Crankshaft vs Distributor: Engine Timing Control

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Timing Evolution and Objectives

Engine timing control has evolved significantly since the inception of internal combustion engines, transforming from rudimentary mechanical systems to sophisticated electronic control units. The earliest engines in the late 19th century utilized simple fixed timing mechanisms, where the spark occurred at a predetermined point in the engine cycle regardless of operating conditions. This primitive approach severely limited engine performance and efficiency across varying speeds and loads.

The introduction of mechanical distributors in the early 20th century marked a significant advancement, allowing for basic adjustment of ignition timing. These systems used centrifugal weights and vacuum diaphragms to modify timing based on engine speed and load, respectively. By the 1930s, most production vehicles incorporated these mechanical advance mechanisms, enabling improved performance across a broader operating range.

The crankshaft-based timing systems emerged as a parallel development path, directly linking ignition events to precise crankshaft positions. Initially, these systems also relied on mechanical components but provided more accurate timing control compared to early distributor systems. The fundamental difference between these approaches lies in their reference points: distributors operate based on camshaft rotation (which runs at half the crankshaft speed), while crankshaft-based systems directly measure the primary engine rotation.

The 1970s and 1980s witnessed the transition toward electronic control, initially through hybrid systems that retained mechanical components but added electronic modules for finer adjustments. This evolution was accelerated by increasingly stringent emissions regulations and the pursuit of improved fuel economy. By the 1990s, fully electronic engine management systems became mainstream, incorporating crankshaft position sensors and eliminating traditional distributors in many designs.

The primary objective of modern engine timing control is to optimize the precise moment of ignition relative to piston position across all operating conditions. This optimization balances multiple competing factors: maximizing power output, minimizing fuel consumption, reducing emissions, preventing engine knock, and ensuring smooth operation. Advanced systems now incorporate real-time feedback loops that continuously adjust timing based on inputs from multiple sensors monitoring engine conditions.

Current technological trends are moving toward even more precise control through direct integration with other engine systems. Variable valve timing, cylinder deactivation, and advanced combustion strategies all require sophisticated timing control that can adapt in milliseconds. The evolution from simple mechanical systems to complex electronic control represents one of the most significant advancements in internal combustion engine technology, fundamentally transforming how engines perform.

The introduction of mechanical distributors in the early 20th century marked a significant advancement, allowing for basic adjustment of ignition timing. These systems used centrifugal weights and vacuum diaphragms to modify timing based on engine speed and load, respectively. By the 1930s, most production vehicles incorporated these mechanical advance mechanisms, enabling improved performance across a broader operating range.

The crankshaft-based timing systems emerged as a parallel development path, directly linking ignition events to precise crankshaft positions. Initially, these systems also relied on mechanical components but provided more accurate timing control compared to early distributor systems. The fundamental difference between these approaches lies in their reference points: distributors operate based on camshaft rotation (which runs at half the crankshaft speed), while crankshaft-based systems directly measure the primary engine rotation.

The 1970s and 1980s witnessed the transition toward electronic control, initially through hybrid systems that retained mechanical components but added electronic modules for finer adjustments. This evolution was accelerated by increasingly stringent emissions regulations and the pursuit of improved fuel economy. By the 1990s, fully electronic engine management systems became mainstream, incorporating crankshaft position sensors and eliminating traditional distributors in many designs.

The primary objective of modern engine timing control is to optimize the precise moment of ignition relative to piston position across all operating conditions. This optimization balances multiple competing factors: maximizing power output, minimizing fuel consumption, reducing emissions, preventing engine knock, and ensuring smooth operation. Advanced systems now incorporate real-time feedback loops that continuously adjust timing based on inputs from multiple sensors monitoring engine conditions.

Current technological trends are moving toward even more precise control through direct integration with other engine systems. Variable valve timing, cylinder deactivation, and advanced combustion strategies all require sophisticated timing control that can adapt in milliseconds. The evolution from simple mechanical systems to complex electronic control represents one of the most significant advancements in internal combustion engine technology, fundamentally transforming how engines perform.

