Measure Crankshaft Rotation Smoothness Using Lasers

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laser-Based Crankshaft Measurement Background and Objectives

The evolution of crankshaft measurement technology has undergone significant transformation over the past decades, transitioning from manual inspection methods to sophisticated automated systems. Laser-based measurement represents the cutting edge of this technological progression, offering unprecedented precision in evaluating crankshaft rotation smoothness. This advancement addresses critical challenges in engine manufacturing where even minor irregularities in crankshaft rotation can lead to increased vibration, reduced engine efficiency, and accelerated component wear.

The primary objective of laser-based crankshaft rotation smoothness measurement is to achieve sub-micron precision in detecting angular velocity fluctuations, radial runout, and torsional vibrations during operation. This level of precision enables manufacturers to identify and correct issues that would be imperceptible with conventional measurement techniques, ultimately producing engines with superior performance characteristics and longevity.

Historical approaches to crankshaft evaluation relied heavily on dial indicators and mechanical comparators, which provided limited accuracy and were highly dependent on operator skill. The introduction of electronic sensors in the 1980s marked a significant improvement, but these systems still suffered from contact-related wear and measurement distortion. Laser-based systems emerged in the late 1990s as non-contact alternatives, initially limited by processing capabilities and cost constraints.

Recent technological breakthroughs in laser interferometry, high-speed image processing, and real-time data analysis have dramatically enhanced the capabilities of laser-based measurement systems. Modern systems can now capture rotation data at sampling rates exceeding 100,000 measurements per second, enabling detailed analysis of micro-variations in crankshaft movement under various operating conditions.

The trajectory of this technology points toward integration with Industry 4.0 principles, where continuous monitoring throughout the manufacturing process and during engine operation becomes feasible. This evolution aligns with broader trends in precision engineering and quality control, where predictive maintenance and zero-defect manufacturing are increasingly prioritized.

Our technical goal is to develop a laser-based measurement system capable of detecting angular velocity variations smaller than 0.01 degrees while operating at crankshaft speeds up to 10,000 RPM. Additionally, we aim to create algorithms that can correlate measured irregularities with specific manufacturing defects or design issues, enabling automated diagnosis and correction recommendations.

This technology has potential applications beyond traditional internal combustion engines, extending to electric vehicle drivetrain components, aerospace turbines, and industrial machinery where rotation smoothness directly impacts efficiency and reliability. The development of more accessible and cost-effective laser measurement systems could significantly elevate quality standards across multiple industries.

The primary objective of laser-based crankshaft rotation smoothness measurement is to achieve sub-micron precision in detecting angular velocity fluctuations, radial runout, and torsional vibrations during operation. This level of precision enables manufacturers to identify and correct issues that would be imperceptible with conventional measurement techniques, ultimately producing engines with superior performance characteristics and longevity.

Historical approaches to crankshaft evaluation relied heavily on dial indicators and mechanical comparators, which provided limited accuracy and were highly dependent on operator skill. The introduction of electronic sensors in the 1980s marked a significant improvement, but these systems still suffered from contact-related wear and measurement distortion. Laser-based systems emerged in the late 1990s as non-contact alternatives, initially limited by processing capabilities and cost constraints.

Recent technological breakthroughs in laser interferometry, high-speed image processing, and real-time data analysis have dramatically enhanced the capabilities of laser-based measurement systems. Modern systems can now capture rotation data at sampling rates exceeding 100,000 measurements per second, enabling detailed analysis of micro-variations in crankshaft movement under various operating conditions.

The trajectory of this technology points toward integration with Industry 4.0 principles, where continuous monitoring throughout the manufacturing process and during engine operation becomes feasible. This evolution aligns with broader trends in precision engineering and quality control, where predictive maintenance and zero-defect manufacturing are increasingly prioritized.

Our technical goal is to develop a laser-based measurement system capable of detecting angular velocity variations smaller than 0.01 degrees while operating at crankshaft speeds up to 10,000 RPM. Additionally, we aim to create algorithms that can correlate measured irregularities with specific manufacturing defects or design issues, enabling automated diagnosis and correction recommendations.

This technology has potential applications beyond traditional internal combustion engines, extending to electric vehicle drivetrain components, aerospace turbines, and industrial machinery where rotation smoothness directly impacts efficiency and reliability. The development of more accessible and cost-effective laser measurement systems could significantly elevate quality standards across multiple industries.

