Quantify Crankshaft Rotational Inertia for Energy Optimization

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Inertia Measurement Background and Objectives

Crankshaft rotational inertia quantification has evolved significantly over the past decades, transitioning from rudimentary pendulum-based methods to sophisticated digital measurement systems. This evolution reflects the growing importance of precise inertia measurements in modern engine design, particularly as efficiency standards become increasingly stringent. The crankshaft, as a critical rotating component in internal combustion engines, directly influences engine performance, fuel efficiency, and emissions through its inertial properties.

Historically, engineers relied on simplified mathematical models and approximations to estimate crankshaft inertia, often resulting in suboptimal designs. The 1970s energy crisis marked a turning point, catalyzing research into more accurate measurement techniques as manufacturers sought to improve fuel economy. By the 1990s, computer-aided design and simulation tools began supplementing physical testing, though these early computational methods still required validation through experimental measurements.

Today's focus on energy optimization demands unprecedented precision in quantifying rotational inertia. Even minor reductions in crankshaft inertia can yield significant improvements in engine responsiveness, fuel efficiency, and emissions performance. This is particularly relevant for modern downsized turbocharged engines, hybrid powertrains, and start-stop systems where transient performance is critical.

The primary objective of crankshaft inertia measurement is to establish accurate baseline data that enables engineers to optimize mass distribution while maintaining structural integrity. This optimization process aims to reduce energy losses during acceleration and deceleration phases of engine operation, particularly at higher RPMs where inertial forces become dominant. Secondary objectives include minimizing torsional vibrations, improving NVH (Noise, Vibration, Harshness) characteristics, and enhancing overall powertrain efficiency.

Current technological trends point toward integrated measurement systems that combine physical testing with advanced simulation capabilities. Machine learning algorithms are increasingly being employed to predict inertial properties based on geometric data, material composition, and manufacturing variables. These predictive models help reduce development time and costs while maintaining accuracy.

Looking forward, the industry is moving toward real-time inertia monitoring systems that can detect changes in rotational dynamics during engine operation. This advancement would enable adaptive control strategies that optimize performance based on actual inertial properties rather than static design values. Additionally, as materials science progresses, new composite and hybrid metal structures are being explored to fundamentally alter the mass-strength relationship in crankshaft design.

The ultimate goal remains consistent: to quantify crankshaft rotational inertia with sufficient precision to enable meaningful energy optimization across all operating conditions, thereby contributing to the broader objectives of improved efficiency, reduced emissions, and enhanced performance in modern powertrains.

Historically, engineers relied on simplified mathematical models and approximations to estimate crankshaft inertia, often resulting in suboptimal designs. The 1970s energy crisis marked a turning point, catalyzing research into more accurate measurement techniques as manufacturers sought to improve fuel economy. By the 1990s, computer-aided design and simulation tools began supplementing physical testing, though these early computational methods still required validation through experimental measurements.

Today's focus on energy optimization demands unprecedented precision in quantifying rotational inertia. Even minor reductions in crankshaft inertia can yield significant improvements in engine responsiveness, fuel efficiency, and emissions performance. This is particularly relevant for modern downsized turbocharged engines, hybrid powertrains, and start-stop systems where transient performance is critical.

The primary objective of crankshaft inertia measurement is to establish accurate baseline data that enables engineers to optimize mass distribution while maintaining structural integrity. This optimization process aims to reduce energy losses during acceleration and deceleration phases of engine operation, particularly at higher RPMs where inertial forces become dominant. Secondary objectives include minimizing torsional vibrations, improving NVH (Noise, Vibration, Harshness) characteristics, and enhancing overall powertrain efficiency.

Current technological trends point toward integrated measurement systems that combine physical testing with advanced simulation capabilities. Machine learning algorithms are increasingly being employed to predict inertial properties based on geometric data, material composition, and manufacturing variables. These predictive models help reduce development time and costs while maintaining accuracy.

Looking forward, the industry is moving toward real-time inertia monitoring systems that can detect changes in rotational dynamics during engine operation. This advancement would enable adaptive control strategies that optimize performance based on actual inertial properties rather than static design values. Additionally, as materials science progresses, new composite and hybrid metal structures are being explored to fundamentally alter the mass-strength relationship in crankshaft design.

The ultimate goal remains consistent: to quantify crankshaft rotational inertia with sufficient precision to enable meaningful energy optimization across all operating conditions, thereby contributing to the broader objectives of improved efficiency, reduced emissions, and enhanced performance in modern powertrains.

