How to Develop Crankshaft Fatigue Analysis Methods

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Fatigue Analysis Background and Objectives

Crankshaft fatigue analysis has evolved significantly over the past decades, transitioning from simple empirical methods to sophisticated computational approaches. The evolution began in the early 20th century with basic stress calculations and has progressed to include advanced finite element analysis (FEA), multi-body dynamics, and computational fluid dynamics. This technological progression has been driven by the automotive and heavy machinery industries' continuous pursuit of more efficient, durable, and lightweight engine components.

The crankshaft, as a critical component in internal combustion engines, experiences complex loading patterns including bending, torsion, and axial forces during operation. These cyclic loads, combined with stress concentrations at fillets and oil holes, make fatigue failure a primary concern in crankshaft design. Historical data indicates that approximately 80% of mechanical failures in engines can be attributed to fatigue-related issues, with crankshafts being particularly vulnerable.

Recent technological advancements in materials science, manufacturing processes, and computational capabilities have created new opportunities for enhancing crankshaft durability. The introduction of forged steel with improved microstructure, surface treatment technologies like nitriding and induction hardening, and precision manufacturing techniques have all contributed to extending crankshaft service life. However, these advancements necessitate more sophisticated analysis methods to accurately predict fatigue behavior.

The primary objective of developing advanced crankshaft fatigue analysis methods is to establish reliable predictive models that can accurately estimate component life under various operating conditions. These methods aim to bridge the gap between theoretical models and real-world performance, accounting for factors such as material variability, manufacturing tolerances, and dynamic loading conditions.

Secondary objectives include reducing development time and costs by minimizing physical prototyping and testing, optimizing crankshaft design for specific applications, and supporting the trend toward engine downsizing without compromising reliability. Additionally, these methods should facilitate the evaluation of innovative materials and manufacturing processes to meet increasingly stringent emissions regulations and fuel efficiency standards.

The global push toward electrification presents both challenges and opportunities for crankshaft technology. While pure electric vehicles eliminate the need for traditional crankshafts, hybrid powertrains often require specially designed crankshafts to accommodate the integration of electric motors. Furthermore, the remaining internal combustion engine market demands increasingly efficient and durable components, making advanced fatigue analysis methods more crucial than ever for competitive advantage in the automotive and heavy machinery sectors.

The crankshaft, as a critical component in internal combustion engines, experiences complex loading patterns including bending, torsion, and axial forces during operation. These cyclic loads, combined with stress concentrations at fillets and oil holes, make fatigue failure a primary concern in crankshaft design. Historical data indicates that approximately 80% of mechanical failures in engines can be attributed to fatigue-related issues, with crankshafts being particularly vulnerable.

Recent technological advancements in materials science, manufacturing processes, and computational capabilities have created new opportunities for enhancing crankshaft durability. The introduction of forged steel with improved microstructure, surface treatment technologies like nitriding and induction hardening, and precision manufacturing techniques have all contributed to extending crankshaft service life. However, these advancements necessitate more sophisticated analysis methods to accurately predict fatigue behavior.

The primary objective of developing advanced crankshaft fatigue analysis methods is to establish reliable predictive models that can accurately estimate component life under various operating conditions. These methods aim to bridge the gap between theoretical models and real-world performance, accounting for factors such as material variability, manufacturing tolerances, and dynamic loading conditions.

Secondary objectives include reducing development time and costs by minimizing physical prototyping and testing, optimizing crankshaft design for specific applications, and supporting the trend toward engine downsizing without compromising reliability. Additionally, these methods should facilitate the evaluation of innovative materials and manufacturing processes to meet increasingly stringent emissions regulations and fuel efficiency standards.

The global push toward electrification presents both challenges and opportunities for crankshaft technology. While pure electric vehicles eliminate the need for traditional crankshafts, hybrid powertrains often require specially designed crankshafts to accommodate the integration of electric motors. Furthermore, the remaining internal combustion engine market demands increasingly efficient and durable components, making advanced fatigue analysis methods more crucial than ever for competitive advantage in the automotive and heavy machinery sectors.

