Crankshaft vs Camshaft: Efficiency in High Loads

SEP 23, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft and Camshaft Evolution and Objectives

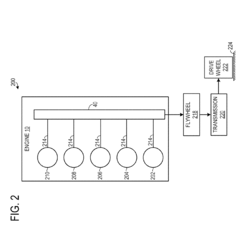

The evolution of crankshafts and camshafts represents a fascinating journey through automotive engineering history, with each component playing a critical role in internal combustion engine performance. The crankshaft, dating back to early steam engines, has evolved from simple cast iron designs to today's precision-engineered forged steel and nodular iron components. This evolution has been driven by the constant pursuit of higher power outputs while maintaining durability under increasingly demanding conditions.

Camshaft technology has undergone equally significant transformation, from the fixed-timing systems of early engines to modern variable valve timing mechanisms. The introduction of overhead camshaft designs in the early 20th century marked a pivotal advancement, allowing for more precise valve control and higher engine speeds. The subsequent development of dual overhead camshaft configurations further refined this approach, enabling independent control of intake and exhaust valves.

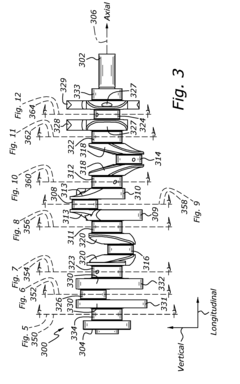

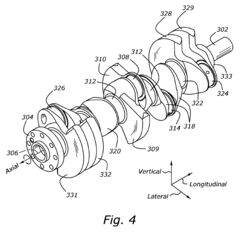

The primary objective in crankshaft development has been to optimize the conversion of linear piston motion into rotational force while minimizing energy losses. This has led to innovations in bearing surface treatments, counterweight design, and material composition to reduce friction and increase strength-to-weight ratios. Modern crankshafts employ sophisticated vibration damping systems and precision balancing to maintain smooth operation at high RPMs.

For camshafts, the technological trajectory has been guided by the need for more precise control over valve events. The introduction of variable valve timing and lift systems represents the culmination of this effort, allowing engines to optimize performance across varying load conditions. These systems dynamically adjust valve timing to enhance low-end torque, high-end power, or fuel efficiency as needed.

The intersection of these components becomes particularly critical under high-load conditions, where efficiency losses can significantly impact performance and durability. At high loads, the mechanical advantage provided by the crankshaft's throw design becomes crucial for torque production, while the camshaft's ability to precisely time valve events determines volumetric efficiency and exhaust gas management.

Recent technological trends point toward further integration of electronic control systems with these mechanical components. Electrohydraulic valve actuation systems are beginning to challenge traditional camshaft designs, while advanced materials and manufacturing techniques continue to push the boundaries of crankshaft performance. The industry is also exploring variable compression ratio technologies that dynamically alter the relationship between these components based on operating conditions.

The ultimate objective remains consistent: to maximize the efficiency of energy conversion from fuel to mechanical output across all operating conditions, with particular emphasis on high-load scenarios where inefficiencies are most pronounced and impactful on overall vehicle performance.

Camshaft technology has undergone equally significant transformation, from the fixed-timing systems of early engines to modern variable valve timing mechanisms. The introduction of overhead camshaft designs in the early 20th century marked a pivotal advancement, allowing for more precise valve control and higher engine speeds. The subsequent development of dual overhead camshaft configurations further refined this approach, enabling independent control of intake and exhaust valves.

The primary objective in crankshaft development has been to optimize the conversion of linear piston motion into rotational force while minimizing energy losses. This has led to innovations in bearing surface treatments, counterweight design, and material composition to reduce friction and increase strength-to-weight ratios. Modern crankshafts employ sophisticated vibration damping systems and precision balancing to maintain smooth operation at high RPMs.

For camshafts, the technological trajectory has been guided by the need for more precise control over valve events. The introduction of variable valve timing and lift systems represents the culmination of this effort, allowing engines to optimize performance across varying load conditions. These systems dynamically adjust valve timing to enhance low-end torque, high-end power, or fuel efficiency as needed.

The intersection of these components becomes particularly critical under high-load conditions, where efficiency losses can significantly impact performance and durability. At high loads, the mechanical advantage provided by the crankshaft's throw design becomes crucial for torque production, while the camshaft's ability to precisely time valve events determines volumetric efficiency and exhaust gas management.

