Crankshaft vs Cylinder Head: Vibration Reduction

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft-Cylinder Head Vibration Background and Objectives

Vibration between the crankshaft and cylinder head represents one of the most significant challenges in internal combustion engine design and operation. This technical phenomenon has evolved considerably since the early development of combustion engines in the late 19th century. Initially, vibration issues were addressed through rudimentary mechanical solutions, but as engines became more powerful and efficient, the complexity of vibration patterns increased exponentially, necessitating more sophisticated approaches.

The evolution of this technical domain has been marked by several key milestones. In the 1950s-1960s, the introduction of computer-aided analysis allowed for the first mathematical modeling of engine vibrations. The 1980s saw significant advancements in materials science, enabling better damping solutions. Most recently, the 2010s brought sophisticated digital twin technology and real-time vibration monitoring systems that revolutionized how engineers approach this challenge.

Current industry trends point toward increasingly stringent requirements for noise, vibration, and harshness (NVH) performance, driven by both regulatory pressures and consumer expectations for quieter, smoother-running engines. Simultaneously, the push for higher power density and fuel efficiency creates conflicting design parameters that exacerbate vibration issues between these critical components.

The primary objective of vibration reduction research between the crankshaft and cylinder head is multifaceted. First, it aims to enhance engine durability by minimizing mechanical stress and fatigue on components. Second, it seeks to improve operational efficiency by reducing energy losses associated with vibration. Third, it targets enhanced user experience through decreased noise and improved comfort. Fourth, it supports regulatory compliance with increasingly strict noise and emissions standards.

Additionally, this research aims to develop predictive models that can accurately simulate vibration patterns across various operating conditions, enabling preemptive design solutions rather than reactive fixes. The ultimate technical goal is to establish a comprehensive framework that balances performance requirements with vibration control across the entire engine operating range.

As electrification trends continue to reshape the automotive industry, this research also extends to hybrid powertrains where combustion engines operate under variable and often challenging conditions, creating new vibration challenges that require innovative solutions combining mechanical engineering principles with advanced electronic control systems.

The evolution of this technical domain has been marked by several key milestones. In the 1950s-1960s, the introduction of computer-aided analysis allowed for the first mathematical modeling of engine vibrations. The 1980s saw significant advancements in materials science, enabling better damping solutions. Most recently, the 2010s brought sophisticated digital twin technology and real-time vibration monitoring systems that revolutionized how engineers approach this challenge.

Current industry trends point toward increasingly stringent requirements for noise, vibration, and harshness (NVH) performance, driven by both regulatory pressures and consumer expectations for quieter, smoother-running engines. Simultaneously, the push for higher power density and fuel efficiency creates conflicting design parameters that exacerbate vibration issues between these critical components.

The primary objective of vibration reduction research between the crankshaft and cylinder head is multifaceted. First, it aims to enhance engine durability by minimizing mechanical stress and fatigue on components. Second, it seeks to improve operational efficiency by reducing energy losses associated with vibration. Third, it targets enhanced user experience through decreased noise and improved comfort. Fourth, it supports regulatory compliance with increasingly strict noise and emissions standards.

Additionally, this research aims to develop predictive models that can accurately simulate vibration patterns across various operating conditions, enabling preemptive design solutions rather than reactive fixes. The ultimate technical goal is to establish a comprehensive framework that balances performance requirements with vibration control across the entire engine operating range.

As electrification trends continue to reshape the automotive industry, this research also extends to hybrid powertrains where combustion engines operate under variable and often challenging conditions, creating new vibration challenges that require innovative solutions combining mechanical engineering principles with advanced electronic control systems.

Market Analysis for Engine Vibration Reduction Solutions

The global market for engine vibration reduction solutions has experienced significant growth in recent years, driven by increasing demands for quieter, more comfortable vehicles and stricter noise, vibration, and harshness (NVH) regulations. The market size for vibration reduction technologies in automotive engines was valued at approximately $7.2 billion in 2022 and is projected to reach $9.8 billion by 2028, representing a compound annual growth rate of 5.3%.

