Crankshaft vs Turbocharger: Horsepower Gain Comparison

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Power Enhancement Technologies Background and Objectives

The evolution of internal combustion engine technology has been driven by the constant pursuit of greater power output, efficiency, and environmental sustainability. Since the invention of the first practical four-stroke engine by Nikolaus Otto in 1876, engineers have continuously sought methods to extract maximum power from a given engine displacement. The comparison between crankshaft modifications and turbocharger implementations represents a fundamental dichotomy in approaches to horsepower enhancement.

Historically, power enhancement initially focused on naturally aspirated solutions, with crankshaft design playing a crucial role in determining an engine's power characteristics. The crankshaft, as the primary component converting reciprocating motion into rotational force, directly influences torque production and power delivery. Early modifications centered on stroke length adjustments, counterweight balancing, and material improvements to withstand higher RPMs.

The development of forced induction systems, particularly turbochargers, marked a paradigm shift in engine power enhancement. First patented by Alfred Büchi in 1905, turbocharger technology saw limited application until the 1970s oil crisis drove manufacturers toward smaller, more efficient engines that could maintain performance standards. The technology utilizes exhaust gas energy to compress intake air, effectively increasing oxygen availability for combustion and consequently enhancing power output.

Current technological objectives in this domain focus on optimizing the balance between these approaches. Modern engineering seeks to determine which method—crankshaft optimization or turbocharging—delivers superior horsepower gains across different engine architectures and application scenarios. This comparison is particularly relevant as the automotive industry navigates the transition toward electrification while still seeking to maximize the potential of internal combustion technology.

The technical goals of this research include quantifying the relative horsepower gains achievable through crankshaft modifications versus turbocharger implementations across various engine displacements and configurations. Additionally, the analysis aims to identify the efficiency implications, implementation complexity, reliability factors, and cost-benefit ratios associated with each approach.

Furthermore, this investigation seeks to establish a framework for determining optimal power enhancement strategies based on specific application requirements, whether for everyday consumer vehicles, performance automobiles, commercial transport, or specialized industrial applications. The findings will contribute to the broader understanding of internal combustion engine optimization techniques during this critical transition period in propulsion technology.

Historically, power enhancement initially focused on naturally aspirated solutions, with crankshaft design playing a crucial role in determining an engine's power characteristics. The crankshaft, as the primary component converting reciprocating motion into rotational force, directly influences torque production and power delivery. Early modifications centered on stroke length adjustments, counterweight balancing, and material improvements to withstand higher RPMs.

The development of forced induction systems, particularly turbochargers, marked a paradigm shift in engine power enhancement. First patented by Alfred Büchi in 1905, turbocharger technology saw limited application until the 1970s oil crisis drove manufacturers toward smaller, more efficient engines that could maintain performance standards. The technology utilizes exhaust gas energy to compress intake air, effectively increasing oxygen availability for combustion and consequently enhancing power output.

Current technological objectives in this domain focus on optimizing the balance between these approaches. Modern engineering seeks to determine which method—crankshaft optimization or turbocharging—delivers superior horsepower gains across different engine architectures and application scenarios. This comparison is particularly relevant as the automotive industry navigates the transition toward electrification while still seeking to maximize the potential of internal combustion technology.

The technical goals of this research include quantifying the relative horsepower gains achievable through crankshaft modifications versus turbocharger implementations across various engine displacements and configurations. Additionally, the analysis aims to identify the efficiency implications, implementation complexity, reliability factors, and cost-benefit ratios associated with each approach.

Furthermore, this investigation seeks to establish a framework for determining optimal power enhancement strategies based on specific application requirements, whether for everyday consumer vehicles, performance automobiles, commercial transport, or specialized industrial applications. The findings will contribute to the broader understanding of internal combustion engine optimization techniques during this critical transition period in propulsion technology.

Market Analysis for Performance Enhancement Solutions

The performance enhancement solutions market for automotive applications has experienced significant growth over the past decade, driven by consumer demand for increased vehicle power and efficiency. Currently valued at approximately $11.2 billion globally, this market segment is projected to grow at a CAGR of 6.8% through 2028, with aftermarket modifications representing over 40% of total market value.

Consumer demographics reveal interesting patterns in this market. Performance enthusiasts aged 25-45 constitute the primary customer base (62%), with higher disposable income groups showing particular interest in premium solutions. Geographic distribution indicates North America leads with 38% market share, followed by Europe (29%) and Asia-Pacific (24%), with the latter showing the fastest growth trajectory.

The crankshaft modification and turbocharger segments represent two distinct approaches to performance enhancement with different market positioning. Crankshaft modifications, valued at $2.3 billion, appeal to traditional performance enthusiasts seeking naturally aspirated power gains. This segment grows steadily at 4.2% annually, with specialized machine shops and performance parts manufacturers as key providers.

Turbocharger solutions command a larger $5.7 billion market share with more robust 8.5% annual growth. This segment benefits from broader appeal across both performance and efficiency-conscious consumers. Major automotive suppliers and specialized aftermarket companies dominate this space, with recent innovations in variable geometry turbochargers expanding market potential.