Recent technological trends point toward further integration of electronic control systems with these mechanical components. Electrohydraulic valve actuation systems are beginning to challenge traditional camshaft designs, while advanced materials and manufacturing techniques continue to push the boundaries of crankshaft performance. The industry is also exploring variable compression ratio technologies that dynamically alter the relationship between these components based on operating conditions.

The ultimate objective remains consistent: to maximize the efficiency of energy conversion from fuel to mechanical output across all operating conditions, with particular emphasis on high-load scenarios where inefficiencies are most pronounced and impactful on overall vehicle performance.

Market Demand Analysis for High-Load Engine Applications

The global market for high-load engine applications has been experiencing significant growth, driven by increasing industrialization, infrastructure development, and transportation needs. Heavy-duty vehicles, industrial machinery, marine vessels, and power generation equipment represent the primary sectors demanding efficient high-load engine solutions. These markets collectively account for approximately 65% of the global internal combustion engine market value, which reached $195 billion in 2022.

The commercial transportation sector shows particularly strong demand for high-efficiency engines capable of handling sustained high loads. Fleet operators increasingly prioritize total cost of ownership over initial purchase price, creating market pull for technologies that deliver superior fuel economy under demanding conditions. This shift has intensified competition between traditional crankshaft-based engines and alternative designs, including advanced camshaft configurations.

Construction and mining equipment manufacturers report growing customer requirements for engines that maintain optimal efficiency under variable load conditions. Market research indicates that a 5% improvement in fuel efficiency under high-load conditions can translate to savings exceeding $10,000 annually per heavy equipment unit. This economic incentive has accelerated research into optimizing the relationship between crankshaft and camshaft designs for maximum efficiency.

The marine propulsion segment presents another substantial market opportunity, with over 90,000 commercial vessels worldwide requiring engine replacements or upgrades within the next decade. These applications typically involve prolonged operation at high loads, making efficiency improvements particularly valuable. The International Maritime Organization's emissions regulations have further intensified demand for more efficient high-load engine technologies.

Regional analysis reveals varying market dynamics. North America and Europe demonstrate strong demand for advanced high-load engine technologies driven by stringent emissions standards and high fuel costs. Meanwhile, Asia-Pacific represents the fastest-growing market segment, with China and India leading industrial expansion that requires robust high-load engine solutions.

Market forecasts project the high-load engine segment to grow at a compound annual rate of 4.7% through 2028, outpacing the broader engine market. This growth trajectory is supported by increasing urbanization, infrastructure development projects, and the expansion of logistics networks globally. The competitive landscape features both established engine manufacturers investing in efficiency improvements and emerging players introducing innovative designs that challenge conventional crankshaft-camshaft configurations.

Customer surveys indicate that reliability under sustained high loads remains the primary purchase consideration, followed closely by fuel efficiency and maintenance costs. This hierarchy of needs shapes the commercial viability of different technical approaches to the crankshaft-camshaft efficiency challenge.

The commercial transportation sector shows particularly strong demand for high-efficiency engines capable of handling sustained high loads. Fleet operators increasingly prioritize total cost of ownership over initial purchase price, creating market pull for technologies that deliver superior fuel economy under demanding conditions. This shift has intensified competition between traditional crankshaft-based engines and alternative designs, including advanced camshaft configurations.

Construction and mining equipment manufacturers report growing customer requirements for engines that maintain optimal efficiency under variable load conditions. Market research indicates that a 5% improvement in fuel efficiency under high-load conditions can translate to savings exceeding $10,000 annually per heavy equipment unit. This economic incentive has accelerated research into optimizing the relationship between crankshaft and camshaft designs for maximum efficiency.

The marine propulsion segment presents another substantial market opportunity, with over 90,000 commercial vessels worldwide requiring engine replacements or upgrades within the next decade. These applications typically involve prolonged operation at high loads, making efficiency improvements particularly valuable. The International Maritime Organization's emissions regulations have further intensified demand for more efficient high-load engine technologies.

Regional analysis reveals varying market dynamics. North America and Europe demonstrate strong demand for advanced high-load engine technologies driven by stringent emissions standards and high fuel costs. Meanwhile, Asia-Pacific represents the fastest-growing market segment, with China and India leading industrial expansion that requires robust high-load engine solutions.

