Cyclone Separator Efficiency: Design Variables And Cut-Size Metrics

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Evolution and Objectives

Cyclone separators have a rich history dating back to the late 19th century when they were first introduced for dust collection in industrial settings. The evolution of these devices has been driven by the increasing demand for efficient particle separation in various industries, including chemical processing, mining, and environmental protection.

The initial designs of cyclone separators were relatively simple, relying on the basic principle of centrifugal force to separate particles from gas streams. As industrial processes became more complex and environmental regulations more stringent, the need for more efficient and versatile cyclone separators grew. This led to significant advancements in design and performance over the years.

One of the key milestones in cyclone separator development was the introduction of the reverse-flow cyclone in the mid-20th century. This design improvement allowed for better separation efficiency and reduced pressure drop, making cyclones more suitable for a wider range of applications. Subsequently, researchers and engineers focused on optimizing various design parameters such as inlet geometry, body dimensions, and cone angle to enhance performance further.

The advent of computational fluid dynamics (CFD) in the late 20th century marked another significant leap in cyclone separator technology. CFD simulations enabled engineers to model and analyze complex flow patterns within cyclones, leading to more sophisticated designs and improved understanding of separation mechanisms. This technological advancement has been instrumental in developing high-efficiency cyclones capable of handling diverse particle sizes and gas flow rates.

In recent years, the objectives of cyclone separator development have expanded beyond mere particle separation. Modern cyclone separators are expected to meet increasingly stringent environmental standards, operate with minimal energy consumption, and integrate seamlessly into complex industrial processes. This has led to the exploration of novel materials, such as advanced composites, to enhance durability and reduce maintenance requirements.

The current focus in cyclone separator research is on achieving higher separation efficiencies, particularly for fine particles, while maintaining low pressure drops. This objective is driven by the need to remove smaller particulates from gas streams to comply with tighter air quality regulations. Additionally, there is a growing interest in developing cyclone separators that can handle higher temperatures and corrosive environments, expanding their applicability in challenging industrial settings.

Looking ahead, the evolution of cyclone separators is likely to continue with a focus on smart, adaptive designs that can automatically adjust to varying process conditions. The integration of sensors and control systems may lead to self-optimizing cyclones capable of maintaining peak performance across a wide range of operating parameters. Furthermore, the development of hybrid systems combining cyclone technology with other separation methods holds promise for addressing complex separation challenges in emerging industries.

The initial designs of cyclone separators were relatively simple, relying on the basic principle of centrifugal force to separate particles from gas streams. As industrial processes became more complex and environmental regulations more stringent, the need for more efficient and versatile cyclone separators grew. This led to significant advancements in design and performance over the years.

One of the key milestones in cyclone separator development was the introduction of the reverse-flow cyclone in the mid-20th century. This design improvement allowed for better separation efficiency and reduced pressure drop, making cyclones more suitable for a wider range of applications. Subsequently, researchers and engineers focused on optimizing various design parameters such as inlet geometry, body dimensions, and cone angle to enhance performance further.

The advent of computational fluid dynamics (CFD) in the late 20th century marked another significant leap in cyclone separator technology. CFD simulations enabled engineers to model and analyze complex flow patterns within cyclones, leading to more sophisticated designs and improved understanding of separation mechanisms. This technological advancement has been instrumental in developing high-efficiency cyclones capable of handling diverse particle sizes and gas flow rates.

In recent years, the objectives of cyclone separator development have expanded beyond mere particle separation. Modern cyclone separators are expected to meet increasingly stringent environmental standards, operate with minimal energy consumption, and integrate seamlessly into complex industrial processes. This has led to the exploration of novel materials, such as advanced composites, to enhance durability and reduce maintenance requirements.

The current focus in cyclone separator research is on achieving higher separation efficiencies, particularly for fine particles, while maintaining low pressure drops. This objective is driven by the need to remove smaller particulates from gas streams to comply with tighter air quality regulations. Additionally, there is a growing interest in developing cyclone separators that can handle higher temperatures and corrosive environments, expanding their applicability in challenging industrial settings.

Looking ahead, the evolution of cyclone separators is likely to continue with a focus on smart, adaptive designs that can automatically adjust to varying process conditions. The integration of sensors and control systems may lead to self-optimizing cyclones capable of maintaining peak performance across a wide range of operating parameters. Furthermore, the development of hybrid systems combining cyclone technology with other separation methods holds promise for addressing complex separation challenges in emerging industries.

Industrial Demand for Efficient Particle Separation

The industrial demand for efficient particle separation has been steadily increasing across various sectors, driven by the need for improved process efficiency, product quality, and environmental compliance. Cyclone separators, known for their simplicity and cost-effectiveness, have become a crucial technology in meeting these demands. Industries such as pharmaceuticals, food processing, chemical manufacturing, and mineral processing rely heavily on cyclone separators for their particle separation needs.

