fluid selections that can operate efficiently across the wide temperature ranges experienced in mechanical systems.

Miniaturization and space constraints further complicate integration efforts. Modern engineering applications, particularly in automotive and aerospace sectors, demand increasingly compact solutions while maintaining or improving performance metrics. Engineers face the difficult task of balancing thermal exchange surface area requirements against spatial limitations imposed by overall system design parameters.

Control system complexity increases exponentially when optimizing for both mechanical performance and thermal efficiency. Traditional control algorithms typically address these aspects separately, leading to suboptimal overall system performance. The development of integrated control strategies that simultaneously manage mechanical loading, thermal conditions, and fluid dynamics represents a frontier challenge requiring advanced computational approaches and sensor integration.

Manufacturing challenges also persist, as the production of integrated crankshaft-heat exchanger systems demands precision engineering across multiple material types and complex geometries. Current manufacturing techniques often require compromises that limit theoretical efficiency gains, particularly in mass production scenarios where cost considerations significantly impact design decisions.

Material science constraints represent a critical obstacle in this domain. Traditional materials used in crankshaft manufacturing, such as forged steel and nodular cast iron, exhibit different thermal expansion properties compared to heat exchanger materials like copper, aluminum, or specialized alloys. These discrepancies create stress points at interface junctions, leading to potential mechanical failures under thermal cycling conditions and reducing system longevity.

Fluid dynamics optimization presents another significant challenge. The integration of heat exchangers with crankshaft systems requires precise control of fluid flow patterns to maximize heat transfer efficiency while minimizing pressure drops. Current computational fluid dynamics (CFD) models struggle to accurately predict behavior in complex geometries where mechanical motion and thermal transfer occur simultaneously, resulting in suboptimal designs that fail to achieve theoretical efficiency limits.

Energy recovery mechanisms remain underdeveloped in existing systems. While waste heat represents a substantial energy source, current technologies capture only 20-30% of available thermal energy from crankshaft operations. The challenge involves developing more effective thermal interfaces and working fluid selections that can operate efficiently across the wide temperature ranges experienced in mechanical systems.

Miniaturization and space constraints further complicate integration efforts. Modern engineering applications, particularly in automotive and aerospace sectors, demand increasingly compact solutions while maintaining or improving performance metrics. Engineers face the difficult task of balancing thermal exchange surface area requirements against spatial limitations imposed by overall system design parameters.

Control system complexity increases exponentially when optimizing for both mechanical performance and thermal efficiency. Traditional control algorithms typically address these aspects separately, leading to suboptimal overall system performance. The development of integrated control strategies that simultaneously manage mechanical loading, thermal conditions, and fluid dynamics represents a frontier challenge requiring advanced computational approaches and sensor integration.

Manufacturing challenges also persist, as the production of integrated crankshaft-heat exchanger systems demands precision engineering across multiple material types and complex geometries. Current manufacturing techniques often require compromises that limit theoretical efficiency gains, particularly in mass production scenarios where cost considerations significantly impact design decisions.

Current Efficiency Enhancement Solutions

01 Crankshaft design optimization for improved efficiency

Various design modifications to crankshafts can significantly improve engine efficiency. These include optimized bearing surfaces, balanced weight distribution, and specialized materials that reduce friction and wear. Advanced manufacturing techniques allow for precise dimensional control and surface finishing, resulting in reduced energy losses during operation. These optimizations contribute to better overall engine performance and fuel economy.- Crankshaft design optimization for improved efficiency: Various design modifications to crankshafts can significantly improve engine efficiency. These include optimized bearing surfaces, reduced friction interfaces, and improved material selection. Advanced manufacturing techniques allow for more precise balancing and weight reduction while maintaining structural integrity. These design improvements contribute to reduced energy losses and improved overall engine performance.

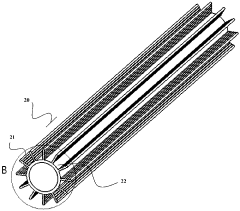

- Heat exchanger configurations for enhanced thermal transfer: Innovative heat exchanger configurations can substantially improve thermal transfer efficiency. These include modified tube arrangements, enhanced surface geometries, and optimized flow patterns. By increasing the contact surface area and improving fluid dynamics, these configurations enable more effective heat transfer with reduced energy input, resulting in higher overall system efficiency.

