Crankshaft vs Exhaust Systems: Effective Power Use

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Power Transfer Technology Background and Objectives

The evolution of internal combustion engine technology spans over a century, with significant advancements in power transfer mechanisms. The relationship between crankshaft design and exhaust systems represents a critical intersection in engine efficiency development. Historically, engine power transfer technologies have progressed from simple single-cylinder designs to complex multi-cylinder configurations with sophisticated timing mechanisms, reflecting the continuous pursuit of improved power-to-weight ratios and fuel efficiency.

The crankshaft, as the primary mechanical component converting reciprocating motion into rotational force, has undergone substantial refinement since the early 20th century. Initial designs focused on basic functionality, while modern crankshafts incorporate precision balancing, advanced metallurgy, and optimized geometry to minimize power losses. Concurrently, exhaust system development has evolved from simple expulsion channels to integrated components that actively contribute to engine performance through pressure wave management and energy recovery.

Current technological objectives in this domain center on maximizing the effective transfer of combustion energy to usable mechanical output while minimizing losses throughout the power delivery chain. This includes reducing friction in crankshaft bearings, optimizing stroke geometry for specific applications, and enhancing the scavenging effects of exhaust systems to improve volumetric efficiency. The industry increasingly recognizes these components not as separate entities but as an integrated system with complex interdependencies.

Recent research indicates that up to 30% of potential engine power is lost through inefficiencies in the power transfer system, with significant portions attributable to suboptimal integration between crankshaft dynamics and exhaust flow characteristics. This represents a substantial opportunity for performance gains through technological innovation and systems-level optimization.

The global push toward reduced emissions and improved fuel economy has accelerated development in this field, with particular emphasis on understanding the dynamic relationship between in-cylinder pressure development, crankshaft loading patterns, and exhaust gas dynamics. Advanced simulation tools now enable engineers to model these interactions with unprecedented accuracy, revealing optimization opportunities previously undetectable through conventional testing methods.

Looking forward, the technological trajectory points toward holistic powertrain design approaches that consider crankshaft and exhaust systems as co-developed components within an integrated power delivery strategy. This evolution is particularly relevant as hybrid powertrains become more prevalent, requiring internal combustion engines to operate efficiently across narrower but more specialized operating ranges.

The convergence of computational fluid dynamics, materials science, and precision manufacturing techniques has created a fertile environment for innovation in this space, with potential breakthroughs in variable geometry components that dynamically optimize power transfer characteristics based on instantaneous operating conditions.

The crankshaft, as the primary mechanical component converting reciprocating motion into rotational force, has undergone substantial refinement since the early 20th century. Initial designs focused on basic functionality, while modern crankshafts incorporate precision balancing, advanced metallurgy, and optimized geometry to minimize power losses. Concurrently, exhaust system development has evolved from simple expulsion channels to integrated components that actively contribute to engine performance through pressure wave management and energy recovery.

Current technological objectives in this domain center on maximizing the effective transfer of combustion energy to usable mechanical output while minimizing losses throughout the power delivery chain. This includes reducing friction in crankshaft bearings, optimizing stroke geometry for specific applications, and enhancing the scavenging effects of exhaust systems to improve volumetric efficiency. The industry increasingly recognizes these components not as separate entities but as an integrated system with complex interdependencies.

Recent research indicates that up to 30% of potential engine power is lost through inefficiencies in the power transfer system, with significant portions attributable to suboptimal integration between crankshaft dynamics and exhaust flow characteristics. This represents a substantial opportunity for performance gains through technological innovation and systems-level optimization.

The global push toward reduced emissions and improved fuel economy has accelerated development in this field, with particular emphasis on understanding the dynamic relationship between in-cylinder pressure development, crankshaft loading patterns, and exhaust gas dynamics. Advanced simulation tools now enable engineers to model these interactions with unprecedented accuracy, revealing optimization opportunities previously undetectable through conventional testing methods.

