How to Optimize Crankshaft Balancing Techniques

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Balancing Technology Background and Objectives

Crankshaft balancing technology has evolved significantly since the early days of internal combustion engines. Initially, rudimentary methods relied heavily on manual adjustments and basic mechanical tools to achieve acceptable balance levels. The progression from these early techniques to today's precision-driven approaches represents a fundamental shift in engine manufacturing and performance optimization.

The historical development of crankshaft balancing can be traced through several distinct phases. In the early 20th century, balancing was primarily achieved through careful machining and manual weight adjustments. By mid-century, mechanical balancing machines emerged, offering improved consistency but still limited by the technology of the era. The introduction of electronic sensors and computer-aided analysis in the 1970s and 1980s marked a significant leap forward, enabling more precise measurements and corrections.

Today's crankshaft balancing technology incorporates advanced computational modeling, high-precision measurement systems, and automated correction processes. Modern techniques differentiate between static balancing (addressing the distribution of mass around the rotational axis) and dynamic balancing (addressing the distribution of mass along the length of the crankshaft), recognizing that both are essential for optimal engine performance.

The current technological trajectory points toward increasingly sophisticated balancing methods that can account for complex harmonic vibrations and system-wide interactions. Industry trends indicate growing emphasis on holistic approaches that consider the crankshaft not in isolation but as part of an integrated powertrain system.

The primary objectives of modern crankshaft balancing technology focus on several key areas. First is the enhancement of engine efficiency and performance through minimization of energy losses due to vibration. Second is the extension of engine component lifespan by reducing wear patterns caused by imbalance-induced stresses. Third is the improvement of NVH (Noise, Vibration, and Harshness) characteristics, which directly impacts user experience and perceived quality.

Additional objectives include reducing manufacturing costs through more efficient balancing processes, accommodating the unique challenges presented by alternative engine designs (such as those for hybrid or electric vehicles with range extenders), and meeting increasingly stringent environmental regulations by optimizing combustion efficiency and reducing emissions through better-balanced engine operation.

The evolution of crankshaft balancing technology continues to be driven by demands for higher performance, greater efficiency, and enhanced durability across all segments of the automotive and industrial engine markets. Future developments will likely focus on predictive balancing techniques that can anticipate wear patterns and compensate proactively, further refining what has become an essential aspect of modern engine design and manufacturing.

The historical development of crankshaft balancing can be traced through several distinct phases. In the early 20th century, balancing was primarily achieved through careful machining and manual weight adjustments. By mid-century, mechanical balancing machines emerged, offering improved consistency but still limited by the technology of the era. The introduction of electronic sensors and computer-aided analysis in the 1970s and 1980s marked a significant leap forward, enabling more precise measurements and corrections.

Today's crankshaft balancing technology incorporates advanced computational modeling, high-precision measurement systems, and automated correction processes. Modern techniques differentiate between static balancing (addressing the distribution of mass around the rotational axis) and dynamic balancing (addressing the distribution of mass along the length of the crankshaft), recognizing that both are essential for optimal engine performance.

The current technological trajectory points toward increasingly sophisticated balancing methods that can account for complex harmonic vibrations and system-wide interactions. Industry trends indicate growing emphasis on holistic approaches that consider the crankshaft not in isolation but as part of an integrated powertrain system.

The primary objectives of modern crankshaft balancing technology focus on several key areas. First is the enhancement of engine efficiency and performance through minimization of energy losses due to vibration. Second is the extension of engine component lifespan by reducing wear patterns caused by imbalance-induced stresses. Third is the improvement of NVH (Noise, Vibration, and Harshness) characteristics, which directly impacts user experience and perceived quality.

Additional objectives include reducing manufacturing costs through more efficient balancing processes, accommodating the unique challenges presented by alternative engine designs (such as those for hybrid or electric vehicles with range extenders), and meeting increasingly stringent environmental regulations by optimizing combustion efficiency and reducing emissions through better-balanced engine operation.

The evolution of crankshaft balancing technology continues to be driven by demands for higher performance, greater efficiency, and enhanced durability across all segments of the automotive and industrial engine markets. Future developments will likely focus on predictive balancing techniques that can anticipate wear patterns and compensate proactively, further refining what has become an essential aspect of modern engine design and manufacturing.