- Integration of crankshaft cooling systems with heat exchangers: Systems that integrate crankshaft cooling with heat exchangers can recover waste heat and improve overall efficiency. These systems utilize the thermal energy generated by the crankshaft operation to preheat other fluids or components. By capturing and repurposing waste heat, these integrated systems reduce energy consumption and improve the thermal management of the entire mechanical system.

- Advanced materials and coatings for efficiency improvement: The application of advanced materials and specialized coatings can significantly enhance both crankshaft durability and heat exchanger performance. These materials offer improved thermal conductivity, reduced friction, and enhanced corrosion resistance. Ceramic coatings, composite materials, and specialized alloys can extend component lifespan while simultaneously improving energy transfer efficiency and reducing maintenance requirements.

- Electronic control systems for optimized performance: Electronic control systems can dynamically adjust operating parameters to maximize efficiency in systems involving crankshafts and heat exchangers. These systems use sensors to monitor performance metrics and environmental conditions, then make real-time adjustments to optimize energy usage. Advanced algorithms can predict optimal operating conditions and proactively adjust system parameters to maintain peak efficiency across varying loads and conditions.

02 Heat exchanger configurations for enhanced thermal transfer

Innovative heat exchanger designs can maximize thermal transfer efficiency through optimized flow patterns and surface area utilization. Multi-pass configurations, turbulence-inducing features, and specialized tube arrangements help improve heat transfer coefficients while minimizing pressure drops. These designs enable more effective cooling or heating with reduced energy input, contributing to overall system efficiency in various applications including engine cooling systems.Expand Specific Solutions03 Integration of crankshaft systems with thermal management

Integrating crankshaft systems with thermal management solutions creates synergistic efficiency improvements. By incorporating cooling channels directly into crankshaft components or designing heat recovery systems that capture waste heat from crankshaft operation, overall system efficiency can be enhanced. These integrated approaches allow for better temperature control of critical components, reduced thermal stress, and potential energy recovery from otherwise wasted heat.Expand Specific Solutions04 Advanced materials and coatings for efficiency improvement

The application of advanced materials and specialized coatings can significantly improve both crankshaft durability and heat exchanger performance. Thermal barrier coatings, friction-reducing surface treatments, and corrosion-resistant alloys extend component lifespan while improving operational efficiency. These material innovations allow for higher operating temperatures, reduced friction losses, and enhanced heat transfer properties, contributing to overall system efficiency gains.Expand Specific Solutions05 Monitoring and control systems for optimized performance

Sophisticated monitoring and control systems can dynamically optimize the performance of both crankshafts and heat exchangers during operation. Sensors that track temperature, pressure, vibration, and flow rates provide real-time data for automated adjustment of operating parameters. These intelligent systems can anticipate changing conditions, prevent inefficient operation, and maintain optimal performance across varying loads, significantly improving overall system efficiency and reliability.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The automotive thermal management technology landscape is evolving rapidly, with the competition between crankshaft-based systems and heat exchangers representing a critical efficiency frontier. The market is in a growth phase, valued at approximately $45 billion globally with projected CAGR of 5-7% through 2030. Leading players like Valeo, DENSO, and MAHLE are advancing heat exchanger technologies, while BMW, Mercedes-Benz, and Honda focus on integrated crankshaft-thermal solutions. Technological maturity varies significantly: traditional crankshaft systems are well-established but reaching efficiency plateaus, while advanced heat exchangers from Hanon Systems, Modine, and Daikin are demonstrating superior thermal efficiency in newer applications. Conflux Technology and Resonac are pioneering additive manufacturing approaches, creating next-generation heat exchangers with complex geometries impossible with conventional manufacturing.

Behr GmbH & Co. KG

Technical Solution: Behr (now part of MAHLE Behr) has developed the Dual Circuit Cooling System (DCC) that revolutionizes the relationship between crankshaft performance and heat exchange efficiency. Their technology separates cooling circuits for the cylinder head and engine block, allowing for optimized temperature management in different engine regions. The system incorporates advanced heat exchangers with turbulence-inducing microstructures that enhance heat transfer coefficients by up to 35%. Behr's solution also features variable-speed electric water pumps that adjust flow rates based on real-time thermal demands, reducing parasitic losses on the crankshaft by approximately 25% compared to traditional belt-driven pumps. Their heat exchangers utilize advanced brazing techniques and optimized tube designs that maximize surface contact while minimizing pressure drops, resulting in more efficient heat transfer without additional pumping energy requirements.