In the pharmaceutical industry, cyclone separators play a vital role in the production of powdered medications and the recovery of valuable active ingredients. The demand for high-precision separation has led to the development of advanced cyclone designs capable of achieving finer cut sizes and higher efficiencies. This trend is particularly evident in the production of inhalable drugs, where particle size distribution is critical for effective drug delivery.

The food processing sector has seen a surge in the use of cyclone separators for tasks such as flour milling, sugar refining, and spice processing. The ability to separate particles based on size and density while maintaining product purity has made cyclones indispensable in these applications. Additionally, the dairy industry utilizes cyclones for powder recovery in spray drying processes, contributing to improved yield and reduced waste.

Chemical manufacturers have embraced cyclone technology for a wide range of applications, including catalyst recovery, polymer production, and gas cleaning. The demand for cyclones capable of handling corrosive or abrasive materials has led to innovations in materials science and coating technologies. Furthermore, the petrochemical industry relies on cyclones for the removal of catalyst fines from fluidized catalytic cracking (FCC) units, driving the need for high-efficiency designs that can operate under extreme conditions.

In the mineral processing industry, cyclones are extensively used for classification and dewatering operations. The push for more efficient resource utilization has led to the development of cyclones with improved separation efficiency and higher throughput capacities. This trend is particularly evident in the mining sector, where cyclones are employed in grinding circuits to optimize particle size distribution and enhance overall process performance.

The growing focus on environmental protection and air quality has also contributed to the increased demand for cyclone separators in pollution control applications. Industries are under pressure to reduce particulate emissions, leading to the adoption of cyclones as pre-cleaners in air pollution control systems. This has spurred research into cyclone designs that can effectively capture fine particles while maintaining low pressure drops.

As industries continue to seek ways to improve their processes and meet stringent regulatory requirements, the demand for more efficient and versatile cyclone separators is expected to grow. This has led to a renewed interest in optimizing cyclone design variables and developing more accurate cut-size metrics to meet the diverse needs of various industrial applications.

In the pharmaceutical industry, cyclone separators play a vital role in the production of powdered medications and the recovery of valuable active ingredients. The demand for high-precision separation has led to the development of advanced cyclone designs capable of achieving finer cut sizes and higher efficiencies. This trend is particularly evident in the production of inhalable drugs, where particle size distribution is critical for effective drug delivery.

The food processing sector has seen a surge in the use of cyclone separators for tasks such as flour milling, sugar refining, and spice processing. The ability to separate particles based on size and density while maintaining product purity has made cyclones indispensable in these applications. Additionally, the dairy industry utilizes cyclones for powder recovery in spray drying processes, contributing to improved yield and reduced waste.

Chemical manufacturers have embraced cyclone technology for a wide range of applications, including catalyst recovery, polymer production, and gas cleaning. The demand for cyclones capable of handling corrosive or abrasive materials has led to innovations in materials science and coating technologies. Furthermore, the petrochemical industry relies on cyclones for the removal of catalyst fines from fluidized catalytic cracking (FCC) units, driving the need for high-efficiency designs that can operate under extreme conditions.

In the mineral processing industry, cyclones are extensively used for classification and dewatering operations. The push for more efficient resource utilization has led to the development of cyclones with improved separation efficiency and higher throughput capacities. This trend is particularly evident in the mining sector, where cyclones are employed in grinding circuits to optimize particle size distribution and enhance overall process performance.

The growing focus on environmental protection and air quality has also contributed to the increased demand for cyclone separators in pollution control applications. Industries are under pressure to reduce particulate emissions, leading to the adoption of cyclones as pre-cleaners in air pollution control systems. This has spurred research into cyclone designs that can effectively capture fine particles while maintaining low pressure drops.

As industries continue to seek ways to improve their processes and meet stringent regulatory requirements, the demand for more efficient and versatile cyclone separators is expected to grow. This has led to a renewed interest in optimizing cyclone design variables and developing more accurate cut-size metrics to meet the diverse needs of various industrial applications.

Current Challenges in Cyclone Separator Design

Cyclone separators face several significant challenges in their design and optimization, primarily stemming from the complex interplay of fluid dynamics and particle behavior within the separator. One of the foremost issues is the trade-off between separation efficiency and pressure drop. As designers strive to improve the separation performance, they often encounter increased pressure losses, which can lead to higher energy consumption and operational costs.

The geometry of cyclone separators presents another critical challenge. The optimal dimensions and proportions of various components, such as the inlet, vortex finder, and cone section, are highly dependent on the specific application and particle characteristics. This interdependence makes it difficult to develop a universally applicable design, necessitating careful consideration and often extensive experimentation for each unique scenario.

Particle re-entrainment is a persistent problem that can significantly reduce separation efficiency. As particles are separated and move towards the walls, they can be caught in turbulent eddies and re-entrained into the main flow, potentially exiting through the vortex finder. This phenomenon is particularly pronounced for smaller particles and at higher flow rates, making it challenging to achieve high efficiencies across a wide range of particle sizes.

