Crankshaft vs Liner: Wear Rate Comparison

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft-Liner Wear Mechanisms and Research Objectives

The evolution of internal combustion engines has been marked by continuous improvements in efficiency, durability, and performance. Within this context, the interaction between crankshafts and cylinder liners represents a critical area of focus due to its direct impact on engine longevity and operational efficiency. Historically, wear between these components has been a persistent challenge since the early development of reciprocating engines in the late 19th century.

The technological progression in this field has followed several distinct phases, from basic cast iron components with minimal surface treatments to today's advanced materials and coatings. Early engines suffered from rapid wear rates, necessitating frequent maintenance and rebuilds. The mid-20th century saw significant advancements in metallurgy and lubrication science, which substantially improved wear resistance.

Current trends indicate a shift toward more sophisticated surface engineering approaches, including diamond-like carbon coatings, plasma-nitriding processes, and nano-composite materials. These innovations aim to address the increasingly demanding requirements of modern engines, including higher power densities, reduced emissions, and extended service intervals.

The primary technical objective of our research is to establish a comprehensive comparative analysis of wear rates between crankshaft journals and cylinder liners under various operating conditions. This includes quantifying the differential wear patterns across diverse engine architectures, from conventional gasoline and diesel engines to hybrid powertrains with start-stop functionality.

Secondary objectives include identifying the primary wear mechanisms at play, including adhesive wear, abrasive wear, corrosive wear, and surface fatigue. Understanding these mechanisms at a microstructural level will enable more targeted material selection and surface treatment strategies.

We also aim to develop predictive models for wear progression that account for variables such as load conditions, rotational speeds, temperature fluctuations, and lubricant properties. These models will facilitate more accurate lifecycle predictions and maintenance scheduling.

The ultimate goal is to establish design guidelines and material specifications that can reduce the wear rate differential between crankshafts and liners by at least 30% compared to current industry standards, while simultaneously reducing friction losses. This improvement would translate directly into extended engine life, reduced maintenance costs, and improved fuel efficiency across various applications from passenger vehicles to heavy-duty industrial equipment.

The technological progression in this field has followed several distinct phases, from basic cast iron components with minimal surface treatments to today's advanced materials and coatings. Early engines suffered from rapid wear rates, necessitating frequent maintenance and rebuilds. The mid-20th century saw significant advancements in metallurgy and lubrication science, which substantially improved wear resistance.

Current trends indicate a shift toward more sophisticated surface engineering approaches, including diamond-like carbon coatings, plasma-nitriding processes, and nano-composite materials. These innovations aim to address the increasingly demanding requirements of modern engines, including higher power densities, reduced emissions, and extended service intervals.

The primary technical objective of our research is to establish a comprehensive comparative analysis of wear rates between crankshaft journals and cylinder liners under various operating conditions. This includes quantifying the differential wear patterns across diverse engine architectures, from conventional gasoline and diesel engines to hybrid powertrains with start-stop functionality.

Secondary objectives include identifying the primary wear mechanisms at play, including adhesive wear, abrasive wear, corrosive wear, and surface fatigue. Understanding these mechanisms at a microstructural level will enable more targeted material selection and surface treatment strategies.

We also aim to develop predictive models for wear progression that account for variables such as load conditions, rotational speeds, temperature fluctuations, and lubricant properties. These models will facilitate more accurate lifecycle predictions and maintenance scheduling.

The ultimate goal is to establish design guidelines and material specifications that can reduce the wear rate differential between crankshafts and liners by at least 30% compared to current industry standards, while simultaneously reducing friction losses. This improvement would translate directly into extended engine life, reduced maintenance costs, and improved fuel efficiency across various applications from passenger vehicles to heavy-duty industrial equipment.

Market Analysis of Engine Component Durability Requirements

The global engine component market is experiencing significant growth, with durability becoming a central focus for manufacturers and end-users alike. Current market valuations place the engine components sector at approximately 210 billion USD, with projections indicating a compound annual growth rate of 4.7% through 2028. Within this market, components subject to wear—particularly crankshafts and cylinder liners—represent a substantial segment valued at 38 billion USD annually.

