Crankshaft vs Timing Gear: Power Transfer Impact

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft and Timing Gear Technology Background

The evolution of power transfer mechanisms in internal combustion engines represents one of the most significant technological developments in automotive engineering. The crankshaft and timing gear systems have undergone substantial transformation since the early days of engine design in the late 19th century. Initially, simple timing mechanisms relied on rudimentary gear arrangements with limited precision and durability, often resulting in inconsistent engine performance and frequent maintenance requirements.

By the 1920s, as automotive manufacturing scaled up, engineers began developing more sophisticated crankshaft designs with improved metallurgical properties. Cast iron gave way to forged steel crankshafts, dramatically enhancing durability while reducing rotational mass. Concurrently, timing gear systems evolved from simple spur gear arrangements to more complex helical gear configurations that offered smoother operation and reduced noise.

The post-World War II era witnessed significant advancements in both technologies. Precision manufacturing techniques enabled tighter tolerances in crankshaft bearing journals and timing gear mesh patterns. The introduction of timing chains in the 1950s represented a paradigm shift, offering a flexible alternative to rigid gear systems while maintaining precise valve timing across varying engine speeds.

The oil crisis of the 1970s drove further innovation focused on efficiency. Lightweight crankshaft designs incorporating microalloyed steels emerged, while timing belt systems gained popularity as a quieter, lighter alternative to chains and gears. These developments coincided with the industry's shift toward overhead camshaft designs, which placed new demands on power transfer systems.

Computer-aided design and manufacturing revolutionized both components in the 1980s and 1990s. Finite element analysis enabled engineers to optimize crankshaft geometry for strength while minimizing weight. Similarly, timing gear systems benefited from advanced tooth profile designs that maximized power transfer efficiency while minimizing wear.

Recent technological trends have focused on addressing emissions regulations and fuel economy standards. Variable valve timing systems have introduced new complexities to the timing mechanism, requiring more sophisticated gear and actuator arrangements. Meanwhile, crankshaft designs have incorporated features like counterweights and harmonic balancers to reduce vibration and improve NVH characteristics.

Today's research focuses on materials science innovations, with carbon fiber composite crankshafts and ceramic-coated timing components emerging as potential future technologies. Additionally, the rise of hybrid and electric vehicles has prompted reconsideration of traditional power transfer mechanisms, with some designs incorporating motor-generator units directly into the crankshaft assembly or eliminating conventional timing systems altogether.

By the 1920s, as automotive manufacturing scaled up, engineers began developing more sophisticated crankshaft designs with improved metallurgical properties. Cast iron gave way to forged steel crankshafts, dramatically enhancing durability while reducing rotational mass. Concurrently, timing gear systems evolved from simple spur gear arrangements to more complex helical gear configurations that offered smoother operation and reduced noise.

The post-World War II era witnessed significant advancements in both technologies. Precision manufacturing techniques enabled tighter tolerances in crankshaft bearing journals and timing gear mesh patterns. The introduction of timing chains in the 1950s represented a paradigm shift, offering a flexible alternative to rigid gear systems while maintaining precise valve timing across varying engine speeds.

The oil crisis of the 1970s drove further innovation focused on efficiency. Lightweight crankshaft designs incorporating microalloyed steels emerged, while timing belt systems gained popularity as a quieter, lighter alternative to chains and gears. These developments coincided with the industry's shift toward overhead camshaft designs, which placed new demands on power transfer systems.

Computer-aided design and manufacturing revolutionized both components in the 1980s and 1990s. Finite element analysis enabled engineers to optimize crankshaft geometry for strength while minimizing weight. Similarly, timing gear systems benefited from advanced tooth profile designs that maximized power transfer efficiency while minimizing wear.

Recent technological trends have focused on addressing emissions regulations and fuel economy standards. Variable valve timing systems have introduced new complexities to the timing mechanism, requiring more sophisticated gear and actuator arrangements. Meanwhile, crankshaft designs have incorporated features like counterweights and harmonic balancers to reduce vibration and improve NVH characteristics.

Today's research focuses on materials science innovations, with carbon fiber composite crankshafts and ceramic-coated timing components emerging as potential future technologies. Additionally, the rise of hybrid and electric vehicles has prompted reconsideration of traditional power transfer mechanisms, with some designs incorporating motor-generator units directly into the crankshaft assembly or eliminating conventional timing systems altogether.

Market Analysis of Power Transfer Systems

The power transfer systems market is experiencing significant transformation driven by technological advancements and changing consumer preferences. Currently valued at approximately $45 billion globally, this market encompasses various components including crankshafts, timing gears, chains, belts, and related power transfer mechanisms used across automotive, industrial machinery, and power generation sectors. The market is projected to grow at a compound annual growth rate of 4.7% through 2028, with particularly strong expansion in electric and hybrid vehicle applications.

Traditional crankshaft-based power transfer systems continue to dominate the internal combustion engine segment, representing nearly 65% of the conventional automotive power transfer market. However, timing gear systems are gaining traction due to their superior precision and durability advantages, especially in high-performance and commercial vehicle applications. The premium automotive segment has seen a 12% increase in timing gear adoption over the past three years.