Price sensitivity analysis reveals distinct consumer segments. Entry-level performance seekers (annual income $40,000-70,000) prioritize cost-effectiveness, favoring basic bolt-on solutions with demonstrable power gains. Premium consumers (income above $100,000) emphasize quality, brand reputation, and comprehensive performance packages regardless of higher price points.

Market research indicates horsepower gain remains the primary purchasing factor (cited by 78% of consumers), followed by reliability (65%), installation complexity (52%), and cost-to-performance ratio (49%). Turbochargers typically deliver 30-70% horsepower increases versus 10-25% for crankshaft modifications, explaining their growing market dominance despite higher average costs.

Distribution channels are evolving rapidly, with online direct-to-consumer sales growing at 14.3% annually, now representing 37% of total market transactions. Traditional performance shops maintain relevance through specialized installation services and customization expertise, particularly for complex modifications requiring technical knowledge.

Consumer demographics reveal interesting patterns in this market. Performance enthusiasts aged 25-45 constitute the primary customer base (62%), with higher disposable income groups showing particular interest in premium solutions. Geographic distribution indicates North America leads with 38% market share, followed by Europe (29%) and Asia-Pacific (24%), with the latter showing the fastest growth trajectory.

The crankshaft modification and turbocharger segments represent two distinct approaches to performance enhancement with different market positioning. Crankshaft modifications, valued at $2.3 billion, appeal to traditional performance enthusiasts seeking naturally aspirated power gains. This segment grows steadily at 4.2% annually, with specialized machine shops and performance parts manufacturers as key providers.

Turbocharger solutions command a larger $5.7 billion market share with more robust 8.5% annual growth. This segment benefits from broader appeal across both performance and efficiency-conscious consumers. Major automotive suppliers and specialized aftermarket companies dominate this space, with recent innovations in variable geometry turbochargers expanding market potential.

Price sensitivity analysis reveals distinct consumer segments. Entry-level performance seekers (annual income $40,000-70,000) prioritize cost-effectiveness, favoring basic bolt-on solutions with demonstrable power gains. Premium consumers (income above $100,000) emphasize quality, brand reputation, and comprehensive performance packages regardless of higher price points.

Market research indicates horsepower gain remains the primary purchasing factor (cited by 78% of consumers), followed by reliability (65%), installation complexity (52%), and cost-to-performance ratio (49%). Turbochargers typically deliver 30-70% horsepower increases versus 10-25% for crankshaft modifications, explaining their growing market dominance despite higher average costs.

Distribution channels are evolving rapidly, with online direct-to-consumer sales growing at 14.3% annually, now representing 37% of total market transactions. Traditional performance shops maintain relevance through specialized installation services and customization expertise, particularly for complex modifications requiring technical knowledge.

Current Technical Limitations and Challenges

Despite the proven effectiveness of both crankshafts and turbochargers in enhancing engine performance, several technical limitations and challenges persist in their implementation and optimization. For naturally aspirated engines relying on crankshaft modifications, the primary constraint lies in the physical limitations of stroke length and rod ratio adjustments. Increasing stroke length beyond certain thresholds introduces excessive piston speeds and detrimental side loading forces, which significantly compromise engine reliability and longevity.

Material science presents another substantial challenge, particularly for high-performance crankshafts. While forged steel crankshafts offer superior strength compared to cast alternatives, they still face fatigue limitations under extreme conditions. The industry continues to search for advanced materials and manufacturing techniques that can withstand higher RPM and torque loads without dimensional compromise.

Turbocharger systems face their own set of technical hurdles, with turbo lag remaining a persistent challenge despite decades of engineering advancements. The inherent delay between throttle input and boost delivery continues to impact drivability and throttle response, particularly in larger displacement engines or those with oversized turbochargers optimized for peak power.

Heat management represents another critical challenge for turbocharged systems. The extreme temperatures generated during compression can lead to pre-ignition, detonation, and accelerated component wear. While intercooling systems mitigate these issues, they add complexity, weight, and packaging challenges to the overall engine design.

Durability concerns affect both technologies differently. Crankshaft modifications often require corresponding upgrades to connecting rods, pistons, and bearings to maintain reliability, creating a cascade of necessary modifications. Turbochargers introduce additional failure points through their rotating assemblies, bearings, and oil supply systems, requiring precise maintenance schedules and specialized servicing.

Control system integration presents increasing complexity, particularly for turbocharged applications. Modern engine management systems must precisely regulate boost pressure, fuel delivery, and ignition timing across varying conditions to prevent catastrophic engine damage while maximizing performance. This requires sophisticated sensors, actuators, and computational algorithms that add cost and complexity.

Emissions compliance further complicates both approaches to horsepower gains. Crankshaft modifications that increase displacement often alter combustion characteristics, potentially increasing emissions. Similarly, turbocharging can lead to higher NOx production due to increased combustion temperatures, requiring additional emissions control technologies to maintain regulatory compliance.