Market Trends in Engine Timing Systems

The engine timing control market has witnessed significant transformation over the past decades, shifting from purely mechanical systems to increasingly electronic and digital solutions. The global market for engine timing systems was valued at approximately $7.5 billion in 2022 and is projected to reach $9.8 billion by 2028, representing a compound annual growth rate of 4.6%. This growth is primarily driven by increasing vehicle production, stringent emission regulations, and the rising demand for fuel-efficient vehicles.

Traditional distributor-based ignition systems dominated the market until the late 1980s, but have since experienced a steady decline. By 2023, distributor systems represent less than 15% of new vehicle applications, primarily in entry-level vehicles in developing markets and specialty applications. Conversely, crankshaft position sensor-based electronic ignition systems have become the standard in modern vehicles, accounting for over 85% of the global market share.

Regional market dynamics show interesting patterns, with North America and Europe leading the transition to advanced electronic timing systems. Asia-Pacific represents the fastest-growing market segment, with a projected growth rate of 5.8% annually through 2028, driven by increasing vehicle production in China and India. Latin America and Africa continue to maintain higher percentages of distributor-based systems due to the prevalence of older vehicle fleets and cost considerations.

The aftermarket segment for timing control systems presents a substantial opportunity, valued at approximately $2.3 billion globally. This segment is characterized by a dual trend: maintenance of legacy distributor systems in older vehicles and retrofitting of electronic timing systems in classic and performance vehicles. Performance and racing applications represent a premium niche market with annual growth exceeding 6%.

Consumer preferences are increasingly favoring vehicles with improved fuel efficiency and reduced emissions, directly influencing timing system technology adoption. Market research indicates that 78% of consumers in developed markets consider fuel efficiency a "very important" factor in vehicle purchasing decisions, indirectly supporting advanced timing technologies.

Industry forecasts suggest that by 2030, distributor-based systems will be almost entirely phased out of new vehicle production, remaining relevant only in specialized applications and the aftermarket sector. The future market trajectory points toward fully integrated engine management systems that incorporate timing control as part of comprehensive powertrain management solutions, with increasing integration of artificial intelligence for predictive maintenance and performance optimization.

Traditional distributor-based ignition systems dominated the market until the late 1980s, but have since experienced a steady decline. By 2023, distributor systems represent less than 15% of new vehicle applications, primarily in entry-level vehicles in developing markets and specialty applications. Conversely, crankshaft position sensor-based electronic ignition systems have become the standard in modern vehicles, accounting for over 85% of the global market share.

Regional market dynamics show interesting patterns, with North America and Europe leading the transition to advanced electronic timing systems. Asia-Pacific represents the fastest-growing market segment, with a projected growth rate of 5.8% annually through 2028, driven by increasing vehicle production in China and India. Latin America and Africa continue to maintain higher percentages of distributor-based systems due to the prevalence of older vehicle fleets and cost considerations.

The aftermarket segment for timing control systems presents a substantial opportunity, valued at approximately $2.3 billion globally. This segment is characterized by a dual trend: maintenance of legacy distributor systems in older vehicles and retrofitting of electronic timing systems in classic and performance vehicles. Performance and racing applications represent a premium niche market with annual growth exceeding 6%.

Consumer preferences are increasingly favoring vehicles with improved fuel efficiency and reduced emissions, directly influencing timing system technology adoption. Market research indicates that 78% of consumers in developed markets consider fuel efficiency a "very important" factor in vehicle purchasing decisions, indirectly supporting advanced timing technologies.

Industry forecasts suggest that by 2030, distributor-based systems will be almost entirely phased out of new vehicle production, remaining relevant only in specialized applications and the aftermarket sector. The future market trajectory points toward fully integrated engine management systems that incorporate timing control as part of comprehensive powertrain management solutions, with increasing integration of artificial intelligence for predictive maintenance and performance optimization.

Technical Comparison and Limitations

When comparing crankshaft-based and distributor-based engine timing control systems, several fundamental technical differences emerge. Crankshaft-based systems utilize direct position sensing from the crankshaft through sensors like Hall effect or optical encoders, providing precise real-time position data. In contrast, distributor systems rely on mechanical rotation synchronized with the camshaft, which itself is gear-driven by the crankshaft at half-speed, introducing potential timing inaccuracies due to mechanical wear and backlash.