Market Demand for Advanced Crankshaft Durability Solutions

The global automotive industry is experiencing a significant shift towards more efficient, durable, and environmentally friendly vehicles. This transformation has intensified the demand for advanced crankshaft durability solutions, particularly in the realm of fatigue analysis methods. Market research indicates that the automotive engine components market, where crankshafts are a critical element, is projected to grow substantially over the next decade, driven by both regulatory pressures and consumer expectations.

Engine manufacturers are increasingly seeking sophisticated fatigue analysis methods to extend crankshaft lifespan while simultaneously reducing weight to meet fuel efficiency standards. This dual requirement has created a robust market for advanced analytical tools and methodologies that can accurately predict fatigue behavior under various operating conditions. The demand is particularly strong in high-performance and commercial vehicle segments, where engine reliability directly impacts operational costs and brand reputation.

Regulatory frameworks worldwide are becoming more stringent regarding emissions and fuel efficiency, indirectly driving the need for optimized crankshaft designs that can withstand higher pressures and temperatures in modern downsized engines. This regulatory push has created a market pull for more sophisticated fatigue analysis capabilities that can support the development of lighter yet more durable crankshafts.

The aftermarket sector represents another significant demand driver, with maintenance and replacement services requiring precise understanding of fatigue behavior to predict component lifespan accurately. This knowledge enables more effective preventive maintenance schedules and reduces costly unplanned downtime, especially critical in commercial transportation and industrial applications.

Emerging markets in Asia-Pacific and Latin America are showing accelerated demand for these advanced solutions as their automotive manufacturing capabilities mature and local OEMs seek to compete on quality and durability metrics with established global players. This geographical expansion of demand is creating new market opportunities for fatigue analysis expertise and technologies.

The electrification trend in the automotive industry might seem contradictory to crankshaft development, but hybrid vehicles continue to require robust internal combustion engines, maintaining demand for advanced durability solutions. Additionally, the knowledge and methodologies developed for crankshaft fatigue analysis have transferable applications in electric powertrain components, extending their market relevance.

Industry surveys indicate that engineering teams are willing to invest substantially in advanced simulation and testing capabilities that can reduce development cycles and improve prediction accuracy for crankshaft durability. This willingness to invest reflects the high cost of field failures and warranty claims associated with crankshaft fatigue issues, creating a value proposition for sophisticated analysis methods that can prevent such occurrences.

Engine manufacturers are increasingly seeking sophisticated fatigue analysis methods to extend crankshaft lifespan while simultaneously reducing weight to meet fuel efficiency standards. This dual requirement has created a robust market for advanced analytical tools and methodologies that can accurately predict fatigue behavior under various operating conditions. The demand is particularly strong in high-performance and commercial vehicle segments, where engine reliability directly impacts operational costs and brand reputation.

Regulatory frameworks worldwide are becoming more stringent regarding emissions and fuel efficiency, indirectly driving the need for optimized crankshaft designs that can withstand higher pressures and temperatures in modern downsized engines. This regulatory push has created a market pull for more sophisticated fatigue analysis capabilities that can support the development of lighter yet more durable crankshafts.

The aftermarket sector represents another significant demand driver, with maintenance and replacement services requiring precise understanding of fatigue behavior to predict component lifespan accurately. This knowledge enables more effective preventive maintenance schedules and reduces costly unplanned downtime, especially critical in commercial transportation and industrial applications.

Emerging markets in Asia-Pacific and Latin America are showing accelerated demand for these advanced solutions as their automotive manufacturing capabilities mature and local OEMs seek to compete on quality and durability metrics with established global players. This geographical expansion of demand is creating new market opportunities for fatigue analysis expertise and technologies.

The electrification trend in the automotive industry might seem contradictory to crankshaft development, but hybrid vehicles continue to require robust internal combustion engines, maintaining demand for advanced durability solutions. Additionally, the knowledge and methodologies developed for crankshaft fatigue analysis have transferable applications in electric powertrain components, extending their market relevance.

Industry surveys indicate that engineering teams are willing to invest substantially in advanced simulation and testing capabilities that can reduce development cycles and improve prediction accuracy for crankshaft durability. This willingness to invest reflects the high cost of field failures and warranty claims associated with crankshaft fatigue issues, creating a value proposition for sophisticated analysis methods that can prevent such occurrences.