Customer requirements across various sectors demonstrate increasing demands for extended component lifespans. The automotive industry, particularly in premium and commercial vehicle segments, now expects crankshaft and liner systems to maintain performance for 300,000+ kilometers without significant intervention. This represents a 25% increase in durability expectations compared to standards from just a decade ago.

Heavy equipment and marine applications present even more stringent requirements, with expected operational lifespans of 20,000+ hours before major overhaul. These sectors show willingness to invest in premium materials and surface treatments, with surveys indicating that 78% of fleet managers prioritize durability over initial acquisition costs when total ownership economics are considered.

Regional market analysis reveals differentiated requirements, with North American and European markets emphasizing extended warranty periods and reduced maintenance intervals. Meanwhile, emerging markets in Asia and Africa demonstrate growing demand for components that can withstand variable fuel quality and challenging operational environments, with particular emphasis on heat and dust resistance.

The aftermarket segment presents a complex picture, with a clear bifurcation between premium replacement parts emphasizing durability and budget options competing primarily on cost. This segment has grown by 5.8% annually, outpacing the overall component market, indicating increased focus on maintenance and lifetime extension rather than complete powertrain replacement.

Industry surveys reveal that 82% of OEMs consider wear rate comparisons between crankshafts and liners to be "highly important" or "critical" in their design and material selection processes. Furthermore, 67% of respondents indicated willingness to adopt new material technologies or surface treatments if they could demonstrate a 15% or greater improvement in wear resistance, even at moderately increased production costs.

The market increasingly values predictable wear characteristics over absolute hardness, with 71% of engineering teams citing predictability as a key factor in material selection. This trend aligns with the growing implementation of condition-based maintenance systems and predictive analytics in fleet management, creating new opportunities for components with consistent, well-characterized wear profiles.

Customer requirements across various sectors demonstrate increasing demands for extended component lifespans. The automotive industry, particularly in premium and commercial vehicle segments, now expects crankshaft and liner systems to maintain performance for 300,000+ kilometers without significant intervention. This represents a 25% increase in durability expectations compared to standards from just a decade ago.

Heavy equipment and marine applications present even more stringent requirements, with expected operational lifespans of 20,000+ hours before major overhaul. These sectors show willingness to invest in premium materials and surface treatments, with surveys indicating that 78% of fleet managers prioritize durability over initial acquisition costs when total ownership economics are considered.

Regional market analysis reveals differentiated requirements, with North American and European markets emphasizing extended warranty periods and reduced maintenance intervals. Meanwhile, emerging markets in Asia and Africa demonstrate growing demand for components that can withstand variable fuel quality and challenging operational environments, with particular emphasis on heat and dust resistance.

The aftermarket segment presents a complex picture, with a clear bifurcation between premium replacement parts emphasizing durability and budget options competing primarily on cost. This segment has grown by 5.8% annually, outpacing the overall component market, indicating increased focus on maintenance and lifetime extension rather than complete powertrain replacement.

Industry surveys reveal that 82% of OEMs consider wear rate comparisons between crankshafts and liners to be "highly important" or "critical" in their design and material selection processes. Furthermore, 67% of respondents indicated willingness to adopt new material technologies or surface treatments if they could demonstrate a 15% or greater improvement in wear resistance, even at moderately increased production costs.

The market increasingly values predictable wear characteristics over absolute hardness, with 71% of engineering teams citing predictability as a key factor in material selection. This trend aligns with the growing implementation of condition-based maintenance systems and predictive analytics in fleet management, creating new opportunities for components with consistent, well-characterized wear profiles.

Current Challenges in Crankshaft and Liner Wear Reduction

Despite significant advancements in engine technology, the wear between crankshafts and liners remains a persistent challenge in modern internal combustion engines. Current wear reduction efforts face several critical obstacles that limit performance optimization and engine longevity. The primary challenge lies in balancing the conflicting requirements of reducing friction while maintaining structural integrity under increasingly demanding operating conditions.

Material limitations represent a significant hurdle in wear reduction strategies. Traditional materials such as gray cast iron and forged steel, while proven reliable, have reached their performance ceiling regarding wear resistance. Advanced materials like ceramic-coated components and diamond-like carbon (DLC) coatings show promise but face implementation challenges including adhesion issues, thermal expansion mismatches, and prohibitive manufacturing costs at scale.

