How to Simplify Crankshaft Machining Tolerances

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Machining Evolution and Precision Goals

Crankshaft manufacturing has undergone significant evolution since the early days of internal combustion engines. Initially, crankshafts were produced through labor-intensive forging and manual machining processes with relatively loose tolerances of ±0.1mm or greater. The post-World War II era saw the introduction of automated machining centers that improved precision to approximately ±0.05mm, marking a substantial advancement in manufacturing capability.

The 1970s and 1980s brought computer numerical control (CNC) technology to crankshaft production, enabling tolerances to reach ±0.02mm. This technological leap allowed for more consistent quality and higher production volumes to meet growing automotive industry demands. By the 1990s, the integration of in-line measurement systems and adaptive machining techniques further refined tolerances to ±0.01mm, significantly enhancing engine performance and durability.

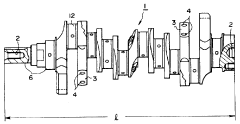

Today's modern crankshaft manufacturing employs multi-axis machining centers with advanced tooling materials and sophisticated process control systems. Current industry standards typically require main bearing journal tolerances of ±0.005mm and crankpin journal tolerances of ±0.008mm. These tight specifications ensure optimal engine balance, reduced vibration, and extended service life across various operating conditions.

The precision goals for crankshaft manufacturing continue to evolve in response to increasing demands for engine efficiency, emissions reduction, and performance optimization. Current technical objectives include achieving consistent journal roundness within 0.003mm, surface finish quality of Ra 0.2μm or better, and bearing-to-bearing alignment within 0.004mm total indicated runout (TIR).

Future precision targets are being driven by several factors: the need for lighter crankshafts to reduce reciprocating mass, higher combustion pressures in downsized engines, and extended durability requirements. Industry roadmaps suggest pushing tolerances to ±0.003mm for critical dimensions by 2025, with particular emphasis on geometric form control rather than just dimensional accuracy.

The simplification of crankshaft machining tolerances represents a paradoxical challenge—maintaining or improving functional performance while potentially relaxing certain non-critical tolerances to reduce manufacturing costs. This requires sophisticated understanding of the relationship between manufacturing variations and functional performance, supported by advanced simulation tools and statistical process control methodologies.

The 1970s and 1980s brought computer numerical control (CNC) technology to crankshaft production, enabling tolerances to reach ±0.02mm. This technological leap allowed for more consistent quality and higher production volumes to meet growing automotive industry demands. By the 1990s, the integration of in-line measurement systems and adaptive machining techniques further refined tolerances to ±0.01mm, significantly enhancing engine performance and durability.

Today's modern crankshaft manufacturing employs multi-axis machining centers with advanced tooling materials and sophisticated process control systems. Current industry standards typically require main bearing journal tolerances of ±0.005mm and crankpin journal tolerances of ±0.008mm. These tight specifications ensure optimal engine balance, reduced vibration, and extended service life across various operating conditions.

The precision goals for crankshaft manufacturing continue to evolve in response to increasing demands for engine efficiency, emissions reduction, and performance optimization. Current technical objectives include achieving consistent journal roundness within 0.003mm, surface finish quality of Ra 0.2μm or better, and bearing-to-bearing alignment within 0.004mm total indicated runout (TIR).

Future precision targets are being driven by several factors: the need for lighter crankshafts to reduce reciprocating mass, higher combustion pressures in downsized engines, and extended durability requirements. Industry roadmaps suggest pushing tolerances to ±0.003mm for critical dimensions by 2025, with particular emphasis on geometric form control rather than just dimensional accuracy.

The simplification of crankshaft machining tolerances represents a paradoxical challenge—maintaining or improving functional performance while potentially relaxing certain non-critical tolerances to reduce manufacturing costs. This requires sophisticated understanding of the relationship between manufacturing variations and functional performance, supported by advanced simulation tools and statistical process control methodologies.

Market Demand Analysis for Simplified Crankshaft Manufacturing

The global crankshaft manufacturing market is experiencing significant transformation driven by automotive and industrial machinery sectors' evolving demands. Current market analysis indicates a growing preference for simplified manufacturing processes that maintain precision while reducing production costs. The automotive industry, representing approximately 65% of the crankshaft market, is particularly vocal about the need for optimized machining tolerances that can accelerate production cycles without compromising structural integrity.