Material science presents another substantial challenge, particularly for high-performance crankshafts. While forged steel crankshafts offer superior strength compared to cast alternatives, they still face fatigue limitations under extreme conditions. The industry continues to search for advanced materials and manufacturing techniques that can withstand higher RPM and torque loads without dimensional compromise.

Turbocharger systems face their own set of technical hurdles, with turbo lag remaining a persistent challenge despite decades of engineering advancements. The inherent delay between throttle input and boost delivery continues to impact drivability and throttle response, particularly in larger displacement engines or those with oversized turbochargers optimized for peak power.

Heat management represents another critical challenge for turbocharged systems. The extreme temperatures generated during compression can lead to pre-ignition, detonation, and accelerated component wear. While intercooling systems mitigate these issues, they add complexity, weight, and packaging challenges to the overall engine design.

Durability concerns affect both technologies differently. Crankshaft modifications often require corresponding upgrades to connecting rods, pistons, and bearings to maintain reliability, creating a cascade of necessary modifications. Turbochargers introduce additional failure points through their rotating assemblies, bearings, and oil supply systems, requiring precise maintenance schedules and specialized servicing.

Control system integration presents increasing complexity, particularly for turbocharged applications. Modern engine management systems must precisely regulate boost pressure, fuel delivery, and ignition timing across varying conditions to prevent catastrophic engine damage while maximizing performance. This requires sophisticated sensors, actuators, and computational algorithms that add cost and complexity.

Emissions compliance further complicates both approaches to horsepower gains. Crankshaft modifications that increase displacement often alter combustion characteristics, potentially increasing emissions. Similarly, turbocharging can lead to higher NOx production due to increased combustion temperatures, requiring additional emissions control technologies to maintain regulatory compliance.

Comparative Analysis of Crankshaft and Turbocharger Solutions

01 Turbocharger design optimization for horsepower gain

Optimizing turbocharger design can significantly increase engine horsepower. This includes improvements in turbine geometry, compressor efficiency, and overall turbocharger configuration. Advanced designs reduce lag and increase boost pressure at various engine speeds, resulting in better power delivery across the RPM range. Innovations in materials and aerodynamics allow for higher operating temperatures and improved airflow, directly contributing to increased horsepower output.- Turbocharger design optimization for horsepower gain: Optimizing turbocharger design can significantly increase engine horsepower. This includes improving compressor and turbine wheel geometries, enhancing wastegate control systems, and implementing variable geometry turbochargers that adjust to different engine speeds. Advanced materials and aerodynamic improvements in the turbocharger components can reduce lag and increase boost pressure, resulting in substantial horsepower gains across the engine's operating range.

- Crankshaft modifications for improved power output: Modifications to the crankshaft design can enhance engine performance and horsepower. These include optimizing counterweight design, improving journal bearing surfaces, and using lightweight materials to reduce rotational mass. Balancing techniques and stroke modifications can also contribute to higher RPM capabilities and improved power delivery. Specialized heat treatments and surface hardening processes can increase durability while maintaining performance gains.

- Electronic control systems for power enhancement: Advanced electronic control systems can optimize the interaction between crankshaft operation and turbocharger performance. These systems monitor engine parameters in real-time and adjust boost pressure, ignition timing, and fuel delivery accordingly. Adaptive algorithms can learn driving patterns and optimize power delivery based on conditions. Electronic wastegate control and variable valve timing coordination with turbocharger operation can significantly increase horsepower while maintaining reliability.

- Integrated cooling and lubrication systems for performance: Enhanced cooling and lubrication systems are crucial for maintaining optimal performance in high-output turbocharged engines. Oil cooling systems for turbochargers prevent heat-related degradation, while improved crankshaft lubrication channels reduce friction losses. Integrated cooling solutions that address both components allow for higher boost pressures and engine speeds without compromising reliability. These systems enable sustained horsepower gains by preventing thermal limitations that would otherwise restrict performance.

- Testing and measurement methods for horsepower optimization: Specialized testing and measurement techniques are essential for optimizing the horsepower gains from crankshaft and turbocharger modifications. These include dynamometer testing under various load conditions, real-time monitoring of turbocharger efficiency, and crankshaft strain analysis. Advanced sensors can measure parameters such as turbine inlet temperature, shaft speed, and bearing loads. These data-driven approaches enable precise tuning of the engine components to achieve maximum horsepower while ensuring system durability.