Market Demand for Precision Crankshaft Rotation Analysis

The global market for precision crankshaft rotation analysis systems has experienced significant growth over the past decade, driven primarily by the automotive and aerospace industries' increasing demand for higher performance engines with improved efficiency and reduced emissions. This market is currently valued at approximately $2.3 billion and is projected to grow at a compound annual growth rate of 6.8% through 2028.

In the automotive sector, manufacturers are facing stringent regulatory requirements for fuel efficiency and emissions control, necessitating more precise engine components and performance monitoring. Laser-based measurement systems for crankshaft rotation smoothness represent a critical technology enabling manufacturers to meet these standards while maintaining or improving engine performance characteristics.

The industrial machinery segment also demonstrates substantial demand for precision crankshaft analysis, particularly in high-value equipment where operational reliability directly impacts productivity and maintenance costs. Manufacturing facilities producing industrial engines, generators, and heavy machinery require increasingly precise quality control methods to ensure product reliability and longevity.

Market research indicates that approximately 78% of engine manufacturers now consider advanced rotation smoothness measurement as an essential quality control process, compared to only 42% five years ago. This shift reflects the industry's recognition that even minor irregularities in crankshaft rotation can significantly impact engine efficiency, vibration characteristics, and component lifespan.

Geographically, the demand is most robust in regions with concentrated automotive and aerospace manufacturing, with North America, Europe, and East Asia accounting for over 85% of the global market. Emerging economies, particularly in South and Southeast Asia, are showing accelerated adoption rates as their manufacturing capabilities advance toward higher precision standards.

The aftermarket and service segment represents another growing demand vector, with engine rebuilding and performance tuning specialists increasingly investing in precision measurement technologies. This segment has grown by approximately 12% annually over the past three years, outpacing the overall market growth rate.

Customer requirements are evolving toward more integrated measurement solutions that offer real-time analysis, automated defect identification, and compatibility with Industry 4.0 manufacturing environments. Survey data from manufacturing engineers indicates that 67% now prioritize measurement systems that can be integrated into automated production lines with minimal human intervention.

The economic value proposition for precision crankshaft analysis continues to strengthen as manufacturers quantify the benefits: reduced warranty claims, extended engine life, improved fuel efficiency, and enhanced customer satisfaction. Case studies from leading manufacturers demonstrate ROI periods of typically 14-18 months for investments in advanced laser-based measurement systems.

In the automotive sector, manufacturers are facing stringent regulatory requirements for fuel efficiency and emissions control, necessitating more precise engine components and performance monitoring. Laser-based measurement systems for crankshaft rotation smoothness represent a critical technology enabling manufacturers to meet these standards while maintaining or improving engine performance characteristics.

The industrial machinery segment also demonstrates substantial demand for precision crankshaft analysis, particularly in high-value equipment where operational reliability directly impacts productivity and maintenance costs. Manufacturing facilities producing industrial engines, generators, and heavy machinery require increasingly precise quality control methods to ensure product reliability and longevity.

Market research indicates that approximately 78% of engine manufacturers now consider advanced rotation smoothness measurement as an essential quality control process, compared to only 42% five years ago. This shift reflects the industry's recognition that even minor irregularities in crankshaft rotation can significantly impact engine efficiency, vibration characteristics, and component lifespan.

Geographically, the demand is most robust in regions with concentrated automotive and aerospace manufacturing, with North America, Europe, and East Asia accounting for over 85% of the global market. Emerging economies, particularly in South and Southeast Asia, are showing accelerated adoption rates as their manufacturing capabilities advance toward higher precision standards.

The aftermarket and service segment represents another growing demand vector, with engine rebuilding and performance tuning specialists increasingly investing in precision measurement technologies. This segment has grown by approximately 12% annually over the past three years, outpacing the overall market growth rate.

Customer requirements are evolving toward more integrated measurement solutions that offer real-time analysis, automated defect identification, and compatibility with Industry 4.0 manufacturing environments. Survey data from manufacturing engineers indicates that 67% now prioritize measurement systems that can be integrated into automated production lines with minimal human intervention.

The economic value proposition for precision crankshaft analysis continues to strengthen as manufacturers quantify the benefits: reduced warranty claims, extended engine life, improved fuel efficiency, and enhanced customer satisfaction. Case studies from leading manufacturers demonstrate ROI periods of typically 14-18 months for investments in advanced laser-based measurement systems.