Market research reveals that manufacturers are facing increasing pressure to reduce production time and material waste while maintaining high-quality standards. Traditional crankshaft manufacturing processes often involve complex machining operations with extremely tight tolerances, resulting in extended production cycles and higher costs. Industry surveys indicate that manufacturing efficiency improvements of even 5-10% in crankshaft production can translate to substantial cost savings across production lines.

The heavy equipment and industrial machinery segments demonstrate growing demand for crankshafts with simplified tolerance specifications that still meet performance requirements. These sectors value manufacturing approaches that reduce complexity while ensuring reliability under demanding operational conditions. Market feedback suggests that manufacturers who can deliver such solutions gain significant competitive advantages in terms of production capacity and pricing flexibility.

Regional market analysis shows varying demands across different manufacturing hubs. European manufacturers emphasize precision and durability, while Asian markets prioritize cost-effectiveness and production speed. North American manufacturers seek balanced solutions that optimize both quality and production efficiency. This regional variation creates diverse market opportunities for simplified crankshaft machining technologies tailored to specific regional priorities.

Economic factors are also driving market demand for simplified machining tolerances. Rising labor costs in traditional manufacturing centers have accelerated the need for more efficient production methods. Additionally, fluctuating raw material prices have pushed manufacturers to seek processes that minimize material waste through optimized machining approaches. Industry experts project that technologies enabling simplified tolerance management could reduce overall production costs by 7-12%.

Market forecasts indicate that the demand for simplified crankshaft manufacturing solutions will continue to grow at a compound annual rate exceeding the overall industry average. This growth is supported by the ongoing transition toward more fuel-efficient engines and electric vehicle powertrains, which require different crankshaft specifications but still benefit from simplified manufacturing approaches. Manufacturers who can develop and implement these simplified tolerance systems stand to capture significant market share in this evolving landscape.

Market research reveals that manufacturers are facing increasing pressure to reduce production time and material waste while maintaining high-quality standards. Traditional crankshaft manufacturing processes often involve complex machining operations with extremely tight tolerances, resulting in extended production cycles and higher costs. Industry surveys indicate that manufacturing efficiency improvements of even 5-10% in crankshaft production can translate to substantial cost savings across production lines.

The heavy equipment and industrial machinery segments demonstrate growing demand for crankshafts with simplified tolerance specifications that still meet performance requirements. These sectors value manufacturing approaches that reduce complexity while ensuring reliability under demanding operational conditions. Market feedback suggests that manufacturers who can deliver such solutions gain significant competitive advantages in terms of production capacity and pricing flexibility.

Regional market analysis shows varying demands across different manufacturing hubs. European manufacturers emphasize precision and durability, while Asian markets prioritize cost-effectiveness and production speed. North American manufacturers seek balanced solutions that optimize both quality and production efficiency. This regional variation creates diverse market opportunities for simplified crankshaft machining technologies tailored to specific regional priorities.

Economic factors are also driving market demand for simplified machining tolerances. Rising labor costs in traditional manufacturing centers have accelerated the need for more efficient production methods. Additionally, fluctuating raw material prices have pushed manufacturers to seek processes that minimize material waste through optimized machining approaches. Industry experts project that technologies enabling simplified tolerance management could reduce overall production costs by 7-12%.

Market forecasts indicate that the demand for simplified crankshaft manufacturing solutions will continue to grow at a compound annual rate exceeding the overall industry average. This growth is supported by the ongoing transition toward more fuel-efficient engines and electric vehicle powertrains, which require different crankshaft specifications but still benefit from simplified manufacturing approaches. Manufacturers who can develop and implement these simplified tolerance systems stand to capture significant market share in this evolving landscape.

Current Challenges in Crankshaft Tolerance Control

Crankshaft manufacturing faces significant challenges in tolerance control due to the component's complex geometry and critical functional requirements. Current machining processes require extremely tight tolerances, typically ranging from 5-10 microns for main bearing journals and 10-15 microns for connecting rod journals. These stringent requirements stem from the crankshaft's role in converting linear piston motion to rotational motion while maintaining precise balance and alignment within the engine system.

