How to Execute Crankshaft Contamination Tests

SEP 23, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Crankshaft Contamination Testing Background and Objectives

Crankshaft contamination testing has evolved significantly over the past several decades, driven by increasingly stringent engine performance requirements and environmental regulations. Initially developed in the 1950s as basic visual inspections, these tests have transformed into sophisticated analytical procedures utilizing advanced technologies such as spectroscopic analysis, electron microscopy, and computerized particle counting systems. The evolution reflects the automotive industry's growing understanding of how even microscopic contaminants can significantly impact engine reliability, efficiency, and longevity.

The primary objective of crankshaft contamination testing is to identify, quantify, and characterize foreign particles and substances that may compromise the integrity and performance of engine crankshafts during manufacturing, assembly, and operation. These contaminants—ranging from metallic debris and abrasive particles to chemical residues and biological materials—can accelerate wear, initiate fatigue cracking, impair lubrication, and ultimately lead to catastrophic engine failure if not properly detected and mitigated.

Current technological trends in this field include the development of real-time monitoring systems capable of detecting contamination during the manufacturing process, non-destructive testing methodologies that preserve component integrity, and machine learning algorithms that can predict contamination-related failures before they occur. The integration of Industry 4.0 principles has further enhanced testing capabilities through automated data collection, analysis, and quality control feedback loops.

The global push toward more fuel-efficient engines with reduced emissions has intensified the importance of contamination testing, as modern high-precision engine components operate with tighter tolerances and are therefore more susceptible to contamination-related issues. Additionally, the transition toward alternative materials such as composites and specialized alloys in crankshaft manufacturing necessitates adapted testing protocols to address unique contamination vulnerabilities.

Technical goals for advancing crankshaft contamination testing include developing more sensitive detection methods capable of identifying nano-scale contaminants, establishing standardized testing protocols across the industry, reducing testing time and costs without compromising accuracy, and creating comprehensive contamination databases that facilitate predictive maintenance strategies. These advancements aim to support the automotive industry's pursuit of engines with extended service intervals, reduced warranty claims, and improved overall reliability.

The convergence of materials science, tribology, fluid dynamics, and data analytics continues to drive innovation in this specialized field, with cross-disciplinary approaches yielding promising new methodologies for contamination detection, analysis, and prevention. As engine designs continue to evolve toward greater efficiency and reduced environmental impact, crankshaft contamination testing remains a critical quality assurance measure in modern powertrain development and manufacturing.

The primary objective of crankshaft contamination testing is to identify, quantify, and characterize foreign particles and substances that may compromise the integrity and performance of engine crankshafts during manufacturing, assembly, and operation. These contaminants—ranging from metallic debris and abrasive particles to chemical residues and biological materials—can accelerate wear, initiate fatigue cracking, impair lubrication, and ultimately lead to catastrophic engine failure if not properly detected and mitigated.

Current technological trends in this field include the development of real-time monitoring systems capable of detecting contamination during the manufacturing process, non-destructive testing methodologies that preserve component integrity, and machine learning algorithms that can predict contamination-related failures before they occur. The integration of Industry 4.0 principles has further enhanced testing capabilities through automated data collection, analysis, and quality control feedback loops.

The global push toward more fuel-efficient engines with reduced emissions has intensified the importance of contamination testing, as modern high-precision engine components operate with tighter tolerances and are therefore more susceptible to contamination-related issues. Additionally, the transition toward alternative materials such as composites and specialized alloys in crankshaft manufacturing necessitates adapted testing protocols to address unique contamination vulnerabilities.

Technical goals for advancing crankshaft contamination testing include developing more sensitive detection methods capable of identifying nano-scale contaminants, establishing standardized testing protocols across the industry, reducing testing time and costs without compromising accuracy, and creating comprehensive contamination databases that facilitate predictive maintenance strategies. These advancements aim to support the automotive industry's pursuit of engines with extended service intervals, reduced warranty claims, and improved overall reliability.