Regional analysis reveals distinct market characteristics. North America and Europe maintain strong demand for advanced timing gear systems in premium vehicles and industrial applications, while Asia-Pacific leads in overall market volume with significant production of both crankshaft and timing gear components. China alone accounts for 38% of global manufacturing capacity for power transfer components, though Japan and Germany lead in high-precision timing gear technology.

The aftermarket segment presents substantial opportunities, valued at $12 billion annually, with replacement parts for both crankshaft and timing gear systems showing consistent demand patterns. Timing gear replacement components command premium pricing, typically 30-40% higher than comparable crankshaft components, reflecting their technical sophistication and durability benefits.

Customer demand is increasingly influenced by efficiency considerations, with OEMs reporting that power transfer efficiency has risen from the eighth to the third most important purchasing criterion over the past decade. This shift benefits timing gear systems, which typically demonstrate 4-7% better power transfer efficiency compared to traditional crankshaft arrangements in standardized testing environments.

Emerging market trends include the integration of advanced materials such as carbon-reinforced polymers and specialized alloys in both crankshaft and timing gear applications, reducing weight while improving durability. Additionally, the growing electric vehicle segment is creating demand for specialized power transfer systems optimized for the unique requirements of electric drivetrains, with an estimated market value of $3.2 billion in 2023 and projected annual growth exceeding 15%.

Traditional crankshaft-based power transfer systems continue to dominate the internal combustion engine segment, representing nearly 65% of the conventional automotive power transfer market. However, timing gear systems are gaining traction due to their superior precision and durability advantages, especially in high-performance and commercial vehicle applications. The premium automotive segment has seen a 12% increase in timing gear adoption over the past three years.

Regional analysis reveals distinct market characteristics. North America and Europe maintain strong demand for advanced timing gear systems in premium vehicles and industrial applications, while Asia-Pacific leads in overall market volume with significant production of both crankshaft and timing gear components. China alone accounts for 38% of global manufacturing capacity for power transfer components, though Japan and Germany lead in high-precision timing gear technology.

The aftermarket segment presents substantial opportunities, valued at $12 billion annually, with replacement parts for both crankshaft and timing gear systems showing consistent demand patterns. Timing gear replacement components command premium pricing, typically 30-40% higher than comparable crankshaft components, reflecting their technical sophistication and durability benefits.

Customer demand is increasingly influenced by efficiency considerations, with OEMs reporting that power transfer efficiency has risen from the eighth to the third most important purchasing criterion over the past decade. This shift benefits timing gear systems, which typically demonstrate 4-7% better power transfer efficiency compared to traditional crankshaft arrangements in standardized testing environments.

Emerging market trends include the integration of advanced materials such as carbon-reinforced polymers and specialized alloys in both crankshaft and timing gear applications, reducing weight while improving durability. Additionally, the growing electric vehicle segment is creating demand for specialized power transfer systems optimized for the unique requirements of electric drivetrains, with an estimated market value of $3.2 billion in 2023 and projected annual growth exceeding 15%.

Technical Challenges in Power Transfer Mechanisms

Power transfer mechanisms in internal combustion engines face several significant technical challenges that impact efficiency, durability, and performance. The comparison between crankshaft and timing gear systems reveals complex engineering trade-offs that continue to challenge automotive designers and engineers.

Material selection represents a primary challenge in both systems. Crankshafts require materials with exceptional fatigue resistance and torsional strength to withstand cyclic loading, while timing gears demand materials with superior wear resistance and dimensional stability. The conflicting requirements of weight reduction and strength enhancement create a persistent engineering dilemma, particularly as manufacturers pursue improved fuel efficiency.

Vibration and noise management presents another substantial challenge. Crankshaft systems generate torsional vibrations that must be dampened to prevent resonance effects throughout the powertrain. Timing gear systems, while generally more precise in maintaining valve timing, can produce gear mesh noise that requires sophisticated engineering solutions to mitigate. The challenge intensifies as engines operate at higher RPMs, where vibration amplitudes increase exponentially.

Lubrication system design poses unique challenges for both mechanisms. Crankshafts require precise oil delivery to journal bearings under varying load conditions, while timing gears need consistent lubrication at the gear mesh interface to prevent premature wear. The challenge becomes more complex when considering cold-start conditions and high-temperature operation, where oil viscosity changes dramatically affect protection levels.

Thermal management represents a critical challenge, particularly in high-performance applications. Crankshafts experience thermal expansion that can alter critical clearances, while timing gears must maintain precise mesh patterns despite temperature fluctuations. Engineers must design systems that accommodate these thermal effects without compromising performance or reliability.

Manufacturing precision and tolerance control present ongoing challenges. Crankshafts require extremely tight tolerances for bearing journals and counterweight balancing, while timing gears demand precise tooth profiles to ensure smooth, quiet operation. As engines evolve toward higher specific outputs, these tolerance requirements become increasingly stringent, pushing manufacturing capabilities to their limits.

Durability testing methodology presents a final significant challenge. Accelerated life testing must accurately predict decades of real-world operation, requiring sophisticated test protocols that can reliably simulate the complex loading patterns these components experience. The correlation between test results and actual field performance remains an area of ongoing research and development.