Market Demand Analysis for Precision Balanced Crankshafts

The global market for precision balanced crankshafts has been experiencing significant growth, driven primarily by the automotive and aerospace industries' increasing demand for higher performance, fuel efficiency, and reduced emissions. Current market analysis indicates that the precision crankshaft market is valued at approximately $7.2 billion globally, with projections showing a compound annual growth rate of 4.8% through 2028.

The automotive sector represents the largest market segment, accounting for nearly 65% of the total demand. This is largely attributed to stringent emission regulations worldwide, particularly in Europe and North America, which necessitate more efficient engine designs. Precision balanced crankshafts directly contribute to reduced vibration, lower noise levels, and improved fuel economy – all critical factors in meeting these regulatory requirements.

Commercial vehicle manufacturers are increasingly demanding crankshafts with superior balancing specifications as they seek to extend engine life and reduce maintenance costs. Market research indicates that a properly balanced crankshaft can extend engine life by up to 30% and reduce maintenance costs by 15-20% over the vehicle's operational lifetime.

In the high-performance automotive segment, racing teams and luxury vehicle manufacturers represent a premium market niche with demand for ultra-precision balanced crankshafts. This segment, though smaller in volume, generates higher profit margins with willingness to pay 40-50% more for crankshafts with superior balancing characteristics.

The aerospace industry constitutes another significant market segment, with approximately 18% market share. In this sector, the demand for precision is even more critical due to safety requirements and the catastrophic consequences of mechanical failures. The market for aerospace crankshafts is expected to grow at 5.7% annually, outpacing the overall market growth rate.

Emerging markets, particularly in Asia-Pacific, are showing the fastest growth rates in demand. China and India, with their rapidly expanding automotive manufacturing bases, are projected to increase their consumption of precision balanced crankshafts by 7.3% and 6.8% annually, respectively.

Market surveys indicate that end-users are increasingly prioritizing vibration characteristics in their purchasing decisions, with 78% of OEM manufacturers citing reduced vibration as a "very important" or "critical" factor. This represents a significant shift from a decade ago when only 45% of manufacturers placed such emphasis on this characteristic.

The aftermarket segment also presents substantial opportunities, with a growing trend toward performance upgrades and rebuilds of existing engines. This segment is expected to grow at 5.2% annually, driven by both consumer and commercial fleet optimization initiatives.

The automotive sector represents the largest market segment, accounting for nearly 65% of the total demand. This is largely attributed to stringent emission regulations worldwide, particularly in Europe and North America, which necessitate more efficient engine designs. Precision balanced crankshafts directly contribute to reduced vibration, lower noise levels, and improved fuel economy – all critical factors in meeting these regulatory requirements.

Commercial vehicle manufacturers are increasingly demanding crankshafts with superior balancing specifications as they seek to extend engine life and reduce maintenance costs. Market research indicates that a properly balanced crankshaft can extend engine life by up to 30% and reduce maintenance costs by 15-20% over the vehicle's operational lifetime.

In the high-performance automotive segment, racing teams and luxury vehicle manufacturers represent a premium market niche with demand for ultra-precision balanced crankshafts. This segment, though smaller in volume, generates higher profit margins with willingness to pay 40-50% more for crankshafts with superior balancing characteristics.

The aerospace industry constitutes another significant market segment, with approximately 18% market share. In this sector, the demand for precision is even more critical due to safety requirements and the catastrophic consequences of mechanical failures. The market for aerospace crankshafts is expected to grow at 5.7% annually, outpacing the overall market growth rate.

Emerging markets, particularly in Asia-Pacific, are showing the fastest growth rates in demand. China and India, with their rapidly expanding automotive manufacturing bases, are projected to increase their consumption of precision balanced crankshafts by 7.3% and 6.8% annually, respectively.

Market surveys indicate that end-users are increasingly prioritizing vibration characteristics in their purchasing decisions, with 78% of OEM manufacturers citing reduced vibration as a "very important" or "critical" factor. This represents a significant shift from a decade ago when only 45% of manufacturers placed such emphasis on this characteristic.

The aftermarket segment also presents substantial opportunities, with a growing trend toward performance upgrades and rebuilds of existing engines. This segment is expected to grow at 5.2% annually, driven by both consumer and commercial fleet optimization initiatives.

Current Challenges in Crankshaft Balancing Techniques

Despite significant advancements in crankshaft balancing technology, the industry continues to face several persistent challenges that impede optimal performance and efficiency. Traditional balancing methods often struggle with the increasing complexity of modern engine designs, particularly in high-performance and lightweight applications where precision is paramount.