The convergence of materials science, tribology, fluid dynamics, and data analytics continues to drive innovation in this specialized field, with cross-disciplinary approaches yielding promising new methodologies for contamination detection, analysis, and prevention. As engine designs continue to evolve toward greater efficiency and reduced environmental impact, crankshaft contamination testing remains a critical quality assurance measure in modern powertrain development and manufacturing.

Market Requirements for Crankshaft Cleanliness Standards

The automotive industry has established increasingly stringent requirements for crankshaft cleanliness due to the direct impact of contamination on engine performance, reliability, and longevity. Market analysis indicates that OEMs (Original Equipment Manufacturers) are demanding cleanliness standards that exceed ISO 16232 and VDA 19 specifications, with particular emphasis on particle size distribution and total contamination weight.

Current market requirements specify maximum allowable contamination levels ranging from 10-20 mg per crankshaft, with stricter limits for premium and high-performance engine applications. Particle size thresholds have become more rigorous, with most manufacturers requiring that no metallic particles exceed 600 μm in length, while some luxury and performance brands specify even lower thresholds of 400 μm.

The geographical distribution of cleanliness requirements shows notable variations, with European manufacturers typically enforcing the most stringent standards, followed closely by Japanese and Korean OEMs. North American manufacturers have been rapidly adopting similar specifications, particularly for their premium vehicle lines and newer engine platforms designed for improved fuel efficiency.

Market research reveals that engine warranty claims related to contamination-induced failures represent a significant cost factor for manufacturers, estimated at hundreds of millions of dollars annually across the industry. This economic pressure has intensified the focus on cleanliness standards as a preventive measure against costly field failures and recalls.

The aftermarket segment demonstrates growing awareness of cleanliness standards, with professional engine rebuilders and performance shops increasingly adopting testing protocols similar to those used by OEMs. This trend is expanding the market for contamination testing equipment and services beyond traditional manufacturing environments.

Industry surveys indicate that manufacturers are willing to invest in advanced contamination testing technologies that offer higher accuracy, better repeatability, and faster processing times. The market shows particular interest in automated systems that can integrate with production lines and provide real-time data on cleanliness metrics.

Emerging requirements include the need for testing protocols that can identify not just metallic particles but also non-metallic contaminants such as casting sand, machining debris, and cleaning agent residues. Additionally, there is growing demand for testing methods that can distinguish between different types of metallic particles to better identify their sources within the manufacturing process.

Current market requirements specify maximum allowable contamination levels ranging from 10-20 mg per crankshaft, with stricter limits for premium and high-performance engine applications. Particle size thresholds have become more rigorous, with most manufacturers requiring that no metallic particles exceed 600 μm in length, while some luxury and performance brands specify even lower thresholds of 400 μm.

The geographical distribution of cleanliness requirements shows notable variations, with European manufacturers typically enforcing the most stringent standards, followed closely by Japanese and Korean OEMs. North American manufacturers have been rapidly adopting similar specifications, particularly for their premium vehicle lines and newer engine platforms designed for improved fuel efficiency.

Market research reveals that engine warranty claims related to contamination-induced failures represent a significant cost factor for manufacturers, estimated at hundreds of millions of dollars annually across the industry. This economic pressure has intensified the focus on cleanliness standards as a preventive measure against costly field failures and recalls.

The aftermarket segment demonstrates growing awareness of cleanliness standards, with professional engine rebuilders and performance shops increasingly adopting testing protocols similar to those used by OEMs. This trend is expanding the market for contamination testing equipment and services beyond traditional manufacturing environments.

Industry surveys indicate that manufacturers are willing to invest in advanced contamination testing technologies that offer higher accuracy, better repeatability, and faster processing times. The market shows particular interest in automated systems that can integrate with production lines and provide real-time data on cleanliness metrics.

Emerging requirements include the need for testing protocols that can identify not just metallic particles but also non-metallic contaminants such as casting sand, machining debris, and cleaning agent residues. Additionally, there is growing demand for testing methods that can distinguish between different types of metallic particles to better identify their sources within the manufacturing process.