Material selection represents a primary challenge in both systems. Crankshafts require materials with exceptional fatigue resistance and torsional strength to withstand cyclic loading, while timing gears demand materials with superior wear resistance and dimensional stability. The conflicting requirements of weight reduction and strength enhancement create a persistent engineering dilemma, particularly as manufacturers pursue improved fuel efficiency.

Vibration and noise management presents another substantial challenge. Crankshaft systems generate torsional vibrations that must be dampened to prevent resonance effects throughout the powertrain. Timing gear systems, while generally more precise in maintaining valve timing, can produce gear mesh noise that requires sophisticated engineering solutions to mitigate. The challenge intensifies as engines operate at higher RPMs, where vibration amplitudes increase exponentially.

Lubrication system design poses unique challenges for both mechanisms. Crankshafts require precise oil delivery to journal bearings under varying load conditions, while timing gears need consistent lubrication at the gear mesh interface to prevent premature wear. The challenge becomes more complex when considering cold-start conditions and high-temperature operation, where oil viscosity changes dramatically affect protection levels.

Thermal management represents a critical challenge, particularly in high-performance applications. Crankshafts experience thermal expansion that can alter critical clearances, while timing gears must maintain precise mesh patterns despite temperature fluctuations. Engineers must design systems that accommodate these thermal effects without compromising performance or reliability.

Manufacturing precision and tolerance control present ongoing challenges. Crankshafts require extremely tight tolerances for bearing journals and counterweight balancing, while timing gears demand precise tooth profiles to ensure smooth, quiet operation. As engines evolve toward higher specific outputs, these tolerance requirements become increasingly stringent, pushing manufacturing capabilities to their limits.

Durability testing methodology presents a final significant challenge. Accelerated life testing must accurately predict decades of real-world operation, requiring sophisticated test protocols that can reliably simulate the complex loading patterns these components experience. The correlation between test results and actual field performance remains an area of ongoing research and development.