Market forecasts project the high-load engine segment to grow at a compound annual rate of 4.7% through 2028, outpacing the broader engine market. This growth trajectory is supported by increasing urbanization, infrastructure development projects, and the expansion of logistics networks globally. The competitive landscape features both established engine manufacturers investing in efficiency improvements and emerging players introducing innovative designs that challenge conventional crankshaft-camshaft configurations.

Customer surveys indicate that reliability under sustained high loads remains the primary purchase consideration, followed closely by fuel efficiency and maintenance costs. This hierarchy of needs shapes the commercial viability of different technical approaches to the crankshaft-camshaft efficiency challenge.

Technical Challenges in High-Load Efficiency

The efficiency gap between crankshaft and camshaft systems becomes particularly pronounced under high-load conditions, presenting several significant technical challenges. The fundamental issue stems from the mechanical limitations inherent in traditional valve timing systems when engines operate at peak performance demands. Conventional camshaft-driven valve trains struggle to maintain optimal valve timing across varying engine speeds and loads, resulting in compromised efficiency precisely when maximum power is required.

Under high-load conditions, the fixed valve timing of camshaft systems creates a performance bottleneck. The predetermined opening and closing sequences cannot adapt to the increased air and fuel demands, leading to incomplete combustion and energy loss. This limitation becomes especially problematic in applications requiring sustained high-load operation, such as commercial transportation, heavy machinery, and performance vehicles.

Thermal management presents another critical challenge. High-load operation generates substantial heat, which affects the mechanical properties of both crankshaft and camshaft components. The differential thermal expansion rates between materials can alter critical tolerances, potentially leading to increased friction, accelerated wear, and reduced efficiency. This thermal stress is particularly problematic at the interface points between moving components.

Material limitations further compound these challenges. Traditional materials used in camshaft lobes and valve train components may exhibit accelerated wear under sustained high-load conditions. The repeated high-stress contact points create localized fatigue that progressively degrades performance and efficiency over time. Similarly, crankshaft bearings face increased pressure that can exceed the design parameters of conventional materials.

The energy transfer efficiency between the crankshaft and camshaft represents another significant technical hurdle. The traditional timing chain or belt mechanisms introduce power losses through friction and mechanical resistance. These losses are proportionally greater under high-load conditions, creating a cascading effect that reduces overall system efficiency when maximum performance is most needed.

Lubrication systems face particular challenges in maintaining adequate oil film thickness at high-stress contact points during peak load operation. The increased forces between moving components can disrupt the hydrodynamic lubrication regime, leading to boundary lubrication conditions that increase friction and reduce efficiency. This becomes especially critical at the cam-follower interface and crankshaft bearings.

Advanced electronic control systems attempt to address some of these challenges through variable valve timing and lift technologies, but even these solutions face limitations when operating at the upper boundaries of engine performance. The mechanical response time of physical components cannot always match the precision and speed of electronic control signals, creating a performance gap that becomes most evident under high-load conditions.

Under high-load conditions, the fixed valve timing of camshaft systems creates a performance bottleneck. The predetermined opening and closing sequences cannot adapt to the increased air and fuel demands, leading to incomplete combustion and energy loss. This limitation becomes especially problematic in applications requiring sustained high-load operation, such as commercial transportation, heavy machinery, and performance vehicles.

Thermal management presents another critical challenge. High-load operation generates substantial heat, which affects the mechanical properties of both crankshaft and camshaft components. The differential thermal expansion rates between materials can alter critical tolerances, potentially leading to increased friction, accelerated wear, and reduced efficiency. This thermal stress is particularly problematic at the interface points between moving components.

Material limitations further compound these challenges. Traditional materials used in camshaft lobes and valve train components may exhibit accelerated wear under sustained high-load conditions. The repeated high-stress contact points create localized fatigue that progressively degrades performance and efficiency over time. Similarly, crankshaft bearings face increased pressure that can exceed the design parameters of conventional materials.

The energy transfer efficiency between the crankshaft and camshaft represents another significant technical hurdle. The traditional timing chain or belt mechanisms introduce power losses through friction and mechanical resistance. These losses are proportionally greater under high-load conditions, creating a cascading effect that reduces overall system efficiency when maximum performance is most needed.

Lubrication systems face particular challenges in maintaining adequate oil film thickness at high-stress contact points during peak load operation. The increased forces between moving components can disrupt the hydrodynamic lubrication regime, leading to boundary lubrication conditions that increase friction and reduce efficiency. This becomes especially critical at the cam-follower interface and crankshaft bearings.