Current Testing Methodologies and Technical Limitations

Crankshaft contamination testing currently employs several established methodologies, each with specific applications and limitations. The most widely used approach involves visual inspection, where trained technicians examine crankshaft surfaces under controlled lighting conditions to identify visible contaminants. While cost-effective and non-destructive, this method suffers from significant subjectivity and inability to detect microscopic contaminants that may still impact performance.

Microscopic analysis represents a more advanced technique, utilizing optical or electron microscopy to examine surface contamination at much higher magnification. This methodology provides excellent detection capabilities for particulate matter down to micron levels but requires specialized equipment, trained personnel, and is time-consuming for large surface areas.

Chemical analysis techniques, including solvent extraction followed by gas chromatography-mass spectrometry (GC-MS), offer quantitative assessment of organic contaminants. These methods excel at identifying specific chemical compounds but require destructive sampling and complex laboratory procedures that limit throughput in production environments.

Surface energy testing has emerged as a non-destructive alternative, measuring the wettability of crankshaft surfaces to infer contamination levels. While providing rapid results, this approach lacks specificity regarding contaminant type and may yield inconsistent results across different material compositions.

A significant technical limitation across all methodologies is the challenge of establishing standardized contamination thresholds. Industry standards vary considerably, with different manufacturers employing proprietary acceptance criteria that complicate cross-industry comparisons and quality benchmarking.

Sample preparation represents another critical limitation, as improper handling can introduce new contaminants or remove existing ones, potentially invalidating test results. This challenge is particularly acute for large components like crankshafts, where consistent handling protocols are difficult to maintain throughout the testing process.

Environmental factors also impact test reliability, with temperature, humidity, and airborne particulates all capable of influencing results. Most current methodologies lack robust environmental controls, leading to potential variability in test outcomes across different facilities or testing conditions.

Automation remains underdeveloped in this field, with many testing protocols still relying heavily on manual operations. This dependence on human operators introduces variability and limits throughput, particularly problematic for high-volume production environments where rapid, consistent testing is essential for quality control.

Microscopic analysis represents a more advanced technique, utilizing optical or electron microscopy to examine surface contamination at much higher magnification. This methodology provides excellent detection capabilities for particulate matter down to micron levels but requires specialized equipment, trained personnel, and is time-consuming for large surface areas.

Chemical analysis techniques, including solvent extraction followed by gas chromatography-mass spectrometry (GC-MS), offer quantitative assessment of organic contaminants. These methods excel at identifying specific chemical compounds but require destructive sampling and complex laboratory procedures that limit throughput in production environments.

Surface energy testing has emerged as a non-destructive alternative, measuring the wettability of crankshaft surfaces to infer contamination levels. While providing rapid results, this approach lacks specificity regarding contaminant type and may yield inconsistent results across different material compositions.

A significant technical limitation across all methodologies is the challenge of establishing standardized contamination thresholds. Industry standards vary considerably, with different manufacturers employing proprietary acceptance criteria that complicate cross-industry comparisons and quality benchmarking.

Sample preparation represents another critical limitation, as improper handling can introduce new contaminants or remove existing ones, potentially invalidating test results. This challenge is particularly acute for large components like crankshafts, where consistent handling protocols are difficult to maintain throughout the testing process.

Environmental factors also impact test reliability, with temperature, humidity, and airborne particulates all capable of influencing results. Most current methodologies lack robust environmental controls, leading to potential variability in test outcomes across different facilities or testing conditions.

Automation remains underdeveloped in this field, with many testing protocols still relying heavily on manual operations. This dependence on human operators introduces variability and limits throughput, particularly problematic for high-volume production environments where rapid, consistent testing is essential for quality control.