Market Demand for Energy-Efficient Powertrain Systems

The global automotive industry is experiencing a significant shift towards energy efficiency, driven by stringent emissions regulations, rising fuel costs, and increasing consumer awareness of environmental impacts. This transformation has created a robust market demand for energy-efficient powertrain systems, where crankshaft rotational inertia optimization plays a crucial role in overall vehicle performance and efficiency.

Market research indicates that the global automotive powertrain market was valued at approximately $680 billion in 2022, with projections showing growth to reach $950 billion by 2030. Within this market, technologies focused on energy efficiency are experiencing the fastest growth rates, averaging 8-10% annually compared to 3-5% for traditional powertrain technologies.

Vehicle manufacturers are under increasing pressure to meet regulatory standards such as the European Union's CO2 emissions targets, which mandate fleet-wide emissions of 95g CO2/km, and similar regulations in North America and Asia. These regulatory pressures have created a direct market pull for technologies that can optimize every aspect of powertrain efficiency, including crankshaft inertia management.

Consumer preferences have also evolved significantly, with fuel economy now ranking among the top five purchase considerations for new vehicle buyers across major markets. A 2023 J.D. Power survey revealed that 67% of new car buyers consider fuel efficiency "extremely important" or "very important" in their purchase decision, up from 52% in 2018.

The commercial vehicle sector represents another substantial market segment, where even marginal improvements in powertrain efficiency can translate to significant operational cost savings. Fleet operators typically calculate that a 1% improvement in fuel efficiency can result in savings of thousands of dollars per vehicle annually, creating strong economic incentives for adoption of optimized powertrain technologies.

Emerging markets present particularly strong growth opportunities, with countries like China and India implementing increasingly stringent emissions standards while simultaneously experiencing rapid growth in vehicle ownership. The Chinese market alone is expected to demand over 30 million new vehicles annually by 2025, with government policies strongly favoring energy-efficient technologies.

The aftermarket segment also shows promising demand, with performance-oriented consumers and fleet operators seeking retrofitting solutions that can improve efficiency in existing vehicles. This segment was valued at approximately $45 billion in 2022 for powertrain optimization components and services.

Electric and hybrid vehicle manufacturers are similarly concerned with energy optimization, as crankshaft inertia quantification and optimization in hybrid powertrains can significantly extend electric range and improve overall system efficiency, addressing the critical "range anxiety" barrier to wider electric vehicle adoption.

Market research indicates that the global automotive powertrain market was valued at approximately $680 billion in 2022, with projections showing growth to reach $950 billion by 2030. Within this market, technologies focused on energy efficiency are experiencing the fastest growth rates, averaging 8-10% annually compared to 3-5% for traditional powertrain technologies.

Vehicle manufacturers are under increasing pressure to meet regulatory standards such as the European Union's CO2 emissions targets, which mandate fleet-wide emissions of 95g CO2/km, and similar regulations in North America and Asia. These regulatory pressures have created a direct market pull for technologies that can optimize every aspect of powertrain efficiency, including crankshaft inertia management.

Consumer preferences have also evolved significantly, with fuel economy now ranking among the top five purchase considerations for new vehicle buyers across major markets. A 2023 J.D. Power survey revealed that 67% of new car buyers consider fuel efficiency "extremely important" or "very important" in their purchase decision, up from 52% in 2018.

The commercial vehicle sector represents another substantial market segment, where even marginal improvements in powertrain efficiency can translate to significant operational cost savings. Fleet operators typically calculate that a 1% improvement in fuel efficiency can result in savings of thousands of dollars per vehicle annually, creating strong economic incentives for adoption of optimized powertrain technologies.

Emerging markets present particularly strong growth opportunities, with countries like China and India implementing increasingly stringent emissions standards while simultaneously experiencing rapid growth in vehicle ownership. The Chinese market alone is expected to demand over 30 million new vehicles annually by 2025, with government policies strongly favoring energy-efficient technologies.

The aftermarket segment also shows promising demand, with performance-oriented consumers and fleet operators seeking retrofitting solutions that can improve efficiency in existing vehicles. This segment was valued at approximately $45 billion in 2022 for powertrain optimization components and services.

Electric and hybrid vehicle manufacturers are similarly concerned with energy optimization, as crankshaft inertia quantification and optimization in hybrid powertrains can significantly extend electric range and improve overall system efficiency, addressing the critical "range anxiety" barrier to wider electric vehicle adoption.