Current Challenges in Crankshaft Fatigue Analysis

Despite significant advancements in crankshaft fatigue analysis methods, several critical challenges persist that impede the development of fully reliable and efficient analytical approaches. One of the primary obstacles is the complex geometry of modern crankshafts, which creates intricate stress distributions that are difficult to model accurately. The fillets, oil holes, and transitions between journals and webs represent areas of stress concentration that require sophisticated modeling techniques beyond traditional approaches.

Material characterization presents another significant challenge. Crankshafts typically undergo various manufacturing processes including forging, heat treatment, and surface hardening, resulting in heterogeneous material properties throughout the component. Current analysis methods often rely on simplified homogeneous material models that fail to capture these variations, leading to potential inaccuracies in fatigue life predictions.

The multiaxial stress states experienced by crankshafts during operation further complicate analysis efforts. Traditional uniaxial fatigue theories prove inadequate when applied to the complex loading conditions involving bending, torsion, and axial forces acting simultaneously. While several multiaxial fatigue criteria exist, there remains considerable debate regarding their applicability and accuracy for specific crankshaft designs and operating conditions.

Dynamic loading effects represent another substantial challenge. Crankshafts experience highly variable loading patterns influenced by combustion pressures, inertial forces, and torsional vibrations. Current analysis methods often struggle to incorporate these dynamic effects comprehensively, particularly in high-performance or variable-speed applications where resonance phenomena may occur.

Computational limitations continue to constrain analysis capabilities. Full finite element models with sufficient mesh refinement to capture stress concentrations accurately require substantial computational resources. This creates a trade-off between analysis accuracy and practical time constraints, particularly during iterative design processes where multiple analyses may be required.

Validation methodologies present ongoing challenges. The correlation between analytical predictions and real-world performance remains imperfect, with discrepancies often attributed to manufacturing variations, assembly influences, and operating condition fluctuations not captured in analytical models. Limited availability of comprehensive test data under diverse operating conditions further complicates validation efforts.

Emerging materials and manufacturing techniques, including advanced alloys and additive manufacturing, introduce additional complexities. Existing fatigue analysis methods may not adequately address the unique microstructural characteristics and potential defect distributions in these novel materials and processes, necessitating new analytical approaches.

Material characterization presents another significant challenge. Crankshafts typically undergo various manufacturing processes including forging, heat treatment, and surface hardening, resulting in heterogeneous material properties throughout the component. Current analysis methods often rely on simplified homogeneous material models that fail to capture these variations, leading to potential inaccuracies in fatigue life predictions.

The multiaxial stress states experienced by crankshafts during operation further complicate analysis efforts. Traditional uniaxial fatigue theories prove inadequate when applied to the complex loading conditions involving bending, torsion, and axial forces acting simultaneously. While several multiaxial fatigue criteria exist, there remains considerable debate regarding their applicability and accuracy for specific crankshaft designs and operating conditions.

Dynamic loading effects represent another substantial challenge. Crankshafts experience highly variable loading patterns influenced by combustion pressures, inertial forces, and torsional vibrations. Current analysis methods often struggle to incorporate these dynamic effects comprehensively, particularly in high-performance or variable-speed applications where resonance phenomena may occur.

Computational limitations continue to constrain analysis capabilities. Full finite element models with sufficient mesh refinement to capture stress concentrations accurately require substantial computational resources. This creates a trade-off between analysis accuracy and practical time constraints, particularly during iterative design processes where multiple analyses may be required.

Validation methodologies present ongoing challenges. The correlation between analytical predictions and real-world performance remains imperfect, with discrepancies often attributed to manufacturing variations, assembly influences, and operating condition fluctuations not captured in analytical models. Limited availability of comprehensive test data under diverse operating conditions further complicates validation efforts.

Emerging materials and manufacturing techniques, including advanced alloys and additive manufacturing, introduce additional complexities. Existing fatigue analysis methods may not adequately address the unique microstructural characteristics and potential defect distributions in these novel materials and processes, necessitating new analytical approaches.