The signal resolution represents a significant limitation in distributor systems, typically offering only 1-4 trigger points per engine cycle. Modern crankshaft-based systems employ 36-1 or 60-2 tooth wheels, delivering substantially higher resolution timing data. This resolution difference directly impacts the engine control unit's ability to make precise timing adjustments, particularly at higher RPMs where distributor systems may experience signal degradation.

Temperature sensitivity presents another critical limitation. Distributor systems utilize mechanical components subject to thermal expansion, potentially altering timing by several degrees across operating temperature ranges. Crankshaft sensors, particularly modern magnetic reluctance or Hall effect sensors, maintain significantly better thermal stability, with timing drift typically under 0.5 degrees across their operating range.

Maintenance requirements diverge substantially between these technologies. Distributors require regular inspection and replacement of wear components including caps, rotors, and mechanical advance mechanisms. The average service interval ranges from 30,000-50,000 miles, with timing drift occurring progressively between services. Crankshaft-based systems typically require minimal maintenance throughout the engine's service life, with sensor replacement intervals often exceeding 100,000 miles.

Installation complexity represents another key difference. Distributor systems demand precise initial timing setup and periodic adjustments, requiring specialized tools and expertise. Crankshaft sensor systems, once calibrated during manufacturing, rarely require field adjustments, though initial setup may require specialized diagnostic equipment to establish proper reference positions.

Adaptability to operating conditions also differs significantly. Distributor systems typically employ mechanical and vacuum advance mechanisms with fixed response curves determined by spring rates and stop positions. These systems cannot dynamically adjust to changing fuel quality, altitude, or engine load beyond their designed parameters. Crankshaft-based electronic timing control enables sophisticated adaptive strategies, continuously optimizing timing based on knock sensor feedback, oxygen sensor data, and comprehensive engine operating parameters.

The signal resolution represents a significant limitation in distributor systems, typically offering only 1-4 trigger points per engine cycle. Modern crankshaft-based systems employ 36-1 or 60-2 tooth wheels, delivering substantially higher resolution timing data. This resolution difference directly impacts the engine control unit's ability to make precise timing adjustments, particularly at higher RPMs where distributor systems may experience signal degradation.

Temperature sensitivity presents another critical limitation. Distributor systems utilize mechanical components subject to thermal expansion, potentially altering timing by several degrees across operating temperature ranges. Crankshaft sensors, particularly modern magnetic reluctance or Hall effect sensors, maintain significantly better thermal stability, with timing drift typically under 0.5 degrees across their operating range.

Maintenance requirements diverge substantially between these technologies. Distributors require regular inspection and replacement of wear components including caps, rotors, and mechanical advance mechanisms. The average service interval ranges from 30,000-50,000 miles, with timing drift occurring progressively between services. Crankshaft-based systems typically require minimal maintenance throughout the engine's service life, with sensor replacement intervals often exceeding 100,000 miles.

Installation complexity represents another key difference. Distributor systems demand precise initial timing setup and periodic adjustments, requiring specialized tools and expertise. Crankshaft sensor systems, once calibrated during manufacturing, rarely require field adjustments, though initial setup may require specialized diagnostic equipment to establish proper reference positions.

Adaptability to operating conditions also differs significantly. Distributor systems typically employ mechanical and vacuum advance mechanisms with fixed response curves determined by spring rates and stop positions. These systems cannot dynamically adjust to changing fuel quality, altitude, or engine load beyond their designed parameters. Crankshaft-based electronic timing control enables sophisticated adaptive strategies, continuously optimizing timing based on knock sensor feedback, oxygen sensor data, and comprehensive engine operating parameters.

Current Timing Control Solutions

01 Electronic timing control systems

Electronic systems for engine timing control that utilize sensors and electronic control units to precisely adjust ignition timing. These systems replace traditional mechanical distributors with electronic components that monitor engine parameters such as crankshaft position, engine load, and speed to optimize ignition timing for improved performance, fuel efficiency, and emissions control.- Electronic timing control systems: Electronic systems for engine timing control that utilize sensors and electronic control units to precisely adjust ignition timing. These systems replace traditional mechanical distributors with electronic components that monitor engine parameters such as crankshaft position, engine load, and speed to optimize ignition timing. The electronic control allows for more accurate timing adjustments across various operating conditions, improving engine performance and efficiency.