Current Challenges in Crankshaft Inertia Quantification

The accurate quantification of crankshaft rotational inertia presents significant challenges that impede energy optimization efforts in modern engine design. Traditional measurement methods often rely on pendulum-based approaches which, while established, suffer from precision limitations when applied to complex crankshaft geometries. These methods typically achieve accuracy levels of only ±3-5%, which is insufficient for advanced energy optimization algorithms that require precision within ±1%.

Computational methods using CAD models and finite element analysis have emerged as alternatives, but they introduce their own set of challenges. Material density variations in actual manufactured crankshafts can deviate from theoretical models by up to 2%, leading to discrepancies between calculated and actual inertial properties. Furthermore, the computational complexity increases exponentially with geometric detail, creating a trade-off between accuracy and processing time that engineers must constantly navigate.

Dynamic measurement systems utilizing torque sensors and angular acceleration measurements face interference from friction, vibration, and signal noise. These environmental factors can introduce measurement errors of up to 7% in industrial settings, significantly compromising the reliability of collected data. The isolation of pure rotational inertia from these confounding variables remains a persistent technical hurdle.

Manufacturing tolerances further complicate inertia quantification. Even with high-precision manufacturing processes, dimensional variations of ±0.05mm are common in crankshaft production. These seemingly minor deviations can result in inertia variations of up to 1.5%, which becomes critical when optimizing for millisecond-level combustion timing and efficiency gains of less than 1%.

Temperature effects introduce another layer of complexity. As engines operate across temperature ranges from -40°C to 150°C, thermal expansion alters the crankshaft's dimensional properties. Current measurement techniques struggle to account for these dynamic changes, with most systems calibrated only at standard room temperature (20-25°C), leaving significant gaps in understanding real-world performance.

The integration challenge cannot be overlooked. Crankshaft inertia must be considered within the context of the entire powertrain system, including the flywheel, clutch, and transmission components. Current methods often isolate the crankshaft for measurement, failing to capture the interactive inertial effects that occur during actual operation. This system-level gap creates discrepancies between laboratory measurements and real-world energy consumption patterns.

Lastly, the industry faces a standardization challenge. Different manufacturers employ varying methodologies for inertia quantification, making cross-platform comparisons difficult and hindering the establishment of universal optimization benchmarks. This fragmentation slows the overall progress toward more energy-efficient engine designs across the automotive and industrial sectors.

Computational methods using CAD models and finite element analysis have emerged as alternatives, but they introduce their own set of challenges. Material density variations in actual manufactured crankshafts can deviate from theoretical models by up to 2%, leading to discrepancies between calculated and actual inertial properties. Furthermore, the computational complexity increases exponentially with geometric detail, creating a trade-off between accuracy and processing time that engineers must constantly navigate.

Dynamic measurement systems utilizing torque sensors and angular acceleration measurements face interference from friction, vibration, and signal noise. These environmental factors can introduce measurement errors of up to 7% in industrial settings, significantly compromising the reliability of collected data. The isolation of pure rotational inertia from these confounding variables remains a persistent technical hurdle.

Manufacturing tolerances further complicate inertia quantification. Even with high-precision manufacturing processes, dimensional variations of ±0.05mm are common in crankshaft production. These seemingly minor deviations can result in inertia variations of up to 1.5%, which becomes critical when optimizing for millisecond-level combustion timing and efficiency gains of less than 1%.

Temperature effects introduce another layer of complexity. As engines operate across temperature ranges from -40°C to 150°C, thermal expansion alters the crankshaft's dimensional properties. Current measurement techniques struggle to account for these dynamic changes, with most systems calibrated only at standard room temperature (20-25°C), leaving significant gaps in understanding real-world performance.

The integration challenge cannot be overlooked. Crankshaft inertia must be considered within the context of the entire powertrain system, including the flywheel, clutch, and transmission components. Current methods often isolate the crankshaft for measurement, failing to capture the interactive inertial effects that occur during actual operation. This system-level gap creates discrepancies between laboratory measurements and real-world energy consumption patterns.

Lastly, the industry faces a standardization challenge. Different manufacturers employ varying methodologies for inertia quantification, making cross-platform comparisons difficult and hindering the establishment of universal optimization benchmarks. This fragmentation slows the overall progress toward more energy-efficient engine designs across the automotive and industrial sectors.