Standard Testing Protocols and Implementation Guidelines

01 Methods for detecting crankshaft contamination

Various methods and systems are used to detect contamination on crankshafts, including optical inspection techniques, spectroscopic analysis, and automated vision systems. These methods can identify different types of contaminants such as oil residues, metal particles, and manufacturing debris that may affect crankshaft performance. Detection systems often incorporate high-resolution cameras and specialized lighting to enhance visibility of surface contaminants.- Methods for detecting contamination in crankshafts: Various methods are employed to detect contamination in crankshafts, including optical inspection systems, spectroscopic analysis, and automated visual inspection technologies. These methods can identify surface contaminants, particulate matter, and residual manufacturing materials that may affect crankshaft performance. Advanced imaging techniques allow for real-time detection of contaminants during production or maintenance processes.

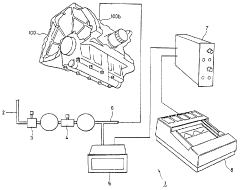

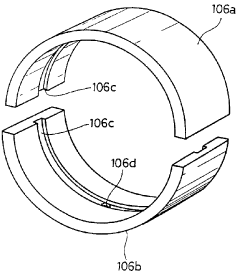

- Contamination testing equipment for engine components: Specialized equipment has been developed for testing contamination in engine components, particularly crankshafts. This includes automated testing stations, sensor-based detection systems, and computerized analysis tools that can evaluate both surface and internal contamination. These systems often incorporate multiple testing methodologies to ensure comprehensive contamination assessment and can be integrated into production lines for quality control.

- Cleaning and decontamination processes for crankshafts: Various cleaning and decontamination processes have been developed specifically for crankshafts, including ultrasonic cleaning, chemical washing, and precision mechanical cleaning. These processes aim to remove manufacturing residues, oils, particulates, and other contaminants that could affect engine performance. Advanced cleaning methods often combine multiple techniques to address different types of contamination while preserving the integrity of the crankshaft surface.

- Contamination standards and quality control for crankshafts: Industry standards and quality control protocols have been established to define acceptable levels of contamination for crankshafts. These standards specify testing methodologies, acceptance criteria, and documentation requirements. Quality control systems often include multiple inspection points throughout the manufacturing process, with specialized tests designed to detect specific contaminants known to affect crankshaft performance and durability.

- Automated systems for crankshaft contamination analysis: Automated systems have been developed to analyze crankshaft contamination with minimal human intervention. These systems incorporate artificial intelligence, machine learning algorithms, and advanced sensors to detect, classify, and quantify various types of contamination. Automated analysis provides consistent results, reduces testing time, and can identify contamination patterns that might be missed by manual inspection methods.

02 Contamination testing equipment for crankshafts

Specialized equipment has been developed for testing crankshaft contamination, including automated test benches, particle analyzers, and contamination measurement devices. These systems often feature precision sensors, controlled testing environments, and data analysis capabilities to quantify contamination levels. Equipment may include fluid sampling mechanisms, filtration systems, and comparative analysis tools to establish contamination thresholds for quality control purposes.Expand Specific Solutions03 Cleaning processes to remove crankshaft contamination

Various cleaning processes have been developed to remove contamination from crankshafts, including ultrasonic cleaning, chemical washing, and mechanical scrubbing techniques. These processes target different types of contaminants such as machining oils, metal chips, and environmental debris. Cleaning methods may incorporate specialized solvents, temperature-controlled baths, and precision cleaning tools designed to access complex crankshaft geometries without causing damage to the component surface.Expand Specific Solutions04 Contamination monitoring systems for crankshaft manufacturing

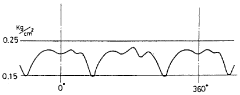

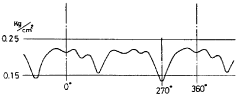

Monitoring systems for tracking contamination throughout the crankshaft manufacturing process include real-time sensors, quality control checkpoints, and data logging systems. These systems help identify contamination sources, track cleaning effectiveness, and ensure compliance with cleanliness specifications. Advanced monitoring approaches may incorporate machine learning algorithms to predict contamination risks and automated alerts when contamination levels exceed acceptable thresholds.Expand Specific Solutions05 Impact analysis of contamination on crankshaft performance