Current Power Transfer Solutions Comparison

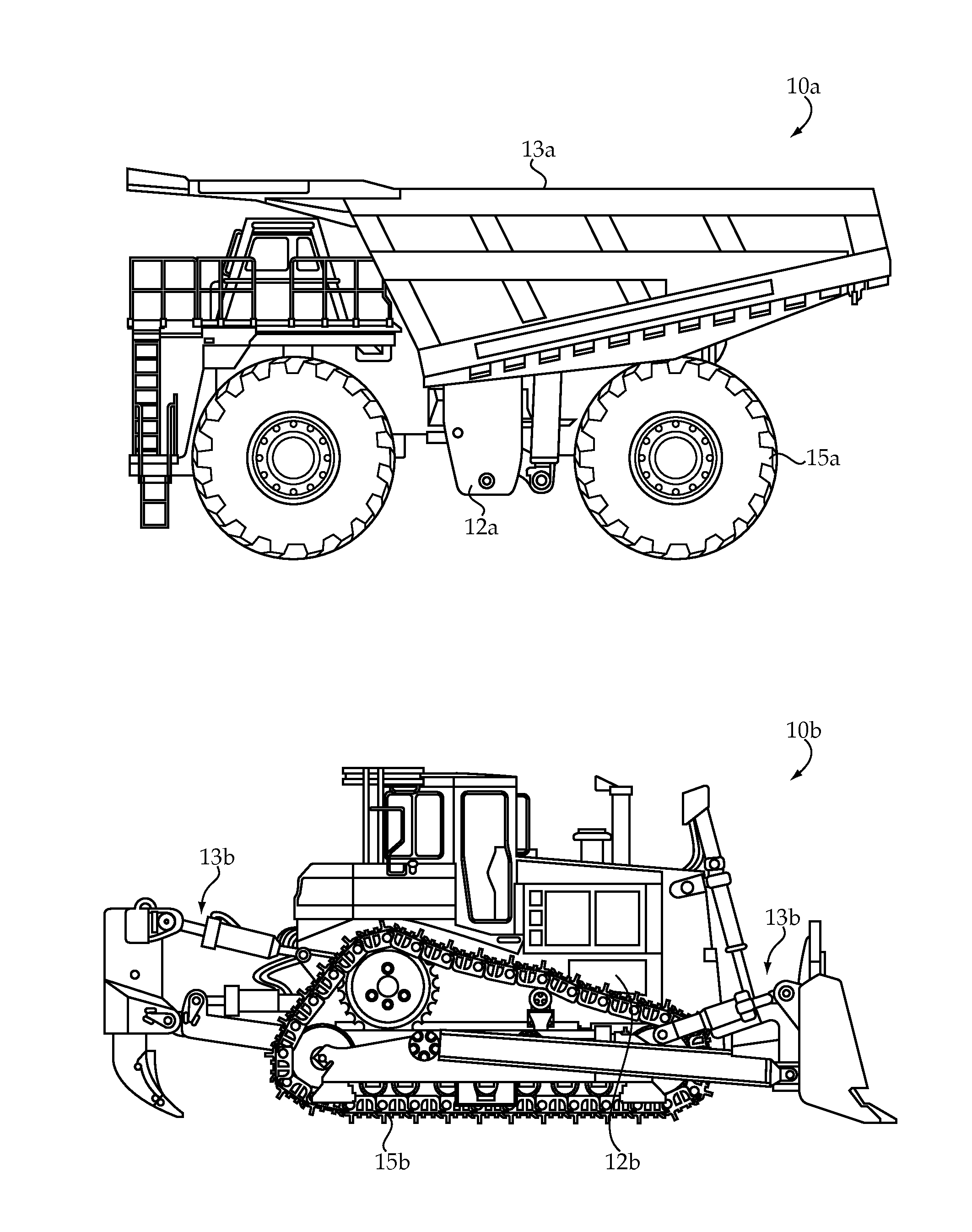

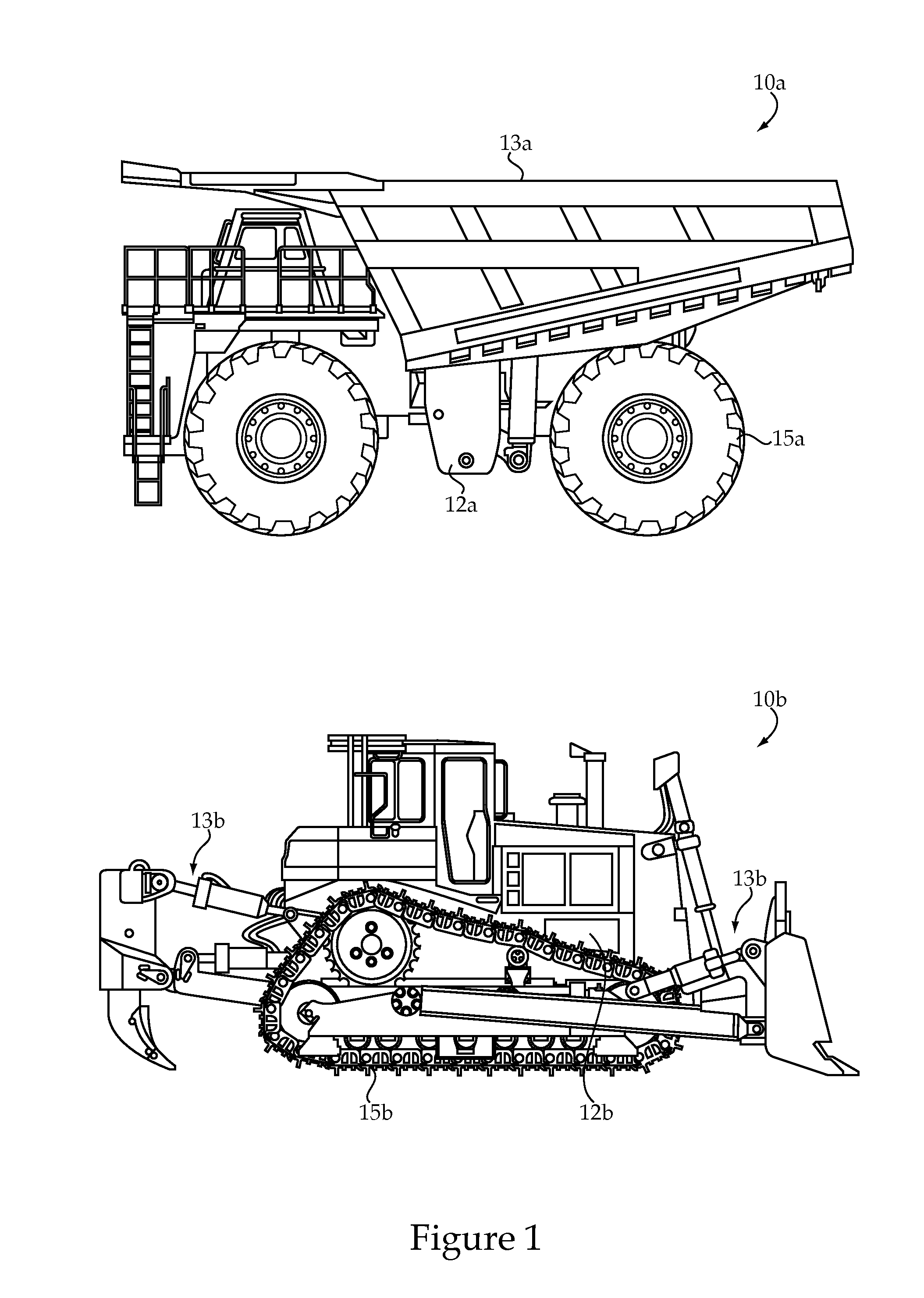

01 Crankshaft and timing gear integration designs

Various designs integrate crankshafts with timing gear systems to optimize power transfer. These designs include specialized configurations that reduce friction, improve durability, and enhance overall engine performance. The integration focuses on maintaining proper timing between the crankshaft rotation and valve operations, ensuring efficient power generation and transfer throughout the engine system.- Crankshaft and timing gear integration designs: Various designs integrate crankshafts with timing gear systems to optimize power transfer. These designs include specialized configurations that reduce friction, improve durability, and enhance overall engine performance. The integration focuses on efficient power transmission from the crankshaft to the timing gear while maintaining precise timing control for valve operations.