Mainstream Crankshaft Fatigue Analysis Techniques

01 Finite Element Analysis for Crankshaft Fatigue

Finite element analysis (FEA) is widely used to evaluate the fatigue life of crankshafts by simulating stress distributions under various loading conditions. This method creates detailed 3D models of the crankshaft structure and applies cyclic loads to identify critical stress points and potential failure locations. The analysis typically incorporates material properties, boundary conditions, and operating parameters to predict fatigue life and optimize crankshaft design before physical testing.- Finite Element Analysis for Crankshaft Fatigue: Finite element analysis (FEA) is widely used to evaluate the fatigue life of crankshafts by simulating stress distributions under various loading conditions. This method involves creating detailed 3D models of the crankshaft, applying boundary conditions that represent real-world forces, and analyzing critical areas prone to fatigue failure. The analysis helps in identifying stress concentration zones and optimizing the design to improve fatigue resistance before physical testing.

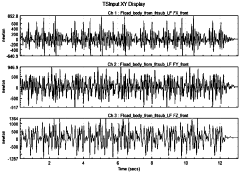

- Experimental Testing Methods for Crankshaft Fatigue: Experimental methods for crankshaft fatigue analysis involve physical testing using specialized equipment to simulate real-world operating conditions. These methods include bench testing, resonance fatigue testing, and strain gauge measurements to collect data on stress cycles and deformation. Accelerated life testing protocols are employed to predict long-term fatigue behavior in shorter timeframes, providing validation for computational models and ensuring reliability in actual service conditions.

- Multi-body Dynamics Simulation for Crankshaft Loading Analysis: Multi-body dynamics simulation techniques are used to analyze the complex loading conditions experienced by crankshafts during engine operation. These methods model the entire powertrain system, including connecting rods, pistons, and bearings, to accurately capture dynamic forces, torsional vibrations, and bending moments acting on the crankshaft. The resulting load histories serve as critical inputs for subsequent fatigue life calculations and help engineers understand how different operating conditions affect crankshaft durability.

- Material Characterization and Fatigue Property Evaluation: Material characterization methods are essential for accurate crankshaft fatigue analysis, involving the determination of fatigue properties through standardized testing procedures. These include rotating bending tests, axial fatigue tests, and torsional fatigue tests to establish S-N curves (stress vs. number of cycles) for crankshaft materials. Advanced techniques such as X-ray diffraction and microstructural analysis are used to evaluate residual stresses and material defects that significantly influence fatigue performance.

- Integrated Computational-Experimental Approaches: Integrated approaches combine computational methods with experimental validation to achieve more accurate crankshaft fatigue life predictions. These hybrid methodologies use machine learning algorithms to correlate simulation results with test data, creating more reliable predictive models. Digital twin technology enables real-time monitoring of crankshaft condition by comparing operational data with simulation models, allowing for predictive maintenance and extending service life through continuous assessment of fatigue damage accumulation.

02 Experimental Testing Methods for Crankshaft Durability

Experimental testing approaches involve physical testing of crankshafts using specialized equipment to simulate real-world operating conditions. These methods include bench testing with hydraulic actuators to apply cyclic loading, strain gauge measurements to capture stress distributions, and accelerated life testing protocols. The experimental data collected provides validation for analytical models and helps establish correlations between predicted and actual fatigue performance under various engine operating conditions.Expand Specific Solutions03 Advanced Material Characterization for Fatigue Prediction

Material characterization techniques are essential for accurate crankshaft fatigue analysis. These methods include microstructural analysis, hardness testing, and determination of fatigue strength coefficients specific to crankshaft materials. Advanced approaches incorporate residual stress measurements and fracture mechanics principles to understand crack initiation and propagation mechanisms. By thoroughly characterizing material properties, engineers can develop more accurate fatigue life prediction models that account for material variability and manufacturing processes.Expand Specific Solutions04 Multi-physics Simulation Approaches for Comprehensive Analysis

Multi-physics simulation approaches combine mechanical stress analysis with thermal and dynamic effects to provide comprehensive crankshaft fatigue evaluation. These methods integrate thermomechanical analysis to account for temperature gradients, fluid-structure interaction to model oil film effects, and dynamic response analysis to capture vibration influences. By considering multiple physical phenomena simultaneously, these approaches deliver more realistic predictions of crankshaft behavior under complex operating conditions and help identify failure mechanisms that might be missed by purely mechanical analyses.Expand Specific Solutions05 Machine Learning and Data-Driven Fatigue Analysis