Research and testing methods have been developed to analyze how different types and levels of contamination affect crankshaft performance, durability, and reliability. These analyses examine factors such as bearing wear, lubrication effectiveness, and mechanical stress distribution when contaminants are present. Testing protocols may include accelerated wear testing, simulation of operating conditions, and comparative performance analysis between clean and contaminated components to establish acceptable contamination thresholds.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The crankshaft contamination testing market is currently in a growth phase, with increasing demand driven by automotive and industrial equipment manufacturers seeking improved engine reliability and performance. The global market size is estimated to exceed $500 million annually, with projected growth of 5-7% through 2025. From a technological maturity perspective, established players like Toyota, Continental Automotive, and Robert Bosch lead with advanced testing methodologies, while emerging companies such as Kanadevia Corp. and specialized research institutions like China Special Equipment Inspection & Research Institute are developing innovative approaches. The competitive landscape features automotive OEMs (Toyota, BMW, Honda) focusing on proprietary methods, while tier-1 suppliers (Continental, Bosch) offer standardized solutions, creating a fragmented but increasingly sophisticated market.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive crankshaft contamination testing protocol that combines multiple testing methodologies. Their approach includes ultrasonic cleaning followed by a three-stage verification process: 1) Visual inspection using high-resolution imaging systems with machine learning algorithms to detect surface contaminants down to 5 microns; 2) Chemical residue analysis using gas chromatography-mass spectrometry (GC-MS) to identify organic contaminants; and 3) Particle count verification using automated optical systems. Toyota's testing facilities implement cleanroom environments (ISO Class 7) for final inspection to prevent environmental contamination during testing. Their protocol includes standardized acceptance criteria based on engine type and performance requirements, with specialized parameters for hybrid vehicle applications.

Strengths: Comprehensive multi-stage approach ensures high detection accuracy; integration with manufacturing systems allows for real-time quality control adjustments; advanced imaging systems reduce human error. Weaknesses: Higher implementation costs compared to traditional methods; requires specialized training for technicians; testing process has longer cycle time than some competitors.

Robert Bosch GmbH

Technical Solution: Bosch has engineered an automated crankshaft contamination testing system that utilizes precision optical scanning combined with advanced spectroscopic analysis. Their system employs laser-induced breakdown spectroscopy (LIBS) to detect metallic contaminants with sensitivity down to 1 ppm, while simultaneously using Fourier-transform infrared spectroscopy (FTIR) for organic contamination detection. The testing process is fully automated with robotic handling systems that minimize human contact with test specimens. Bosch's methodology includes a proprietary "contamination mapping" technique that creates a digital contamination profile of each crankshaft, allowing for statistical process control and trend analysis across production batches. Their system integrates with manufacturing execution systems (MES) to provide real-time feedback for process adjustment and quality control.

Strengths: High precision detection capabilities with dual spectroscopic technologies; fully automated testing reduces human error and increases throughput; digital contamination mapping enables advanced analytics and process improvement. Weaknesses: High capital investment required for implementation; complex calibration procedures needed for different crankshaft materials and geometries; system requires regular maintenance by specialized technicians.

Critical Technologies in Contamination Detection Systems

Confirmation of metal around crank shaft and device therefor

PatentInactiveJP1990152738A

Innovation

- A method involving a compressed air source connected to a pressure reducing valve, which supplies air to the oil passage of the cylinder block and connecting pipe, using a pressure measuring device to record pressure waveforms and determine the presence of metal components around the crankshaft.

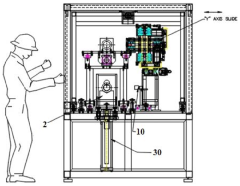

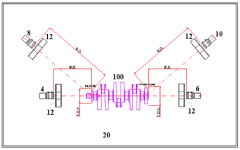

System and method for inspection and feature detection of crankshaft

PatentActiveIN202021040823A

Innovation

- A system utilizing machine vision with CMOS cameras, high-intensity lights, and artificial intelligence for automated inspection and feature detection on crankshafts, including the use of X, Y, Z axis servo slides and inclined bar lights to capture and process images for precise detection of dents, scratches, and features, providing a 'PASS' or 'FAIL' result without human intervention.