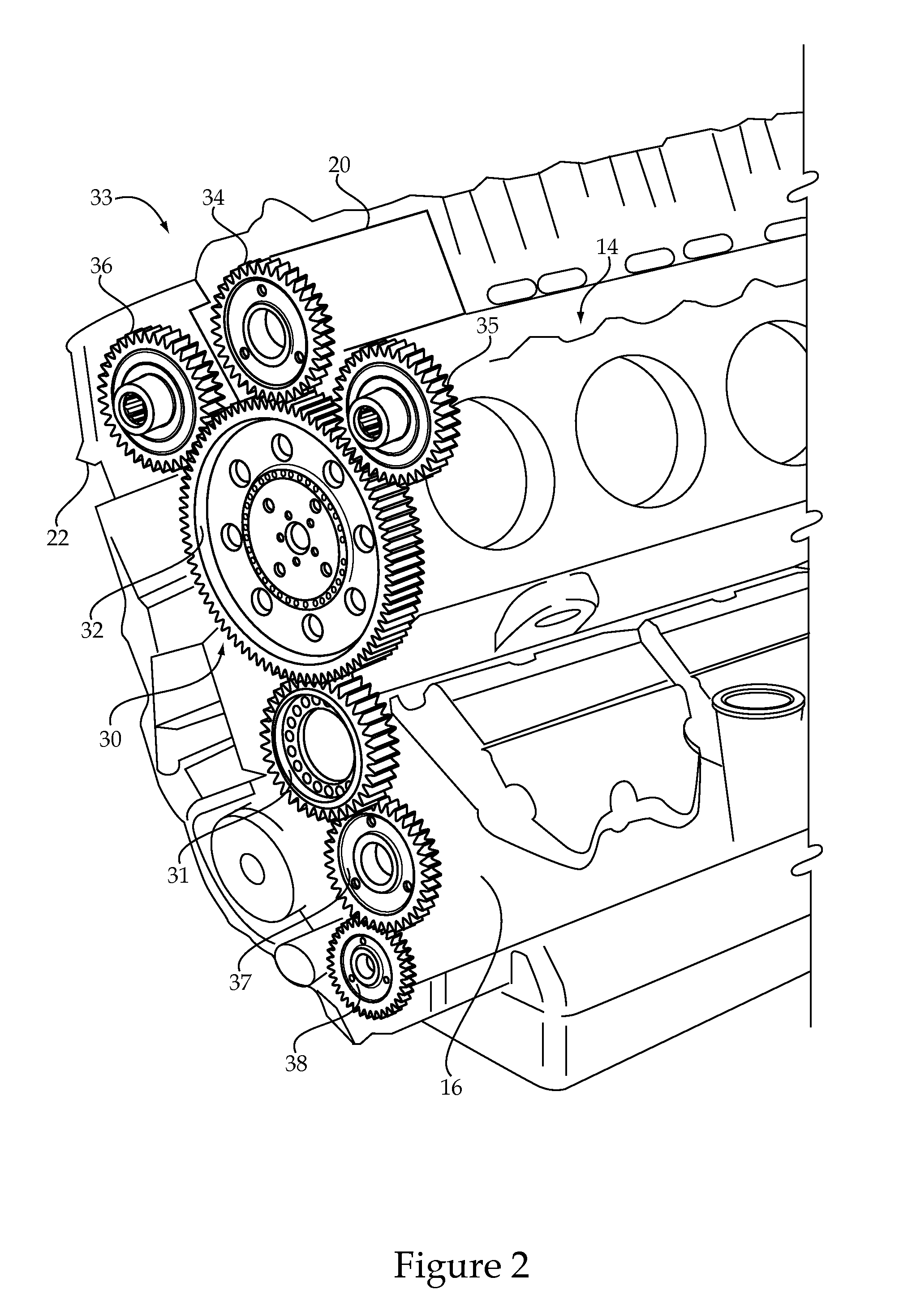

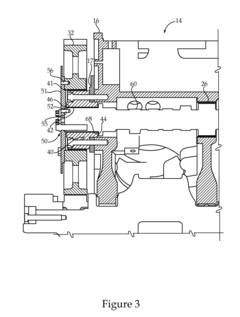

- Gear-driven power transfer mechanisms: Gear-driven systems for transferring power between crankshafts and timing components utilize specialized gear arrangements to ensure smooth and reliable operation. These mechanisms include various gear configurations such as helical, spur, and bevel gears that optimize torque transfer while minimizing backlash and noise. The gear systems are designed to maintain precise timing relationships between rotating components in the engine.

- Chain and belt drive systems for timing control: Chain and belt drive systems provide flexible power transfer solutions between crankshafts and timing gears. These systems use tensioners and guides to maintain proper tension and alignment, ensuring accurate timing throughout the engine's operating range. The designs focus on reducing noise, increasing durability, and providing more efficient power transmission compared to traditional gear-only systems.