Strengths: Precision temperature control for different engine components; reduced warm-up times leading to 3-7% fuel efficiency improvements in cold-start conditions; compatibility with both conventional and electrified powertrains. Weaknesses: Complex system architecture requiring additional sensors and control units; higher initial cost compared to traditional cooling systems; requires careful integration with engine management systems.

DENSO Corp.

Technical Solution: DENSO has pioneered the Advanced Thermal Management Integration (ATMI) system that optimizes the relationship between crankshaft operation and heat exchanger efficiency. Their solution features a variable-flow cooling system that precisely controls coolant circulation based on engine load and operating conditions. DENSO's heat exchangers incorporate their proprietary "wave fin" design that increases surface area by approximately 25% while maintaining compact dimensions. The system includes intelligent oil cooling technology that maintains optimal oil viscosity, reducing crankshaft friction by up to 20% across various operating temperatures. DENSO has also developed specialized coatings for heat exchanger surfaces that prevent fouling and scaling, maintaining thermal efficiency over extended periods. Their integrated approach connects multiple vehicle thermal systems (engine cooling, transmission cooling, cabin climate) through a central electronic control unit that optimizes overall energy usage and heat recovery.

Strengths: Holistic approach to vehicle thermal management; demonstrated fuel economy improvements of 3-8% in various driving cycles; excellent scalability across different vehicle platforms and powertrain types. Weaknesses: Requires sophisticated electronic controls and sensors; higher component complexity that may impact long-term reliability; optimal performance benefits require full system integration rather than component-level implementation.

Core Patents and Technical Innovations

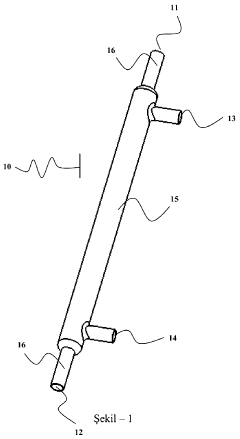

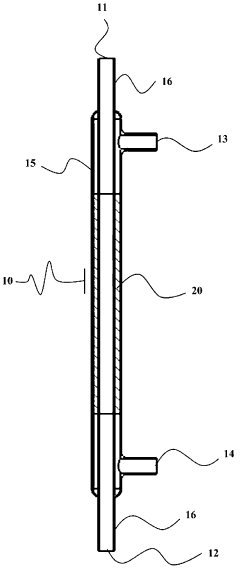

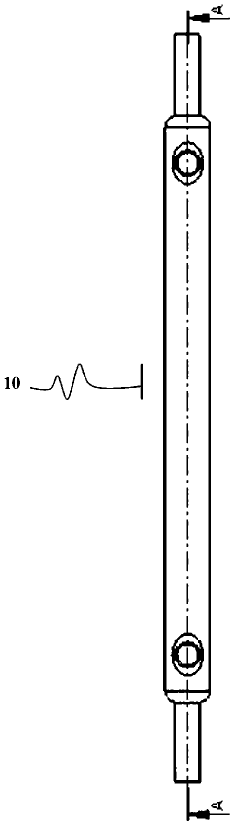

Fluid machinery, heat exchange apparatus, and operation method for fluid machinery