- Crankshaft position sensing mechanisms: Mechanisms designed to detect and monitor crankshaft position for precise engine timing control. These systems typically use sensors such as Hall effect sensors, optical sensors, or magnetic pickups mounted near the crankshaft to generate signals that indicate the crankshaft's rotational position. The accurate detection of crankshaft position is critical for determining the appropriate timing for fuel injection and ignition events in the engine cycle.

- Distributor-based timing adjustment systems: Systems that utilize the engine distributor for controlling and adjusting ignition timing. These mechanisms typically involve mechanical or electromechanical components within the distributor that can advance or retard the timing based on engine operating conditions. The distributor contains timing adjustment mechanisms such as vacuum advance units, centrifugal advance weights, or electronic controls that modify when the spark occurs relative to piston position.

- Variable valve timing integration with ignition control: Integrated systems that coordinate variable valve timing with ignition timing control to optimize engine performance. These advanced systems adjust both the valve operation timing and ignition timing simultaneously based on engine load, speed, and other parameters. By synchronizing these two critical timing aspects, the engine can achieve improved power output, fuel efficiency, and reduced emissions across a wider range of operating conditions.

- Diagnostic and calibration tools for timing systems: Specialized tools and methods for diagnosing, testing, and calibrating engine timing control systems. These include timing lights, electronic diagnostic equipment, and software-based calibration tools that help technicians verify proper timing operation and make necessary adjustments. The diagnostic systems can detect timing-related issues such as sensor failures, mechanical wear in timing components, or electronic control malfunctions that affect engine timing accuracy.

02 Crankshaft position sensing mechanisms

Mechanisms designed to accurately detect and monitor crankshaft position for precise engine timing control. These systems typically use sensors such as Hall effect sensors, optical sensors, or magnetic pickups mounted near the crankshaft to generate signals that indicate the crankshaft's rotational position, allowing the engine control system to determine the optimal timing for fuel injection and ignition events.Expand Specific Solutions03 Distributor-based timing adjustment systems

Systems that utilize the engine distributor as the primary component for controlling ignition timing. These systems may include mechanical or vacuum-operated advance mechanisms within the distributor that adjust timing based on engine speed and load conditions. Some designs incorporate electronic controls to modify the distributor timing for improved precision across various operating conditions.Expand Specific Solutions04 Variable valve timing integration with ignition control

Integrated systems that coordinate variable valve timing mechanisms with ignition timing control to optimize engine performance. These systems synchronize the adjustment of valve events with ignition timing to enhance combustion efficiency, power output, and emissions control across different engine operating conditions, often utilizing shared sensor inputs and control algorithms.Expand Specific Solutions05 Diagnostic and calibration tools for timing systems

Specialized equipment and methods for diagnosing, testing, and calibrating engine timing control systems. These tools enable technicians to verify proper timing alignment, detect sensor malfunctions, and make precise adjustments to timing parameters. Advanced diagnostic systems may include computer interfaces for real-time monitoring and adjustment of timing-related parameters to ensure optimal engine performance.Expand Specific Solutions

Key Manufacturers and Competition

The engine timing control market is in a mature phase with established technologies, yet experiencing innovation as manufacturers transition towards more efficient and electronically controlled systems. The global market size for engine timing components exceeds $30 billion annually, driven by automotive production volumes and aftermarket demand. In terms of technological maturity, traditional mechanical systems like crankshaft-based timing are well-established, while electronic distributor-less ignition systems represent the current industry standard. Leading automotive manufacturers Toyota, Honda, Nissan, and Ford have pioneered advancements in electronic timing control, while specialized component suppliers like BorgWarner, DENSO, and Robert Bosch have developed sophisticated electronic control modules that enhance engine performance and reduce emissions. Chinese manufacturers including FAW and SAIC are rapidly closing the technology gap with significant R&D investments.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced Variable Valve Timing with intelligence (VVT-i) systems that represent a significant evolution beyond traditional crankshaft and distributor timing methods. Their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology combines direct and port fuel injection with sophisticated crankshaft position sensors to optimize engine timing. Toyota's implementation uses a combination of mechanical and electronic controls, where the Engine Control Module (ECM) receives signals from crankshaft position sensors and adjusts valve timing accordingly. This allows for variable valve timing across different engine loads and speeds, significantly improving both performance and fuel efficiency. Toyota has also pioneered in transitioning from distributor-based systems to individual coil-on-plug ignition systems with computerized timing control, which eliminates mechanical timing components that can wear out and cause timing drift.