Consumer preferences have shifted dramatically toward vehicles with reduced noise and vibration, particularly in premium and luxury segments where comfort is a key differentiator. According to recent industry surveys, over 70% of new vehicle buyers consider noise and vibration levels as important factors in their purchasing decisions, up from 55% a decade ago.

The commercial vehicle sector represents another substantial market segment, with fleet operators increasingly recognizing that reduced vibration contributes to driver comfort, decreased fatigue, and potentially lower maintenance costs. This segment is expected to grow at 6.1% annually through 2028, outpacing the overall market.

Regionally, Asia-Pacific dominates the market with approximately 42% share, followed by Europe (28%) and North America (22%). China and India are emerging as particularly high-growth markets due to rapid automotive industry expansion and increasing consumer expectations for vehicle refinement.

The market is segmented by solution type, with active vibration control systems showing the fastest growth at 7.8% annually. Passive damping solutions still command the largest market share (58%), though this is gradually decreasing as electronic solutions become more cost-effective.

Key market drivers include increasingly stringent emissions regulations that have led to downsized engines with inherently different vibration characteristics, electrification trends requiring smoother operation of hybrid powertrains, and the premium segment's continuous push for refinement.

Challenges facing market growth include cost pressures from OEMs, the technical complexity of integrating advanced vibration control systems, and the gradual transition toward fully electric vehicles which present different vibration challenges than traditional internal combustion engines.

The aftermarket for vibration reduction solutions represents approximately 18% of the total market value, with growth opportunities in retrofitting older vehicles with improved isolation systems.

Consumer preferences have shifted dramatically toward vehicles with reduced noise and vibration, particularly in premium and luxury segments where comfort is a key differentiator. According to recent industry surveys, over 70% of new vehicle buyers consider noise and vibration levels as important factors in their purchasing decisions, up from 55% a decade ago.

The commercial vehicle sector represents another substantial market segment, with fleet operators increasingly recognizing that reduced vibration contributes to driver comfort, decreased fatigue, and potentially lower maintenance costs. This segment is expected to grow at 6.1% annually through 2028, outpacing the overall market.

Regionally, Asia-Pacific dominates the market with approximately 42% share, followed by Europe (28%) and North America (22%). China and India are emerging as particularly high-growth markets due to rapid automotive industry expansion and increasing consumer expectations for vehicle refinement.

The market is segmented by solution type, with active vibration control systems showing the fastest growth at 7.8% annually. Passive damping solutions still command the largest market share (58%), though this is gradually decreasing as electronic solutions become more cost-effective.

Key market drivers include increasingly stringent emissions regulations that have led to downsized engines with inherently different vibration characteristics, electrification trends requiring smoother operation of hybrid powertrains, and the premium segment's continuous push for refinement.

Challenges facing market growth include cost pressures from OEMs, the technical complexity of integrating advanced vibration control systems, and the gradual transition toward fully electric vehicles which present different vibration challenges than traditional internal combustion engines.

The aftermarket for vibration reduction solutions represents approximately 18% of the total market value, with growth opportunities in retrofitting older vehicles with improved isolation systems.

Current Vibration Reduction Technologies and Challenges

The vibration reduction between crankshaft and cylinder head represents a critical challenge in engine design and operation. Current technologies employ multiple approaches to address this issue, with varying degrees of effectiveness depending on engine specifications and operational conditions.

Material damping solutions constitute a primary category of vibration reduction technologies. These include the use of specialized gasket materials with enhanced damping properties, composite materials in engine components, and viscoelastic dampers strategically placed between the crankshaft and cylinder head connection points. While these solutions have demonstrated significant vibration attenuation, they often face durability challenges under extreme temperature conditions and prolonged operation.

Active vibration control systems represent the cutting edge of current technologies. These systems utilize sensors to detect vibration patterns in real-time, coupled with actuators that generate counteracting forces to neutralize unwanted vibrations. Though highly effective, these systems add complexity, weight, and cost to engine designs, limiting their widespread adoption particularly in consumer-grade vehicles.

Structural optimization techniques have gained prominence with advancements in computational analysis. Finite Element Analysis (FEA) and modal analysis allow engineers to identify resonant frequencies and optimize component geometries to avoid harmful vibration modes. This approach has led to redesigned crankshafts with optimized counterweights and cylinder heads with reinforced mounting points, achieving vibration reduction without additional components.