PatentPendingEP4446588A1

Innovation

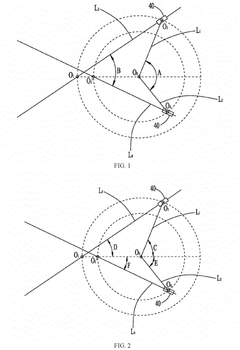

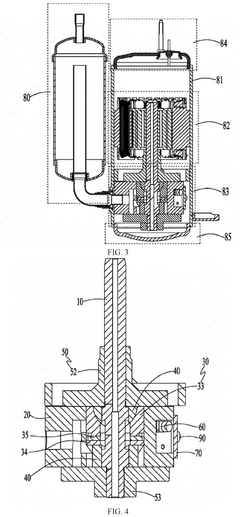

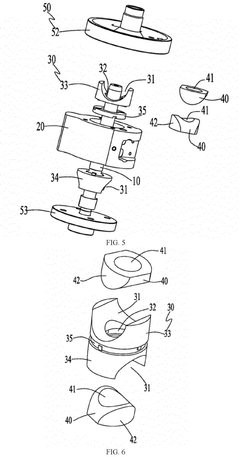

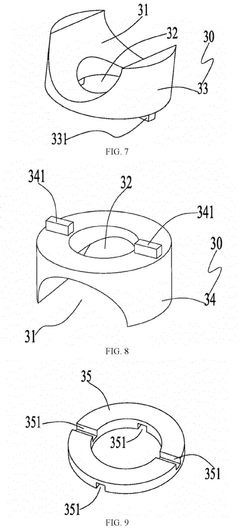

- The design incorporates a crankshaft with two eccentric parts and a crossed groove structure within the cylinder sleeve, featuring sliding blocks that interact to form a volume-variable cavity, allowing for stable operation by avoiding dead-point positions and maximizing driving torque, thus enhancing motion reliability and efficiency.

HIGH EFFICIENCY HEAT EXCHANGER

PatentInactiveTR201713450A2

Innovation

- A heat exchanger design featuring a finned transfer part with increased surface area and curved surfaces, utilizing aluminum and copper materials with high thermal conductivity, and separate paths for fluids to prevent evaporator gas return.

Materials Science Advancements for Performance Improvement

Recent advancements in materials science have significantly transformed the efficiency landscape for both crankshafts and heat exchangers. The development of novel composite materials has enabled crankshafts to withstand higher temperatures and mechanical stresses while maintaining structural integrity. Carbon fiber reinforced polymers (CFRPs) have emerged as promising alternatives to traditional steel crankshafts, offering weight reductions of up to 40% while maintaining comparable strength characteristics.

Ceramic matrix composites (CMCs) represent another breakthrough, particularly for heat exchanger applications. These materials combine the high-temperature resistance of ceramics with improved fracture toughness, addressing the historical brittleness limitations of pure ceramic components. Silicon carbide (SiC) and silicon nitride (Si3N4) based CMCs have demonstrated thermal conductivity improvements of 15-25% compared to conventional metal alloys, while simultaneously reducing thermal expansion issues.

Surface engineering technologies have evolved to enhance both component types. Advanced coating techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) allow for the application of ultra-thin protective layers that significantly reduce friction and wear. Diamond-like carbon (DLC) coatings applied to crankshaft bearing surfaces have shown friction reductions of up to 30%, directly translating to efficiency gains.

For heat exchangers, hydrophobic and oleophobic surface treatments have revolutionized performance by minimizing fouling and scaling—common problems that reduce heat transfer efficiency over time. Self-cleaning surfaces inspired by lotus leaf microstructures maintain optimal thermal conductivity for extended operational periods, reducing maintenance requirements and extending service intervals.

Nanomaterial integration represents the cutting edge of materials advancement for both applications. Graphene-enhanced metal matrices provide exceptional thermal conductivity for heat exchangers, while carbon nanotubes incorporated into crankshaft alloys deliver superior strength-to-weight ratios. These nanomaterials enable more compact designs without compromising performance, contributing to overall system efficiency.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. Machine learning algorithms now optimize material compositions for specific performance parameters, reducing the traditional trial-and-error approach. This has led to the creation of functionally graded materials (FGMs) that feature tailored properties across different regions of the same component, addressing the varying stress and thermal profiles experienced in real-world operation.

Ceramic matrix composites (CMCs) represent another breakthrough, particularly for heat exchanger applications. These materials combine the high-temperature resistance of ceramics with improved fracture toughness, addressing the historical brittleness limitations of pure ceramic components. Silicon carbide (SiC) and silicon nitride (Si3N4) based CMCs have demonstrated thermal conductivity improvements of 15-25% compared to conventional metal alloys, while simultaneously reducing thermal expansion issues.

Surface engineering technologies have evolved to enhance both component types. Advanced coating techniques such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) allow for the application of ultra-thin protective layers that significantly reduce friction and wear. Diamond-like carbon (DLC) coatings applied to crankshaft bearing surfaces have shown friction reductions of up to 30%, directly translating to efficiency gains.

For heat exchangers, hydrophobic and oleophobic surface treatments have revolutionized performance by minimizing fouling and scaling—common problems that reduce heat transfer efficiency over time. Self-cleaning surfaces inspired by lotus leaf microstructures maintain optimal thermal conductivity for extended operational periods, reducing maintenance requirements and extending service intervals.