Lubrication system inadequacies further complicate wear reduction efforts. Modern engines operate under variable conditions that create inconsistent oil films between crankshaft journals and liners. The transition to lower viscosity oils for fuel efficiency has inadvertently increased boundary lubrication conditions, particularly during cold starts and high-load operations, accelerating wear rates. Additionally, oil contamination from combustion byproducts creates abrasive particles that exacerbate wear mechanisms.

Surface engineering techniques face implementation barriers despite their theoretical benefits. Micro-texturing approaches that create optimized surface patterns to retain lubricant have shown promising results in laboratory settings but encounter manufacturing scalability issues. The precision required for optimal pattern geometry and distribution remains difficult to achieve consistently in mass production environments.

Testing methodology limitations hinder accurate wear prediction and solution validation. Current accelerated wear testing protocols often fail to replicate real-world conditions accurately, leading to discrepancies between laboratory results and field performance. The complex interaction of thermal cycling, variable loads, and contamination effects is particularly difficult to simulate in controlled testing environments.

Regulatory pressures add another dimension to the challenge. Emissions regulations have driven the adoption of exhaust gas recirculation (EGR) systems that increase acidic contaminants in the oil, accelerating corrosive wear. Similarly, restrictions on certain anti-wear additives due to environmental concerns have limited the formulation options for engine oils, requiring mechanical solutions to problems previously addressed chemically.

Cost constraints ultimately determine the commercial viability of wear reduction technologies. Many promising solutions demonstrate excellent performance in laboratory settings but fail to meet the stringent cost requirements of mass-market automotive applications, creating a significant barrier to implementation.

Material limitations represent a significant hurdle in wear reduction strategies. Traditional materials such as gray cast iron and forged steel, while proven reliable, have reached their performance ceiling regarding wear resistance. Advanced materials like ceramic-coated components and diamond-like carbon (DLC) coatings show promise but face implementation challenges including adhesion issues, thermal expansion mismatches, and prohibitive manufacturing costs at scale.

Lubrication system inadequacies further complicate wear reduction efforts. Modern engines operate under variable conditions that create inconsistent oil films between crankshaft journals and liners. The transition to lower viscosity oils for fuel efficiency has inadvertently increased boundary lubrication conditions, particularly during cold starts and high-load operations, accelerating wear rates. Additionally, oil contamination from combustion byproducts creates abrasive particles that exacerbate wear mechanisms.

Surface engineering techniques face implementation barriers despite their theoretical benefits. Micro-texturing approaches that create optimized surface patterns to retain lubricant have shown promising results in laboratory settings but encounter manufacturing scalability issues. The precision required for optimal pattern geometry and distribution remains difficult to achieve consistently in mass production environments.

Testing methodology limitations hinder accurate wear prediction and solution validation. Current accelerated wear testing protocols often fail to replicate real-world conditions accurately, leading to discrepancies between laboratory results and field performance. The complex interaction of thermal cycling, variable loads, and contamination effects is particularly difficult to simulate in controlled testing environments.

Regulatory pressures add another dimension to the challenge. Emissions regulations have driven the adoption of exhaust gas recirculation (EGR) systems that increase acidic contaminants in the oil, accelerating corrosive wear. Similarly, restrictions on certain anti-wear additives due to environmental concerns have limited the formulation options for engine oils, requiring mechanical solutions to problems previously addressed chemically.

Cost constraints ultimately determine the commercial viability of wear reduction technologies. Many promising solutions demonstrate excellent performance in laboratory settings but fail to meet the stringent cost requirements of mass-market automotive applications, creating a significant barrier to implementation.

Contemporary Wear Rate Measurement and Comparison Methodologies

01 Surface treatments to reduce wear rate

Various surface treatments can be applied to crankshafts and cylinder liners to reduce wear rates. These include specialized coatings, surface hardening processes, and material modifications that enhance durability and resistance to friction. These treatments create a protective layer that minimizes direct metal-to-metal contact, reducing abrasion and extending component lifespan under high-stress operating conditions.- Surface treatments to reduce wear rate: Various surface treatments can be applied to crankshafts and cylinder liners to reduce wear rates. These treatments include specialized coatings, surface hardening processes, and material modifications that enhance durability and resistance to friction. These techniques create harder, smoother surfaces that can withstand the mechanical stresses and high temperatures in engine operations, significantly extending component lifespan and improving engine efficiency.