Looking forward, the technological trajectory points toward holistic powertrain design approaches that consider crankshaft and exhaust systems as co-developed components within an integrated power delivery strategy. This evolution is particularly relevant as hybrid powertrains become more prevalent, requiring internal combustion engines to operate efficiently across narrower but more specialized operating ranges.

The convergence of computational fluid dynamics, materials science, and precision manufacturing techniques has created a fertile environment for innovation in this space, with potential breakthroughs in variable geometry components that dynamically optimize power transfer characteristics based on instantaneous operating conditions.

Market Analysis of Crankshaft and Exhaust System Innovations

The automotive powertrain component market has witnessed significant growth in recent years, with the global market for crankshafts valued at approximately $2.8 billion in 2022 and projected to reach $3.5 billion by 2028. This represents a compound annual growth rate (CAGR) of 3.8%, driven primarily by increasing vehicle production and the ongoing pursuit of engine efficiency improvements. Similarly, the exhaust system market stood at $38.5 billion in 2022 with forecasts suggesting expansion to $45.7 billion by 2028, reflecting a slightly higher CAGR of 4.2%.

Consumer demand patterns reveal a growing preference for vehicles with improved fuel efficiency and reduced emissions, directly influencing innovation trajectories in both crankshaft and exhaust system technologies. Market research indicates that 67% of new vehicle buyers consider fuel efficiency among their top three purchasing factors, while 58% express concern about environmental impact. These consumer preferences have accelerated development in lightweight crankshaft materials and advanced exhaust gas recirculation systems.

Regional market analysis shows distinct patterns of adoption and innovation. North America and Europe lead in premium exhaust system technologies, particularly in variable geometry turbochargers and integrated exhaust manifolds, commanding 38% and 32% of global market share respectively. Meanwhile, the Asia-Pacific region dominates crankshaft manufacturing volume at 45% of global production, with China alone accounting for 28% of worldwide output.

The competitive landscape features both specialized component manufacturers and integrated system providers. Key players in the crankshaft market include ThyssenKrupp, Maschinenfabrik Alfing Kessler, and Bharat Forge, collectively holding approximately 35% market share. The exhaust system sector is more consolidated, with Tenneco, Faurecia, and Eberspächer controlling nearly 48% of the global market.

Emerging market trends indicate growing interest in integrated powertrain solutions that optimize the relationship between crankshaft dynamics and exhaust energy recovery. The market for systems incorporating both optimized crankshaft designs and exhaust energy recovery technologies is projected to grow at 7.3% annually through 2028, outpacing the growth of either component category individually.

Investment patterns reveal increasing capital allocation toward research in composite materials for crankshafts, with industry R&D spending in this area growing by 12% annually since 2020. Simultaneously, venture capital funding for startups focused on exhaust energy recovery technologies reached $780 million in 2022, representing a 23% increase over the previous year.

Consumer demand patterns reveal a growing preference for vehicles with improved fuel efficiency and reduced emissions, directly influencing innovation trajectories in both crankshaft and exhaust system technologies. Market research indicates that 67% of new vehicle buyers consider fuel efficiency among their top three purchasing factors, while 58% express concern about environmental impact. These consumer preferences have accelerated development in lightweight crankshaft materials and advanced exhaust gas recirculation systems.

Regional market analysis shows distinct patterns of adoption and innovation. North America and Europe lead in premium exhaust system technologies, particularly in variable geometry turbochargers and integrated exhaust manifolds, commanding 38% and 32% of global market share respectively. Meanwhile, the Asia-Pacific region dominates crankshaft manufacturing volume at 45% of global production, with China alone accounting for 28% of worldwide output.

The competitive landscape features both specialized component manufacturers and integrated system providers. Key players in the crankshaft market include ThyssenKrupp, Maschinenfabrik Alfing Kessler, and Bharat Forge, collectively holding approximately 35% market share. The exhaust system sector is more consolidated, with Tenneco, Faurecia, and Eberspächer controlling nearly 48% of the global market.