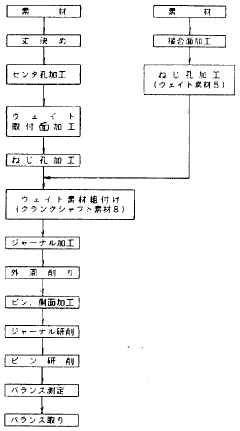

The primary challenge lies in maintaining consistent dimensional accuracy across multiple machining operations. Crankshafts undergo numerous processing steps including forging or casting, rough machining, heat treatment, straightening, finish machining, and final grinding. Each operation introduces potential for cumulative errors, with thermal distortion during heat treatment being particularly problematic as it can cause unpredictable dimensional changes of up to 0.2mm.

Material inconsistency presents another significant obstacle. Variations in material composition and microstructure, especially in forged crankshafts, lead to different machining characteristics across batches and even within the same component. These variations necessitate adaptive machining strategies and frequent tool adjustments, increasing production complexity and cost.

The geometric complexity of crankshafts further complicates tolerance control. The offset arrangement of journals, counterweights, and oil passages creates asymmetric structures that are difficult to fixture consistently. Current fixturing methods struggle to provide uniform support during machining, resulting in deflection under cutting forces that can reach up to 1000N during heavy roughing operations.

Measurement and verification processes also present challenges. Traditional coordinate measuring machines (CMMs) require significant time for comprehensive inspection, creating production bottlenecks. While in-process measurement systems exist, they often lack the accuracy needed for final verification, necessitating redundant inspection steps.

Economic pressures compound these technical challenges. The automotive industry's push for cost reduction conflicts with the need for precision machining. Current high-precision grinding operations can account for up to 30% of total manufacturing costs for crankshafts, yet remain essential for meeting functional requirements.

Environmental factors introduce additional variables. Temperature fluctuations in manufacturing facilities can cause thermal expansion of both the workpiece and machine tools, with each degree Celsius potentially causing dimensional variations of 1-2 microns. Modern facilities implement temperature control systems, but these add significant operational costs and energy consumption.

The industry currently lacks standardized approaches to tolerance simplification, with most manufacturers relying on proprietary methods developed through years of experience rather than systematic engineering approaches. This knowledge gap hinders broader implementation of optimized tolerance strategies across the industry.

The primary challenge lies in maintaining consistent dimensional accuracy across multiple machining operations. Crankshafts undergo numerous processing steps including forging or casting, rough machining, heat treatment, straightening, finish machining, and final grinding. Each operation introduces potential for cumulative errors, with thermal distortion during heat treatment being particularly problematic as it can cause unpredictable dimensional changes of up to 0.2mm.

Material inconsistency presents another significant obstacle. Variations in material composition and microstructure, especially in forged crankshafts, lead to different machining characteristics across batches and even within the same component. These variations necessitate adaptive machining strategies and frequent tool adjustments, increasing production complexity and cost.

The geometric complexity of crankshafts further complicates tolerance control. The offset arrangement of journals, counterweights, and oil passages creates asymmetric structures that are difficult to fixture consistently. Current fixturing methods struggle to provide uniform support during machining, resulting in deflection under cutting forces that can reach up to 1000N during heavy roughing operations.

Measurement and verification processes also present challenges. Traditional coordinate measuring machines (CMMs) require significant time for comprehensive inspection, creating production bottlenecks. While in-process measurement systems exist, they often lack the accuracy needed for final verification, necessitating redundant inspection steps.

Economic pressures compound these technical challenges. The automotive industry's push for cost reduction conflicts with the need for precision machining. Current high-precision grinding operations can account for up to 30% of total manufacturing costs for crankshafts, yet remain essential for meeting functional requirements.

Environmental factors introduce additional variables. Temperature fluctuations in manufacturing facilities can cause thermal expansion of both the workpiece and machine tools, with each degree Celsius potentially causing dimensional variations of 1-2 microns. Modern facilities implement temperature control systems, but these add significant operational costs and energy consumption.