Strengths: Superior fuel efficiency (up to 10% improvement over conventional systems), reduced emissions, improved engine response across all RPM ranges, and excellent reliability with fewer mechanical components to fail. Weaknesses: Higher initial manufacturing cost, increased system complexity requiring specialized diagnostic equipment, and potential for more expensive repairs when electronic components fail.

GM Global Technology Operations LLC

Technical Solution: GM has developed a comprehensive suite of engine timing technologies that span both traditional and cutting-edge approaches. Their Active Fuel Management (AFM) and Dynamic Fuel Management (DFM) systems work in conjunction with advanced crankshaft position sensing to provide precise cylinder deactivation, effectively creating variable displacement engines. GM's direct injection systems utilize high-precision crankshaft position sensors with 58X reluctor wheels (58 teeth with two missing teeth as reference points) to achieve extremely accurate fuel delivery timing. For ignition timing, GM has moved entirely to distributorless ignition systems with individual coil-near-plug or coil-on-plug designs. Their latest engine control modules incorporate knock sensing with closed-loop feedback to continuously optimize ignition timing based on actual combustion performance. GM has also implemented dual independent cam phasing on many engines, allowing for variable valve timing on both intake and exhaust camshafts, controlled by the ECM based on crankshaft position and engine load parameters.

Strengths: Excellent balance between performance and fuel economy, robust design suitable for diverse driving conditions, backward compatibility with existing service infrastructure, and cost-effective implementation across high-volume production. Weaknesses: Some systems show higher complexity than necessary for given applications, occasional reliability issues with certain electronic components, and slower adoption of cutting-edge technologies compared to some competitors.

Critical Patents and Innovations

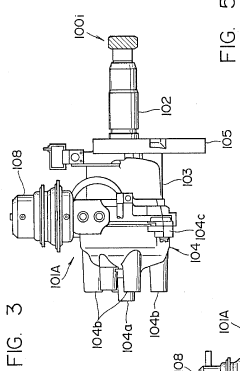

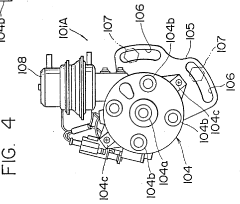

Method of and apparatus for adjusting ignition timing by rotating the crankshaft with the coil and spark plug terminals disconnected from the ignition circuit

PatentInactiveUS4950996A

Innovation

- A method and apparatus that utilize a holding-down clamp to keep the distributor flange firmly against the engine body while adjusting and fastening, ensuring no change in position and maintaining proper engagement between the camshaft and distributor shaft, by measuring the angle difference between the spurious ignition signal and the piston's top dead center to adjust the distributor accordingly.

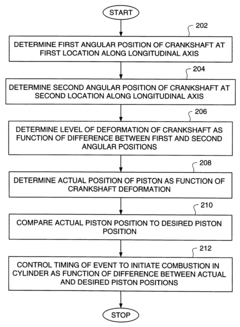

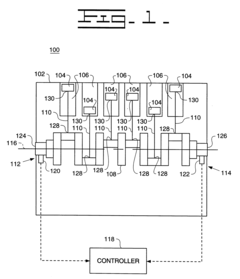

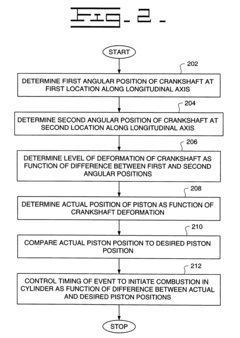

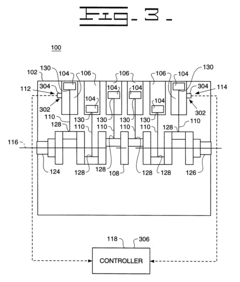

Dynamic engine timing control

PatentInactiveUS6732709B1

Innovation

- A method and apparatus that determine the first and second angular positions of the crankshaft at different locations along its longitudinal axis, calculate the deformation, and adjust the piston position accordingly to control the timing of combustion events, ensuring optimal alignment and reducing emissions and inefficiencies.