Emerging market trends indicate growing interest in integrated powertrain solutions that optimize the relationship between crankshaft dynamics and exhaust energy recovery. The market for systems incorporating both optimized crankshaft designs and exhaust energy recovery technologies is projected to grow at 7.3% annually through 2028, outpacing the growth of either component category individually.

Investment patterns reveal increasing capital allocation toward research in composite materials for crankshafts, with industry R&D spending in this area growing by 12% annually since 2020. Simultaneously, venture capital funding for startups focused on exhaust energy recovery technologies reached $780 million in 2022, representing a 23% increase over the previous year.

Current Challenges in Power Efficiency Technologies

The power efficiency landscape in automotive engineering faces significant challenges as manufacturers strive to meet increasingly stringent emissions regulations while maintaining or improving performance. The traditional balance between crankshaft power generation and exhaust system efficiency has become a critical focal point for innovation, with several key obstacles impeding progress.

Material limitations represent a primary challenge in both crankshaft and exhaust system design. Current high-temperature alloys used in exhaust manifolds and turbochargers approach their thermal limits under extreme operating conditions, restricting potential efficiency gains. Similarly, crankshaft materials must balance durability with weight reduction goals, creating engineering compromises that limit overall system optimization.

Thermal management presents another substantial hurdle. Heat losses throughout the power generation and exhaust cycles significantly reduce effective energy utilization. Modern engines struggle to maintain optimal operating temperatures across varying load conditions, with up to 30% of fuel energy lost as heat through exhaust systems. Innovative thermal recovery technologies show promise but remain commercially challenging to implement cost-effectively.

Integration complexity between powertrain components has increased exponentially with the addition of emissions control systems, turbochargers, and hybrid elements. Engineers face difficult trade-offs between back-pressure reduction in exhaust systems and effective emissions control, while crankshaft design must accommodate variable power inputs from hybrid systems without compromising durability or NVH characteristics.

Regulatory compliance adds another layer of complexity. The global shift toward stricter emissions standards requires sophisticated exhaust aftertreatment systems that often create back-pressure, reducing engine efficiency. These systems must function effectively across the entire operating range while minimizing their impact on power delivery and fuel consumption.

Cost constraints remain perhaps the most pervasive challenge. Advanced materials, precision manufacturing techniques, and complex electronic control systems necessary for optimizing the crankshaft-exhaust relationship significantly increase production costs. Manufacturers must balance efficiency improvements against market-viable pricing, often resulting in compromised solutions.

Computational limitations also hinder progress, as accurate modeling of the complex fluid dynamics and thermodynamic interactions between crankshaft operation and exhaust flow requires immense computing power and sophisticated algorithms. Current simulation tools struggle to capture all relevant variables simultaneously, making holistic system optimization difficult.

These interconnected challenges create a complex engineering environment where improvements in one area often create new obstacles in others, necessitating a systems-level approach to power efficiency advancement in modern automotive powertrains.

Material limitations represent a primary challenge in both crankshaft and exhaust system design. Current high-temperature alloys used in exhaust manifolds and turbochargers approach their thermal limits under extreme operating conditions, restricting potential efficiency gains. Similarly, crankshaft materials must balance durability with weight reduction goals, creating engineering compromises that limit overall system optimization.

Thermal management presents another substantial hurdle. Heat losses throughout the power generation and exhaust cycles significantly reduce effective energy utilization. Modern engines struggle to maintain optimal operating temperatures across varying load conditions, with up to 30% of fuel energy lost as heat through exhaust systems. Innovative thermal recovery technologies show promise but remain commercially challenging to implement cost-effectively.

Integration complexity between powertrain components has increased exponentially with the addition of emissions control systems, turbochargers, and hybrid elements. Engineers face difficult trade-offs between back-pressure reduction in exhaust systems and effective emissions control, while crankshaft design must accommodate variable power inputs from hybrid systems without compromising durability or NVH characteristics.