Environmental Impact of Testing Chemicals and Solutions

Crankshaft contamination testing involves various chemicals and solutions that can have significant environmental implications if not properly managed. The testing procedures typically utilize solvents, detergents, and specialized cleaning agents that contain potentially harmful compounds such as volatile organic compounds (VOCs), petroleum derivatives, and surfactants. When released into the environment, these substances can contaminate soil, water systems, and air quality, leading to ecological disruption and potential human health hazards.

The primary environmental concern stems from improper disposal of used testing solutions. Without adequate treatment, these chemicals can leach into groundwater, affecting drinking water supplies and aquatic ecosystems. Studies have shown that even low concentrations of certain solvents used in contamination testing can be toxic to aquatic organisms, disrupting reproductive cycles and causing population decline in sensitive species.

Air pollution represents another significant environmental impact, as many cleaning agents and solvents used in crankshaft testing emit VOCs during application. These compounds contribute to smog formation and can cause respiratory issues in both wildlife and human populations near testing facilities. The cumulative effect of these emissions from multiple industrial sources has been linked to regional air quality degradation in manufacturing-dense areas.

Waste generation from testing procedures creates additional environmental challenges. Contaminated rags, filters, and other disposable materials used during testing often contain residual chemicals that require specialized disposal methods. When improperly managed, these materials can contribute to landfill contamination and subsequent environmental degradation through leachate production.

Energy consumption associated with testing processes also carries an environmental footprint. Many contamination testing procedures require heating solutions or operating specialized equipment, contributing to carbon emissions and resource depletion. The water usage in testing and subsequent treatment of contaminated wastewater further adds to the environmental burden through increased demand on local water resources.

Progressive companies are implementing more environmentally responsible testing protocols, including closed-loop solvent recovery systems, biodegradable cleaning agents, and water-based alternatives to traditional petroleum-derived solvents. These approaches significantly reduce the environmental impact while maintaining testing efficacy. Additionally, centralized waste treatment facilities specifically designed for industrial testing chemicals have demonstrated substantial improvements in environmental outcomes compared to traditional disposal methods.

The primary environmental concern stems from improper disposal of used testing solutions. Without adequate treatment, these chemicals can leach into groundwater, affecting drinking water supplies and aquatic ecosystems. Studies have shown that even low concentrations of certain solvents used in contamination testing can be toxic to aquatic organisms, disrupting reproductive cycles and causing population decline in sensitive species.

Air pollution represents another significant environmental impact, as many cleaning agents and solvents used in crankshaft testing emit VOCs during application. These compounds contribute to smog formation and can cause respiratory issues in both wildlife and human populations near testing facilities. The cumulative effect of these emissions from multiple industrial sources has been linked to regional air quality degradation in manufacturing-dense areas.

Waste generation from testing procedures creates additional environmental challenges. Contaminated rags, filters, and other disposable materials used during testing often contain residual chemicals that require specialized disposal methods. When improperly managed, these materials can contribute to landfill contamination and subsequent environmental degradation through leachate production.

Energy consumption associated with testing processes also carries an environmental footprint. Many contamination testing procedures require heating solutions or operating specialized equipment, contributing to carbon emissions and resource depletion. The water usage in testing and subsequent treatment of contaminated wastewater further adds to the environmental burden through increased demand on local water resources.

Progressive companies are implementing more environmentally responsible testing protocols, including closed-loop solvent recovery systems, biodegradable cleaning agents, and water-based alternatives to traditional petroleum-derived solvents. These approaches significantly reduce the environmental impact while maintaining testing efficacy. Additionally, centralized waste treatment facilities specifically designed for industrial testing chemicals have demonstrated substantial improvements in environmental outcomes compared to traditional disposal methods.