Existing Methods for Crankshaft Inertia Quantification

01 Crankshaft design optimization for rotational inertia

Optimizing the design of crankshafts to achieve desired rotational inertia characteristics is crucial for engine performance. This includes modifications to the crankshaft geometry, material selection, and weight distribution. By carefully designing counterweights and optimizing the overall structure, engineers can achieve the ideal rotational inertia for specific engine applications, resulting in improved engine balance, reduced vibration, and enhanced performance.- Crankshaft design modifications to optimize rotational inertia: Various design modifications can be implemented to optimize the rotational inertia of crankshafts. These include altering the shape, size, and material composition of counterweights, optimizing the crankshaft geometry, and using lightweight materials. Such modifications help balance the crankshaft, reduce vibrations, and improve engine performance by controlling the rotational inertia to desired levels.

- Counterweight configurations for inertia management: Specific counterweight configurations are employed to manage crankshaft rotational inertia. These configurations include adjustable counterweights, variable mass distribution, and optimized positioning along the crankshaft. By carefully designing the counterweight system, engineers can achieve the desired rotational inertia characteristics, leading to improved engine balance, reduced vibration, and enhanced performance across different operating conditions.

- Measurement and analysis systems for rotational inertia: Specialized systems and methods are used to measure, analyze, and optimize crankshaft rotational inertia. These include digital modeling techniques, simulation software, physical testing apparatus, and real-time monitoring systems. Accurate measurement and analysis allow engineers to fine-tune the rotational inertia properties of crankshafts, ensuring optimal engine performance, fuel efficiency, and durability.

- Inertia reduction techniques for improved engine response: Various techniques are employed to reduce crankshaft rotational inertia for improved engine response. These include using composite materials, hollow shaft designs, advanced manufacturing processes, and strategic material removal. Reduced rotational inertia leads to quicker engine response, improved acceleration, reduced fuel consumption, and enhanced overall engine efficiency, particularly beneficial in high-performance applications.

- Vibration damping systems related to rotational inertia: Specialized vibration damping systems are integrated with crankshafts to manage issues related to rotational inertia. These include harmonic balancers, dual-mass flywheels, tuned mass dampers, and active vibration control systems. By effectively managing vibrations caused by rotational inertia variations, these systems improve engine smoothness, reduce component wear, extend engine life, and enhance overall vehicle comfort.

02 Measurement and analysis of crankshaft rotational inertia

Various methods and systems are employed to accurately measure and analyze the rotational inertia of crankshafts. These include specialized testing equipment, computational models, and simulation techniques. Precise measurement of rotational inertia is essential for engine design, balancing, and performance optimization. Advanced analysis techniques help engineers understand how rotational inertia affects engine dynamics and identify opportunities for improvement.Expand Specific Solutions03 Balancing mechanisms for crankshaft rotational inertia

Balancing mechanisms are implemented to counteract the effects of crankshaft rotational inertia, reducing vibration and improving engine smoothness. These mechanisms include balance shafts, counterweights, and harmonic balancers. By effectively managing rotational inertia through proper balancing, engine manufacturers can achieve smoother operation, reduced wear on components, and improved overall engine efficiency and longevity.Expand Specific Solutions04 Variable inertia crankshaft systems

Advanced crankshaft systems incorporate mechanisms to vary rotational inertia based on operating conditions. These systems can adjust the effective inertia of the crankshaft to optimize performance across different engine speeds and loads. Variable inertia systems may use adjustable counterweights, fluid-based mechanisms, or other innovative approaches to dynamically change the rotational characteristics of the crankshaft, resulting in improved efficiency and performance across a wider operating range.Expand Specific Solutions05 Lightweight materials and construction for reduced inertia

The use of lightweight materials and innovative construction techniques helps reduce crankshaft rotational inertia while maintaining strength and durability. Materials such as high-strength alloys, composites, and specialized manufacturing processes like hollow construction or selective reinforcement are employed. Reducing rotational inertia through lightweight design can improve engine responsiveness, acceleration, and fuel efficiency by decreasing the energy required to change engine speed.Expand Specific Solutions

Leading Companies in Powertrain Optimization Technology

The crankshaft rotational inertia optimization market is currently in a growth phase, with major automotive and industrial equipment manufacturers driving innovation. The market is expanding due to increasing focus on energy efficiency in vehicles and machinery, estimated at approximately $3.5 billion globally. Leading automotive players like Robert Bosch, Continental Automotive, and Toyota Motor Corp. are competing with powertrain specialists such as BorgWarner and Schaeffler Technologies to develop advanced solutions. The technology is reaching maturity in conventional applications but evolving rapidly for electric and hybrid vehicles, with companies like Nissan and Ford Global Technologies investing heavily in research. Academic institutions including Nanjing University of Aeronautics & Astronautics are contributing significant research to advance theoretical frameworks for optimization.