Regulatory compliance adds another layer of complexity. The global shift toward stricter emissions standards requires sophisticated exhaust aftertreatment systems that often create back-pressure, reducing engine efficiency. These systems must function effectively across the entire operating range while minimizing their impact on power delivery and fuel consumption.

Cost constraints remain perhaps the most pervasive challenge. Advanced materials, precision manufacturing techniques, and complex electronic control systems necessary for optimizing the crankshaft-exhaust relationship significantly increase production costs. Manufacturers must balance efficiency improvements against market-viable pricing, often resulting in compromised solutions.

Computational limitations also hinder progress, as accurate modeling of the complex fluid dynamics and thermodynamic interactions between crankshaft operation and exhaust flow requires immense computing power and sophisticated algorithms. Current simulation tools struggle to capture all relevant variables simultaneously, making holistic system optimization difficult.

These interconnected challenges create a complex engineering environment where improvements in one area often create new obstacles in others, necessitating a systems-level approach to power efficiency advancement in modern automotive powertrains.

Contemporary Solutions for Maximizing Power Efficiency

01 Crankshaft design optimization for power efficiency

Optimized crankshaft designs can significantly improve engine power efficiency. These designs focus on reducing friction, optimizing counterweights, and improving overall balance to minimize energy losses. Advanced materials and manufacturing techniques allow for lighter yet stronger crankshafts that reduce rotational mass and inertia, resulting in better fuel economy and increased power output. Specialized coatings and surface treatments further reduce friction between moving parts.- Crankshaft design optimization for power efficiency: Optimized crankshaft designs can significantly improve engine power efficiency. Innovations include counterweight configurations that reduce vibration and friction losses, specialized bearing surfaces that minimize energy loss during rotation, and advanced materials that reduce weight while maintaining strength. These design improvements help convert more of the combustion energy into useful mechanical power, resulting in better overall engine efficiency.

- Exhaust gas energy recovery systems: Systems that recover energy from exhaust gases can substantially improve overall power efficiency. These include turbochargers that use exhaust gas flow to compress intake air, waste heat recovery systems that convert thermal energy to electrical power, and exhaust gas recirculation systems that improve combustion efficiency. By capturing energy that would otherwise be lost, these systems increase the overall efficiency of the engine and reduce fuel consumption.

- Variable valve timing and exhaust flow control: Advanced control systems for exhaust flow and valve timing can optimize engine performance across different operating conditions. Variable valve timing mechanisms adjust the opening and closing of exhaust valves based on engine speed and load, while adaptive exhaust flow control systems regulate back pressure and flow characteristics. These technologies enable better scavenging of exhaust gases, improved combustion efficiency, and enhanced power output at various engine speeds.

- Integrated crankshaft and exhaust system design: Holistic approaches that consider the interaction between crankshaft dynamics and exhaust system performance can yield significant efficiency gains. These integrated designs match exhaust pulse timing with crankshaft position to optimize gas flow, reduce pumping losses, and improve cylinder scavenging. By coordinating the mechanical operation of the crankshaft with the fluid dynamics of the exhaust system, these innovations achieve better overall engine breathing and combustion efficiency.

- Advanced materials and manufacturing techniques: Novel materials and manufacturing methods for both crankshafts and exhaust components can enhance power efficiency. Lightweight alloys and composite materials reduce rotational mass and improve thermal management, while precision manufacturing techniques ensure optimal tolerances and surface finishes. These advancements reduce friction losses, improve heat dissipation, and allow for more complex geometries that optimize flow characteristics and mechanical performance.