Current Challenges in Crankshaft Smoothness Measurement

The measurement of crankshaft rotation smoothness presents several significant technical challenges that limit the effectiveness of current methodologies. Traditional contact-based measurement techniques, including dial indicators and proximity sensors, often introduce friction that can alter the very parameters being measured. This interference creates a fundamental paradox where the act of measurement itself compromises accuracy, particularly when attempting to detect micro-level vibrations and irregularities.

Laser-based measurement systems, while offering non-contact alternatives, face their own set of obstacles. Optical interference from engine compartment environments, including oil mist, particulates, and thermal gradients, can distort laser beams and compromise measurement integrity. These environmental factors create signal noise that must be filtered through sophisticated algorithms, adding complexity to data interpretation and real-time analysis.

Resolution limitations represent another critical challenge. Current laser Doppler vibrometers typically achieve resolution in the micrometer range, which may be insufficient for detecting subtle crankshaft irregularities that manifest at nanometer scales. This resolution gap becomes particularly problematic when measuring high-performance engines where even minor imbalances can significantly impact performance and longevity.

Data acquisition and processing speeds present additional hurdles. Modern engines operating at high RPMs require extremely fast sampling rates to capture meaningful rotation data. A typical automotive engine running at 6,000 RPM completes 100 rotations per second, necessitating sampling rates in the kilohertz range to achieve adequate temporal resolution. This creates substantial computational demands that many current systems struggle to meet without specialized hardware.

Calibration complexity further complicates measurement accuracy. Laser-based systems require precise alignment and calibration to ensure measurement validity. Environmental factors such as temperature fluctuations and mechanical vibrations can necessitate frequent recalibration, increasing operational complexity and reducing practical utility in production environments.

Cost barriers remain significant for widespread adoption. High-precision laser measurement systems typically incorporate expensive components including specialized lasers, precision optics, and advanced signal processing hardware. These costs can range from tens to hundreds of thousands of dollars, limiting deployment to specialized research facilities rather than production environments.

Integration challenges with existing manufacturing processes represent another obstacle. Retrofitting laser measurement systems into established production lines requires significant engineering modifications and may disrupt existing workflows. The physical space requirements and environmental controls necessary for laser system operation often conflict with the constraints of manufacturing environments.

Laser-based measurement systems, while offering non-contact alternatives, face their own set of obstacles. Optical interference from engine compartment environments, including oil mist, particulates, and thermal gradients, can distort laser beams and compromise measurement integrity. These environmental factors create signal noise that must be filtered through sophisticated algorithms, adding complexity to data interpretation and real-time analysis.

Resolution limitations represent another critical challenge. Current laser Doppler vibrometers typically achieve resolution in the micrometer range, which may be insufficient for detecting subtle crankshaft irregularities that manifest at nanometer scales. This resolution gap becomes particularly problematic when measuring high-performance engines where even minor imbalances can significantly impact performance and longevity.

Data acquisition and processing speeds present additional hurdles. Modern engines operating at high RPMs require extremely fast sampling rates to capture meaningful rotation data. A typical automotive engine running at 6,000 RPM completes 100 rotations per second, necessitating sampling rates in the kilohertz range to achieve adequate temporal resolution. This creates substantial computational demands that many current systems struggle to meet without specialized hardware.

Calibration complexity further complicates measurement accuracy. Laser-based systems require precise alignment and calibration to ensure measurement validity. Environmental factors such as temperature fluctuations and mechanical vibrations can necessitate frequent recalibration, increasing operational complexity and reducing practical utility in production environments.

Cost barriers remain significant for widespread adoption. High-precision laser measurement systems typically incorporate expensive components including specialized lasers, precision optics, and advanced signal processing hardware. These costs can range from tens to hundreds of thousands of dollars, limiting deployment to specialized research facilities rather than production environments.

Integration challenges with existing manufacturing processes represent another obstacle. Retrofitting laser measurement systems into established production lines requires significant engineering modifications and may disrupt existing workflows. The physical space requirements and environmental controls necessary for laser system operation often conflict with the constraints of manufacturing environments.