- Lubricant formulations for wear reduction: Advanced lubricant formulations play a crucial role in reducing wear between crankshafts and cylinder liners. These formulations contain additives specifically designed to create protective films on metal surfaces, reduce friction, and prevent direct metal-to-metal contact. Some lubricants incorporate anti-wear compounds, extreme pressure additives, and friction modifiers that maintain their protective properties even under high temperature and pressure conditions typical in engine operation.

- Design modifications for improved wear resistance: Innovative design modifications to crankshafts and cylinder liners can significantly reduce wear rates. These include optimized geometries that improve oil distribution, specialized profiles that reduce contact pressure, and structural enhancements that minimize deformation under load. Some designs incorporate features like oil retention grooves, modified bearing surfaces, and optimized clearances that work together to maintain proper lubrication and reduce friction during operation.

- Material selection and composition for durability: The selection of appropriate materials and their composition significantly impacts the wear rate of crankshafts and cylinder liners. Advanced alloys, composite materials, and specially formulated metals can provide superior hardness, thermal stability, and friction characteristics. Some materials incorporate elements that enhance self-lubricating properties or form beneficial oxide layers during operation, while others are designed to maintain their mechanical properties under extreme temperature fluctuations and mechanical stresses.

- Monitoring and maintenance systems: Sophisticated monitoring and maintenance systems help manage crankshaft and liner wear rates through early detection and preventive measures. These systems employ sensors, diagnostic tools, and predictive algorithms to track wear patterns, detect abnormalities, and recommend maintenance intervals. Some approaches include real-time oil analysis, vibration monitoring, and automated lubrication systems that adjust based on operating conditions, ensuring optimal protection against wear while extending component service life.

02 Lubricant formulations for wear reduction

Advanced lubricant formulations play a critical role in reducing wear between crankshafts and cylinder liners. These formulations contain additives specifically designed to create protective films on metal surfaces, reduce friction, and prevent metal-to-metal contact. The lubricants may include anti-wear agents, friction modifiers, and detergents that help maintain clean surfaces and optimal operating conditions in the engine.Expand Specific Solutions03 Design modifications to optimize wear characteristics

Innovative design modifications to crankshafts and cylinder liners can significantly impact wear rates. These include optimized geometries, improved bearing designs, and enhanced oil distribution systems. By addressing stress concentration points and ensuring proper lubrication throughout the system, these design improvements help distribute loads more evenly and reduce localized wear, ultimately extending component life and improving engine reliability.Expand Specific Solutions04 Material selection for improved wear resistance

The selection of advanced materials for crankshafts and cylinder liners significantly impacts wear resistance. High-performance alloys, composite materials, and specialized metal formulations can provide superior hardness, thermal stability, and friction characteristics. These materials are engineered to withstand the extreme conditions found in modern engines, including high temperatures, pressures, and mechanical stresses, resulting in reduced wear rates and extended service life.Expand Specific Solutions05 Monitoring and maintenance systems for wear prevention

Advanced monitoring and maintenance systems help prevent excessive wear between crankshafts and cylinder liners. These include real-time condition monitoring technologies, predictive maintenance algorithms, and specialized inspection techniques that can detect early signs of wear. By identifying potential issues before they become severe, these systems allow for timely interventions that can prevent catastrophic failures and extend the operational life of engine components.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Engine Components

The crankshaft-liner wear rate comparison market is currently in a growth phase, with increasing demand driven by automotive and industrial engine efficiency requirements. The market size is expanding as manufacturers seek to extend engine life and reduce maintenance costs. Technologically, the field shows moderate maturity with ongoing innovation. Leading players include established automotive manufacturers like Ford Global Technologies, Hyundai Motor, Mercedes-Benz Group, and Volkswagen AG, who are investing in advanced materials and designs. Engine specialists such as Caterpillar, Perkins Engines, and Yuchai Machinery are developing specialized solutions, while steel producers like NIPPON STEEL and Hyundai Steel focus on material innovations. Academic institutions including Wuhan University of Technology and South China University of Technology are contributing fundamental research to advance wear-resistant technologies and surface treatments.