Material inconsistencies represent a fundamental challenge in crankshaft balancing. Even with sophisticated manufacturing processes, variations in material density and composition create inherent imbalances that are difficult to predict and address systematically. These microscopic inconsistencies can manifest as vibration issues that compromise engine performance and longevity.

Measurement precision limitations continue to plague balancing operations. While equipment sensitivity has improved dramatically, detecting ultra-fine imbalances at the microscopic level remains problematic, especially when balancing requirements approach the theoretical limits of measurement technology. This creates a technological ceiling that is increasingly relevant as engine tolerances become tighter.

Dynamic versus static balancing considerations present another significant challenge. Many current balancing techniques excel at addressing static imbalance but fall short when compensating for dynamic imbalances that occur during actual operation. The complex interplay of forces during high-RPM operation creates imbalance patterns that static methods cannot fully anticipate or correct.

Cost-efficiency trade-offs remain a persistent industry concern. High-precision balancing techniques often require expensive equipment and specialized expertise, creating economic barriers for widespread adoption. This is particularly problematic for mass-production environments where cost constraints are significant but performance expectations remain high.

Integration with modern manufacturing workflows presents logistical challenges. Balancing operations must seamlessly fit into increasingly automated production lines without creating bottlenecks or requiring excessive human intervention. This integration challenge is compounded by the need for real-time quality control and verification.

Emerging materials and designs further complicate balancing procedures. As manufacturers explore composite materials, hybrid designs, and unconventional geometries to improve performance and efficiency, traditional balancing approaches require significant adaptation. These novel configurations often exhibit unexpected dynamic behaviors that conventional balancing wisdom fails to address adequately.

Environmental factors such as temperature fluctuations and operating conditions introduce variables that can undermine even perfectly balanced crankshafts. Current techniques struggle to account for how thermal expansion, lubricant viscosity changes, and other operational factors affect balance during actual use rather than in controlled testing environments.

Human Engineering

Material inconsistencies represent a fundamental challenge in crankshaft balancing. Even with sophisticated manufacturing processes, variations in material density and composition create inherent imbalances that are difficult to predict and address systematically. These microscopic inconsistencies can manifest as vibration issues that compromise engine performance and longevity.

Measurement precision limitations continue to plague balancing operations. While equipment sensitivity has improved dramatically, detecting ultra-fine imbalances at the microscopic level remains problematic, especially when balancing requirements approach the theoretical limits of measurement technology. This creates a technological ceiling that is increasingly relevant as engine tolerances become tighter.

Dynamic versus static balancing considerations present another significant challenge. Many current balancing techniques excel at addressing static imbalance but fall short when compensating for dynamic imbalances that occur during actual operation. The complex interplay of forces during high-RPM operation creates imbalance patterns that static methods cannot fully anticipate or correct.

Cost-efficiency trade-offs remain a persistent industry concern. High-precision balancing techniques often require expensive equipment and specialized expertise, creating economic barriers for widespread adoption. This is particularly problematic for mass-production environments where cost constraints are significant but performance expectations remain high.

Integration with modern manufacturing workflows presents logistical challenges. Balancing operations must seamlessly fit into increasingly automated production lines without creating bottlenecks or requiring excessive human intervention. This integration challenge is compounded by the need for real-time quality control and verification.

Emerging materials and designs further complicate balancing procedures. As manufacturers explore composite materials, hybrid designs, and unconventional geometries to improve performance and efficiency, traditional balancing approaches require significant adaptation. These novel configurations often exhibit unexpected dynamic behaviors that conventional balancing wisdom fails to address adequately.

Environmental factors such as temperature fluctuations and operating conditions introduce variables that can undermine even perfectly balanced crankshafts. Current techniques struggle to account for how thermal expansion, lubricant viscosity changes, and other operational factors affect balance during actual use rather than in controlled testing environments.