Balance shaft technology remains a standard solution in many engine designs. These counter-rotating shafts, synchronized with the crankshaft, generate forces that offset primary and secondary vibrations. However, they add weight, complexity, and parasitic power losses to the engine system.

Fluid-based damping systems, including hydraulic engine mounts and oil-filled dampers, offer another approach. These systems provide variable damping characteristics that can adapt to different operating conditions but may suffer from performance degradation over time due to fluid property changes.

The primary challenges facing current vibration reduction technologies include the trade-off between effectiveness and added weight/complexity, durability concerns under extreme operating conditions, and cost considerations for mass production. Additionally, as engines evolve toward higher power densities and lighter constructions, vibration characteristics change, requiring continuous adaptation of reduction strategies.

Another significant challenge is the integration of vibration reduction technologies with other engine systems without compromising overall performance, efficiency, or emissions compliance. This becomes particularly relevant as automotive manufacturers transition toward electrification and hybrid powertrains, where new vibration patterns emerge from the interaction between conventional engines and electric motors.

Material damping solutions constitute a primary category of vibration reduction technologies. These include the use of specialized gasket materials with enhanced damping properties, composite materials in engine components, and viscoelastic dampers strategically placed between the crankshaft and cylinder head connection points. While these solutions have demonstrated significant vibration attenuation, they often face durability challenges under extreme temperature conditions and prolonged operation.

Active vibration control systems represent the cutting edge of current technologies. These systems utilize sensors to detect vibration patterns in real-time, coupled with actuators that generate counteracting forces to neutralize unwanted vibrations. Though highly effective, these systems add complexity, weight, and cost to engine designs, limiting their widespread adoption particularly in consumer-grade vehicles.

Structural optimization techniques have gained prominence with advancements in computational analysis. Finite Element Analysis (FEA) and modal analysis allow engineers to identify resonant frequencies and optimize component geometries to avoid harmful vibration modes. This approach has led to redesigned crankshafts with optimized counterweights and cylinder heads with reinforced mounting points, achieving vibration reduction without additional components.

Balance shaft technology remains a standard solution in many engine designs. These counter-rotating shafts, synchronized with the crankshaft, generate forces that offset primary and secondary vibrations. However, they add weight, complexity, and parasitic power losses to the engine system.

Fluid-based damping systems, including hydraulic engine mounts and oil-filled dampers, offer another approach. These systems provide variable damping characteristics that can adapt to different operating conditions but may suffer from performance degradation over time due to fluid property changes.

The primary challenges facing current vibration reduction technologies include the trade-off between effectiveness and added weight/complexity, durability concerns under extreme operating conditions, and cost considerations for mass production. Additionally, as engines evolve toward higher power densities and lighter constructions, vibration characteristics change, requiring continuous adaptation of reduction strategies.

Another significant challenge is the integration of vibration reduction technologies with other engine systems without compromising overall performance, efficiency, or emissions compliance. This becomes particularly relevant as automotive manufacturers transition toward electrification and hybrid powertrains, where new vibration patterns emerge from the interaction between conventional engines and electric motors.

Existing Crankshaft-Cylinder Head Vibration Dampening Solutions

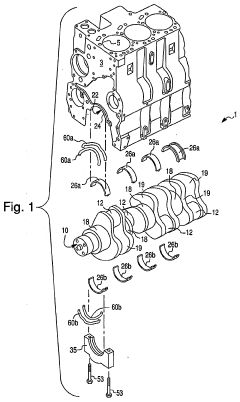

01 Vibration damping mechanisms for crankshafts

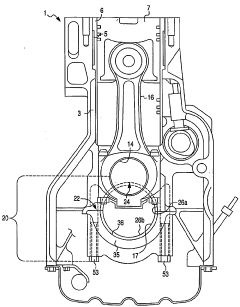

Various mechanisms can be employed to reduce vibrations in crankshafts, including dampers, counterweights, and specialized mounting systems. These components work by absorbing or counteracting the vibrational forces generated during engine operation. Effective damping mechanisms can significantly reduce the transmission of vibrations to other engine components, including the cylinder head, thereby improving engine performance and longevity.- Vibration damping mechanisms for crankshafts: Various mechanisms can be implemented to reduce vibrations in crankshafts, including dampers, counterweights, and specialized mounting systems. These solutions help absorb and neutralize vibrations generated during engine operation, preventing them from transferring to the cylinder head and other engine components. Effective damping mechanisms can significantly improve engine performance, reduce wear, and extend component lifespan.