02 Crankshaft modifications for enhanced power output

Modifications to crankshaft design and materials can lead to significant horsepower gains. Lightweight crankshafts reduce rotational mass, allowing the engine to accelerate more quickly. Strengthened crankshafts can withstand higher torque loads from turbocharged applications. Optimized counterweights and journal designs improve balance and reduce friction losses. These modifications work together to increase the efficiency of power transfer from combustion to the drivetrain.Expand Specific Solutions03 Electronic control systems for turbocharger and engine performance

Advanced electronic control systems can optimize the relationship between crankshaft operation and turbocharger performance. These systems monitor engine parameters in real-time and adjust boost pressure, ignition timing, and fuel delivery accordingly. Variable geometry turbochargers controlled electronically can provide optimal boost across the entire RPM range. Engine mapping and tuning through electronic control units can maximize the power potential of turbocharged engines while maintaining reliability.Expand Specific Solutions04 Integrated cooling and lubrication systems for high-performance applications

Enhanced cooling and lubrication systems are crucial for achieving maximum horsepower in turbocharged engines. Improved oil circulation systems reduce friction in crankshaft bearings and turbocharger components. Advanced cooling solutions prevent heat-related power losses and component failure under high boost conditions. Integrated systems that manage both crankshaft and turbocharger thermal loads allow engines to operate safely at higher power levels for extended periods.Expand Specific Solutions05 Testing and measurement methods for horsepower optimization

Specialized testing and measurement techniques are essential for optimizing the horsepower gains from crankshaft and turbocharger modifications. Dynamometer testing provides accurate power measurements under controlled conditions. Advanced sensors can monitor crankshaft vibration, turbocharger speed, and exhaust gas temperatures to identify performance bottlenecks. Computer modeling and simulation help predict the effects of component changes before physical implementation. These methods enable precise tuning of the engine system for maximum horsepower output.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The turbocharger vs. crankshaft horsepower gain comparison market is currently in a growth phase, with increasing demand for performance enhancement solutions across automotive and industrial sectors. The global turbocharger market alone is projected to reach approximately $24 billion by 2025, driven by stringent emission regulations and consumer demand for fuel-efficient yet powerful engines. Technologically, turbochargers have reached higher maturity than advanced crankshaft modifications, with companies like BorgWarner and SuperTurbo Technologies leading innovation in turbocharging technology. Traditional automotive manufacturers such as Ford, GM, and Geely are integrating these technologies into their product lines, while specialized players like Bostic Motors focus on retrofit solutions. Chinese manufacturers including Chery and BYD are rapidly advancing their capabilities, particularly in the electric-hybrid powertrain segment where turbocharging technologies are being adapted for new applications.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed advanced turbocharger technologies including variable geometry turbochargers (VGT) that dynamically adjust airflow based on engine conditions. Their EFR (Engineered For Racing) series turbochargers feature ceramic ball bearings, gamma-titanium aluminide turbine wheels, and dual-row ceramic ball bearing systems that significantly reduce friction and improve spool-up time by approximately 15% compared to traditional journal bearings. BorgWarner's turbocharger solutions can deliver up to 30% more horsepower and torque compared to naturally aspirated engines of similar displacement, while their twin-scroll technology separates exhaust pulses for improved low-end torque and reduced turbo lag. Their integrated exhaust manifold designs have shown efficiency improvements of up to 20% in certain applications.

Strengths: Industry-leading turbocharger efficiency with up to 30% power gains; advanced materials reducing inertia and improving response time; comprehensive range covering passenger cars to heavy-duty applications. Weaknesses: Higher cost compared to conventional systems; complex VGT systems require sophisticated control systems; potential reliability concerns in extreme high-performance applications.

Ford Global Technologies LLC

Technical Solution: Ford has pioneered the EcoBoost engine technology, combining turbocharging with direct fuel injection to maximize both power output and fuel efficiency. Their 3.5L EcoBoost V6 delivers approximately 365-450 horsepower depending on application, comparable to naturally aspirated V8 engines with 5.0-6.2L displacement while offering 15-20% better fuel economy. Ford's PowerBoost technology further integrates hybrid systems with turbocharged engines, achieving both performance gains and efficiency improvements. Their advanced crankshaft designs feature micro-polished journals and optimized counterweights that reduce rotational mass by up to 10%, allowing for quicker engine response. Ford's patented anti-friction coatings on crankshaft bearings have demonstrated a 2-3% reduction in parasitic losses, contributing to overall power gains when combined with their turbocharging solutions.

Strengths: Excellent balance between performance and fuel economy; proven reliability in mass-market applications; comprehensive integration of turbocharging with other engine technologies. Weaknesses: Less focused on extreme high-performance applications compared to specialty manufacturers; turbo lag still present in some applications despite mitigation efforts; higher complexity increases maintenance costs over naturally aspirated engines.