02 Exhaust system configuration for improved flow dynamics

Innovative exhaust system configurations focus on optimizing flow dynamics to reduce back pressure and improve engine breathing. These systems incorporate carefully designed header geometry, collector shapes, and pipe diameters to maximize scavenging effects. Advanced computational fluid dynamics modeling helps create exhaust paths that minimize flow restrictions while maintaining necessary back pressure for optimal combustion. Some designs include variable geometry components that adapt to different engine operating conditions.Expand Specific Solutions03 Integration of crankshaft and exhaust timing mechanisms

Systems that integrate crankshaft position with exhaust timing mechanisms can significantly enhance power efficiency. These designs synchronize exhaust valve operation with crankshaft position to optimize exhaust gas evacuation at different engine speeds. Variable timing mechanisms adjust exhaust flow characteristics based on engine load and RPM, improving volumetric efficiency across the operating range. Some advanced systems incorporate electronic control units that continuously adjust timing based on multiple sensor inputs.Expand Specific Solutions04 Waste heat recovery systems for exhaust

Waste heat recovery systems capture thermal energy from exhaust gases that would otherwise be lost, converting it to useful mechanical or electrical power. These systems include turbochargers, exhaust gas recirculation coolers, and thermoelectric generators. By harnessing waste heat, these technologies improve overall system efficiency without requiring additional fuel input. Some advanced designs incorporate phase-change materials or Rankine cycle systems to maximize energy recovery across various operating conditions.Expand Specific Solutions05 Lightweight materials and manufacturing techniques

The use of lightweight materials and advanced manufacturing techniques for both crankshafts and exhaust systems contributes to improved power efficiency. Materials such as high-strength alloys, titanium, and carbon composites reduce overall weight while maintaining or improving structural integrity. Additive manufacturing enables complex geometries that optimize flow characteristics and reduce weight. Surface treatments and coatings provide thermal barriers in exhaust systems and reduce friction in crankshaft applications.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The crankshaft and exhaust systems market is currently in a mature growth phase with increasing focus on efficiency optimization. The global market size is estimated at $25-30 billion, driven by stringent emission regulations and demand for fuel-efficient vehicles. Leading players like BorgWarner, Toyota, and Robert Bosch have established strong technological capabilities in power optimization systems, while companies such as AVL List and FEV Europe provide specialized engineering expertise. Chinese manufacturers including Weichai Power and FAW are rapidly gaining market share through cost-effective solutions. The technology landscape shows high maturity in traditional applications, with innovation now focused on integration with hybrid and electric powertrains, as evidenced by recent developments from Schaeffler Technologies and Hitachi.

GM Global Technology Operations LLC

Technical Solution: GM has developed Dynamic Fuel Management (DFM) technology that coordinates crankshaft operation with exhaust system dynamics to optimize power efficiency. Their system can deactivate any combination of cylinders in V8 engines, creating 17 different firing patterns that are seamlessly managed through sophisticated crankshaft position sensing and exhaust pulse control. The crankshaft features specialized counterweights and journal designs that maintain smooth operation regardless of which cylinders are active. GM's exhaust system incorporates active valves that adjust back pressure and flow characteristics to match the active cylinder pattern, ensuring optimal scavenging effects. Their integrated approach includes variable camshaft timing that works in concert with the exhaust system to maximize volumetric efficiency across all operating conditions. This technology delivers up to 15% improved fuel economy while maintaining power availability when needed, representing an effective balance between crankshaft operation and exhaust system management.

Strengths: Highly flexible cylinder deactivation capability; smooth operation across varied load conditions; effective integration with existing powertrain architectures. Weaknesses: System complexity increases potential failure points; requires sophisticated control algorithms that need extensive calibration.

Schaeffler Technologies AG & Co. KG

Technical Solution: Schaeffler has developed advanced variable valve train systems that optimize the interaction between crankshaft dynamics and exhaust energy utilization. Their UniAir electrohydraulic valve control system enables fully variable control of valve lift and timing, allowing precise management of exhaust gas flow relative to crankshaft position. The technology incorporates specialized camshaft designs that work with the crankshaft to optimize valve events based on engine operating conditions. Schaeffler's system includes thermal management components that regulate exhaust temperatures to maximize energy extraction while protecting catalytic converters. Their crankshaft bearings feature low-friction coatings that reduce parasitic losses, complementing the exhaust system optimization. The integrated approach allows engines to operate with optimized valve overlap periods that enhance scavenging effects, resulting in up to 10% improvement in power output and efficiency across the operating range while reducing emissions through better combustion control and exhaust gas management.