Robert Bosch GmbH

Technical Solution: Bosch has developed an advanced crankshaft rotational inertia measurement system that combines laser vibrometry with digital signal processing to achieve high-precision quantification. Their approach utilizes torsional vibration analysis to determine the moment of inertia without disassembling the engine. The system employs multiple sensors positioned strategically around the crankshaft to capture vibration data during controlled acceleration and deceleration phases. This data is processed through proprietary algorithms that filter out noise and isolate the inertial characteristics. Bosch's solution integrates with their engine management systems to dynamically adjust fuel injection timing and valve actuation based on real-time inertia measurements, resulting in up to 3.5% improvement in fuel efficiency across various operating conditions[1]. The technology has been implemented across their powertrain development platforms and is being utilized in both conventional and hybrid vehicle applications.

Strengths: Superior integration with existing engine management systems, allowing for real-time optimization. High measurement accuracy (±0.5%) enables precise energy optimization. Weaknesses: Requires sophisticated sensor arrays that increase implementation costs. System calibration is complex and requires specialized expertise.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has pioneered a comprehensive crankshaft inertia optimization approach combining experimental measurement with advanced simulation techniques. Their method employs a pendulum-based measurement system that utilizes precision bearings and optical encoders to determine rotational inertia with accuracy up to 0.3%. The company has developed specialized finite element analysis (FEA) models that can predict inertial properties of complex crankshaft geometries while accounting for material variations and manufacturing tolerances. Schaeffler's technology incorporates dynamic mass redistribution principles, where the crankshaft design is iteratively optimized to concentrate mass closer to the rotation axis in non-critical areas while maintaining structural integrity. Their latest innovation includes a variable inertia crankshaft system that can adjust its effective rotational inertia by up to 15% during different operating conditions through controlled fluid dynamics within specially designed chambers[2]. This adaptive system has demonstrated fuel economy improvements of 2.8-4.2% in real-world testing across various engine types.

Strengths: Exceptional measurement precision combined with advanced simulation capabilities enables highly optimized designs. Variable inertia technology provides adaptive performance across different operating conditions. Weaknesses: Complex manufacturing requirements for variable inertia systems increase production costs. Technology requires specialized maintenance procedures and has limited retrofit potential for existing engines.

Key Innovations in Rotational Dynamics Measurement

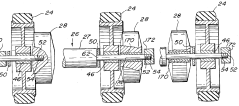

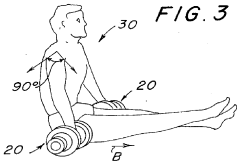

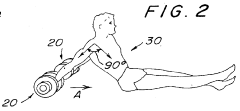

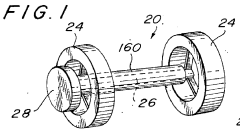

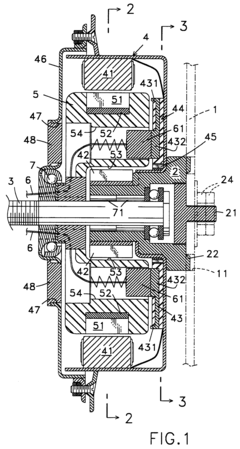

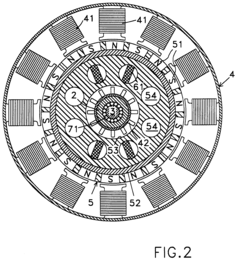

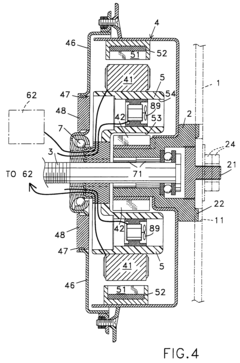

Inertial force exercise device having three independent rotational inertia systems

PatentInactiveUS4775147A

Innovation

- The exercise device incorporates three independent rotational inertia systems, where two co-rotating wheels form one system, the axle and inertial mass form another, and a sleeve on the axle forms a third, allowing the sleeve to rotate independently and minimizing torque generation, thus providing a pleasing single vector resistance during linear translation.