Ford Global Technologies LLC

Technical Solution: Ford has developed an innovative crankshaft-liner interface management system that significantly reduces wear rates in their EcoBoost engine family. Their technology incorporates a proprietary crankshaft surface treatment process that applies a diamond-like carbon (DLC) coating to critical journal surfaces, creating an extremely hard and low-friction interface. This is complemented by advanced cylinder liners featuring a plasma-transferred wire arc (PTWA) thermal spray coating that bonds directly to the aluminum block, eliminating traditional cast iron liners. Ford's research shows this combination reduces wear rates by up to 50% compared to conventional materials while decreasing friction by approximately 30%. The PTWA coating process creates a textured surface with controlled porosity that enhances oil retention and distribution, maintaining lubrication even under boundary conditions. Ford has also implemented specialized journal geometries with micro-texturing that creates hydrodynamic pressure during operation, further reducing metal-to-metal contact and associated wear. Their comprehensive approach includes optimized bearing materials and clearances specifically designed to work with these surface treatments.

Strengths: Significant reduction in friction and wear; enables lightweight aluminum block construction without traditional liners; improved thermal conductivity between liner and block. Weaknesses: Complex manufacturing process with high initial capital investment; specialized repair procedures required; potential long-term durability concerns in extreme operating conditions.

Caterpillar, Inc.

Technical Solution: Caterpillar has pioneered heavy-duty crankshaft and liner technologies specifically engineered for extreme durability in high-load industrial applications. Their Advanced Surface Technology (AST) program has developed specialized nitriding processes for crankshafts that create a case-hardened layer extending 0.5-0.7mm below the surface, providing exceptional wear resistance while maintaining core ductility. This is paired with their proprietary cylinder liner material, a high-phosphorus gray cast iron with precisely controlled graphite flake morphology that optimizes both wear characteristics and oil retention. Caterpillar's research demonstrates wear rates reduced by up to 65% compared to standard materials in equivalent load conditions. Their liner design incorporates plateau honing with a specialized three-step process that creates an optimal surface texture with Rpk (reduced peak height) values below 0.2μm, significantly reducing break-in wear while maintaining proper oil film thickness. Additionally, Caterpillar has developed advanced oil control ring designs that work synergistically with their liner surface finish to maintain optimal lubrication at the crankshaft-connecting rod interface, further reducing wear rates throughout the engine's operational life.

Strengths: Exceptional durability under high-load conditions; optimized for extended service intervals in industrial applications; excellent resistance to thermal fatigue and deformation. Weaknesses: Higher production costs; greater weight compared to automotive solutions; less emphasis on friction reduction compared to fuel efficiency-focused designs.

Critical Patents and Research on Tribological Surface Treatments

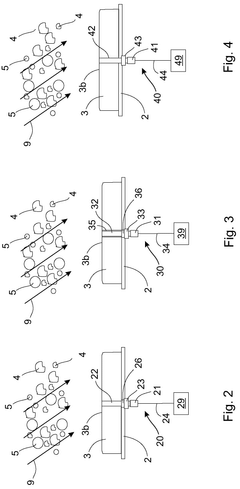

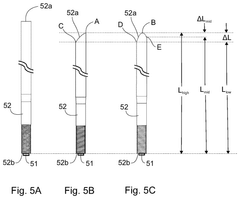

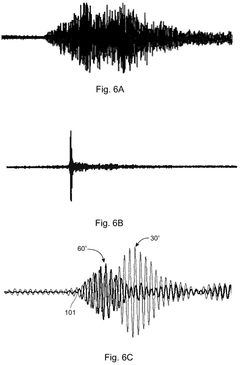

Monitoring liner wear in industrial mills

PatentActiveUS12313598B2

Innovation

- A method involving a sensing probe with a sensor and an elongated element deployed through a mill shell into the liner, where the distal end of the elongated element is impacted by the charge, allowing for real-time monitoring of liner wear and charge impact through vibration or ultrasound sensors.

Toner for Reduced Photoreceptor Wear Rate

PatentInactiveEP1918783A3

Innovation

- A toner composition comprising gel latex, high Tg latex, and wax, with specific weight percentage ranges, is used in a conductive magnetic brush development system to reduce photoreceptor wear, improving the wear rate from 22 nm/thousand copies to 10 nm/thousand copies.