Strengths: Exceptional flexibility in valve timing and lift control; excellent integration potential with existing engine designs; proven reliability in production applications. Weaknesses: Higher system cost compared to conventional valvetrains; requires sophisticated control systems and additional hydraulic components.

Critical Patents in Crankshaft and Exhaust System Design

Crankshaft

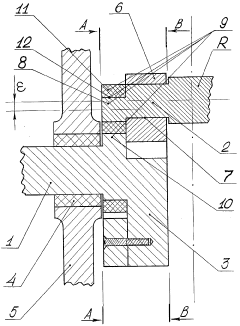

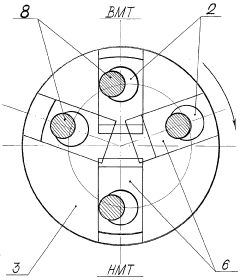

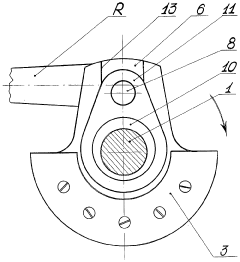

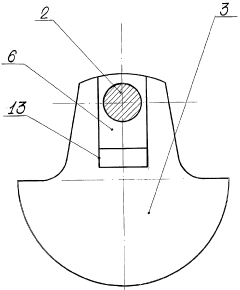

PatentWO2003006836A1

Innovation

- The design incorporates an additional connecting rod journal with bearings, a rigid connection between the connecting rod neck and slider, and axial crankpins, along with internal and external ribs, allowing for reduced friction and mass by decoupling the shaft's sealing bearings from the clutch and optimizing the movement of sliders.

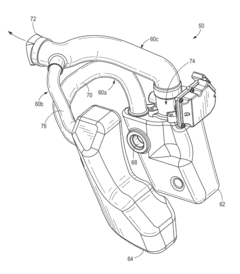

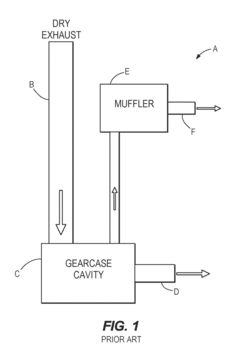

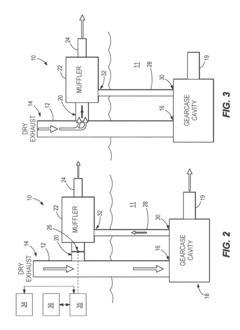

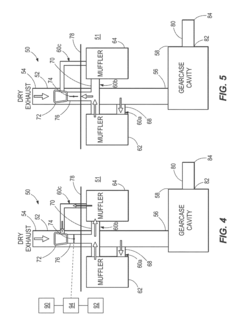

Actively tunable exhaust systems for outboard marine engines

PatentActiveUS9944376B1

Innovation

- An actively tunable exhaust system with a primary and intermediate conduit configuration, including a bypass valve and mufflers, allows the operator to control the exhaust gas flow to atmosphere or through a propeller housing, enabling selection of different sound qualities by positioning the bypass valve into open, closed, or intermediate positions, and optionally using an operator input device and controller to manage this flow.

Environmental Impact and Emissions Regulations

The automotive industry faces increasingly stringent emissions regulations worldwide, significantly impacting the design and optimization of crankshaft and exhaust systems. These regulations, such as Euro 7 in Europe, China 6 in Asia, and Tier 3 in the United States, have established progressively lower limits for nitrogen oxides (NOx), particulate matter (PM), and carbon dioxide (CO2) emissions, forcing manufacturers to reconsider traditional power generation and transmission approaches.