- Cylinder head vibration isolation techniques: Specialized mounting systems and isolation techniques can be employed to minimize vibration transfer between the crankshaft and cylinder head. These include flexible mounting brackets, vibration-absorbing materials, and strategic placement of reinforcement structures. By isolating the cylinder head from crankshaft-induced vibrations, these techniques help maintain proper valve timing, prevent gasket failures, and ensure optimal combustion efficiency.

- Vibration monitoring and detection systems: Advanced monitoring systems can be implemented to detect and analyze vibrations in the crankshaft and cylinder head. These systems utilize sensors, accelerometers, and computerized analysis to identify abnormal vibration patterns before they cause damage. Early detection allows for preventive maintenance and adjustments to operating parameters, helping to avoid catastrophic failures and extend engine life.

- Structural design improvements for vibration reduction: Innovative structural designs can significantly reduce vibrations in both crankshafts and cylinder heads. These include optimized component geometries, strategic material selection, and reinforced mounting points. Computer-aided design and finite element analysis help engineers develop components with natural frequencies that minimize resonance effects. These design improvements result in smoother engine operation and reduced mechanical stress.

- Balance shaft systems for vibration compensation: Balance shaft systems can be incorporated into engine designs to counteract vibrations generated by the crankshaft. These systems use counter-rotating shafts with precisely positioned weights to generate forces that offset primary and secondary vibrations. By neutralizing these vibrations at their source, balance shaft systems prevent them from reaching the cylinder head and other engine components, resulting in smoother operation and reduced wear.

02 Cylinder head design modifications to reduce vibration

Specific design modifications to the cylinder head can help minimize vibration issues. These include reinforced mounting points, optimized material distribution, and structural enhancements that increase rigidity. By improving the structural integrity of the cylinder head, these modifications help to resist deformation under vibrational forces and reduce the propagation of vibrations throughout the engine assembly.Expand Specific Solutions03 Vibration monitoring and diagnostic systems

Advanced monitoring systems can be implemented to detect and analyze vibrations in crankshafts and cylinder heads. These systems typically employ sensors to measure vibration patterns and frequencies, allowing for early detection of potential issues. The collected data can be processed using specialized algorithms to diagnose problems before they lead to component failure, enabling preventive maintenance and reducing downtime.Expand Specific Solutions04 Integration of balancing shafts and counterweights

Balancing shafts and strategically placed counterweights can be integrated into engine designs to offset the inherent imbalances in crankshaft rotation. These components work by generating opposing forces that cancel out primary and secondary vibrations. Proper placement and sizing of these elements is critical to effectively reducing vibrations that would otherwise be transmitted to the cylinder head and other engine components.Expand Specific Solutions05 Advanced materials and manufacturing techniques

The use of advanced materials and manufacturing techniques can significantly reduce vibration issues in crankshafts and cylinder heads. Materials with superior damping properties, such as specialized alloys or composite materials, can absorb vibrational energy more effectively. Additionally, precision manufacturing techniques ensure better component balance and fit, reducing the generation of vibrations during operation and improving overall engine performance.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Vibration Control