The industry currently lacks standardized approaches to tolerance simplification, with most manufacturers relying on proprietary methods developed through years of experience rather than systematic engineering approaches. This knowledge gap hinders broader implementation of optimized tolerance strategies across the industry.

Current Tolerance Simplification Methodologies

01 Precision machining techniques for crankshaft tolerances

Advanced machining techniques are employed to achieve precise tolerances in crankshaft manufacturing. These techniques include specialized grinding processes, computer-controlled machining centers, and multi-axis turning operations that can maintain dimensional accuracy within micrometers. The precision machining ensures proper bearing clearances, reduces vibration, and extends engine life by creating consistent journal diameters and surface finishes.- Precision machining techniques for crankshaft tolerances: Various precision machining techniques are employed to achieve tight tolerances in crankshaft manufacturing. These include specialized grinding processes, CNC machining centers with high precision capabilities, and advanced measurement systems to ensure dimensional accuracy. These techniques help maintain critical tolerances for journal diameters, bearing surfaces, and overall crankshaft geometry, which are essential for proper engine performance and durability.

- Tolerance control for crankshaft journal surfaces: Specific tolerance control methods are implemented for crankshaft journal surfaces, which are critical for bearing performance and engine reliability. These methods include specialized grinding operations, surface finishing techniques, and precise measurement protocols to ensure roundness, cylindricity, and surface finish requirements are met. Maintaining tight tolerances on journal surfaces is essential for proper oil film formation, reduced friction, and extended bearing life in engine applications.

- Fixture and alignment systems for crankshaft machining: Advanced fixture and alignment systems are utilized to ensure proper positioning and support during crankshaft machining operations. These systems include specialized clamping mechanisms, centering devices, and support structures that minimize deflection and vibration during machining. Proper fixturing is critical for maintaining geometric tolerances such as straightness, parallelism, and concentricity between journal surfaces, which directly impact engine balance and performance.

- In-process measurement and quality control for crankshaft tolerances: In-process measurement and quality control systems are implemented to monitor and maintain crankshaft tolerances throughout the manufacturing process. These systems include automated gauging, optical measurement technologies, and statistical process control methods to detect and correct deviations before they result in non-conforming parts. Continuous monitoring ensures that critical dimensions such as journal diameters, fillet radii, and stroke dimensions remain within specified tolerance ranges.

- Heat treatment and stress relief processes for dimensional stability: Specialized heat treatment and stress relief processes are employed to ensure dimensional stability and maintain tolerances in finished crankshafts. These processes include controlled heating and cooling cycles, stress relieving operations, and thermal stabilization techniques that minimize distortion and dimensional changes. Proper thermal processing is essential for maintaining critical tolerances after machining operations and throughout the service life of the crankshaft.

02 Measurement and inspection systems for crankshaft tolerances

Sophisticated measurement and inspection systems are utilized to verify crankshaft tolerances during and after machining. These systems include laser measurement devices, coordinate measuring machines (CMMs), and automated optical inspection equipment that can detect deviations from specified tolerances. Real-time monitoring during the machining process allows for immediate adjustments to maintain dimensional accuracy and ensure compliance with strict tolerance requirements.Expand Specific Solutions03 Fixture and tooling designs for maintaining crankshaft tolerances

Specialized fixtures and tooling are designed to hold crankshafts securely during machining operations to maintain critical tolerances. These fixtures minimize deflection and vibration during cutting operations, ensuring consistent dimensional accuracy. Custom-designed cutting tools with specific geometries and coatings are employed to achieve the required surface finish and dimensional tolerances on journal surfaces and oil passages.Expand Specific Solutions04 Heat treatment and stress relief processes for dimensional stability

Heat treatment and stress relief processes are critical for maintaining crankshaft tolerances. These thermal processes help stabilize the metal structure, prevent warping, and ensure dimensional stability throughout the service life of the crankshaft. Controlled cooling techniques and tempering processes are employed to achieve the desired hardness while maintaining precise tolerances on bearing journals and counterweight dimensions.Expand Specific Solutions05 Automated machining processes for consistent crankshaft tolerances