Emerging machine learning and data-driven approaches are transforming crankshaft fatigue analysis by leveraging historical test data and operational measurements. These methods use neural networks, pattern recognition algorithms, and statistical models to identify correlations between design parameters and fatigue performance. Digital twins that continuously update with real-time engine data enable predictive maintenance and remaining useful life estimation. This approach complements traditional analysis methods by incorporating actual usage patterns and environmental factors into fatigue life predictions.Expand Specific Solutions

Leading Companies and Research Institutions in Fatigue Analysis

The crankshaft fatigue analysis methods market is currently in a growth phase, characterized by increasing demand for more reliable and efficient engine components across automotive and industrial sectors. The global market size is estimated to be expanding steadily due to rising vehicle production and stringent durability requirements. From a technological maturity perspective, the field shows varied development levels, with established automotive manufacturers like Hyundai, Honda, Kia, and Isuzu leading conventional analysis methods, while specialized companies such as Maschinenfabrik ALFING Keßler and Robert Bosch are advancing more sophisticated computational approaches. Major industrial players including Mitsubishi Heavy Industries and Weichai Power are integrating advanced simulation techniques with physical testing, creating a competitive landscape where collaboration between academic institutions and industry is driving innovation in fatigue prediction methodologies.

Maschinenfabrik ALFING Keßler GmbH

Technical Solution: ALFING has developed comprehensive crankshaft fatigue analysis methods combining experimental and numerical approaches. Their methodology integrates finite element analysis (FEA) with specialized fatigue calculation software to predict crankshaft lifespan under various loading conditions. The company employs multi-axial fatigue criteria specifically calibrated for crankshaft materials and utilizes strain-life approaches for high-cycle fatigue prediction. ALFING's testing facilities include specialized crankshaft test benches capable of simulating real-world loading conditions with precise control of temperature, load frequency, and amplitude. Their approach incorporates residual stress analysis from manufacturing processes like induction hardening and fillet rolling, which significantly impacts fatigue performance. The company has developed proprietary algorithms for crack initiation and propagation prediction based on decades of empirical data collection.

Strengths: Industry-leading expertise in crankshaft manufacturing and testing; proprietary fatigue analysis algorithms based on extensive empirical data; comprehensive understanding of manufacturing process effects on fatigue performance. Weaknesses: Highly specialized methodologies may require significant adaptation for different engine designs; proprietary nature of some analysis tools limits broader industry application.

Hyundai Motor Co., Ltd.

Technical Solution: Hyundai has developed a sophisticated crankshaft fatigue analysis framework that combines advanced computational methods with extensive physical testing. Their approach begins with multi-body dynamic simulation to determine realistic loading conditions across various engine operating states. Hyundai employs non-linear FEA incorporating elasto-plastic material models to accurately capture stress concentrations at critical fillets and oil holes. Their methodology includes specialized sub-modeling techniques to analyze localized high-stress regions with extreme mesh refinement while maintaining computational efficiency. Hyundai has pioneered probabilistic fatigue analysis methods that account for material property variations, manufacturing tolerances, and loading uncertainties to provide reliability-based life predictions. Their system incorporates advanced fracture mechanics approaches for crack propagation prediction and has developed specialized algorithms for evaluating the impact of surface treatments like fillet rolling and induction hardening on fatigue performance. Hyundai maintains extensive material testing facilities dedicated to generating precise fatigue data for various crankshaft materials under different loading conditions and environmental factors.

Strengths: Comprehensive integration of probabilistic methods providing reliability-based predictions; advanced consideration of manufacturing variations; extensive physical testing capabilities for validation. Weaknesses: Computationally intensive approach may require significant resources; methodology optimized for passenger vehicle applications may need adaptation for other engine types.

Critical Patents and Literature in Fatigue Assessment

Fatigue analysis method based on virtual test field technology

PatentInactiveCN110298125A

Innovation

- The fatigue analysis method based on virtual test field technology is adopted, and through the digitization of durable pavement in the real test field, Ftire tire testing and parameter identification, the establishment and debugging verification of the vehicle multi-body dynamics model, the extraction of virtual load signals and fatigue calculation, it is realized in the automobile Dynamic load data of internal members of the body and suspension are obtained early in development.