The vibration reduction technology between crankshaft and cylinder head is currently in a growth phase, with an expanding market driven by increasing demand for quieter, more efficient engines. The global market is estimated to reach $5-7 billion by 2025, with automotive OEMs leading adoption. Toyota, Honda, and Volkswagen demonstrate advanced technical maturity through extensive patent portfolios and commercial implementations, while companies like DENSO, BorgWarner, and Schaeffler provide specialized component solutions. Emerging players such as Guangxi Yuchai and Changan Automobile are rapidly developing capabilities, particularly in emerging markets. The technology continues to evolve with hybrid and electric powertrain integration becoming a key focus area for industry leaders like Toyota and Nissan.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced vibration reduction technologies between crankshaft and cylinder head through their Dynamic Vibration Absorber (DVA) system. This system incorporates tuned mass dampers strategically positioned to counteract specific vibration frequencies generated during engine operation. Toyota's approach includes a multi-layered solution with engine mount optimization using hydraulic fluid-filled mounts that change damping characteristics based on engine speed and load. Their Active Control Engine Mount (ACEM) technology uses sensors to detect vibration patterns and counteracts them with precisely timed opposing forces. Toyota has also implemented a crankshaft pulley with a rubber damping layer that absorbs torsional vibrations before they can propagate to the cylinder head. Their cylinder head gasket design incorporates multiple metal layers with elastomeric coatings to provide both sealing and vibration isolation properties.

Strengths: Toyota's integrated approach combines passive and active vibration control systems, providing effective damping across various engine operating conditions. Their solutions are highly refined through extensive testing and real-world implementation across their vehicle lineup. Weaknesses: The complexity of Toyota's active vibration control systems adds cost and potential reliability concerns, particularly in their more sophisticated implementations requiring electronic controls and actuators.

Honda Motor Co., Ltd.

Technical Solution: Honda has pioneered innovative vibration reduction technologies between crankshaft and cylinder head through their Active Noise Control (ANC) and Active Vibration Cancellation (AVC) systems. Their approach integrates both mechanical and electronic solutions, including a patented balancer shaft system that counteracts second-order vibrations inherent in four-cylinder engines. Honda's Variable Cylinder Management (VCM) system selectively deactivates cylinders during light load conditions, which is complemented by active engine mounts that use electromagnetic actuators to generate counter-vibrations based on real-time sensor data. Their crankshaft design incorporates precision balancing and specialized journal bearings with optimized oil clearances to minimize vibration transmission. Honda has also developed a unique cylinder head mounting system with variable-stiffness insulators that adapt to different engine speeds, effectively isolating the cylinder head from crankshaft-induced vibrations while maintaining proper sealing and alignment.

Strengths: Honda's solutions demonstrate excellent vibration reduction across a wide RPM range, particularly at idle and low speeds where vibration is most noticeable to occupants. Their systems are well-integrated with other engine technologies and have proven durability in long-term operation. Weaknesses: Some of Honda's more advanced vibration control systems add complexity and weight to the engine assembly, potentially impacting fuel efficiency and increasing manufacturing costs.

Key Patents and Technical Literature on Engine Vibration Reduction

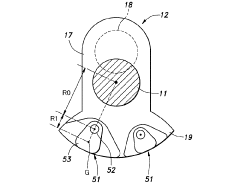

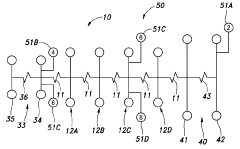

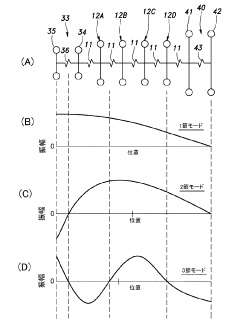

Vibration reducing device of internal combustion engine

PatentInactiveJP2019015316A

Innovation

- A vibration reducing device for internal combustion engines that includes centrifugal pendulum dampers positioned at specific antinodes corresponding to the one-node, two-node, and three-node modes of torsional vibration, with multiple dampers placed at strategic points along the crankshaft to suppress resonance and natural vibrations.

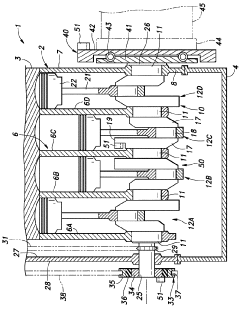

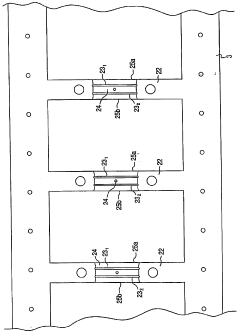

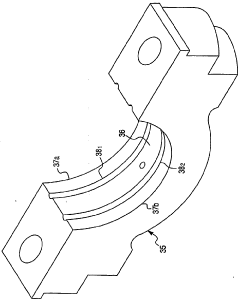

Vibration dampening arrangement for internal combustion engines

PatentWO2004072463A1

Innovation

- A vibration dampener arrangement is integrated into the engine design, featuring semi-annular recessed portions in the main bearing cap and crankshaft support members, filled with elastomeric rubber-like material to form O-ring-like vibration dampener members that reduce vibration transmission between connecting rods, the crankshaft, and the cylinder block.