Key Technical Patents and Innovations

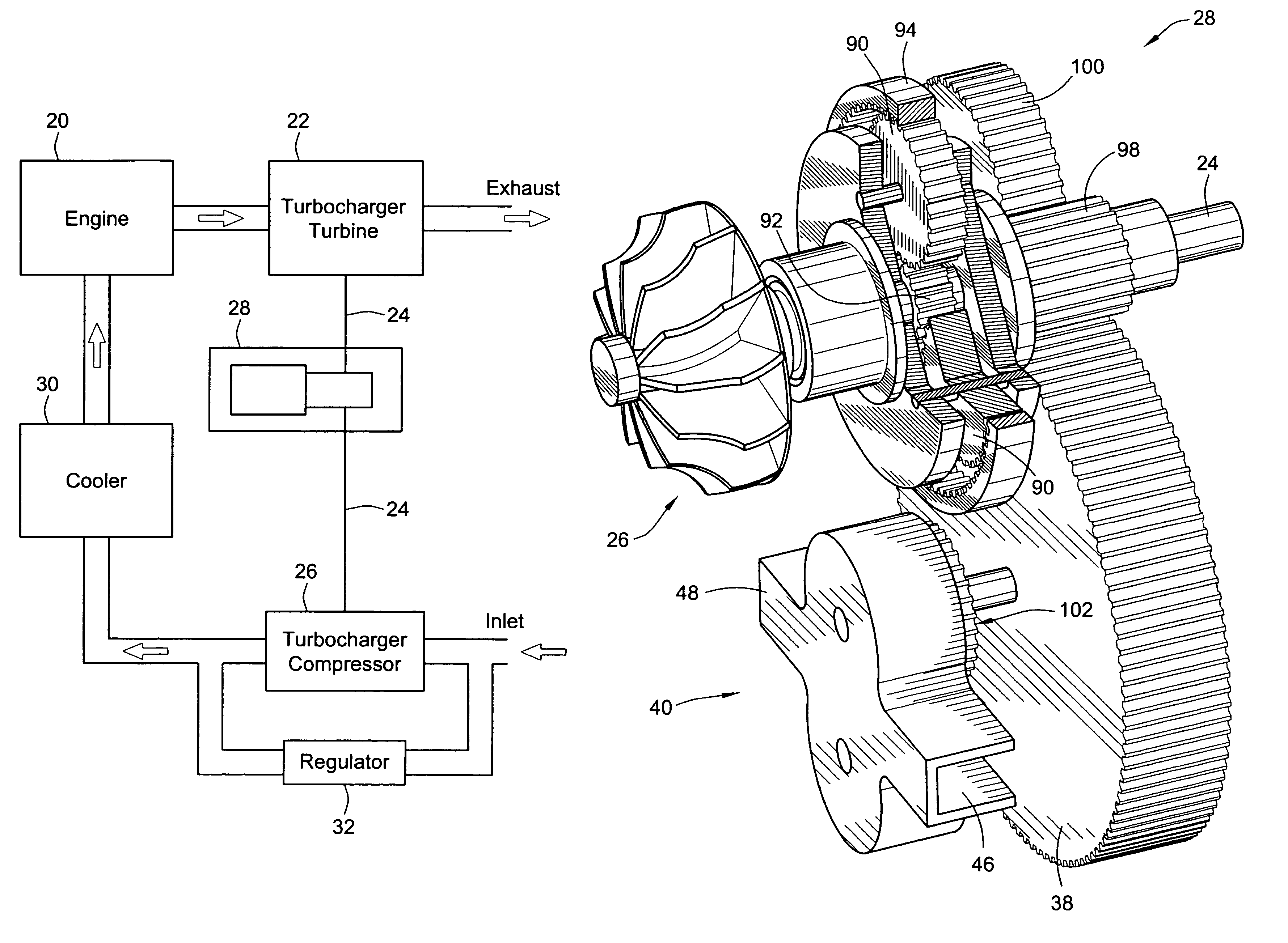

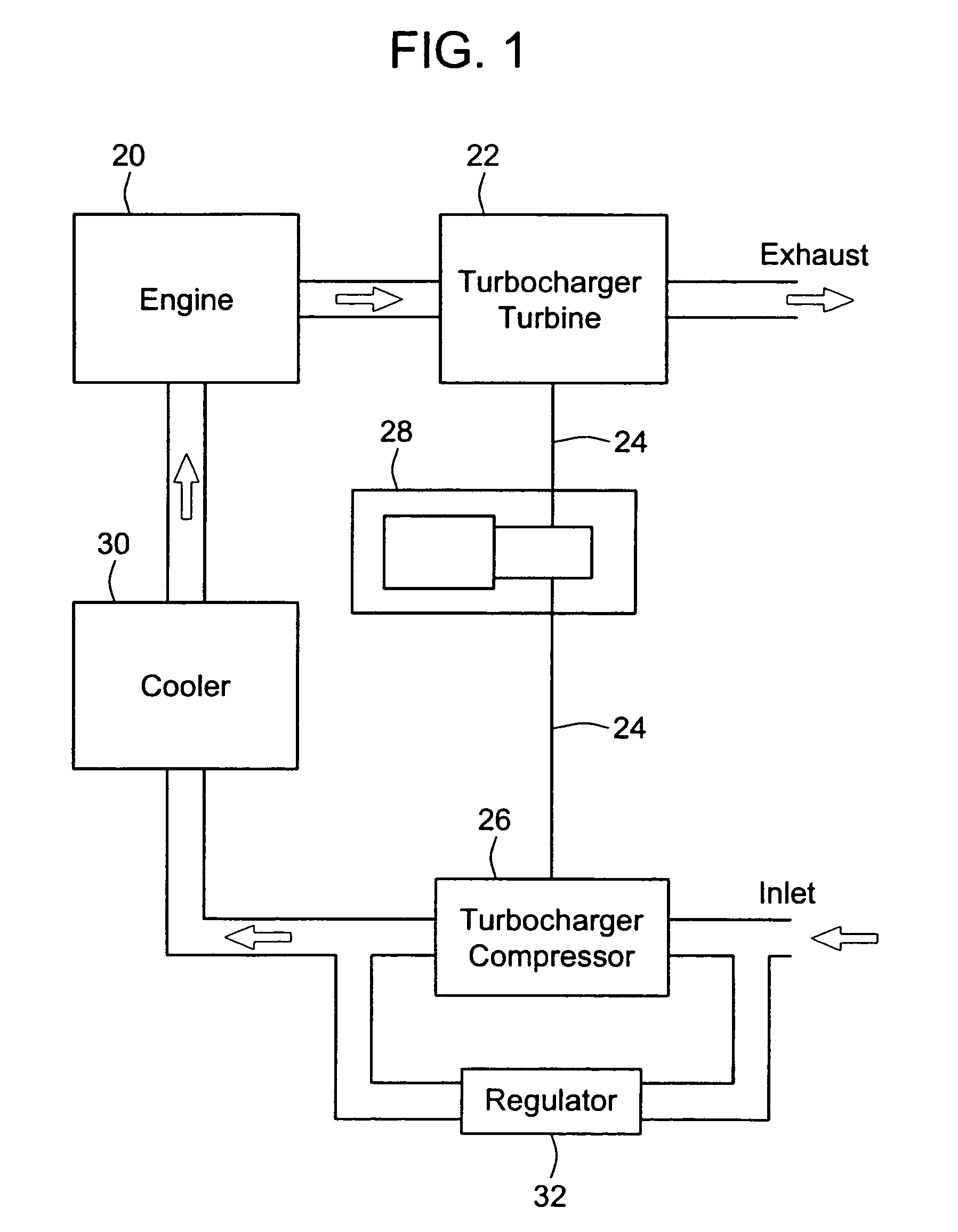

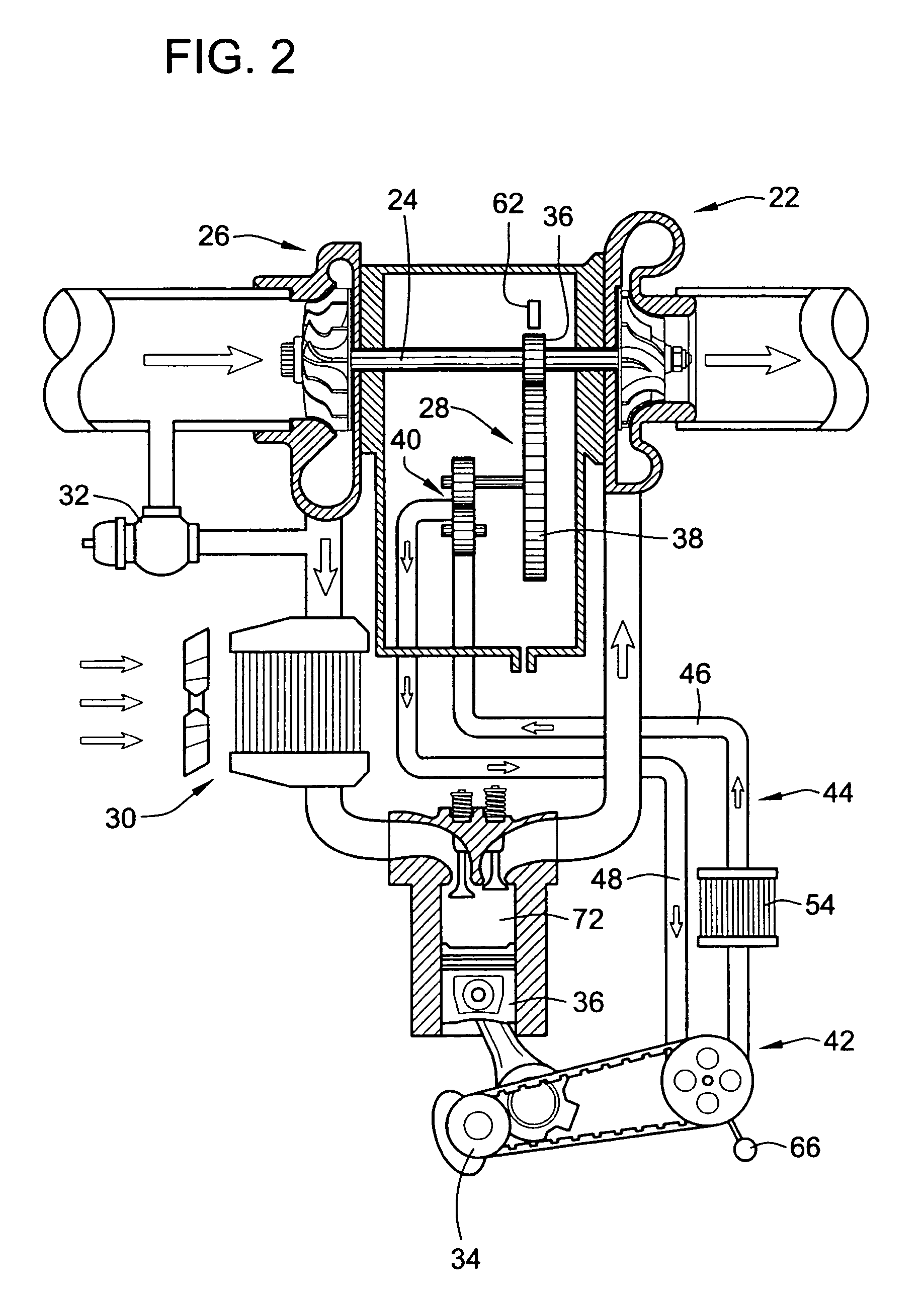

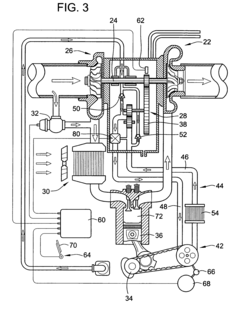

Super-turbocharger

PatentInactiveUS7490594B2

Innovation

- A super-turbocharger system that combines a turbocharger and a supercharger using a hydraulic pump to drive the turbocharger to specific speeds, recovering excess energy by diverting it to the crankshaft, eliminating the need for wastegates and enhancing efficiency through a planetary gear system and variable displacement hydraulic pump.

Efficiency and Fuel Economy Considerations

When comparing crankshaft modifications versus turbocharger installations for horsepower gains, efficiency and fuel economy considerations play a crucial role in the overall assessment. Turbochargers fundamentally alter the engine's breathing capability by forcing more air into the combustion chamber, allowing for more fuel to be burned and thus generating more power from the same displacement.

From an efficiency standpoint, turbochargers offer a significant advantage by recovering energy from exhaust gases that would otherwise be wasted. This energy recovery mechanism can improve thermal efficiency by 15-30% compared to naturally aspirated engines. In contrast, crankshaft modifications typically focus on reducing rotational mass or increasing stroke length, which may improve mechanical efficiency but offer limited gains in thermal efficiency.