Automated machining processes are implemented to ensure consistent crankshaft tolerances across production batches. These processes include robotic handling systems, automated tool changers, and computer numerical control (CNC) machining centers that follow precisely programmed toolpaths. The automation reduces human error, maintains consistent cutting parameters, and ensures repeatable tolerances in high-volume production environments.Expand Specific Solutions

Leading Manufacturers and Technology Providers

The crankshaft machining tolerance simplification market is currently in a growth phase, with increasing demand driven by automotive and industrial manufacturing sectors seeking cost reduction and efficiency improvements. The global market size for precision machining technologies is estimated at $15-20 billion, with crankshaft-specific solutions representing a significant segment. Leading automotive manufacturers like Toyota, Honda, Mercedes-Benz, and Mazda are driving innovation alongside specialized machine tool companies such as MAG Industrial Automation Systems, Boehringer Werkzeugmaschinen, and Erwin Junker Maschinenfabrik. Technology maturity varies across applications, with traditional machining approaches reaching maturity while advanced solutions incorporating AI-driven tolerance optimization and in-process measurement systems are still evolving. Component suppliers like Robert Bosch and Kennametal are developing specialized tooling solutions to address increasingly stringent tolerance requirements while reducing manufacturing complexity.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a proprietary crankshaft machining system that integrates advanced robotics with precision machining centers in a flexible manufacturing cell. Their approach focuses on statistical process control combined with automated in-process measurement to continuously optimize machining parameters. Honda's system employs specialized fixturing that references the crankshaft from its main bearing journals, establishing a consistent datum structure throughout the manufacturing process. A key innovation in their approach is the use of "functional tolerance zones" that prioritize critical geometric relationships affecting engine performance rather than applying uniform tolerances across all features. Honda's machining centers incorporate thermal stabilization systems that maintain consistent temperature throughout the machining cycle, with active compensation for thermal growth of both the machine structure and workpiece. Their process includes a unique two-stage rough-finishing strategy where initial operations establish geometric relationships between features, followed by finish operations that focus on surface quality and final dimensional accuracy. Honda has also pioneered the use of specialized cutting tools with optimized geometries specifically designed for crankshaft materials and features.

Strengths: Honda's system achieves exceptional balance between precision and production efficiency, with documented improvements in engine performance metrics including power output, fuel efficiency, and NVH characteristics. Their approach reduces the need for post-machining balancing operations by achieving more consistent mass distribution during the initial machining. Weaknesses: The system requires significant integration expertise and is optimized primarily for Honda's specific engine designs and production volumes, making it less adaptable for contract manufacturers or those with highly variable production requirements.

Boehringer Werkzeugmaschinen GmbH

Technical Solution: Boehringer Werkzeugmaschinen has pioneered a comprehensive crankshaft machining solution centered around their VDF series of specialized machine tools. Their technology incorporates hydrostatic guideways and bearings that virtually eliminate stick-slip effects during precision machining operations, allowing for more consistent surface finishes and dimensional accuracy. A key innovation is their "single-setup machining" approach where multiple operations (rough turning, finish turning, milling, and grinding) can be performed on a single machine, dramatically reducing the tolerance stack-up issues that typically occur when transferring workpieces between different machines. Boehringer's system employs thermal stabilization throughout the machine structure and workpiece, with active cooling systems that maintain temperature consistency to within ±0.5°C during the entire machining cycle. Their proprietary software algorithms compensate for predictable deflection patterns in both the machine structure and the crankshaft itself during various cutting operations, effectively "pre-distorting" the toolpath to achieve the desired final geometry.

Strengths: Their integrated approach significantly reduces setup errors and alignment issues between operations, resulting in up to 40% fewer quality rejections. The hydrostatic technology provides exceptional vibration damping, enabling higher material removal rates without sacrificing accuracy. Weaknesses: The specialized nature of their equipment makes it less flexible for manufacturers who produce a wide variety of crankshaft designs, and the initial capital investment is substantially higher than conventional machining centers.

Key Innovations in Precision Machining Technologies

Crankshaft machining and finishing

PatentInactiveEP1007276A1

Innovation

- Reducing the processing stages from three to two by eliminating grinding and using high-speed turning or milling methods for machining and finishing, with specific cutting edges to achieve close final dimensions and minimize material removal, thereby reducing costs and improving surface quality.