NVH Performance Standards and Testing Methodologies

The establishment of comprehensive NVH (Noise, Vibration, and Harshness) performance standards and testing methodologies is crucial for effective vibration reduction between the crankshaft and cylinder head. Industry standards such as ISO 16063 for vibration calibration and SAE J1074 for engine vibration measurement provide foundational frameworks for evaluating powertrain vibration characteristics.

Performance standards typically categorize vibration levels into three tiers: acceptable (below 0.5 mm/s RMS), marginal (0.5-1.2 mm/s RMS), and unacceptable (above 1.2 mm/s RMS) for passenger vehicles. These thresholds vary based on engine displacement, configuration, and vehicle class, with premium vehicles requiring more stringent vibration control.

Testing methodologies for crankshaft-cylinder head vibration assessment encompass both component-level and system-level approaches. Component testing involves modal analysis of individual parts using impact hammers and accelerometers to identify natural frequencies and mode shapes. System-level evaluations employ operational deflection shape (ODS) analysis during engine operation across various RPM ranges to capture dynamic behavior under actual loading conditions.

Frequency domain analysis remains the cornerstone of vibration assessment, with particular attention to the 30-300 Hz range where crankshaft-cylinder head interactions are most pronounced. Fast Fourier Transform (FFT) analysis enables identification of dominant frequencies, while order tracking techniques correlate vibration patterns with specific engine events such as combustion pulses and valve train operations.

Advanced testing protocols now incorporate multi-channel data acquisition systems with simultaneous measurement at multiple locations. This approach enables transfer path analysis (TPA) to quantify vibration transmission routes between the crankshaft and cylinder head, identifying critical paths requiring intervention.

Standardized test cycles have been developed to ensure repeatability, including cold start evaluation, steady-state operation at multiple load points, and transient response during acceleration and deceleration. These cycles must be performed under controlled environmental conditions (20±2°C) to minimize external variables.

Digital twin methodologies are increasingly integrated into testing protocols, allowing correlation between physical measurements and simulation models. This hybrid approach facilitates rapid evaluation of design modifications without requiring physical prototypes for each iteration, significantly accelerating the development process while maintaining adherence to established performance standards.

Performance standards typically categorize vibration levels into three tiers: acceptable (below 0.5 mm/s RMS), marginal (0.5-1.2 mm/s RMS), and unacceptable (above 1.2 mm/s RMS) for passenger vehicles. These thresholds vary based on engine displacement, configuration, and vehicle class, with premium vehicles requiring more stringent vibration control.

Testing methodologies for crankshaft-cylinder head vibration assessment encompass both component-level and system-level approaches. Component testing involves modal analysis of individual parts using impact hammers and accelerometers to identify natural frequencies and mode shapes. System-level evaluations employ operational deflection shape (ODS) analysis during engine operation across various RPM ranges to capture dynamic behavior under actual loading conditions.

Frequency domain analysis remains the cornerstone of vibration assessment, with particular attention to the 30-300 Hz range where crankshaft-cylinder head interactions are most pronounced. Fast Fourier Transform (FFT) analysis enables identification of dominant frequencies, while order tracking techniques correlate vibration patterns with specific engine events such as combustion pulses and valve train operations.

Advanced testing protocols now incorporate multi-channel data acquisition systems with simultaneous measurement at multiple locations. This approach enables transfer path analysis (TPA) to quantify vibration transmission routes between the crankshaft and cylinder head, identifying critical paths requiring intervention.

Standardized test cycles have been developed to ensure repeatability, including cold start evaluation, steady-state operation at multiple load points, and transient response during acceleration and deceleration. These cycles must be performed under controlled environmental conditions (20±2°C) to minimize external variables.