Fuel economy implications differ substantially between these approaches. Turbochargers enable engine downsizing—maintaining power output while reducing displacement—which can improve fuel economy by 8-10% under normal driving conditions. This is achieved through reduced pumping losses and lower engine weight. However, when driven aggressively, turbocharged engines may actually consume more fuel than their naturally aspirated counterparts due to enrichment requirements at high boost levels.

Crankshaft modifications generally do not yield significant fuel economy benefits. Lightweight crankshafts may marginally reduce parasitic losses, but the effect on fuel consumption is typically less than 2%. Stroke-increasing modifications often negatively impact fuel economy by increasing friction and requiring more fuel to maintain higher displacement operation.

The brake specific fuel consumption (BSFC) metrics reveal that modern turbocharged engines can achieve values as low as 230-250 g/kWh, while naturally aspirated engines with crankshaft modifications typically operate in the 270-290 g/kWh range. This translates to approximately 15% better fuel efficiency for turbocharged solutions under optimal conditions.

Emissions considerations also favor turbocharging technology. The ability to precisely control air-fuel ratios with modern engine management systems allows turbocharged engines to maintain cleaner combustion across a wider operating range. Crankshaft modifications, particularly those increasing displacement, often result in higher emissions without corresponding control system updates.

For daily driving applications, the part-load efficiency of turbocharged engines provides a clear advantage, as most vehicles operate at 20-30% of maximum power during normal use. The turbocharger's ability to provide on-demand power while maintaining efficiency during cruise conditions represents a technological advantage that crankshaft modifications cannot match in terms of balancing performance gains with fuel economy.

From an efficiency standpoint, turbochargers offer a significant advantage by recovering energy from exhaust gases that would otherwise be wasted. This energy recovery mechanism can improve thermal efficiency by 15-30% compared to naturally aspirated engines. In contrast, crankshaft modifications typically focus on reducing rotational mass or increasing stroke length, which may improve mechanical efficiency but offer limited gains in thermal efficiency.

Fuel economy implications differ substantially between these approaches. Turbochargers enable engine downsizing—maintaining power output while reducing displacement—which can improve fuel economy by 8-10% under normal driving conditions. This is achieved through reduced pumping losses and lower engine weight. However, when driven aggressively, turbocharged engines may actually consume more fuel than their naturally aspirated counterparts due to enrichment requirements at high boost levels.

Crankshaft modifications generally do not yield significant fuel economy benefits. Lightweight crankshafts may marginally reduce parasitic losses, but the effect on fuel consumption is typically less than 2%. Stroke-increasing modifications often negatively impact fuel economy by increasing friction and requiring more fuel to maintain higher displacement operation.