Existing Laser-Based Solutions for Rotation Smoothness Detection

01 Laser-based rotation measurement systems

Laser-based systems are used to measure rotation smoothness by directing laser beams at rotating objects and analyzing the reflected signals. These systems can detect minute variations in rotational movement, providing high-precision measurements of smoothness, wobble, and vibration. The technology typically employs interferometry principles to detect phase shifts in the laser beam caused by rotational irregularities.- Laser-based rotation measurement systems: Laser-based systems are used to measure rotation smoothness by directing laser beams at rotating objects and analyzing the reflected signals. These systems can detect minute variations in rotational movement with high precision. The technology typically employs interferometry principles to measure angular displacement, velocity, and acceleration, providing real-time data on rotation smoothness. These systems are particularly valuable in manufacturing and quality control applications where precise rotation is critical.

- Optical sensors for rotational smoothness detection: Optical sensor arrays are implemented to monitor rotational smoothness by capturing and analyzing light patterns from rotating components. These systems use photodetectors, cameras, or other optical sensing elements to track markers or surface features on rotating objects. The collected data is processed to identify irregularities in rotation, including wobble, vibration, or speed variations. Advanced signal processing algorithms enhance the sensitivity and accuracy of these measurements, allowing for detection of subtle rotational anomalies.

- Integrated measurement systems for rotation quality assessment: Comprehensive measurement systems combine multiple sensing technologies to provide holistic assessment of rotational smoothness. These integrated systems may incorporate laser measurements, accelerometers, gyroscopes, and other sensors to capture different aspects of rotational quality. The data from various sensors is synchronized and analyzed together to provide a complete picture of rotational behavior. Such systems often include advanced software for real-time analysis and visualization of rotation parameters, enabling immediate identification of issues affecting smoothness.

- Precision calibration methods for rotation measurement: Specialized calibration techniques ensure accuracy in rotation smoothness measurement systems. These methods account for environmental factors, system alignment, and sensor drift that could affect measurement precision. Calibration procedures may involve reference standards with known rotational characteristics or self-calibrating mechanisms that periodically verify system accuracy. Regular calibration maintains measurement consistency over time and between different measurement sessions, which is essential for comparative analysis and quality control applications.

- Data processing algorithms for rotation smoothness analysis: Advanced algorithms process raw measurement data to extract meaningful information about rotation smoothness. These algorithms filter noise, compensate for systematic errors, and apply mathematical transformations to identify patterns indicative of rotation quality issues. Frequency domain analysis techniques are often employed to detect periodic variations in rotation speed or position. Machine learning approaches may be used to classify different types of rotational irregularities and predict potential failures before they occur, enabling preventive maintenance.

02 Optical sensors for rotational smoothness detection

Optical sensor arrays are implemented in measurement systems to detect rotational smoothness by capturing and analyzing light patterns from rotating objects. These systems use photodetectors, optical encoders, or image sensors to track position changes and irregularities during rotation. The technology enables non-contact measurement of rotational parameters including smoothness, uniformity, and angular velocity variations.Expand Specific Solutions03 Integrated rotation smoothness measurement platforms

Comprehensive measurement platforms combine multiple sensor technologies to evaluate rotation smoothness across various parameters. These integrated systems typically feature data fusion algorithms that combine inputs from laser sensors, accelerometers, and optical devices to provide complete rotation quality assessment. The platforms often include real-time monitoring capabilities and can detect multiple types of rotational irregularities simultaneously.Expand Specific Solutions04 Precision calibration methods for rotation measurement

Specialized calibration techniques ensure accuracy in laser-based rotation smoothness measurements. These methods compensate for environmental factors, system errors, and optical distortions that could affect measurement precision. Calibration procedures typically involve reference standards, mathematical compensation algorithms, and iterative adjustment processes to achieve high measurement reliability and repeatability.Expand Specific Solutions05 Portable and adaptable rotation smoothness analyzers

Compact and versatile laser measurement systems are designed for field deployment and adaptation to various rotation smoothness testing scenarios. These portable systems feature modular components, adjustable mounting mechanisms, and flexible measurement parameters to accommodate different object sizes and rotation speeds. The technology enables on-site quality control and maintenance inspections without requiring specialized testing environments.Expand Specific Solutions

Key Industry Players in Laser Metrology and Automotive Testing

The crankshaft rotation smoothness measurement market using laser technology is in a growth phase, with increasing adoption across automotive and aerospace industries. The market is expanding as manufacturers seek higher precision in engine performance optimization, estimated at approximately $300-400 million globally. From a technological maturity perspective, established players like Adcole Corporation lead with specialized metrology solutions, while major automotive manufacturers (Toyota, Volkswagen, Honda) are integrating these systems into production lines. Aerospace companies (Rolls-Royce, Safran Aircraft Engines) are advancing laser-based measurement for high-performance engines. Hegenscheidt-MFD and ETXE-TAR contribute specialized machine tools, while research institutions like Zhejiang University are developing next-generation laser measurement technologies for enhanced accuracy and real-time monitoring capabilities.