Digital twin methodologies are increasingly integrated into testing protocols, allowing correlation between physical measurements and simulation models. This hybrid approach facilitates rapid evaluation of design modifications without requiring physical prototypes for each iteration, significantly accelerating the development process while maintaining adherence to established performance standards.

Environmental Impact of Vibration Reduction Technologies

The environmental implications of vibration reduction technologies in crankshaft-cylinder head systems extend far beyond operational efficiency. Engine vibrations contribute significantly to noise pollution, which has been linked to various health issues including stress, hearing impairment, and cardiovascular problems in urban environments. By implementing advanced vibration reduction technologies, manufacturers can substantially decrease noise emissions from vehicles and industrial machinery, contributing to healthier living and working environments.

Energy efficiency represents another critical environmental dimension of vibration reduction. Excessive vibration in engine systems leads to energy losses through friction and mechanical inefficiency. Studies indicate that effective vibration dampening can improve fuel efficiency by 2-5%, translating to substantial reductions in carbon emissions when applied across global vehicle fleets. For instance, a 3% efficiency improvement in commercial vehicles could reduce annual CO2 emissions by millions of tons worldwide.

Material sustainability also benefits from vibration control technologies. Reduced vibration extends component lifespan, decreasing the frequency of replacements and associated manufacturing impacts. Modern vibration reduction materials increasingly incorporate recycled content and bio-based alternatives to traditional petroleum-derived elastomers. These innovations align with circular economy principles while maintaining or improving performance characteristics.

Manufacturing processes for vibration reduction components have evolved toward greater environmental responsibility. Water-based adhesives have replaced solvent-based systems in damper production, reducing volatile organic compound (VOC) emissions. Additionally, computer-optimized design has minimized material usage while maintaining performance standards, reducing the overall environmental footprint of vibration control systems.

Lifecycle assessment studies demonstrate that the environmental benefits of vibration reduction technologies typically outweigh their production impacts within the first 20-30% of component lifespan. This favorable environmental return on investment strengthens the case for widespread adoption across industrial applications, particularly in transportation and power generation sectors where vibration issues are prevalent.

Regulatory frameworks increasingly recognize these environmental benefits, with noise emission standards becoming more stringent globally. The European Union's Environmental Noise Directive and similar regulations worldwide have accelerated research and implementation of advanced vibration control technologies, creating market incentives that align economic and environmental objectives in engineering design.

Energy efficiency represents another critical environmental dimension of vibration reduction. Excessive vibration in engine systems leads to energy losses through friction and mechanical inefficiency. Studies indicate that effective vibration dampening can improve fuel efficiency by 2-5%, translating to substantial reductions in carbon emissions when applied across global vehicle fleets. For instance, a 3% efficiency improvement in commercial vehicles could reduce annual CO2 emissions by millions of tons worldwide.

Material sustainability also benefits from vibration control technologies. Reduced vibration extends component lifespan, decreasing the frequency of replacements and associated manufacturing impacts. Modern vibration reduction materials increasingly incorporate recycled content and bio-based alternatives to traditional petroleum-derived elastomers. These innovations align with circular economy principles while maintaining or improving performance characteristics.

Manufacturing processes for vibration reduction components have evolved toward greater environmental responsibility. Water-based adhesives have replaced solvent-based systems in damper production, reducing volatile organic compound (VOC) emissions. Additionally, computer-optimized design has minimized material usage while maintaining performance standards, reducing the overall environmental footprint of vibration control systems.

Lifecycle assessment studies demonstrate that the environmental benefits of vibration reduction technologies typically outweigh their production impacts within the first 20-30% of component lifespan. This favorable environmental return on investment strengthens the case for widespread adoption across industrial applications, particularly in transportation and power generation sectors where vibration issues are prevalent.

Regulatory frameworks increasingly recognize these environmental benefits, with noise emission standards becoming more stringent globally. The European Union's Environmental Noise Directive and similar regulations worldwide have accelerated research and implementation of advanced vibration control technologies, creating market incentives that align economic and environmental objectives in engineering design.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!