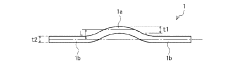

Method for evaluating fatigue strength of filleted portion and method for evaluating rolling condition of filleted portion

PatentInactiveJP2017211185A

Innovation

- A fatigue strength evaluation method using a plate-shaped test piece with specific dimensions and conditions (A) 1 mm ≤ t1 ≤ 10 mm, 0.5 < L/t1 ≤ 2.0, and 0.1 ≤ t1³/t2³ ≤ 0.7, subjected to a fatigue test with axial force, allowing for the evaluation of rolling conditions at a lower cost.

Material Science Advancements for Crankshaft Durability

Recent advancements in material science have significantly contributed to enhancing crankshaft durability and fatigue resistance. Traditional crankshaft materials like forged steel and nodular cast iron are being supplemented or replaced by innovative alloys and composites specifically engineered to withstand higher stress levels and extended service life in modern high-performance engines.

Microalloyed steels have emerged as promising materials for crankshaft applications, incorporating precise amounts of elements such as vanadium, niobium, and titanium. These elements form fine precipitates that strengthen the material without compromising ductility, resulting in superior fatigue resistance. Research indicates that microalloyed steel crankshafts can demonstrate up to 25% improvement in fatigue life compared to conventional steel counterparts.

Surface engineering technologies have evolved substantially, offering enhanced protection against fatigue failure initiation. Advanced nitriding processes, including plasma nitriding and gas nitriding with controlled potential, create deeper and more uniform case hardened layers. These treatments significantly improve surface hardness while maintaining core ductility, addressing the critical balance needed for crankshaft performance.

Nanostructured materials represent another frontier in crankshaft durability enhancement. By refining grain structures to nanometer scale, these materials exhibit exceptional strength-to-weight ratios and fatigue resistance. Ultrafine-grained steels produced through severe plastic deformation techniques have demonstrated fatigue strength improvements of 30-40% in laboratory testing, though commercial implementation remains limited.

Composite metal matrix materials, particularly those reinforced with ceramic particles or carbon nanotubes, are being investigated for next-generation crankshafts. These materials offer superior specific strength and wear resistance while potentially reducing overall weight. Aluminum-silicon carbide composites, for example, maintain strength comparable to steel while reducing mass by up to 40%, though challenges in manufacturing consistency and cost remain significant barriers.

Computational materials science has accelerated development through predictive modeling of material behavior under cyclic loading. Machine learning algorithms now enable the design of tailored microstructures optimized specifically for crankshaft applications, considering factors such as grain boundary engineering and precipitate distribution to maximize fatigue resistance.

Residual stress management through controlled heat treatment and mechanical processing has become increasingly sophisticated. Techniques such as deep rolling and shot peening induce beneficial compressive residual stresses at critical surface locations, effectively increasing fatigue strength by up to 35% in high-stress regions of the crankshaft.

Microalloyed steels have emerged as promising materials for crankshaft applications, incorporating precise amounts of elements such as vanadium, niobium, and titanium. These elements form fine precipitates that strengthen the material without compromising ductility, resulting in superior fatigue resistance. Research indicates that microalloyed steel crankshafts can demonstrate up to 25% improvement in fatigue life compared to conventional steel counterparts.

Surface engineering technologies have evolved substantially, offering enhanced protection against fatigue failure initiation. Advanced nitriding processes, including plasma nitriding and gas nitriding with controlled potential, create deeper and more uniform case hardened layers. These treatments significantly improve surface hardness while maintaining core ductility, addressing the critical balance needed for crankshaft performance.

Nanostructured materials represent another frontier in crankshaft durability enhancement. By refining grain structures to nanometer scale, these materials exhibit exceptional strength-to-weight ratios and fatigue resistance. Ultrafine-grained steels produced through severe plastic deformation techniques have demonstrated fatigue strength improvements of 30-40% in laboratory testing, though commercial implementation remains limited.

Composite metal matrix materials, particularly those reinforced with ceramic particles or carbon nanotubes, are being investigated for next-generation crankshafts. These materials offer superior specific strength and wear resistance while potentially reducing overall weight. Aluminum-silicon carbide composites, for example, maintain strength comparable to steel while reducing mass by up to 40%, though challenges in manufacturing consistency and cost remain significant barriers.