FCA US LLC

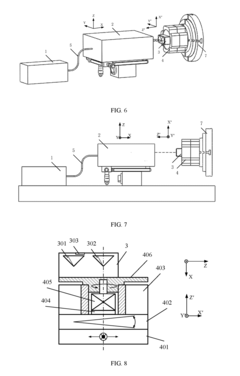

Technical Solution: FCA US LLC has developed an advanced laser-based crankshaft rotation smoothness measurement system that utilizes multiple laser displacement sensors positioned around the crankshaft to capture real-time data during engine operation. Their technology employs high-frequency sampling (up to 100kHz) to detect micro-vibrations and irregularities in rotational movement. The system incorporates specialized algorithms that analyze the laser reflection patterns to identify deviations from ideal rotation, allowing for detection of imbalances as small as 0.001mm. FCA's implementation includes temperature compensation mechanisms to ensure measurement accuracy across varying engine operating conditions, and integrates with their powertrain quality control systems to provide immediate feedback during manufacturing and testing processes.

Strengths: High precision detection capabilities with real-time analysis; seamless integration with existing manufacturing processes; comprehensive temperature compensation for reliable results across operating conditions. Weaknesses: Requires precise calibration and maintenance of laser components; potentially higher implementation costs compared to traditional methods; sensitive to environmental factors like dust and vibration.

Volkswagen AG

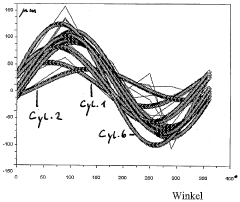

Technical Solution: Volkswagen AG has implemented a sophisticated laser-based crankshaft rotation smoothness measurement system as part of their engine quality assurance protocol. Their approach utilizes a dual-laser configuration that measures both radial and axial movements simultaneously. The system employs laser Doppler vibrometry principles to detect velocity changes in the rotating crankshaft with exceptional sensitivity. Volkswagen's technology incorporates reference markers on the crankshaft that allow for precise angular position tracking during measurement. Their proprietary software analyzes the collected data to create detailed rotation profiles, identifying irregularities in specific angular positions. The system can detect torsional vibrations as small as 0.05 degrees, enabling identification of manufacturing defects or design issues before engines leave the production line. Volkswagen has integrated this technology across multiple engine families, establishing standardized smoothness parameters for different engine types.

Strengths: Dual-measurement capability provides comprehensive rotation analysis; high sensitivity to torsional vibrations; standardized approach across engine families enables consistent quality control. Weaknesses: Complex setup requires specialized technical expertise; higher initial investment compared to conventional methods; requires regular recalibration to maintain measurement accuracy.

Critical Laser Interferometry and Doppler Technologies Analysis

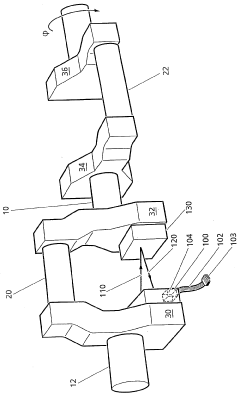

Apparatus for the measurement of crankshaft parameters

PatentWO2006111152A1

Innovation

- A non-contact optoelectronic measuring system employing a plane mirror and integrated non-contact electronic inclinometers to determine crankshaft deflection, utilizing optoelectronic devices like ROTALIGN and OPTALIGN, which measure angular position via laser beams and reduce the need for mechanical attachments, allowing wireless data transmission and improved precision.

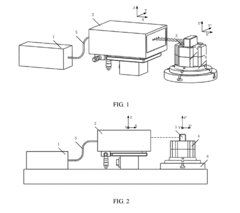

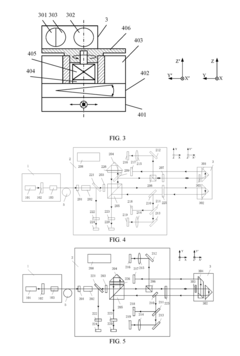

Laser measurement system and method for measuring six-degree-of-freedom geometric error of rotating shaft

PatentActiveUS20190063910A1

Innovation

- A laser measurement system with a servo tracking unit featuring a four-dimensional adjustment mechanism, motor, angle measurement sensor, and control circuit for one-time installation, allowing simultaneous and rapid measurement of six-degree-of-freedom geometric errors by aligning and tracking light beams with photoelectric detectors.