- Variable timing mechanisms for performance optimization: Variable timing mechanisms allow for dynamic adjustment of the timing relationship between the crankshaft and camshaft. These systems incorporate advanced control elements that can modify timing based on engine load, speed, and other operating conditions. By optimizing valve timing across different operating conditions, these mechanisms improve fuel efficiency, power output, and emissions performance.

- Compact and lightweight power transfer solutions: Innovative designs focus on creating more compact and lightweight solutions for transferring power between crankshafts and timing gears. These designs incorporate advanced materials and space-saving configurations to reduce overall engine size and weight while maintaining reliability. The compact solutions are particularly valuable for modern vehicles where engine compartment space is limited and weight reduction is critical for fuel efficiency.

02 Timing gear power transfer mechanisms

Specific mechanisms for transferring power between the crankshaft and timing gears include gear trains, belt drives, and chain systems. These mechanisms are designed to maintain precise timing relationships while efficiently transferring rotational force. Advanced designs incorporate features to reduce noise, minimize backlash, and provide consistent power delivery under various operating conditions.Expand Specific Solutions03 Crankshaft power distribution systems

Systems for distributing power from the crankshaft to various engine components utilize specialized gearing arrangements and power take-off points. These systems ensure that appropriate torque is delivered to timing gears, accessory drives, and other engine components. The designs focus on balancing power requirements, minimizing energy losses, and maintaining operational stability across different engine speeds.Expand Specific Solutions04 Timing gear alignment and tensioning solutions

Solutions for maintaining proper alignment and tension in timing gear systems include automatic tensioners, adjustable mounting systems, and precision alignment mechanisms. These solutions help prevent timing errors, reduce wear, and extend component life. Advanced designs incorporate self-adjusting features that compensate for thermal expansion and component wear over time.Expand Specific Solutions05 Innovative materials and manufacturing for crankshaft-timing gear interfaces

The use of advanced materials and manufacturing techniques improves the durability and efficiency of crankshaft and timing gear interfaces. These innovations include specialized coatings, heat treatments, and precision machining processes that reduce friction, increase wear resistance, and improve load-bearing capacity. Composite materials and optimized geometries further enhance performance while reducing weight and inertial losses.Expand Specific Solutions

Leading Manufacturers and Industry Competition

The crankshaft vs timing gear power transfer technology landscape is currently in a mature development stage with ongoing innovation. The global market size is substantial, estimated in billions of dollars, driven by automotive and industrial applications. From a technical maturity perspective, established manufacturers like Honda, Toyota, and Mercedes-Benz have developed sophisticated crankshaft technologies, while companies such as BorgWarner, ZF Friedrichshafen, and Schaeffler lead in timing gear innovations. Japanese manufacturers (Honda, Toyota, Mitsubishi) and German engineering firms (Mercedes-Benz, ThyssenKrupp) dominate the competitive landscape, with emerging players from China (Chery, Great Wall Motor) gaining market share through cost-effective solutions. The technology continues to evolve toward greater efficiency, reduced friction, and integration with hybrid/electric powertrains.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed the Earth Dreams Technology platform that incorporates advanced Variable Timing Control (VTC) systems using an innovative oil-pressure actuated phasing mechanism between the crankshaft and timing gear. This system achieves a remarkable 60-degree phase angle adjustment capability, significantly broader than industry standards. Honda's VTEC (Variable Valve Timing and Lift Electronic Control) technology works in conjunction with precision-engineered timing gears to optimize power transfer across different engine speeds. Their research shows that the integration of variable valve timing with optimized timing gear design reduces mechanical losses by approximately 13% compared to conventional systems. Honda has also pioneered the use of silent timing chains with specialized gear tooth profiles that reduce noise while maintaining precise timing accuracy. Their i-VTEC system incorporates both timing gear and crankshaft innovations to achieve a balance of performance and efficiency, with test data showing 9-11% improvement in specific output compared to non-variable systems.

Strengths: Exceptional reliability and durability; smooth operation across wide RPM ranges; excellent balance of performance and efficiency. Weaknesses: Relatively complex systems require specialized service knowledge; higher manufacturing precision requirements increase costs; limited adaptability to aftermarket modifications.

Toyota Motor Corp.

Technical Solution: Toyota has developed the Dynamic Force Engine platform featuring a high-efficiency direct power transfer system that optimizes the relationship between crankshaft dynamics and timing gear operation. Their Variable Valve Timing-intelligent Electric (VVT-iE) system uses an electric motor rather than conventional hydraulic pressure to adjust the timing gear phase angle relative to the crankshaft, achieving response times approximately 30% faster than hydraulic systems. Toyota's research demonstrates that their integrated approach to crankshaft and timing gear design reduces internal friction by up to 20% compared to conventional engines. Their D-4S dual injection system works in concert with precision timing gear mechanisms to maintain optimal valve timing under varying load conditions, improving combustion efficiency by 8-10%. Toyota has also pioneered lightweight timing gear materials that reduce rotational inertia while maintaining durability, with test data showing a 15% reduction in parasitic losses during acceleration events compared to conventional timing gear systems.

Strengths: Industry-leading reliability; excellent thermal efficiency; sophisticated electronic control integration. Weaknesses: Conservative design approach may limit performance potential; higher initial manufacturing costs; requires specialized diagnostic equipment for service.