Human Engineering

Contemporary Crankshaft Balancing Approaches

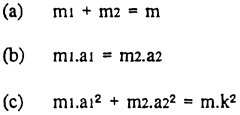

01 Dynamic balancing methods for crankshafts

Dynamic balancing techniques involve measuring and correcting imbalances in rotating crankshafts while they are in motion. These methods typically use specialized equipment to detect vibration patterns and identify the location and magnitude of imbalances. By adding or removing material at specific points, engineers can optimize the rotational stability of crankshafts, reducing vibration and extending engine life. Advanced dynamic balancing considers multiple planes and can be performed at various operational speeds to ensure optimal performance across the engine's operating range.- Dynamic balancing methods for crankshafts: Dynamic balancing techniques involve measuring and correcting imbalances in rotating crankshafts while they are in motion. These methods typically use specialized equipment to detect vibration patterns and identify the location and magnitude of imbalances. Correction is then applied by adding or removing material at specific points on the crankshaft to achieve optimal balance. This approach is particularly effective for high-performance engines where precision balancing is critical for reducing vibration and extending component life.

- Counterweight design optimization for crankshaft balancing: Optimizing the design of counterweights is a key technique for improving crankshaft balance. This involves precise calculation of counterweight mass, positioning, and geometry to offset the rotating and reciprocating forces generated during engine operation. Advanced computational methods allow for the simulation and analysis of different counterweight configurations to achieve optimal balance. Some approaches include variable-density counterweights, asymmetric designs, and material selection strategies to minimize overall crankshaft weight while maintaining balance.

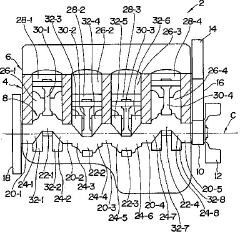

- Automated balancing systems and equipment: Automated systems for crankshaft balancing utilize computer-controlled equipment to measure imbalance and perform corrective actions with minimal human intervention. These systems typically incorporate sensors, precision measurement devices, and automated material removal tools. The automation improves consistency, reduces processing time, and enhances the accuracy of the balancing process. Modern systems may include real-time monitoring capabilities, adaptive algorithms for optimization, and integration with manufacturing execution systems for quality control.

- Computational methods for crankshaft balance analysis: Advanced computational methods are employed to analyze and optimize crankshaft balance. These include finite element analysis (FEA), computational fluid dynamics (CFD), and specialized simulation software that can model the dynamic behavior of crankshafts under various operating conditions. These computational approaches allow engineers to predict imbalance issues before physical prototyping, optimize design parameters, and evaluate the effectiveness of different balancing strategies. Machine learning algorithms are increasingly being applied to further refine these computational models and improve prediction accuracy.

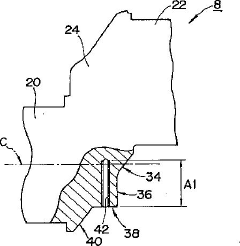

- Material selection and manufacturing techniques for balanced crankshafts: The selection of appropriate materials and manufacturing techniques plays a crucial role in achieving optimal crankshaft balance. High-strength alloys with consistent density properties are preferred for predictable balance characteristics. Advanced manufacturing methods such as precision forging, CNC machining, and specialized heat treatments help maintain dimensional accuracy and material integrity. Some innovative approaches include composite materials, selective reinforcement of high-stress areas, and post-manufacturing treatments to enhance durability while maintaining optimal balance properties.

02 Counterweight design optimization

Optimizing the design of counterweights is crucial for effective crankshaft balancing. This involves precise calculation of counterweight mass, positioning, and geometry to offset the rotating and reciprocating forces generated during engine operation. Advanced techniques include computer modeling to determine optimal counterweight configurations, variable density materials for more efficient mass distribution, and integrated counterweight designs that reduce overall crankshaft weight while maintaining balance. These optimizations help minimize vibration, reduce stress on engine components, and improve fuel efficiency.Expand Specific Solutions03 Automated balancing systems and equipment

Automated systems for crankshaft balancing utilize advanced sensors, computer control, and precision machinery to achieve optimal balance with minimal human intervention. These systems can automatically detect imbalances, calculate necessary corrections, and perform material removal or addition operations. Features include high-precision measurement capabilities, real-time feedback control, multi-plane balancing capabilities, and integration with manufacturing systems. Automated balancing equipment significantly improves accuracy, consistency, and efficiency in the crankshaft balancing process while reducing labor costs and human error.Expand Specific Solutions04 Computational methods for balance optimization

Computational approaches to crankshaft balancing leverage advanced algorithms, finite element analysis, and simulation techniques to predict and optimize balance characteristics before physical manufacturing. These methods model the dynamic behavior of crankshafts under various operating conditions, accounting for material properties, geometric complexities, and engine-specific requirements. Machine learning algorithms can identify optimal balancing solutions based on historical data and performance metrics. Computational optimization reduces development time, minimizes material waste, and enables engineers to evaluate multiple design iterations virtually before committing to physical prototypes.Expand Specific Solutions05 Material selection and manufacturing techniques