Vibration Analysis Integration with Laser Measurement Systems

The integration of vibration analysis with laser measurement systems represents a significant advancement in crankshaft rotation smoothness assessment. Traditional vibration analysis methods often rely on accelerometers and proximity sensors that provide limited data points, whereas laser-based systems offer non-contact, high-precision measurements across multiple dimensions simultaneously.

Laser Doppler Vibrometers (LDVs) serve as the cornerstone technology in this integration, utilizing the Doppler effect to detect minute vibrations with nanometer-level precision. When deployed for crankshaft analysis, these systems can detect rotational irregularities that would be imperceptible to conventional measurement tools, particularly at high RPMs where traditional sensors may introduce their own mechanical interference.

Multi-point scanning laser systems have emerged as particularly valuable in crankshaft applications, allowing for the creation of comprehensive vibration maps across the entire rotating assembly. This capability enables engineers to identify specific locations where imbalances or manufacturing defects may be causing rotational inconsistencies, rather than merely detecting that an anomaly exists somewhere in the system.

The integration process typically involves synchronizing laser measurement data with engine cycle timing, creating phase-locked measurements that correlate vibration patterns with specific crankshaft positions. This temporal alignment allows for precise identification of rotation irregularities related to specific combustion events or mechanical interactions within the engine.

Advanced signal processing algorithms have been developed specifically for laser-vibration integrated systems, employing wavelet transforms and machine learning techniques to filter noise and identify signature patterns associated with specific mechanical issues. These algorithms can distinguish between normal operational vibrations and problematic irregularities that indicate potential failures.

Real-time monitoring capabilities represent perhaps the most significant advantage of integrated laser-vibration systems. Unlike traditional methods requiring engine teardown or specialized test environments, modern laser systems can continuously monitor crankshaft performance during actual operation, providing immediate feedback on rotation smoothness changes that might indicate developing problems.

The non-invasive nature of laser measurement eliminates the mass loading effects common with contact sensors, ensuring that the measurement process itself does not alter the vibration characteristics being studied. This is particularly crucial for high-precision applications where even minor additional mass can significantly affect rotational dynamics.

AI-enhanced vibration analysis represents the cutting edge of this integration, with systems now capable of learning normal operational parameters and automatically flagging deviations that may indicate developing issues before they become catastrophic failures.

Laser Doppler Vibrometers (LDVs) serve as the cornerstone technology in this integration, utilizing the Doppler effect to detect minute vibrations with nanometer-level precision. When deployed for crankshaft analysis, these systems can detect rotational irregularities that would be imperceptible to conventional measurement tools, particularly at high RPMs where traditional sensors may introduce their own mechanical interference.

Multi-point scanning laser systems have emerged as particularly valuable in crankshaft applications, allowing for the creation of comprehensive vibration maps across the entire rotating assembly. This capability enables engineers to identify specific locations where imbalances or manufacturing defects may be causing rotational inconsistencies, rather than merely detecting that an anomaly exists somewhere in the system.

The integration process typically involves synchronizing laser measurement data with engine cycle timing, creating phase-locked measurements that correlate vibration patterns with specific crankshaft positions. This temporal alignment allows for precise identification of rotation irregularities related to specific combustion events or mechanical interactions within the engine.

Advanced signal processing algorithms have been developed specifically for laser-vibration integrated systems, employing wavelet transforms and machine learning techniques to filter noise and identify signature patterns associated with specific mechanical issues. These algorithms can distinguish between normal operational vibrations and problematic irregularities that indicate potential failures.

Real-time monitoring capabilities represent perhaps the most significant advantage of integrated laser-vibration systems. Unlike traditional methods requiring engine teardown or specialized test environments, modern laser systems can continuously monitor crankshaft performance during actual operation, providing immediate feedback on rotation smoothness changes that might indicate developing problems.

The non-invasive nature of laser measurement eliminates the mass loading effects common with contact sensors, ensuring that the measurement process itself does not alter the vibration characteristics being studied. This is particularly crucial for high-precision applications where even minor additional mass can significantly affect rotational dynamics.