Machining method for builtup crankshaft

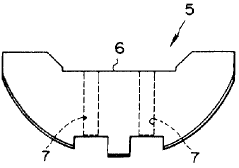

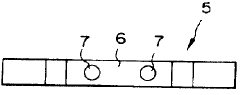

PatentInactiveJP1991204408A

Innovation

- The method involves forming a crankshaft body blank and integrating weight material machining steps, allowing for simultaneous processing and reduced assembly errors, thereby enabling effective balancing correction and simplifying the manufacturing process.

Cost-Benefit Analysis of Tolerance Optimization

Optimizing machining tolerances for crankshafts presents a significant opportunity for cost reduction while maintaining or improving product quality. The financial implications of tolerance adjustments must be thoroughly evaluated through comprehensive cost-benefit analysis to ensure optimal decision-making.

Initial investment in tolerance optimization typically includes engineering analysis costs, potential tooling modifications, and process validation expenses. These upfront costs range from $50,000 to $200,000 depending on production volume and complexity. However, these investments can yield substantial returns through reduced material waste, decreased machining time, and lower inspection requirements.

Manufacturing cost reductions represent the most immediate benefit of tolerance optimization. Studies across automotive manufacturing indicate that optimizing crankshaft tolerances can reduce machining time by 15-25%, translating to approximately $3-7 per unit in direct cost savings. For high-volume production facilities producing 100,000 units annually, this represents $300,000-$700,000 in annual savings from machining operations alone.

Quality-related costs show equally impressive improvements. Optimized tolerances lead to fewer rejections and rework requirements, with data from industry benchmarks suggesting a potential 30-40% reduction in quality-related expenses. This improvement stems from the elimination of unnecessarily tight tolerances that add no functional value but increase manufacturing complexity.

Lifecycle cost analysis reveals additional benefits beyond immediate production savings. Optimized crankshafts with appropriately specified tolerances demonstrate comparable or superior durability metrics, with warranty claim data showing no adverse effects when scientifically justified tolerance adjustments are implemented. In some cases, more appropriate tolerance specifications have actually improved performance by ensuring better balance between flexibility and rigidity where needed.

Return on investment calculations typically show breakeven periods of 6-18 months for tolerance optimization initiatives, with larger production volumes achieving faster returns. The net present value of these projects frequently exceeds initial investments by factors of 3-5 over a five-year period, making tolerance optimization one of the highest-yield engineering investments available to powertrain manufacturers.

Risk assessment must accompany any tolerance modification. The primary risk lies in potential performance degradation if tolerances are excessively relaxed. This risk can be effectively mitigated through comprehensive testing and validation protocols, gradually implementing changes with careful monitoring of performance metrics.

Initial investment in tolerance optimization typically includes engineering analysis costs, potential tooling modifications, and process validation expenses. These upfront costs range from $50,000 to $200,000 depending on production volume and complexity. However, these investments can yield substantial returns through reduced material waste, decreased machining time, and lower inspection requirements.

Manufacturing cost reductions represent the most immediate benefit of tolerance optimization. Studies across automotive manufacturing indicate that optimizing crankshaft tolerances can reduce machining time by 15-25%, translating to approximately $3-7 per unit in direct cost savings. For high-volume production facilities producing 100,000 units annually, this represents $300,000-$700,000 in annual savings from machining operations alone.

Quality-related costs show equally impressive improvements. Optimized tolerances lead to fewer rejections and rework requirements, with data from industry benchmarks suggesting a potential 30-40% reduction in quality-related expenses. This improvement stems from the elimination of unnecessarily tight tolerances that add no functional value but increase manufacturing complexity.

Lifecycle cost analysis reveals additional benefits beyond immediate production savings. Optimized crankshafts with appropriately specified tolerances demonstrate comparable or superior durability metrics, with warranty claim data showing no adverse effects when scientifically justified tolerance adjustments are implemented. In some cases, more appropriate tolerance specifications have actually improved performance by ensuring better balance between flexibility and rigidity where needed.

Return on investment calculations typically show breakeven periods of 6-18 months for tolerance optimization initiatives, with larger production volumes achieving faster returns. The net present value of these projects frequently exceeds initial investments by factors of 3-5 over a five-year period, making tolerance optimization one of the highest-yield engineering investments available to powertrain manufacturers.