The choice of materials and manufacturing processes significantly impacts crankshaft balance optimization. Advanced materials with specific density and strength characteristics can be strategically employed to achieve better balance with less added weight. Manufacturing techniques such as precision forging, advanced machining, and controlled heat treatment processes ensure dimensional accuracy and material consistency critical for balance. Post-manufacturing treatments like shot peening can also improve balance characteristics while enhancing fatigue resistance. Innovative manufacturing approaches include selective material deposition and hybrid construction methods that optimize weight distribution throughout the crankshaft.Expand Specific Solutions

Major Industry Players in Crankshaft Balancing Solutions

Crankshaft balancing technology is currently in a mature development stage with established methodologies, though continuous innovation persists. The global market for crankshaft balancing equipment is estimated at $1.2-1.5 billion annually, growing steadily with automotive and industrial machinery demand. Leading automotive manufacturers like GM, Ford, Toyota, Honda, and Hyundai have developed proprietary balancing techniques, while specialized equipment providers such as Hegenscheidt-MFD and MAG Industrial Automation Systems offer advanced solutions. Recent technological advancements focus on high-precision dynamic balancing, AI-assisted optimization, and integration with Industry 4.0 systems. Academic institutions like Shandong University of Technology contribute research on theoretical modeling and simulation techniques to further enhance balancing efficiency and reduce vibration.

GM Global Technology Operations LLC

Technical Solution: GM Global Technology Operations has developed a comprehensive crankshaft balancing approach that integrates advanced simulation techniques with precision manufacturing processes. Their technology begins with finite element analysis (FEA) during the design phase to predict potential imbalance issues before physical prototyping. GM's system incorporates multi-plane dynamic balancing that accounts for both rotating and reciprocating mass effects across the entire engine assembly. Their proprietary algorithms optimize material removal locations to maintain structural integrity while achieving target balance specifications. GM has implemented machine learning techniques that analyze historical balancing data to continuously improve process parameters and prediction accuracy. Their manufacturing systems feature automated in-line verification that ensures balanced crankshafts meet specifications before proceeding to subsequent assembly operations. GM's approach also includes thermal compensation algorithms that account for dimensional changes during engine operation, ensuring balanced performance across all operating conditions.

Strengths: Comprehensive approach that addresses balancing from design through manufacturing to final assembly. Excellent integration with broader powertrain development processes. Weaknesses: System complexity requires significant engineering resources to implement and maintain. Some proprietary technologies may limit compatibility with third-party manufacturing equipment.

MAG Industrial Automation Systems LLC

Technical Solution: MAG Industrial Automation Systems has pioneered an integrated approach to crankshaft balancing that combines advanced sensing technology with precision material removal processes. Their system utilizes multi-axis CNC machining centers specifically designed for crankshaft balancing operations. MAG's technology incorporates high-frequency vibration analysis to detect imbalance characteristics across multiple planes simultaneously. Their proprietary software algorithms translate these measurements into optimal material removal strategies, considering both static and dynamic balancing requirements. The company has developed specialized tooling systems that can perform targeted material removal with minimal impact on crankshaft structural integrity. MAG's latest systems feature adaptive control mechanisms that automatically adjust cutting parameters based on material hardness variations and geometric complexities. Their technology also includes comprehensive documentation and traceability features that record all balancing operations for quality assurance purposes.

Strengths: Highly versatile systems capable of handling diverse crankshaft designs from small automotive to large industrial applications. Excellent integration capabilities with existing production lines. Weaknesses: Complex setup procedures require specialized technical expertise. Higher maintenance requirements compared to simpler balancing systems.

Key Technical Innovations in Dynamic Balancing Systems

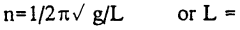

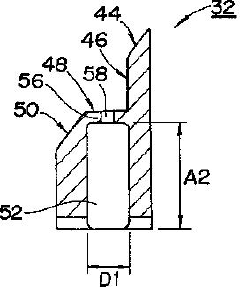

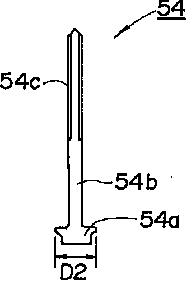

Advance balancing process for crankshaft

PatentWO1997007929A1

Innovation

- An advanced balancing process that uses a substitute revolving weight to correct both revolving and reciprocating imbalances by determining the center of gravity of connecting rods and adjusting counter weights in the crankshaft discs, allowing for 100% correction of revolving unbalance and 50% correction of reciprocating unbalance, thereby achieving optimal balancing conditions.