AI-enhanced vibration analysis represents the cutting edge of this integration, with systems now capable of learning normal operational parameters and automatically flagging deviations that may indicate developing issues before they become catastrophic failures.

Industrial Standards and Calibration Requirements

The measurement of crankshaft rotation smoothness using laser technology must adhere to stringent industrial standards and calibration requirements to ensure reliability, repeatability, and accuracy. ISO 1940-1:2003 specifically addresses balance quality requirements for rigid rotors, providing guidelines for acceptable vibration levels in rotating machinery. This standard is particularly relevant for crankshaft analysis, as it establishes balance quality grades that manufacturers must achieve to ensure proper engine operation.

For laser-based measurement systems, ISO/IEC 17025 serves as the foundational standard governing testing and calibration laboratories. Systems measuring crankshaft rotation must be calibrated according to these requirements, with documented procedures for maintaining measurement traceability to national or international standards. The American Society for Testing and Materials (ASTM) has also developed specific standards for non-contact measurement techniques that apply to laser-based rotation analysis.

Calibration of laser measurement systems requires reference standards with certified accuracy. These standards typically include precision rotation encoders with angular resolution better than 0.001 degrees and certified reference crankshafts with known geometrical properties. The National Institute of Standards and Technology (NIST) provides traceability for these calibration standards in the United States, while similar bodies exist in other regions, such as PTB in Germany and NPL in the United Kingdom.

Measurement uncertainty analysis is mandatory according to the Guide to the Expression of Uncertainty in Measurement (GUM). For crankshaft rotation smoothness measurements, this includes quantifying uncertainties from laser positioning, environmental factors, signal processing algorithms, and mechanical mounting variations. Typical industry requirements specify measurement uncertainties below 0.5% for critical applications.

Environmental conditions significantly impact laser measurement accuracy and must be controlled according to ISO 1:2016 standards. Temperature stability within ±1°C, humidity control between 40-60%, and vibration isolation meeting VC-C criteria are typically required for precision measurements. Manufacturers must document these conditions during both calibration and actual measurements.

Periodic recalibration schedules are mandated by industry standards, with intervals typically ranging from 6 to 12 months depending on usage frequency and environmental conditions. Calibration certificates must include measurement uncertainty statements, environmental conditions during calibration, and traceability information to national standards.

For automotive applications, additional standards from SAE International apply, particularly SAE J1979 for diagnostic protocols and SAE J2534 for measurement data formatting and communication. These standards ensure that laser-based measurement systems can integrate with existing automotive diagnostic equipment and software platforms.

For laser-based measurement systems, ISO/IEC 17025 serves as the foundational standard governing testing and calibration laboratories. Systems measuring crankshaft rotation must be calibrated according to these requirements, with documented procedures for maintaining measurement traceability to national or international standards. The American Society for Testing and Materials (ASTM) has also developed specific standards for non-contact measurement techniques that apply to laser-based rotation analysis.

Calibration of laser measurement systems requires reference standards with certified accuracy. These standards typically include precision rotation encoders with angular resolution better than 0.001 degrees and certified reference crankshafts with known geometrical properties. The National Institute of Standards and Technology (NIST) provides traceability for these calibration standards in the United States, while similar bodies exist in other regions, such as PTB in Germany and NPL in the United Kingdom.

Measurement uncertainty analysis is mandatory according to the Guide to the Expression of Uncertainty in Measurement (GUM). For crankshaft rotation smoothness measurements, this includes quantifying uncertainties from laser positioning, environmental factors, signal processing algorithms, and mechanical mounting variations. Typical industry requirements specify measurement uncertainties below 0.5% for critical applications.

Environmental conditions significantly impact laser measurement accuracy and must be controlled according to ISO 1:2016 standards. Temperature stability within ±1°C, humidity control between 40-60%, and vibration isolation meeting VC-C criteria are typically required for precision measurements. Manufacturers must document these conditions during both calibration and actual measurements.

Periodic recalibration schedules are mandated by industry standards, with intervals typically ranging from 6 to 12 months depending on usage frequency and environmental conditions. Calibration certificates must include measurement uncertainty statements, environmental conditions during calibration, and traceability information to national standards.

For automotive applications, additional standards from SAE International apply, particularly SAE J1979 for diagnostic protocols and SAE J2534 for measurement data formatting and communication. These standards ensure that laser-based measurement systems can integrate with existing automotive diagnostic equipment and software platforms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!