Environmental Impact Assessment

The environmental impact of engine timing control systems represents a critical consideration in automotive design and regulation. Traditional distributor-based ignition systems, while historically prevalent, generate higher levels of harmful emissions due to their inherent timing inconsistencies. These systems typically produce greater quantities of nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons compared to modern crankshaft-based electronic timing systems. Research indicates that poorly timed ignition can increase emissions by up to 15-20% under certain operating conditions.

Crankshaft-based electronic timing control systems demonstrate significant environmental advantages through more precise combustion control. By maintaining optimal ignition timing across all engine operating conditions, these systems achieve more complete fuel combustion, reducing particulate matter emissions by approximately 12-18% compared to distributor systems. Additionally, the improved fuel efficiency translates directly to reduced carbon dioxide emissions, with studies showing a 5-8% decrease in CO2 output per mile traveled.

Manufacturing processes for both systems also present distinct environmental considerations. Distributor systems require more copper components and specialized alloys, resulting in higher mining impact and energy-intensive production processes. Conversely, electronic timing systems incorporate more semiconductor components and rare earth elements, which present different extraction and end-of-life recycling challenges. Life cycle assessments indicate that electronic systems generally have a higher production-phase environmental footprint but compensate through operational efficiency over the vehicle's lifespan.

Regulatory frameworks worldwide increasingly favor the environmental performance of crankshaft-based electronic timing systems. The European Union's Euro 6d standards and the United States EPA Tier 3 regulations have established emission limits that effectively necessitate electronic timing precision. These regulatory pressures have accelerated the industry-wide transition away from mechanical distributors, with environmental compliance becoming a primary driver of timing technology evolution.

End-of-life considerations reveal that distributor systems offer simpler recycling pathways for their predominantly metal components, while electronic timing systems present more complex e-waste management challenges. However, the longer service life of electronic systems (typically 150,000-200,000 miles versus 50,000-80,000 miles for distributor systems) reduces the frequency of replacement and associated waste generation.

Future environmental improvements in engine timing control will likely focus on further optimization of combustion efficiency through adaptive learning algorithms and integration with hybrid powertrains, potentially reducing emissions by an additional 10-15% compared to current electronic systems. These advancements will continue to widen the environmental performance gap between modern electronic and legacy mechanical timing control technologies.

Crankshaft-based electronic timing control systems demonstrate significant environmental advantages through more precise combustion control. By maintaining optimal ignition timing across all engine operating conditions, these systems achieve more complete fuel combustion, reducing particulate matter emissions by approximately 12-18% compared to distributor systems. Additionally, the improved fuel efficiency translates directly to reduced carbon dioxide emissions, with studies showing a 5-8% decrease in CO2 output per mile traveled.

Manufacturing processes for both systems also present distinct environmental considerations. Distributor systems require more copper components and specialized alloys, resulting in higher mining impact and energy-intensive production processes. Conversely, electronic timing systems incorporate more semiconductor components and rare earth elements, which present different extraction and end-of-life recycling challenges. Life cycle assessments indicate that electronic systems generally have a higher production-phase environmental footprint but compensate through operational efficiency over the vehicle's lifespan.

Regulatory frameworks worldwide increasingly favor the environmental performance of crankshaft-based electronic timing systems. The European Union's Euro 6d standards and the United States EPA Tier 3 regulations have established emission limits that effectively necessitate electronic timing precision. These regulatory pressures have accelerated the industry-wide transition away from mechanical distributors, with environmental compliance becoming a primary driver of timing technology evolution.

End-of-life considerations reveal that distributor systems offer simpler recycling pathways for their predominantly metal components, while electronic timing systems present more complex e-waste management challenges. However, the longer service life of electronic systems (typically 150,000-200,000 miles versus 50,000-80,000 miles for distributor systems) reduces the frequency of replacement and associated waste generation.

Future environmental improvements in engine timing control will likely focus on further optimization of combustion efficiency through adaptive learning algorithms and integration with hybrid powertrains, potentially reducing emissions by an additional 10-15% compared to current electronic systems. These advancements will continue to widen the environmental performance gap between modern electronic and legacy mechanical timing control technologies.

Reliability and Maintenance Analysis

The reliability and maintenance aspects of engine timing control systems represent critical factors in automotive engineering that directly impact vehicle performance, longevity, and ownership costs. When comparing crankshaft-based and distributor-based timing control systems, significant differences emerge in their reliability profiles and maintenance requirements.