The brake specific fuel consumption (BSFC) metrics reveal that modern turbocharged engines can achieve values as low as 230-250 g/kWh, while naturally aspirated engines with crankshaft modifications typically operate in the 270-290 g/kWh range. This translates to approximately 15% better fuel efficiency for turbocharged solutions under optimal conditions.

Emissions considerations also favor turbocharging technology. The ability to precisely control air-fuel ratios with modern engine management systems allows turbocharged engines to maintain cleaner combustion across a wider operating range. Crankshaft modifications, particularly those increasing displacement, often result in higher emissions without corresponding control system updates.

For daily driving applications, the part-load efficiency of turbocharged engines provides a clear advantage, as most vehicles operate at 20-30% of maximum power during normal use. The turbocharger's ability to provide on-demand power while maintaining efficiency during cruise conditions represents a technological advantage that crankshaft modifications cannot match in terms of balancing performance gains with fuel economy.

Environmental Impact and Emissions Regulations

The environmental impact of engine performance enhancement technologies has become a critical consideration in the automotive industry, particularly as emissions regulations continue to tighten globally. When comparing crankshafts and turbochargers for horsepower gains, their respective environmental footprints must be thoroughly examined.

Naturally aspirated engines with modified crankshafts typically produce higher emissions during power increases due to the fundamental relationship between displacement, fuel consumption, and exhaust output. The increased stroke length and subsequent larger displacement directly correlates with greater fuel consumption, resulting in higher carbon dioxide emissions per unit of power gained.

Turbochargers, conversely, offer a more environmentally favorable approach to horsepower enhancement. By recycling exhaust gases to force additional air into the combustion chamber, turbochargers improve combustion efficiency without necessarily increasing displacement. This technology aligns with the global automotive trend of "downsizing" - reducing engine displacement while maintaining or improving performance through forced induction.

Recent emissions regulations have significantly influenced the adoption of these technologies. The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have imposed stringent limits on nitrogen oxides (NOx), carbon monoxide, and particulate matter emissions. Turbochargers, particularly when combined with direct injection systems, help manufacturers meet these standards while delivering consumer-demanded performance.

However, turbochargers present their own environmental challenges. The higher combustion temperatures associated with turbocharged engines can increase NOx emissions if not properly managed through exhaust gas recirculation (EGR) systems or selective catalytic reduction (SCR) technology. Additionally, the production of turbochargers requires specialized materials and manufacturing processes with their own environmental footprint.

Future emissions regulations will likely continue to favor technologies that maximize efficiency while minimizing environmental impact. The upcoming Euro 7 standards and equivalent regulations in other markets are expected to further restrict emissions, potentially accelerating the shift toward electrification. In this regulatory landscape, traditional crankshaft modifications may become increasingly difficult to implement in production vehicles without significant additional emissions control technologies.

For aftermarket modifications, many regions have implemented testing requirements that limit the legality of performance enhancements that increase emissions beyond factory specifications. This regulatory environment creates additional considerations for consumers and manufacturers when choosing between crankshaft modifications and turbocharging for horsepower gains.

Naturally aspirated engines with modified crankshafts typically produce higher emissions during power increases due to the fundamental relationship between displacement, fuel consumption, and exhaust output. The increased stroke length and subsequent larger displacement directly correlates with greater fuel consumption, resulting in higher carbon dioxide emissions per unit of power gained.

Turbochargers, conversely, offer a more environmentally favorable approach to horsepower enhancement. By recycling exhaust gases to force additional air into the combustion chamber, turbochargers improve combustion efficiency without necessarily increasing displacement. This technology aligns with the global automotive trend of "downsizing" - reducing engine displacement while maintaining or improving performance through forced induction.

Recent emissions regulations have significantly influenced the adoption of these technologies. The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have imposed stringent limits on nitrogen oxides (NOx), carbon monoxide, and particulate matter emissions. Turbochargers, particularly when combined with direct injection systems, help manufacturers meet these standards while delivering consumer-demanded performance.

However, turbochargers present their own environmental challenges. The higher combustion temperatures associated with turbocharged engines can increase NOx emissions if not properly managed through exhaust gas recirculation (EGR) systems or selective catalytic reduction (SCR) technology. Additionally, the production of turbochargers requires specialized materials and manufacturing processes with their own environmental footprint.

Future emissions regulations will likely continue to favor technologies that maximize efficiency while minimizing environmental impact. The upcoming Euro 7 standards and equivalent regulations in other markets are expected to further restrict emissions, potentially accelerating the shift toward electrification. In this regulatory landscape, traditional crankshaft modifications may become increasingly difficult to implement in production vehicles without significant additional emissions control technologies.

For aftermarket modifications, many regions have implemented testing requirements that limit the legality of performance enhancements that increase emissions beyond factory specifications. This regulatory environment creates additional considerations for consumers and manufacturers when choosing between crankshaft modifications and turbocharging for horsepower gains.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!