Nanomaterial integration represents the cutting edge of materials advancement for both applications. Graphene-enhanced metal matrices provide exceptional thermal conductivity for heat exchangers, while carbon nanotubes incorporated into crankshaft alloys deliver superior strength-to-weight ratios. These nanomaterials enable more compact designs without compromising performance, contributing to overall system efficiency.

Computational materials science has accelerated development cycles through predictive modeling of material behavior under various operating conditions. Machine learning algorithms now optimize material compositions for specific performance parameters, reducing the traditional trial-and-error approach. This has led to the creation of functionally graded materials (FGMs) that feature tailored properties across different regions of the same component, addressing the varying stress and thermal profiles experienced in real-world operation.

Environmental Impact and Sustainability Considerations

The environmental implications of efficiency enhancement technologies in crankshaft and heat exchanger systems represent a critical dimension of modern engineering considerations. Traditional crankshaft systems in internal combustion engines have historically contributed significantly to greenhouse gas emissions and resource depletion through inefficient energy conversion processes. The thermal efficiency limitations of conventional crankshaft designs result in substantial heat waste, directly translating to increased carbon footprint per unit of useful work produced.

Heat exchanger technologies, by contrast, offer promising pathways toward reduced environmental impact through more effective thermal management. By recovering waste heat that would otherwise be released into the atmosphere, advanced heat exchanger systems can reduce primary energy consumption by 15-30% in typical industrial applications. This translates directly to proportional reductions in carbon dioxide, nitrogen oxides, and particulate matter emissions associated with fossil fuel combustion.

Material considerations also play a substantial role in the sustainability profile of both technologies. Modern crankshaft manufacturing typically involves energy-intensive processes and materials with significant embedded carbon, including specialized alloy steels and precision machining. Innovative heat exchanger designs increasingly incorporate recycled materials and manufacturing processes with lower environmental footprints, such as additive manufacturing techniques that minimize material waste.

Lifecycle assessment studies indicate that the environmental advantages of heat exchanger efficiency enhancements extend beyond operational benefits. The extended service life of properly designed heat recovery systems—often 15-20 years compared to 8-12 years for traditional crankshaft components—reduces the environmental burden associated with manufacturing replacement parts and system maintenance.

Water resource management represents another critical environmental consideration. Cooling systems associated with conventional crankshaft operations often require substantial water inputs, contributing to resource stress in water-scarce regions. Advanced heat exchanger technologies can implement closed-loop cooling systems that reduce freshwater consumption by up to 80% compared to once-through cooling approaches.

Regulatory frameworks increasingly recognize these environmental differentials, with carbon pricing mechanisms and emissions standards creating economic incentives that favor more efficient heat exchange technologies. The potential for heat exchangers to integrate with renewable energy systems further enhances their sustainability profile, enabling thermal energy storage capabilities that can address intermittency challenges in renewable power generation.

Heat exchanger technologies, by contrast, offer promising pathways toward reduced environmental impact through more effective thermal management. By recovering waste heat that would otherwise be released into the atmosphere, advanced heat exchanger systems can reduce primary energy consumption by 15-30% in typical industrial applications. This translates directly to proportional reductions in carbon dioxide, nitrogen oxides, and particulate matter emissions associated with fossil fuel combustion.

Material considerations also play a substantial role in the sustainability profile of both technologies. Modern crankshaft manufacturing typically involves energy-intensive processes and materials with significant embedded carbon, including specialized alloy steels and precision machining. Innovative heat exchanger designs increasingly incorporate recycled materials and manufacturing processes with lower environmental footprints, such as additive manufacturing techniques that minimize material waste.

Lifecycle assessment studies indicate that the environmental advantages of heat exchanger efficiency enhancements extend beyond operational benefits. The extended service life of properly designed heat recovery systems—often 15-20 years compared to 8-12 years for traditional crankshaft components—reduces the environmental burden associated with manufacturing replacement parts and system maintenance.

Water resource management represents another critical environmental consideration. Cooling systems associated with conventional crankshaft operations often require substantial water inputs, contributing to resource stress in water-scarce regions. Advanced heat exchanger technologies can implement closed-loop cooling systems that reduce freshwater consumption by up to 80% compared to once-through cooling approaches.

Regulatory frameworks increasingly recognize these environmental differentials, with carbon pricing mechanisms and emissions standards creating economic incentives that favor more efficient heat exchange technologies. The potential for heat exchangers to integrate with renewable energy systems further enhances their sustainability profile, enabling thermal energy storage capabilities that can address intermittency challenges in renewable power generation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!