Key Patents in Crankshaft and Timing Gear Design

Tensioner

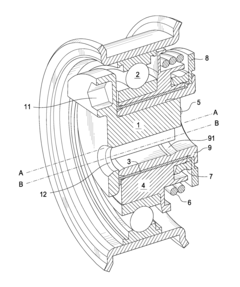

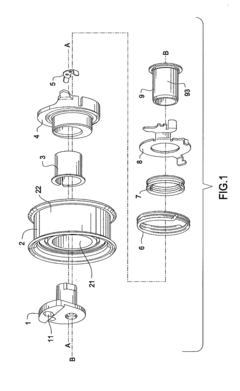

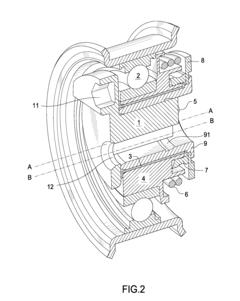

PatentInactiveUS20120316018A1

Innovation

- A tensioner design featuring a damping member fixedly connected to the arm, compressed between the arm and base with a frictional engagement to damp oscillations, and an expandable retainer member connected to the adjuster, engaged with a sleeve groove, utilizing a damping ring made of materials like rubber or fluoroelastomers to provide axial compression and friction damping in oil environments.

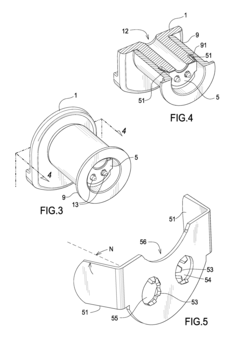

Engine With Stub Shaft Supported Cam Gear And Machine Using Same

PatentActiveUS20120138003A1

Innovation

- A gear train configuration where the cam gear is directly meshed with the crank gear, with a majority of power transmitted to powered gears to drive hydraulic pumps and a minority to drive the cam shaft, utilizing a stub shaft with thrust bearings to support the cam shaft and reduce stress concentrations.

Environmental Impact of Power Transfer Systems

The environmental impact of power transfer systems in automotive engines represents a critical consideration in modern vehicle design. When comparing crankshaft and timing gear mechanisms, their ecological footprints differ significantly across multiple dimensions, including manufacturing processes, operational efficiency, and end-of-life disposal.

Manufacturing crankshaft systems typically requires more energy-intensive processes, including forging and precision machining of large metal components. These processes generate substantial carbon emissions and require significant raw material inputs, primarily steel alloys. Conversely, timing gear systems, while still material-intensive, often incorporate more diverse materials including polymers and composites that may have lower production energy requirements but present different environmental challenges.

Operational environmental impacts reveal notable differences between these power transfer mechanisms. Crankshaft systems generally experience higher friction losses, resulting in marginally reduced fuel efficiency and consequently increased lifetime emissions from vehicles. Studies indicate that the rotational mass of traditional crankshaft assemblies can account for 0.5-2% of total vehicle fuel consumption. Timing gear systems typically demonstrate lower friction coefficients, potentially reducing these operational emissions over vehicle lifespans.

Lubricant requirements also differ substantially between these systems. Crankshaft mechanisms typically demand greater quantities of specialized lubricants to maintain optimal performance, creating additional environmental considerations regarding oil production, distribution, and disposal. Timing gear systems often operate with reduced lubrication needs, potentially decreasing this environmental burden.

Durability and replacement frequency significantly influence lifetime environmental impact. While crankshaft systems generally demonstrate exceptional longevity when properly maintained, timing gear components—particularly those incorporating polymer elements—may require more frequent replacement. This replacement cycle increases the cumulative environmental footprint through additional manufacturing and disposal impacts.

End-of-life considerations reveal that crankshaft systems offer superior recyclability, with their predominantly metal composition allowing for straightforward material recovery. Timing gear systems incorporating composite materials present more complex recycling challenges, potentially resulting in higher landfill contributions or energy-intensive specialized recycling processes.

Noise pollution represents another environmental dimension, with timing gear systems typically offering superior noise reduction characteristics compared to crankshaft mechanisms. This reduced noise footprint contributes to decreased environmental noise pollution, particularly in urban environments where vehicle density is highest.

Manufacturing crankshaft systems typically requires more energy-intensive processes, including forging and precision machining of large metal components. These processes generate substantial carbon emissions and require significant raw material inputs, primarily steel alloys. Conversely, timing gear systems, while still material-intensive, often incorporate more diverse materials including polymers and composites that may have lower production energy requirements but present different environmental challenges.

Operational environmental impacts reveal notable differences between these power transfer mechanisms. Crankshaft systems generally experience higher friction losses, resulting in marginally reduced fuel efficiency and consequently increased lifetime emissions from vehicles. Studies indicate that the rotational mass of traditional crankshaft assemblies can account for 0.5-2% of total vehicle fuel consumption. Timing gear systems typically demonstrate lower friction coefficients, potentially reducing these operational emissions over vehicle lifespans.

Lubricant requirements also differ substantially between these systems. Crankshaft mechanisms typically demand greater quantities of specialized lubricants to maintain optimal performance, creating additional environmental considerations regarding oil production, distribution, and disposal. Timing gear systems often operate with reduced lubrication needs, potentially decreasing this environmental burden.