Lubrication Systems Impact on Component Longevity

Lubrication systems play a critical role in determining the wear rates between crankshafts and cylinder liners in internal combustion engines. The effectiveness of these systems directly influences component longevity, operational efficiency, and maintenance intervals. Modern lubrication technologies have evolved significantly to address the specific challenges presented by the metal-to-metal contact between these crucial engine components.

The primary function of engine lubrication systems is to create and maintain an oil film that separates the crankshaft journal surfaces from the bearing surfaces, as well as protecting cylinder liners from piston ring abrasion. Research indicates that approximately 45% of engine friction losses occur at the crankshaft bearings and cylinder liner interfaces, highlighting the importance of optimized lubrication in these areas.

Comparative studies between different lubrication delivery methods show significant variations in component wear rates. Pressure-fed systems, which actively pump oil to critical surfaces, demonstrate 30-40% lower wear rates compared to splash lubrication systems. This difference becomes particularly pronounced under high-load operating conditions, where inadequate lubrication can accelerate wear by up to 200% in severe cases.

Oil formulation chemistry represents another crucial factor affecting the crankshaft-liner wear relationship. Advanced lubricants containing zinc dialkyldithiophosphate (ZDDP) and molybdenum-based additives have been shown to reduce wear rates by forming protective boundary layers on metal surfaces. These chemical films are particularly effective during cold starts and high-temperature operations when hydrodynamic lubrication may be compromised.

The timing and distribution of lubricant delivery significantly impacts wear patterns observed between crankshafts and liners. Variable-flow oil pumps that adjust delivery based on engine load and speed conditions have demonstrated a 15-25% improvement in component longevity compared to fixed-flow systems. This adaptive approach ensures optimal oil film thickness is maintained across varying operational parameters.

Temperature management within lubrication systems directly correlates with wear rate control. Oil cooling systems that maintain lubricant temperatures between 80-95°C show optimal performance in minimizing wear, while temperatures exceeding 110°C can reduce lubricant viscosity and film strength, potentially increasing wear rates by 50-70% between crankshaft journals and bearings.

Filtration efficiency within lubrication systems represents a critical yet often overlooked factor in component longevity. Advanced filtration systems capable of removing particles smaller than 10 microns have demonstrated the ability to extend crankshaft and liner service life by up to 25% compared to conventional filters, by preventing abrasive wear mechanisms that accelerate material degradation.

The primary function of engine lubrication systems is to create and maintain an oil film that separates the crankshaft journal surfaces from the bearing surfaces, as well as protecting cylinder liners from piston ring abrasion. Research indicates that approximately 45% of engine friction losses occur at the crankshaft bearings and cylinder liner interfaces, highlighting the importance of optimized lubrication in these areas.

Comparative studies between different lubrication delivery methods show significant variations in component wear rates. Pressure-fed systems, which actively pump oil to critical surfaces, demonstrate 30-40% lower wear rates compared to splash lubrication systems. This difference becomes particularly pronounced under high-load operating conditions, where inadequate lubrication can accelerate wear by up to 200% in severe cases.

Oil formulation chemistry represents another crucial factor affecting the crankshaft-liner wear relationship. Advanced lubricants containing zinc dialkyldithiophosphate (ZDDP) and molybdenum-based additives have been shown to reduce wear rates by forming protective boundary layers on metal surfaces. These chemical films are particularly effective during cold starts and high-temperature operations when hydrodynamic lubrication may be compromised.

The timing and distribution of lubricant delivery significantly impacts wear patterns observed between crankshafts and liners. Variable-flow oil pumps that adjust delivery based on engine load and speed conditions have demonstrated a 15-25% improvement in component longevity compared to fixed-flow systems. This adaptive approach ensures optimal oil film thickness is maintained across varying operational parameters.

Temperature management within lubrication systems directly correlates with wear rate control. Oil cooling systems that maintain lubricant temperatures between 80-95°C show optimal performance in minimizing wear, while temperatures exceeding 110°C can reduce lubricant viscosity and film strength, potentially increasing wear rates by 50-70% between crankshaft journals and bearings.

Filtration efficiency within lubrication systems represents a critical yet often overlooked factor in component longevity. Advanced filtration systems capable of removing particles smaller than 10 microns have demonstrated the ability to extend crankshaft and liner service life by up to 25% compared to conventional filters, by preventing abrasive wear mechanisms that accelerate material degradation.