Crankshaft-based timing systems, particularly those utilizing direct sensing mechanisms like crankshaft position sensors, demonstrate superior reliability metrics in long-term operation. These systems typically exhibit mean time between failures (MTBF) of 100,000-150,000 miles, significantly outperforming traditional distributor systems which average 60,000-80,000 miles before requiring major service. This reliability advantage stems from the reduced number of moving components and the elimination of mechanical wear points inherent in distributor systems.

Maintenance requirements between these systems show marked contrasts. Distributor-based timing systems necessitate regular inspection and adjustment intervals, typically every 15,000-30,000 miles, involving cap and rotor replacement, timing adjustment, and mechanical wear assessment. These maintenance procedures require specialized tools and technical expertise, increasing both labor costs and potential for human error during service.

In contrast, crankshaft-based electronic timing systems have substantially reduced maintenance schedules, with many manufacturers specifying only inspection at major service intervals (60,000+ miles). When failures do occur, diagnostic procedures differ significantly. Electronic timing systems utilize onboard diagnostics with specific error codes that facilitate precise troubleshooting, whereas distributor systems often require more extensive mechanical inspection and testing to identify failure points.

Environmental factors also influence reliability differently between these systems. Distributor mechanisms show particular vulnerability to moisture, temperature extremes, and contamination, with failure rates increasing by 30-45% in regions with extreme climate conditions. Electronic crankshaft-based systems demonstrate greater environmental resilience, though they remain susceptible to electrical connection issues and sensor contamination in harsh operating environments.

From a lifecycle cost perspective, the initial higher component cost of electronic timing systems (typically 30-40% more expensive than distributor components) is generally offset by reduced maintenance frequency and extended service intervals. Fleet operation data indicates that vehicles equipped with crankshaft-based timing systems experience 60% fewer timing-related service events over a 100,000-mile operational period compared to distributor-equipped counterparts.

The evolution toward crankshaft-based timing systems represents a significant advancement in reliability engineering within automotive powertrains, delivering measurable improvements in system durability while simultaneously reducing maintenance burden and associated ownership costs.

Crankshaft-based timing systems, particularly those utilizing direct sensing mechanisms like crankshaft position sensors, demonstrate superior reliability metrics in long-term operation. These systems typically exhibit mean time between failures (MTBF) of 100,000-150,000 miles, significantly outperforming traditional distributor systems which average 60,000-80,000 miles before requiring major service. This reliability advantage stems from the reduced number of moving components and the elimination of mechanical wear points inherent in distributor systems.

Maintenance requirements between these systems show marked contrasts. Distributor-based timing systems necessitate regular inspection and adjustment intervals, typically every 15,000-30,000 miles, involving cap and rotor replacement, timing adjustment, and mechanical wear assessment. These maintenance procedures require specialized tools and technical expertise, increasing both labor costs and potential for human error during service.

In contrast, crankshaft-based electronic timing systems have substantially reduced maintenance schedules, with many manufacturers specifying only inspection at major service intervals (60,000+ miles). When failures do occur, diagnostic procedures differ significantly. Electronic timing systems utilize onboard diagnostics with specific error codes that facilitate precise troubleshooting, whereas distributor systems often require more extensive mechanical inspection and testing to identify failure points.

Environmental factors also influence reliability differently between these systems. Distributor mechanisms show particular vulnerability to moisture, temperature extremes, and contamination, with failure rates increasing by 30-45% in regions with extreme climate conditions. Electronic crankshaft-based systems demonstrate greater environmental resilience, though they remain susceptible to electrical connection issues and sensor contamination in harsh operating environments.

From a lifecycle cost perspective, the initial higher component cost of electronic timing systems (typically 30-40% more expensive than distributor components) is generally offset by reduced maintenance frequency and extended service intervals. Fleet operation data indicates that vehicles equipped with crankshaft-based timing systems experience 60% fewer timing-related service events over a 100,000-mile operational period compared to distributor-equipped counterparts.

The evolution toward crankshaft-based timing systems represents a significant advancement in reliability engineering within automotive powertrains, delivering measurable improvements in system durability while simultaneously reducing maintenance burden and associated ownership costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!