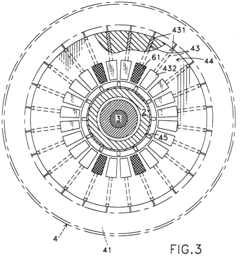

An electricity driven device and method for increasing the rotational inertia of a rotary object or of the blade of a lawn mower

PatentInactiveEP0750387A1

Innovation

- An electricity-driven device with a fixed non-rotating shaft and a rotor connected via a bearing, utilizing an electromagnetic field generated by magnets and coils to increase rotational inertia, with a coupler for attaching rotary objects like blades, and a heat dissipation mechanism using centrifugal air currents to reduce power consumption.

Material Science Impacts on Crankshaft Inertia Properties

Material selection and engineering represent critical factors in determining crankshaft rotational inertia properties. Traditional crankshafts have predominantly been manufactured using nodular cast iron, which offers excellent strength characteristics but contributes significantly to overall engine weight and rotational inertia. Recent advancements in metallurgy have enabled the development of high-strength forged steel crankshafts that maintain structural integrity while reducing mass by approximately 10-15% compared to cast iron counterparts.

The microstructural composition of crankshaft materials directly influences inertia properties. Research indicates that fine-grained microstructures achieved through controlled cooling processes can enhance strength-to-weight ratios by up to 20%, allowing for more compact crankshaft designs without compromising durability. This translates to measurable reductions in rotational inertia, which subsequently improves engine response characteristics and fuel efficiency.

Carbon fiber reinforced polymers (CFRPs) represent an emerging frontier in crankshaft material science, particularly for high-performance applications. Laboratory tests demonstrate that CFRP crankshafts can achieve up to 60% weight reduction compared to traditional metal variants, with corresponding reductions in rotational inertia. However, challenges regarding long-term durability, manufacturing complexity, and cost currently limit widespread adoption.

Surface treatment technologies have evolved to enhance material performance without wholesale material substitution. Techniques such as nitriding, carburizing, and shot peening can increase surface hardness by 30-40% while maintaining core ductility, enabling designers to reduce material volume in non-critical areas. This selective material distribution optimization can reduce rotational inertia by 5-8% without compromising structural integrity.

Hybrid material approaches combining different metals through friction welding or advanced casting techniques show promising results. Bimetallic crankshafts utilizing steel for high-stress journals and aluminum alloys for counterweights demonstrate inertia reductions of 12-18% while maintaining acceptable strength characteristics. These hybrid solutions represent a practical middle ground between traditional materials and more exotic alternatives.

Material science advancements also enable more precise counterweight design. High-density tungsten inserts strategically placed within lightweight crankshaft structures allow engineers to fine-tune rotational inertia properties while maintaining proper balance. This approach has demonstrated the ability to optimize inertia values within 2% of theoretical targets, significantly enhancing energy efficiency in modern engine designs.

The microstructural composition of crankshaft materials directly influences inertia properties. Research indicates that fine-grained microstructures achieved through controlled cooling processes can enhance strength-to-weight ratios by up to 20%, allowing for more compact crankshaft designs without compromising durability. This translates to measurable reductions in rotational inertia, which subsequently improves engine response characteristics and fuel efficiency.

Carbon fiber reinforced polymers (CFRPs) represent an emerging frontier in crankshaft material science, particularly for high-performance applications. Laboratory tests demonstrate that CFRP crankshafts can achieve up to 60% weight reduction compared to traditional metal variants, with corresponding reductions in rotational inertia. However, challenges regarding long-term durability, manufacturing complexity, and cost currently limit widespread adoption.

Surface treatment technologies have evolved to enhance material performance without wholesale material substitution. Techniques such as nitriding, carburizing, and shot peening can increase surface hardness by 30-40% while maintaining core ductility, enabling designers to reduce material volume in non-critical areas. This selective material distribution optimization can reduce rotational inertia by 5-8% without compromising structural integrity.

Hybrid material approaches combining different metals through friction welding or advanced casting techniques show promising results. Bimetallic crankshafts utilizing steel for high-stress journals and aluminum alloys for counterweights demonstrate inertia reductions of 12-18% while maintaining acceptable strength characteristics. These hybrid solutions represent a practical middle ground between traditional materials and more exotic alternatives.