Exhaust systems have evolved from simple pipes to complex integrated systems incorporating catalytic converters, particulate filters, and selective catalytic reduction (SCR) technology. These components create back pressure that directly affects engine efficiency and power output. Engineers must now balance the trade-off between emissions compliance and performance optimization, particularly in the interaction between crankshaft design and exhaust flow dynamics.

The environmental impact of crankshaft and exhaust system design extends beyond tailpipe emissions. Manufacturing processes for high-performance crankshafts often involve energy-intensive forging and machining operations. Advanced materials like microalloyed steel and nodular cast iron are being adopted to reduce weight while maintaining strength, thereby improving fuel efficiency and reducing lifecycle emissions.

Thermal management has emerged as a critical factor in emissions control. Exhaust gas recirculation (EGR) systems, which reduce NOx formation by lowering combustion temperatures, create additional challenges for crankshaft design due to increased thermal loads and potential carbon deposits. Engineers must account for these thermal considerations when determining bearing specifications and lubrication requirements.

Real-world driving emissions (RDE) testing has revealed significant discrepancies between laboratory and on-road performance, prompting a shift toward more dynamic power management strategies. Variable valve timing and cylinder deactivation technologies now work in concert with adaptive exhaust systems to optimize emissions across diverse driving conditions, requiring more sophisticated crankshaft designs that can handle variable loading patterns.

Looking forward, electrification trends are reshaping emissions strategies. Hybrid powertrains utilize crankshaft-integrated motor-generator units that recover braking energy and provide electric boost, reducing overall emissions while maintaining performance. These systems require precise integration between traditional mechanical components and electrical systems, presenting new challenges in crankshaft design and exhaust thermal management.

The regulatory landscape continues to evolve, with carbon neutrality targets driving innovation in materials, manufacturing processes, and system integration. Future compliance will likely require holistic approaches that consider the entire vehicle lifecycle emissions rather than focusing solely on tailpipe outputs.

Exhaust systems have evolved from simple pipes to complex integrated systems incorporating catalytic converters, particulate filters, and selective catalytic reduction (SCR) technology. These components create back pressure that directly affects engine efficiency and power output. Engineers must now balance the trade-off between emissions compliance and performance optimization, particularly in the interaction between crankshaft design and exhaust flow dynamics.

The environmental impact of crankshaft and exhaust system design extends beyond tailpipe emissions. Manufacturing processes for high-performance crankshafts often involve energy-intensive forging and machining operations. Advanced materials like microalloyed steel and nodular cast iron are being adopted to reduce weight while maintaining strength, thereby improving fuel efficiency and reducing lifecycle emissions.

Thermal management has emerged as a critical factor in emissions control. Exhaust gas recirculation (EGR) systems, which reduce NOx formation by lowering combustion temperatures, create additional challenges for crankshaft design due to increased thermal loads and potential carbon deposits. Engineers must account for these thermal considerations when determining bearing specifications and lubrication requirements.

Real-world driving emissions (RDE) testing has revealed significant discrepancies between laboratory and on-road performance, prompting a shift toward more dynamic power management strategies. Variable valve timing and cylinder deactivation technologies now work in concert with adaptive exhaust systems to optimize emissions across diverse driving conditions, requiring more sophisticated crankshaft designs that can handle variable loading patterns.

Looking forward, electrification trends are reshaping emissions strategies. Hybrid powertrains utilize crankshaft-integrated motor-generator units that recover braking energy and provide electric boost, reducing overall emissions while maintaining performance. These systems require precise integration between traditional mechanical components and electrical systems, presenting new challenges in crankshaft design and exhaust thermal management.

The regulatory landscape continues to evolve, with carbon neutrality targets driving innovation in materials, manufacturing processes, and system integration. Future compliance will likely require holistic approaches that consider the entire vehicle lifecycle emissions rather than focusing solely on tailpipe outputs.

Cost-Benefit Analysis of Power Enhancement Technologies

When evaluating power enhancement technologies for internal combustion engines, a comprehensive cost-benefit analysis reveals significant differences between crankshaft modifications and exhaust system upgrades. Initial investment costs for crankshaft enhancements typically range from $800-$2,500 for performance-oriented components, while exhaust system modifications generally cost between $300-$1,800 depending on material quality and design complexity.