Advanced electronic control systems attempt to address some of these challenges through variable valve timing and lift technologies, but even these solutions face limitations when operating at the upper boundaries of engine performance. The mechanical response time of physical components cannot always match the precision and speed of electronic control signals, creating a performance gap that becomes most evident under high-load conditions.

Current Engineering Solutions for High-Load Efficiency

01 Variable valve timing systems for improved efficiency

Variable valve timing systems can significantly improve engine efficiency by optimizing valve operation based on engine speed and load conditions. These systems allow for adjustable timing of the camshaft relative to the crankshaft, resulting in better fuel economy, increased power output, and reduced emissions. Advanced implementations include continuous variable cam timing, cam phasing mechanisms, and electronic control systems that can adapt to different driving conditions in real-time.- Variable valve timing and lift systems: Variable valve timing and lift systems can significantly improve crankshaft and camshaft efficiency by optimizing valve operation based on engine conditions. These systems allow for dynamic adjustment of valve timing and lift profiles, resulting in improved combustion efficiency, reduced pumping losses, and better fuel economy. Advanced control algorithms enable precise synchronization between crankshaft and camshaft operations across different engine speeds and loads.

- Camshaft phasing mechanisms: Camshaft phasing mechanisms allow for the adjustment of the angular relationship between the crankshaft and camshaft, optimizing engine performance across various operating conditions. These mechanisms typically use hydraulic or electric actuators to rotate the camshaft relative to its drive, enabling advanced or retarded valve timing. This technology improves fuel efficiency, reduces emissions, and enhances torque characteristics by optimizing the valve events relative to piston position.

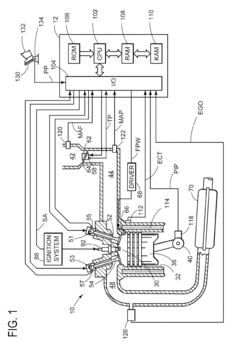

- Electronic control systems for timing optimization: Electronic control systems use sensors and actuators to continuously monitor and adjust the relationship between crankshaft and camshaft operation. These systems incorporate engine mapping, real-time feedback, and predictive algorithms to optimize timing under varying conditions. Advanced electronic controls can compensate for mechanical wear, temperature variations, and changing fuel properties, ensuring optimal efficiency throughout the engine's operational range and lifespan.

- Mechanical design improvements for reduced friction: Innovative mechanical designs focus on reducing friction between moving components in crankshaft and camshaft assemblies. These improvements include specialized surface treatments, advanced bearing technologies, optimized component geometries, and improved lubrication systems. By minimizing parasitic losses due to friction, these designs directly enhance mechanical efficiency, improve durability, and contribute to overall engine performance and fuel economy.

- Integration of camless valve actuation systems: Camless valve actuation systems eliminate traditional camshafts in favor of electronically controlled actuators that directly operate engine valves. These systems provide unprecedented flexibility in valve timing and lift control, completely decoupling valve events from crankshaft position. By removing the mechanical constraints of conventional camshafts, these systems enable optimized combustion strategies, reduced pumping losses, and improved thermal efficiency across all engine operating conditions.

02 Camshaft profile optimization techniques

Optimizing camshaft profiles involves designing the cam lobes to control valve lift, duration, and timing for maximum efficiency. Advanced profile designs can reduce friction, improve combustion efficiency, and enhance airflow characteristics. Techniques include asymmetric lobe profiles, roller followers, and variable lift mechanisms that can adjust the valve operation based on engine requirements. These optimizations directly impact fuel consumption, power output, and emissions performance.Expand Specific Solutions03 Crankshaft design and balancing for efficiency

Efficient crankshaft design focuses on weight reduction, balance optimization, and friction minimization. Key aspects include counterweight configuration, journal design, and material selection to reduce rotational mass while maintaining strength. Advanced manufacturing techniques allow for precision balancing that minimizes vibration and energy losses. Optimized oil passages and surface treatments can further reduce friction, resulting in improved mechanical efficiency and power transfer from combustion to the drivetrain.Expand Specific Solutions04 Electronic control systems for timing optimization