Material science advancements also enable more precise counterweight design. High-density tungsten inserts strategically placed within lightweight crankshaft structures allow engineers to fine-tune rotational inertia properties while maintaining proper balance. This approach has demonstrated the ability to optimize inertia values within 2% of theoretical targets, significantly enhancing energy efficiency in modern engine designs.

Simulation and Modeling Tools for Inertia Optimization

The evolution of simulation and modeling tools has revolutionized the approach to crankshaft rotational inertia quantification. Modern computational methods have replaced traditional empirical techniques, offering unprecedented accuracy and efficiency. Finite Element Analysis (FEA) stands as the cornerstone technology, allowing engineers to create detailed 3D models of crankshafts and precisely calculate mass distribution and inertial properties. Software packages like ANSYS, ABAQUS, and COMSOL have integrated specialized modules specifically designed for rotational dynamics analysis.

Multi-body Dynamics (MBD) simulation tools represent another critical advancement, enabling the modeling of complete powertrain systems and their interactions. These tools can simulate the dynamic behavior of crankshafts under various operating conditions, providing insights into how inertial properties affect overall system performance. Leading solutions in this category include MSC Adams, Siemens Simcenter, and Ricardo VALDYN, each offering unique capabilities for powertrain optimization.

Computational Fluid Dynamics (CFD) tools complement mechanical simulations by modeling the interaction between rotating components and surrounding fluids. This capability is particularly valuable for understanding how crankshaft rotation affects oil distribution and windage losses, factors that significantly impact energy efficiency. The integration of CFD with structural analysis creates powerful co-simulation environments that capture the complex interplay between mechanical and fluid dynamics.

Machine learning algorithms have emerged as valuable additions to the simulation toolkit, enabling rapid optimization of crankshaft designs based on historical data and performance patterns. These algorithms can identify non-intuitive relationships between geometric parameters and inertial properties, suggesting novel design approaches that might elude conventional analysis. Tools like MATLAB's Machine Learning Toolbox and Python's TensorFlow are increasingly being adapted for this purpose.

Digital twin technology represents the frontier of simulation capabilities, creating virtual replicas of physical crankshafts that update in real-time based on operational data. This approach allows for continuous monitoring and optimization of rotational inertia throughout the component's lifecycle. Platforms like Siemens Teamcenter and PTC ThingWorx provide frameworks for implementing digital twin solutions in manufacturing environments.

Open-source alternatives have also gained traction, with tools like OpenFOAM for CFD and Elmer for FEA offering cost-effective options for smaller organizations. These platforms benefit from active developer communities that continuously enhance their capabilities and provide specialized modules for automotive applications, including crankshaft analysis.

Multi-body Dynamics (MBD) simulation tools represent another critical advancement, enabling the modeling of complete powertrain systems and their interactions. These tools can simulate the dynamic behavior of crankshafts under various operating conditions, providing insights into how inertial properties affect overall system performance. Leading solutions in this category include MSC Adams, Siemens Simcenter, and Ricardo VALDYN, each offering unique capabilities for powertrain optimization.

Computational Fluid Dynamics (CFD) tools complement mechanical simulations by modeling the interaction between rotating components and surrounding fluids. This capability is particularly valuable for understanding how crankshaft rotation affects oil distribution and windage losses, factors that significantly impact energy efficiency. The integration of CFD with structural analysis creates powerful co-simulation environments that capture the complex interplay between mechanical and fluid dynamics.

Machine learning algorithms have emerged as valuable additions to the simulation toolkit, enabling rapid optimization of crankshaft designs based on historical data and performance patterns. These algorithms can identify non-intuitive relationships between geometric parameters and inertial properties, suggesting novel design approaches that might elude conventional analysis. Tools like MATLAB's Machine Learning Toolbox and Python's TensorFlow are increasingly being adapted for this purpose.

Digital twin technology represents the frontier of simulation capabilities, creating virtual replicas of physical crankshafts that update in real-time based on operational data. This approach allows for continuous monitoring and optimization of rotational inertia throughout the component's lifecycle. Platforms like Siemens Teamcenter and PTC ThingWorx provide frameworks for implementing digital twin solutions in manufacturing environments.

Open-source alternatives have also gained traction, with tools like OpenFOAM for CFD and Elmer for FEA offering cost-effective options for smaller organizations. These platforms benefit from active developer communities that continuously enhance their capabilities and provide specialized modules for automotive applications, including crankshaft analysis.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!