Balancing structure for crankshaft

PatentInactiveJP1995004425A

Innovation

- Variable balancing mechanism that automatically adjusts counterweight position based on crankshaft revolution speed, transitioning from 0% to 50% balancing rate.

- Spring-controlled counterweight system that uses the opposing forces of a controlling spring and centrifugal force to determine counterweight position.

- Dual-state balancing system that reduces frictional loss and maintains proper oil film thickness by adapting to different operating conditions.

Environmental Impact of Advanced Balancing Technologies

The environmental implications of crankshaft balancing technologies have become increasingly significant as industries face stricter regulations and growing sustainability concerns. Advanced balancing techniques not only improve engine performance but also contribute substantially to environmental protection through multiple pathways. The reduction in vibration and noise pollution represents one of the most immediate environmental benefits, as properly balanced crankshafts minimize the mechanical oscillations that propagate through vehicle structures and into the surrounding environment.

Energy efficiency gains from optimized balancing techniques translate directly into reduced fuel consumption and lower greenhouse gas emissions. Studies indicate that engines with precisely balanced crankshafts can achieve fuel efficiency improvements of 2-5% compared to those with suboptimal balancing. This efficiency multiplied across millions of vehicles worldwide represents a substantial reduction in carbon footprint and conservation of fossil fuel resources.

The manufacturing processes for advanced balancing technologies themselves have evolved to become more environmentally responsible. Modern balancing equipment incorporates energy-efficient motors and controllers that consume significantly less electricity than older systems. Additionally, computer-optimized balancing reduces material waste by minimizing the amount of metal removed during the correction process, preserving resources and reducing manufacturing byproducts.

Lifecycle assessment of balancing technologies reveals further environmental advantages. The extended service life of properly balanced crankshafts reduces the frequency of replacements and repairs, thereby decreasing the environmental impact associated with manufacturing replacement parts. This longevity factor is particularly important when considering the embodied carbon and resource intensity of engine component production.

Water conservation has also become a focus in advanced balancing operations. Newer balancing systems utilize closed-loop cooling systems that dramatically reduce water consumption compared to traditional methods. Some facilities have reported water usage reductions of up to 80% after implementing these systems, contributing significantly to resource conservation efforts.

The waste streams from balancing operations have been addressed through innovative recycling programs. Metal particles removed during balancing are now routinely collected and recycled, while lubricants and coolants are increasingly formulated with biodegradable components. These practices minimize the environmental footprint of balancing operations and reduce the burden on waste management systems.

Looking forward, the integration of digital technologies and artificial intelligence into balancing processes promises further environmental benefits through predictive maintenance and real-time optimization. These systems can anticipate balancing issues before they lead to increased emissions or reduced efficiency, ensuring that engines operate at peak environmental performance throughout their service life.

Energy efficiency gains from optimized balancing techniques translate directly into reduced fuel consumption and lower greenhouse gas emissions. Studies indicate that engines with precisely balanced crankshafts can achieve fuel efficiency improvements of 2-5% compared to those with suboptimal balancing. This efficiency multiplied across millions of vehicles worldwide represents a substantial reduction in carbon footprint and conservation of fossil fuel resources.

The manufacturing processes for advanced balancing technologies themselves have evolved to become more environmentally responsible. Modern balancing equipment incorporates energy-efficient motors and controllers that consume significantly less electricity than older systems. Additionally, computer-optimized balancing reduces material waste by minimizing the amount of metal removed during the correction process, preserving resources and reducing manufacturing byproducts.

Lifecycle assessment of balancing technologies reveals further environmental advantages. The extended service life of properly balanced crankshafts reduces the frequency of replacements and repairs, thereby decreasing the environmental impact associated with manufacturing replacement parts. This longevity factor is particularly important when considering the embodied carbon and resource intensity of engine component production.

Water conservation has also become a focus in advanced balancing operations. Newer balancing systems utilize closed-loop cooling systems that dramatically reduce water consumption compared to traditional methods. Some facilities have reported water usage reductions of up to 80% after implementing these systems, contributing significantly to resource conservation efforts.