Computational materials science has accelerated development through predictive modeling of material behavior under cyclic loading. Machine learning algorithms now enable the design of tailored microstructures optimized specifically for crankshaft applications, considering factors such as grain boundary engineering and precipitate distribution to maximize fatigue resistance.

Residual stress management through controlled heat treatment and mechanical processing has become increasingly sophisticated. Techniques such as deep rolling and shot peening induce beneficial compressive residual stresses at critical surface locations, effectively increasing fatigue strength by up to 35% in high-stress regions of the crankshaft.

Simulation and Digital Twin Applications in Fatigue Testing

Simulation and digital twin technologies have revolutionized fatigue testing methodologies for crankshafts, enabling engineers to conduct comprehensive analyses without extensive physical testing. These virtual environments replicate real-world conditions with increasing accuracy, allowing for rapid iteration and optimization of crankshaft designs before physical prototypes are manufactured.

Advanced finite element analysis (FEA) simulations now incorporate sophisticated material models that account for microstructural changes during cyclic loading. These simulations can predict crack initiation sites and propagation paths with remarkable precision when properly calibrated against experimental data. Multi-physics simulations further enhance this capability by integrating thermal effects, lubrication dynamics, and structural responses in a unified computational framework.

Digital twins represent the next evolution in this technological progression, creating virtual replicas of physical crankshafts that continuously update based on operational data. By implementing sensors on test rigs or production engines, real-time data can be fed into these digital models, allowing for continuous refinement of fatigue life predictions. This approach bridges the gap between theoretical models and actual performance, accounting for manufacturing variations and operational conditions that traditional simulations might overlook.

Machine learning algorithms have significantly enhanced these digital twin applications by identifying complex patterns in fatigue behavior that might escape conventional analytical methods. Neural networks trained on extensive datasets can predict fatigue failure with increasing accuracy, particularly when dealing with variable loading conditions typical in modern engine applications.

Cloud-based simulation platforms now enable collaborative development across engineering teams, with high-performance computing resources making previously impractical analyses feasible. These platforms support parameter sweeps and optimization studies that would be prohibitively expensive or time-consuming using physical testing alone.

The integration of augmented reality interfaces with simulation results provides intuitive visualization of stress distributions and potential failure modes. Engineers can literally walk through three-dimensional stress fields, examining critical regions from multiple perspectives and gaining insights that might be obscured in traditional two-dimensional representations.

Cost-benefit analyses indicate that organizations implementing these advanced simulation and digital twin approaches typically reduce development cycles by 30-40% while improving product reliability. The initial investment in computational infrastructure and expertise is increasingly offset by reduced prototype iterations and field failures.

Advanced finite element analysis (FEA) simulations now incorporate sophisticated material models that account for microstructural changes during cyclic loading. These simulations can predict crack initiation sites and propagation paths with remarkable precision when properly calibrated against experimental data. Multi-physics simulations further enhance this capability by integrating thermal effects, lubrication dynamics, and structural responses in a unified computational framework.

Digital twins represent the next evolution in this technological progression, creating virtual replicas of physical crankshafts that continuously update based on operational data. By implementing sensors on test rigs or production engines, real-time data can be fed into these digital models, allowing for continuous refinement of fatigue life predictions. This approach bridges the gap between theoretical models and actual performance, accounting for manufacturing variations and operational conditions that traditional simulations might overlook.

Machine learning algorithms have significantly enhanced these digital twin applications by identifying complex patterns in fatigue behavior that might escape conventional analytical methods. Neural networks trained on extensive datasets can predict fatigue failure with increasing accuracy, particularly when dealing with variable loading conditions typical in modern engine applications.

Cloud-based simulation platforms now enable collaborative development across engineering teams, with high-performance computing resources making previously impractical analyses feasible. These platforms support parameter sweeps and optimization studies that would be prohibitively expensive or time-consuming using physical testing alone.

The integration of augmented reality interfaces with simulation results provides intuitive visualization of stress distributions and potential failure modes. Engineers can literally walk through three-dimensional stress fields, examining critical regions from multiple perspectives and gaining insights that might be obscured in traditional two-dimensional representations.

Cost-benefit analyses indicate that organizations implementing these advanced simulation and digital twin approaches typically reduce development cycles by 30-40% while improving product reliability. The initial investment in computational infrastructure and expertise is increasingly offset by reduced prototype iterations and field failures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!