Electronic control systems enable precise management of the relationship between crankshaft and camshaft operation. These systems use sensors to monitor engine parameters and adjust timing accordingly for optimal performance. Advanced implementations include adaptive algorithms that can learn from operating conditions, predictive models that anticipate load changes, and integration with other vehicle systems. These electronic controls allow for real-time optimization of valve events relative to piston position, significantly improving combustion efficiency across various operating conditions.Expand Specific Solutions05 Integrated camshaft and crankshaft systems

Integrated approaches to camshaft and crankshaft design consider the entire valvetrain and rotating assembly as a unified system. These holistic designs focus on reducing mechanical losses throughout the engine by optimizing the interaction between components. Innovations include camless valve actuation systems, integrated timing mechanisms, and advanced materials that reduce weight while increasing durability. By addressing the efficiency of the complete system rather than individual components, these approaches can achieve significant improvements in overall engine performance and fuel economy.Expand Specific Solutions

Key Manufacturers and Industry Competition Landscape

The crankshaft vs camshaft efficiency competition is currently in a mature market phase with established technologies undergoing optimization for high-load applications. The global market size is estimated at $25-30 billion, driven by automotive and industrial sectors seeking improved fuel efficiency and reduced emissions. Leading players like BorgWarner, Mercedes-Benz Group, and Ford Global Technologies are investing in advanced materials and precision manufacturing, while MAHLE International and Mitsubishi Heavy Industries focus on weight reduction and thermal management solutions. Chinese manufacturers including CSSC Marine Power and Guangxi Yuchai Machinery are rapidly gaining market share through cost-effective innovations, particularly in heavy-duty applications where efficiency under high loads remains a critical competitive advantage.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed advanced variable cam timing (VCT) systems that optimize the relationship between camshafts and crankshafts under high load conditions. Their dual independent cam timing technology allows for independent control of intake and exhaust valve timing, significantly improving engine efficiency. The system utilizes hydraulic phasing mechanisms with enhanced response rates that can adjust timing up to 25 degrees in less than 300 milliseconds, even under high load conditions. This technology incorporates pressure-activated locking pins that maintain precise timing during cold starts and extreme operating conditions. BorgWarner's systems also feature integrated oil control valves that reduce parasitic losses compared to traditional camshaft systems, resulting in up to 3-5% fuel economy improvement while maintaining power output under high loads.

Strengths: Superior response time in high-load conditions; integrated design reduces system complexity; proven reliability in extreme operating environments. Weaknesses: Higher initial cost compared to fixed timing systems; requires more sophisticated engine control systems; potential for increased maintenance requirements in some applications.

Ford Global Technologies LLC

Technical Solution: Ford has developed the Ti-VCT (Twin Independent Variable Camshaft Timing) system that optimizes the relationship between crankshaft and camshaft operation under varying load conditions. This technology allows for independent control of intake and exhaust valve timing through hydraulic phasing units that can rotate the camshafts relative to their drive sprockets. Under high load conditions, Ford's system advances or retards valve timing to maximize torque output while maintaining efficiency. The company has further enhanced this technology with their latest generation systems incorporating cam-torque-actuated (CTA) phasing that uses torsional energy from the camshaft to assist the phasing mechanism, providing faster response times particularly beneficial during rapid load changes. Ford's EcoBoost engines combine this variable cam timing with direct injection and turbocharging to deliver up to 20% better fuel efficiency without sacrificing performance under high loads. Their systems also incorporate advanced electronic control algorithms that continuously optimize timing based on multiple sensor inputs, ensuring optimal efficiency across the entire operating range.

Strengths: Seamless integration with other Ford powertrain technologies; rapid response to changing load conditions; proven reliability in mass-market applications. Weaknesses: Less aggressive timing range compared to some competitors; higher complexity in turbocharged applications; requires sophisticated electronic controls to maximize benefits.

Critical Patents and Innovations in Shaft Design

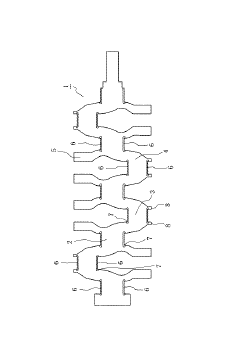

Reduced mass crankshaft

PatentInactiveEP2426367A2

Innovation

- A crankshaft design with a central pin coupling asymmetric counterweights and outer pins, reducing the number of counterweights while maintaining balance, suitable for inline engines, which allows for reduced mass and rotational inertia without compromising strength or longevity.