Risk assessment must accompany any tolerance modification. The primary risk lies in potential performance degradation if tolerances are excessively relaxed. This risk can be effectively mitigated through comprehensive testing and validation protocols, gradually implementing changes with careful monitoring of performance metrics.

Material Science Advancements for Crankshaft Production

Recent advancements in material science have significantly impacted crankshaft production technologies, offering promising solutions to simplify machining tolerances. Traditional crankshaft manufacturing has relied heavily on steel alloys that require precise machining to achieve the necessary tolerances, often resulting in complex and costly production processes. However, emerging materials and treatment methods are changing this landscape dramatically.

High-strength aluminum alloys with enhanced wear resistance properties have been developed specifically for automotive components, including crankshafts. These alloys offer reduced weight while maintaining structural integrity, allowing for less stringent machining tolerances due to their superior dimensional stability during thermal cycling. The incorporation of silicon carbide particles in these aluminum matrices has further improved their performance characteristics.

Powder metallurgy techniques have revolutionized material composition control, enabling the creation of near-net-shape crankshafts with more homogeneous microstructures. This homogeneity reduces internal stresses and warping tendencies, thereby widening acceptable tolerance ranges during machining operations. Studies indicate that powder metallurgy crankshafts can maintain performance specifications with up to 15% broader tolerances compared to conventional forged components.

Surface treatment innovations have also contributed significantly to tolerance simplification. Advanced nitriding processes and thermal spray coatings can be applied to lower-precision machined surfaces, effectively compensating for wider tolerances while ensuring the necessary wear resistance and fatigue strength. These treatments create hardened surface layers without dimensional distortion, preserving the geometric integrity achieved during machining.

Composite materials represent another frontier in crankshaft production. Carbon fiber reinforced polymers (CFRP) with metal inserts at critical bearing surfaces are being explored for high-performance applications. While not yet mainstream, these hybrid materials demonstrate exceptional vibration damping properties and can be manufactured with wider tolerances due to their inherent flexibility in design parameters.

Nano-structured steel alloys have emerged as particularly promising for crankshaft applications. These materials feature grain structures refined to the nanometer scale, resulting in unprecedented combinations of strength, toughness, and machinability. The enhanced uniformity of these alloys allows for more predictable material behavior during machining, effectively widening the acceptable tolerance window without compromising performance specifications.

High-strength aluminum alloys with enhanced wear resistance properties have been developed specifically for automotive components, including crankshafts. These alloys offer reduced weight while maintaining structural integrity, allowing for less stringent machining tolerances due to their superior dimensional stability during thermal cycling. The incorporation of silicon carbide particles in these aluminum matrices has further improved their performance characteristics.

Powder metallurgy techniques have revolutionized material composition control, enabling the creation of near-net-shape crankshafts with more homogeneous microstructures. This homogeneity reduces internal stresses and warping tendencies, thereby widening acceptable tolerance ranges during machining operations. Studies indicate that powder metallurgy crankshafts can maintain performance specifications with up to 15% broader tolerances compared to conventional forged components.

Surface treatment innovations have also contributed significantly to tolerance simplification. Advanced nitriding processes and thermal spray coatings can be applied to lower-precision machined surfaces, effectively compensating for wider tolerances while ensuring the necessary wear resistance and fatigue strength. These treatments create hardened surface layers without dimensional distortion, preserving the geometric integrity achieved during machining.

Composite materials represent another frontier in crankshaft production. Carbon fiber reinforced polymers (CFRP) with metal inserts at critical bearing surfaces are being explored for high-performance applications. While not yet mainstream, these hybrid materials demonstrate exceptional vibration damping properties and can be manufactured with wider tolerances due to their inherent flexibility in design parameters.

Nano-structured steel alloys have emerged as particularly promising for crankshaft applications. These materials feature grain structures refined to the nanometer scale, resulting in unprecedented combinations of strength, toughness, and machinability. The enhanced uniformity of these alloys allows for more predictable material behavior during machining, effectively widening the acceptable tolerance window without compromising performance specifications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!