Durability and replacement frequency significantly influence lifetime environmental impact. While crankshaft systems generally demonstrate exceptional longevity when properly maintained, timing gear components—particularly those incorporating polymer elements—may require more frequent replacement. This replacement cycle increases the cumulative environmental footprint through additional manufacturing and disposal impacts.

End-of-life considerations reveal that crankshaft systems offer superior recyclability, with their predominantly metal composition allowing for straightforward material recovery. Timing gear systems incorporating composite materials present more complex recycling challenges, potentially resulting in higher landfill contributions or energy-intensive specialized recycling processes.

Noise pollution represents another environmental dimension, with timing gear systems typically offering superior noise reduction characteristics compared to crankshaft mechanisms. This reduced noise footprint contributes to decreased environmental noise pollution, particularly in urban environments where vehicle density is highest.

Durability and Maintenance Considerations

When comparing crankshaft and timing gear systems for power transfer, durability and maintenance considerations represent critical factors that significantly impact long-term operational costs and reliability. Crankshaft systems typically demonstrate exceptional durability under normal operating conditions, with modern manufacturing techniques enabling service lives exceeding 200,000 miles in automotive applications. The primary wear points occur at bearing surfaces and journal interfaces, where metal-to-metal contact creates friction despite lubrication systems.

Timing gear systems, by contrast, offer distinct durability advantages through their solid-state power transfer mechanism. The elimination of flexible components reduces wear patterns associated with tension and stretching. High-quality timing gears manufactured from hardened steel or composite materials can maintain precise timing relationships throughout the engine's service life, often requiring minimal adjustment during standard maintenance intervals.

Maintenance requirements differ substantially between these systems. Crankshaft-based power transfer typically involves periodic inspection of bearing surfaces, oil analysis to detect metal particulates, and occasional balancing to address vibration issues. The connecting components, particularly in belt-driven systems, require regular replacement intervals—typically every 60,000 to 100,000 miles depending on application and environmental conditions.

Timing gear systems generally demand less frequent maintenance intervention but present more complex service procedures when maintenance becomes necessary. The enclosed nature of gear systems provides protection from environmental contaminants but complicates visual inspection. When service is required, it often involves more extensive disassembly, specialized tools, and precise measurement techniques to verify proper gear mesh and backlash specifications.

Environmental factors significantly influence the durability equation. In high-temperature environments, crankshaft systems with belt drives may experience accelerated deterioration of non-metallic components. Conversely, timing gear systems demonstrate superior performance in extreme temperature conditions but may be more susceptible to damage from inadequate lubrication or contaminated oil conditions.

Cost considerations for maintenance reveal that while timing gear systems typically require less frequent service, the complexity and labor intensity of such maintenance events often results in higher per-service costs. Crankshaft systems with belt drives present more predictable maintenance schedules with lower per-service costs, though their more frequent service intervals may result in comparable lifetime maintenance expenditures.

Failure mode analysis indicates that crankshaft systems tend toward progressive degradation with detectable warning signs, while timing gear failures more commonly manifest as catastrophic events with minimal advance indicators. This distinction significantly impacts preventive maintenance strategies and the potential for collateral damage during failure events.

Timing gear systems, by contrast, offer distinct durability advantages through their solid-state power transfer mechanism. The elimination of flexible components reduces wear patterns associated with tension and stretching. High-quality timing gears manufactured from hardened steel or composite materials can maintain precise timing relationships throughout the engine's service life, often requiring minimal adjustment during standard maintenance intervals.

Maintenance requirements differ substantially between these systems. Crankshaft-based power transfer typically involves periodic inspection of bearing surfaces, oil analysis to detect metal particulates, and occasional balancing to address vibration issues. The connecting components, particularly in belt-driven systems, require regular replacement intervals—typically every 60,000 to 100,000 miles depending on application and environmental conditions.

Timing gear systems generally demand less frequent maintenance intervention but present more complex service procedures when maintenance becomes necessary. The enclosed nature of gear systems provides protection from environmental contaminants but complicates visual inspection. When service is required, it often involves more extensive disassembly, specialized tools, and precise measurement techniques to verify proper gear mesh and backlash specifications.

Environmental factors significantly influence the durability equation. In high-temperature environments, crankshaft systems with belt drives may experience accelerated deterioration of non-metallic components. Conversely, timing gear systems demonstrate superior performance in extreme temperature conditions but may be more susceptible to damage from inadequate lubrication or contaminated oil conditions.

Cost considerations for maintenance reveal that while timing gear systems typically require less frequent service, the complexity and labor intensity of such maintenance events often results in higher per-service costs. Crankshaft systems with belt drives present more predictable maintenance schedules with lower per-service costs, though their more frequent service intervals may result in comparable lifetime maintenance expenditures.

Failure mode analysis indicates that crankshaft systems tend toward progressive degradation with detectable warning signs, while timing gear failures more commonly manifest as catastrophic events with minimal advance indicators. This distinction significantly impacts preventive maintenance strategies and the potential for collateral damage during failure events.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!