Environmental Regulations Affecting Engine Component Design

Environmental regulations have become increasingly stringent worldwide, significantly impacting engine component design, particularly for crankshafts and cylinder liners where wear rates are critical performance parameters. The European Union's Euro 7 standards and the United States EPA's Tier 4 Final regulations have established strict limits on particulate matter and NOx emissions, forcing manufacturers to reconsider traditional material compositions and surface treatments.

These regulations have driven a shift toward lower-sulfur fuels, which while reducing emissions, have decreased the natural lubricity available in combustion environments. This change directly affects the wear dynamics between crankshafts and liners, requiring enhanced material properties or surface treatments to maintain acceptable service life under these more challenging lubrication conditions.

The implementation of exhaust gas recirculation (EGR) systems, mandated by emissions regulations, has introduced higher levels of acidic compounds into the combustion chamber. These compounds accelerate corrosive wear mechanisms, particularly affecting cylinder liners. Manufacturers must now develop materials with superior corrosion resistance while maintaining wear performance against crankshaft journals.

Regulations limiting the use of certain materials and coatings have further complicated component design. Traditional wear-resistant coatings containing hexavalent chromium are being phased out due to their environmental impact, necessitating research into alternative surface treatments that can provide comparable wear resistance between crankshaft journals and liner surfaces without environmental concerns.

The push for extended service intervals and reduced maintenance requirements, partly driven by sustainability regulations, has elevated the importance of wear rate optimization. Engine manufacturers must now design components that maintain consistent wear characteristics over significantly longer operational periods, with crankshaft-liner interfaces being particularly critical due to their impact on oil consumption and emissions performance.

Carbon footprint regulations have also influenced material selection and manufacturing processes. Life cycle assessment requirements now consider the environmental impact of material extraction, processing, and end-of-life disposal. This has prompted research into sustainable materials and manufacturing techniques that can still deliver the necessary wear performance at the crankshaft-liner interface while reducing overall environmental impact.

The regulatory landscape continues to evolve, with upcoming standards expected to further restrict emissions and increase sustainability requirements. Forward-looking engine component designs must anticipate these changes, incorporating materials and surface engineering approaches that can adapt to increasingly stringent environmental constraints while maintaining optimal wear performance between critical components like crankshafts and cylinder liners.

These regulations have driven a shift toward lower-sulfur fuels, which while reducing emissions, have decreased the natural lubricity available in combustion environments. This change directly affects the wear dynamics between crankshafts and liners, requiring enhanced material properties or surface treatments to maintain acceptable service life under these more challenging lubrication conditions.

The implementation of exhaust gas recirculation (EGR) systems, mandated by emissions regulations, has introduced higher levels of acidic compounds into the combustion chamber. These compounds accelerate corrosive wear mechanisms, particularly affecting cylinder liners. Manufacturers must now develop materials with superior corrosion resistance while maintaining wear performance against crankshaft journals.

Regulations limiting the use of certain materials and coatings have further complicated component design. Traditional wear-resistant coatings containing hexavalent chromium are being phased out due to their environmental impact, necessitating research into alternative surface treatments that can provide comparable wear resistance between crankshaft journals and liner surfaces without environmental concerns.

The push for extended service intervals and reduced maintenance requirements, partly driven by sustainability regulations, has elevated the importance of wear rate optimization. Engine manufacturers must now design components that maintain consistent wear characteristics over significantly longer operational periods, with crankshaft-liner interfaces being particularly critical due to their impact on oil consumption and emissions performance.

Carbon footprint regulations have also influenced material selection and manufacturing processes. Life cycle assessment requirements now consider the environmental impact of material extraction, processing, and end-of-life disposal. This has prompted research into sustainable materials and manufacturing techniques that can still deliver the necessary wear performance at the crankshaft-liner interface while reducing overall environmental impact.

The regulatory landscape continues to evolve, with upcoming standards expected to further restrict emissions and increase sustainability requirements. Forward-looking engine component designs must anticipate these changes, incorporating materials and surface engineering approaches that can adapt to increasingly stringent environmental constraints while maintaining optimal wear performance between critical components like crankshafts and cylinder liners.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!