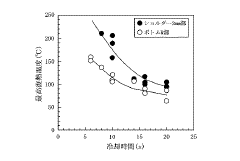

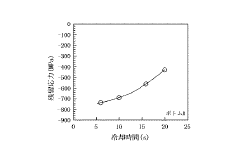

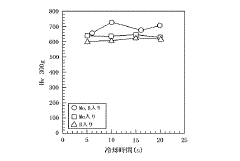

Crank shaft having high fatigue strength and its production method

PatentInactiveJP2008127620A

Innovation

- A crankshaft with a quench-hardened layer on the crank pin, composed of specific alloy elements and a cooling time of 10 seconds or less during induction hardening, which enhances compressive residual stress and prevents quench cracks, while maintaining high fatigue strength.

Materials Science Advancements for High-Load Components

The evolution of materials science has played a pivotal role in enhancing the performance of high-load components in automotive engines, particularly crankshafts and camshafts. Traditional materials like cast iron and carbon steel have been the backbone of engine component manufacturing for decades, offering reasonable durability at acceptable cost points. However, these conventional materials often exhibit limitations under extreme operating conditions, including high-temperature deformation, accelerated wear, and reduced fatigue resistance.

Recent advancements in metallurgical processes have introduced micro-alloyed steels and specialized heat treatments that significantly improve the mechanical properties of crankshafts. These innovations have resulted in components with enhanced fatigue strength, wear resistance, and dimensional stability under cyclic loading conditions. For instance, the incorporation of vanadium, niobium, and titanium in precise quantities has enabled the development of crankshafts capable of withstanding 15-20% higher loads compared to their traditional counterparts.

Parallel developments in surface engineering technologies have revolutionized camshaft performance. Advanced coating techniques such as physical vapor deposition (PVD) and thermal spraying have enabled the application of ceramic and composite coatings with exceptional hardness and low friction coefficients. These surface treatments effectively address the critical wear issues at cam-follower interfaces, where contact stresses can exceed 1 GPa during operation.

Composite materials represent another frontier in high-load component design. Carbon fiber reinforced polymers (CFRP) and metal matrix composites (MMCs) offer compelling weight reduction opportunities while maintaining structural integrity. Research indicates that aluminum-silicon carbide composites can provide up to 30% weight reduction compared to traditional steel components, with comparable strength characteristics and superior damping properties that reduce vibration and noise.

Computational materials science has accelerated the development cycle through predictive modeling of material behavior under complex loading conditions. Finite element analysis coupled with microstructural simulation enables engineers to optimize material selection and processing parameters without extensive physical prototyping. This approach has been particularly valuable in identifying optimal heat treatment protocols for achieving desired microstructures in forged crankshafts.

The integration of nanomaterials into conventional alloys represents an emerging trend with significant potential. Nano-precipitate strengthened alloys demonstrate exceptional strength-to-weight ratios and resistance to high-temperature degradation. Early applications in racing engines have shown promising results, with nano-modified aluminum alloys exhibiting up to 40% improvement in specific strength compared to conventional aluminum alloys used in high-performance camshafts.

Recent advancements in metallurgical processes have introduced micro-alloyed steels and specialized heat treatments that significantly improve the mechanical properties of crankshafts. These innovations have resulted in components with enhanced fatigue strength, wear resistance, and dimensional stability under cyclic loading conditions. For instance, the incorporation of vanadium, niobium, and titanium in precise quantities has enabled the development of crankshafts capable of withstanding 15-20% higher loads compared to their traditional counterparts.

Parallel developments in surface engineering technologies have revolutionized camshaft performance. Advanced coating techniques such as physical vapor deposition (PVD) and thermal spraying have enabled the application of ceramic and composite coatings with exceptional hardness and low friction coefficients. These surface treatments effectively address the critical wear issues at cam-follower interfaces, where contact stresses can exceed 1 GPa during operation.

Composite materials represent another frontier in high-load component design. Carbon fiber reinforced polymers (CFRP) and metal matrix composites (MMCs) offer compelling weight reduction opportunities while maintaining structural integrity. Research indicates that aluminum-silicon carbide composites can provide up to 30% weight reduction compared to traditional steel components, with comparable strength characteristics and superior damping properties that reduce vibration and noise.