Quality Assurance Integration and Compliance Standards

Quality assurance integration for crankshaft contamination testing requires comprehensive alignment with both industry standards and internal manufacturing protocols. The implementation of ISO 16232 standards serves as the foundation for particulate contamination analysis in automotive components, providing specific methodologies for sample collection, extraction procedures, and quantitative assessment of contaminants. These standards must be seamlessly integrated into the testing workflow to ensure consistent and reliable results across all testing facilities.

Compliance with automotive industry specifications, particularly those established by organizations such as SAE, ASTM, and manufacturer-specific requirements (like Ford WSS-M99P9999-A1 or GM 3651M), is essential for crankshaft contamination testing. These standards typically define acceptable contamination levels, particle size distributions, and specific test parameters that must be rigorously followed to meet quality certification requirements.

Documentation systems play a critical role in quality assurance integration, requiring detailed test protocols, calibration records, and result traceability. Modern contamination testing facilities implement electronic documentation systems that automatically record test parameters, environmental conditions, and results, creating an unbroken chain of evidence that supports compliance verification during audits.

Laboratory accreditation represents another crucial aspect of quality assurance, with facilities conducting crankshaft contamination tests typically requiring ISO/IEC 17025 certification. This accreditation validates the technical competence of testing laboratories and ensures that results are recognized internationally, facilitating global supply chain integration and regulatory acceptance.

Statistical process control methodologies must be incorporated into contamination testing procedures to monitor test consistency and identify potential deviations before they impact product quality. Implementation of control charts, capability indices, and measurement system analysis helps maintain testing precision and accuracy over time, ensuring reliable detection of contamination issues.

Cross-functional integration between quality departments, production teams, and engineering groups ensures that contamination test results drive meaningful improvements in manufacturing processes. Establishing clear communication channels and response protocols when contamination thresholds are exceeded helps maintain production quality while minimizing disruptions to manufacturing operations.

Regular compliance audits and certification renewals are necessary to maintain quality assurance standards for crankshaft contamination testing. These audits should evaluate both procedural adherence and technical performance, with findings incorporated into continuous improvement initiatives that enhance testing capabilities and ensure ongoing compliance with evolving industry standards.

Compliance with automotive industry specifications, particularly those established by organizations such as SAE, ASTM, and manufacturer-specific requirements (like Ford WSS-M99P9999-A1 or GM 3651M), is essential for crankshaft contamination testing. These standards typically define acceptable contamination levels, particle size distributions, and specific test parameters that must be rigorously followed to meet quality certification requirements.

Documentation systems play a critical role in quality assurance integration, requiring detailed test protocols, calibration records, and result traceability. Modern contamination testing facilities implement electronic documentation systems that automatically record test parameters, environmental conditions, and results, creating an unbroken chain of evidence that supports compliance verification during audits.

Laboratory accreditation represents another crucial aspect of quality assurance, with facilities conducting crankshaft contamination tests typically requiring ISO/IEC 17025 certification. This accreditation validates the technical competence of testing laboratories and ensures that results are recognized internationally, facilitating global supply chain integration and regulatory acceptance.

Statistical process control methodologies must be incorporated into contamination testing procedures to monitor test consistency and identify potential deviations before they impact product quality. Implementation of control charts, capability indices, and measurement system analysis helps maintain testing precision and accuracy over time, ensuring reliable detection of contamination issues.

Cross-functional integration between quality departments, production teams, and engineering groups ensures that contamination test results drive meaningful improvements in manufacturing processes. Establishing clear communication channels and response protocols when contamination thresholds are exceeded helps maintain production quality while minimizing disruptions to manufacturing operations.

Regular compliance audits and certification renewals are necessary to maintain quality assurance standards for crankshaft contamination testing. These audits should evaluate both procedural adherence and technical performance, with findings incorporated into continuous improvement initiatives that enhance testing capabilities and ensure ongoing compliance with evolving industry standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!