The waste streams from balancing operations have been addressed through innovative recycling programs. Metal particles removed during balancing are now routinely collected and recycled, while lubricants and coolants are increasingly formulated with biodegradable components. These practices minimize the environmental footprint of balancing operations and reduce the burden on waste management systems.

Looking forward, the integration of digital technologies and artificial intelligence into balancing processes promises further environmental benefits through predictive maintenance and real-time optimization. These systems can anticipate balancing issues before they lead to increased emissions or reduced efficiency, ensuring that engines operate at peak environmental performance throughout their service life.

Cost-Benefit Analysis of Precision Balancing Investments

Investing in precision balancing equipment and techniques requires careful financial analysis to determine the return on investment. Initial costs for high-precision balancing equipment can range from $50,000 for basic systems to over $500,000 for advanced automated solutions with integrated measurement capabilities. These capital expenditures must be weighed against the long-term operational benefits and cost savings.

The primary financial benefits of precision balancing investments include reduced warranty claims, decreased maintenance costs, and extended component lifespans. Studies from automotive manufacturing indicate that properly balanced crankshafts can reduce engine warranty claims by 15-22%, representing significant cost savings for high-volume production. For a medium-sized engine manufacturer producing 100,000 units annually, this can translate to savings of $1.2-1.8 million per year in warranty-related expenses alone.

Production efficiency improvements present another substantial benefit. Advanced balancing systems can reduce balancing cycle times by up to 40% compared to conventional methods, increasing throughput and reducing labor costs. The automation of previously manual processes can decrease labor requirements by 30-50% in balancing operations, with corresponding reductions in human error rates from approximately 3% to under 0.5%.

Energy efficiency gains should also factor into the cost-benefit analysis. Precisely balanced crankshafts contribute to overall engine efficiency improvements of 2-5%, resulting in fuel consumption reductions that become significant multipliers when calculated across the lifetime of thousands of engines. For industrial applications, these efficiency gains translate directly to operational cost savings for end users.

The payback period for precision balancing investments varies by implementation scale and industry. Small to medium manufacturers typically see returns within 18-36 months, while large-scale operations may achieve breakeven in 12-24 months due to volume advantages. Aerospace and high-performance automotive sectors, where component failure costs are exceptionally high, often realize returns in under 12 months despite higher initial investment requirements.

Risk mitigation represents an often-overlooked financial benefit. Precision balancing significantly reduces the probability of catastrophic failures, which can result in production stoppages, safety incidents, and reputational damage. While difficult to quantify precisely, risk reduction benefits can be modeled using failure probability statistics and associated downtime costs, typically showing risk-adjusted savings of 8-15% annually.

The primary financial benefits of precision balancing investments include reduced warranty claims, decreased maintenance costs, and extended component lifespans. Studies from automotive manufacturing indicate that properly balanced crankshafts can reduce engine warranty claims by 15-22%, representing significant cost savings for high-volume production. For a medium-sized engine manufacturer producing 100,000 units annually, this can translate to savings of $1.2-1.8 million per year in warranty-related expenses alone.

Production efficiency improvements present another substantial benefit. Advanced balancing systems can reduce balancing cycle times by up to 40% compared to conventional methods, increasing throughput and reducing labor costs. The automation of previously manual processes can decrease labor requirements by 30-50% in balancing operations, with corresponding reductions in human error rates from approximately 3% to under 0.5%.

Energy efficiency gains should also factor into the cost-benefit analysis. Precisely balanced crankshafts contribute to overall engine efficiency improvements of 2-5%, resulting in fuel consumption reductions that become significant multipliers when calculated across the lifetime of thousands of engines. For industrial applications, these efficiency gains translate directly to operational cost savings for end users.

The payback period for precision balancing investments varies by implementation scale and industry. Small to medium manufacturers typically see returns within 18-36 months, while large-scale operations may achieve breakeven in 12-24 months due to volume advantages. Aerospace and high-performance automotive sectors, where component failure costs are exceptionally high, often realize returns in under 12 months despite higher initial investment requirements.

Risk mitigation represents an often-overlooked financial benefit. Precision balancing significantly reduces the probability of catastrophic failures, which can result in production stoppages, safety incidents, and reputational damage. While difficult to quantify precisely, risk reduction benefits can be modeled using failure probability statistics and associated downtime costs, typically showing risk-adjusted savings of 8-15% annually.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!