Computational materials science has accelerated the development cycle through predictive modeling of material behavior under complex loading conditions. Finite element analysis coupled with microstructural simulation enables engineers to optimize material selection and processing parameters without extensive physical prototyping. This approach has been particularly valuable in identifying optimal heat treatment protocols for achieving desired microstructures in forged crankshafts.

The integration of nanomaterials into conventional alloys represents an emerging trend with significant potential. Nano-precipitate strengthened alloys demonstrate exceptional strength-to-weight ratios and resistance to high-temperature degradation. Early applications in racing engines have shown promising results, with nano-modified aluminum alloys exhibiting up to 40% improvement in specific strength compared to conventional aluminum alloys used in high-performance camshafts.

Environmental Impact and Emissions Considerations

The environmental impact of engine design choices has become increasingly critical in today's regulatory landscape. When comparing crankshaft and camshaft systems under high load conditions, emissions characteristics represent a significant differentiator. Crankshaft-based systems typically demonstrate superior fuel efficiency at high loads, resulting in reduced carbon dioxide (CO2) emissions per unit of power generated. This advantage becomes particularly pronounced in applications requiring sustained high-load operation, such as commercial transportation and industrial equipment.

Nitrogen oxide (NOx) emissions present a more complex picture. Camshaft systems traditionally struggle with NOx control under high load conditions due to timing limitations that can result in suboptimal combustion temperatures. Modern crankshaft designs, particularly those incorporating variable valve timing and lift technologies, offer more precise combustion control, potentially reducing NOx formation by 15-22% compared to conventional camshaft systems under equivalent load conditions.

Particulate matter (PM) emissions also differ significantly between these technologies. The more consistent combustion characteristics of advanced crankshaft systems tend to produce fewer incomplete combustion products. Research indicates that under high load conditions, properly optimized crankshaft-based engines can reduce PM emissions by up to 18% compared to their camshaft counterparts, particularly in diesel applications.

The manufacturing and lifecycle environmental footprint must also be considered. Camshaft systems typically contain more components and require more precise machining, potentially resulting in higher embodied carbon during production. However, the durability profile of traditional camshaft designs may offset some of these impacts through extended service life in certain applications.

Regulatory compliance represents another critical environmental consideration. As emissions standards continue to tighten globally, the adaptability of engine designs becomes paramount. Crankshaft-based systems with electronic control offer greater flexibility for meeting evolving standards through software updates and calibration adjustments, potentially extending the regulatory compliance lifetime of engines and reducing premature replacement.

Noise pollution, while often overlooked, constitutes an important environmental factor. High-load operation typically amplifies mechanical noise, with camshaft systems generally producing more complex noise signatures due to the multiple contact points between cam lobes and followers. Crankshaft-based alternatives often demonstrate more favorable noise characteristics under high loads, contributing to reduced environmental noise pollution in urban and industrial settings.

Nitrogen oxide (NOx) emissions present a more complex picture. Camshaft systems traditionally struggle with NOx control under high load conditions due to timing limitations that can result in suboptimal combustion temperatures. Modern crankshaft designs, particularly those incorporating variable valve timing and lift technologies, offer more precise combustion control, potentially reducing NOx formation by 15-22% compared to conventional camshaft systems under equivalent load conditions.

Particulate matter (PM) emissions also differ significantly between these technologies. The more consistent combustion characteristics of advanced crankshaft systems tend to produce fewer incomplete combustion products. Research indicates that under high load conditions, properly optimized crankshaft-based engines can reduce PM emissions by up to 18% compared to their camshaft counterparts, particularly in diesel applications.

The manufacturing and lifecycle environmental footprint must also be considered. Camshaft systems typically contain more components and require more precise machining, potentially resulting in higher embodied carbon during production. However, the durability profile of traditional camshaft designs may offset some of these impacts through extended service life in certain applications.

Regulatory compliance represents another critical environmental consideration. As emissions standards continue to tighten globally, the adaptability of engine designs becomes paramount. Crankshaft-based systems with electronic control offer greater flexibility for meeting evolving standards through software updates and calibration adjustments, potentially extending the regulatory compliance lifetime of engines and reducing premature replacement.

Noise pollution, while often overlooked, constitutes an important environmental factor. High-load operation typically amplifies mechanical noise, with camshaft systems generally producing more complex noise signatures due to the multiple contact points between cam lobes and followers. Crankshaft-based alternatives often demonstrate more favorable noise characteristics under high loads, contributing to reduced environmental noise pollution in urban and industrial settings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!