From a performance perspective, crankshaft modifications deliver fundamental power improvements by optimizing the engine's mechanical efficiency. Lightweight crankshafts can increase engine response by reducing rotational mass, potentially yielding 2-5% power gains. However, these benefits come with substantial labor costs, as crankshaft replacement requires extensive engine disassembly, adding 8-15 hours of professional labor to the total expense.

Exhaust system upgrades present a more favorable cost-to-benefit ratio in many scenarios. High-flow exhaust manifolds, performance catalytic converters, and optimized mufflers can collectively improve engine output by 3-7% while simultaneously reducing backpressure. Installation typically requires only 2-4 hours of labor, significantly reducing overall implementation costs compared to crankshaft modifications.

Longevity considerations further complicate the analysis. Quality crankshaft components often maintain performance benefits throughout the engine's lifespan (potentially 150,000+ miles) with minimal maintenance requirements. Conversely, exhaust systems face environmental exposure and may require replacement of components after 60,000-80,000 miles, particularly in regions with harsh weather conditions or road salt usage.

Fuel efficiency impacts also differ substantially. Crankshaft modifications rarely yield significant fuel economy improvements, with most changes resulting in neutral or slightly negative effects on consumption. Exhaust system optimizations, particularly those focusing on reducing backpressure while maintaining proper scavenging effects, can improve fuel efficiency by 1-3% under optimal conditions.

The return on investment timeline varies dramatically between these approaches. Exhaust modifications typically demonstrate measurable performance benefits immediately with relatively quick ROI periods of 2-4 years when factoring in potential fuel savings. Crankshaft modifications generally require 5+ years to achieve ROI purely from a financial perspective, making them more appropriate for enthusiasts prioritizing performance over cost considerations.

For manufacturers and performance shops, these distinctions create important strategic considerations when developing upgrade packages that balance customer expectations with realistic performance outcomes and budget constraints.

From a performance perspective, crankshaft modifications deliver fundamental power improvements by optimizing the engine's mechanical efficiency. Lightweight crankshafts can increase engine response by reducing rotational mass, potentially yielding 2-5% power gains. However, these benefits come with substantial labor costs, as crankshaft replacement requires extensive engine disassembly, adding 8-15 hours of professional labor to the total expense.

Exhaust system upgrades present a more favorable cost-to-benefit ratio in many scenarios. High-flow exhaust manifolds, performance catalytic converters, and optimized mufflers can collectively improve engine output by 3-7% while simultaneously reducing backpressure. Installation typically requires only 2-4 hours of labor, significantly reducing overall implementation costs compared to crankshaft modifications.

Longevity considerations further complicate the analysis. Quality crankshaft components often maintain performance benefits throughout the engine's lifespan (potentially 150,000+ miles) with minimal maintenance requirements. Conversely, exhaust systems face environmental exposure and may require replacement of components after 60,000-80,000 miles, particularly in regions with harsh weather conditions or road salt usage.

Fuel efficiency impacts also differ substantially. Crankshaft modifications rarely yield significant fuel economy improvements, with most changes resulting in neutral or slightly negative effects on consumption. Exhaust system optimizations, particularly those focusing on reducing backpressure while maintaining proper scavenging effects, can improve fuel efficiency by 1-3% under optimal conditions.

The return on investment timeline varies dramatically between these approaches. Exhaust modifications typically demonstrate measurable performance benefits immediately with relatively quick ROI periods of 2-4 years when factoring in potential fuel savings. Crankshaft modifications generally require 5+ years to achieve ROI purely from a financial perspective, making them more appropriate for enthusiasts prioritizing performance over cost considerations.

For manufacturers and performance shops, these distinctions create important strategic considerations when developing upgrade packages that balance customer expectations with realistic performance outcomes and budget constraints.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!