The cut-size, which represents the particle size at which the separator achieves 50% collection efficiency, is a crucial metric that designers struggle to optimize. Reducing the cut-size to capture finer particles often comes at the cost of increased pressure drop and energy consumption. Moreover, the cut-size can be influenced by various operational parameters, such as inlet velocity and particle loading, making it difficult to maintain consistent performance under varying conditions.

Another significant challenge lies in predicting and controlling the flow patterns within the cyclone. The complex, three-dimensional swirling flow is highly sensitive to inlet conditions and geometric variations. This sensitivity can lead to instabilities and asymmetries in the flow field, potentially resulting in reduced separation efficiency and increased wear on the separator walls.

The design of cyclone separators for high-temperature or corrosive environments poses additional challenges. Material selection becomes critical, as does the need to account for thermal expansion and potential changes in fluid properties. These factors can significantly impact the separator's performance and longevity, requiring careful consideration in the design process.

Lastly, the scaling of cyclone separators from laboratory or pilot-scale to industrial applications remains a significant challenge. The performance characteristics observed in smaller units do not always translate directly to larger scales, necessitating additional design considerations and often leading to unexpected performance issues in full-scale implementations.

The geometry of cyclone separators presents another critical challenge. The optimal dimensions and proportions of various components, such as the inlet, vortex finder, and cone section, are highly dependent on the specific application and particle characteristics. This interdependence makes it difficult to develop a universally applicable design, necessitating careful consideration and often extensive experimentation for each unique scenario.

Particle re-entrainment is a persistent problem that can significantly reduce separation efficiency. As particles are separated and move towards the walls, they can be caught in turbulent eddies and re-entrained into the main flow, potentially exiting through the vortex finder. This phenomenon is particularly pronounced for smaller particles and at higher flow rates, making it challenging to achieve high efficiencies across a wide range of particle sizes.

The cut-size, which represents the particle size at which the separator achieves 50% collection efficiency, is a crucial metric that designers struggle to optimize. Reducing the cut-size to capture finer particles often comes at the cost of increased pressure drop and energy consumption. Moreover, the cut-size can be influenced by various operational parameters, such as inlet velocity and particle loading, making it difficult to maintain consistent performance under varying conditions.

Another significant challenge lies in predicting and controlling the flow patterns within the cyclone. The complex, three-dimensional swirling flow is highly sensitive to inlet conditions and geometric variations. This sensitivity can lead to instabilities and asymmetries in the flow field, potentially resulting in reduced separation efficiency and increased wear on the separator walls.

The design of cyclone separators for high-temperature or corrosive environments poses additional challenges. Material selection becomes critical, as does the need to account for thermal expansion and potential changes in fluid properties. These factors can significantly impact the separator's performance and longevity, requiring careful consideration in the design process.

Lastly, the scaling of cyclone separators from laboratory or pilot-scale to industrial applications remains a significant challenge. The performance characteristics observed in smaller units do not always translate directly to larger scales, necessitating additional design considerations and often leading to unexpected performance issues in full-scale implementations.

State-of-the-Art Cyclone Separator Designs

01 Geometric design optimization

Improving cyclone separator efficiency through optimized geometric design, including adjustments to inlet configuration, body shape, and cone angle. These modifications can enhance particle separation and reduce pressure drop, leading to better overall performance.- Geometric design optimization: Improving cyclone separator efficiency through optimized geometric design, including adjustments to inlet configuration, body shape, and cone angle. These modifications can enhance particle separation and reduce pressure drop, leading to better overall performance.

- Multi-stage separation systems: Implementing multi-stage cyclone separation systems to increase overall efficiency. This approach involves using multiple cyclones in series or parallel configurations, allowing for better separation of particles across different size ranges and improving the overall collection efficiency.

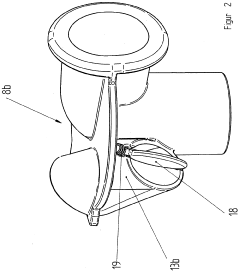

- Flow control mechanisms: Incorporating flow control mechanisms such as vortex finders, guide vanes, or baffles to optimize the flow pattern within the cyclone separator. These elements can help stabilize the vortex, reduce turbulence, and improve particle separation efficiency.

- Surface modifications: Enhancing cyclone separator efficiency through surface modifications of internal components. This can include applying special coatings or textures to reduce particle adhesion, minimize wall losses, and improve overall separation performance.

- Intelligent control systems: Implementing intelligent control systems and sensors to monitor and adjust cyclone separator parameters in real-time. This approach allows for adaptive operation based on changing inlet conditions, optimizing efficiency across various operating scenarios.

02 Multi-stage separation systems

Implementing multi-stage cyclone separation systems to increase overall efficiency. This approach involves using multiple cyclones in series or parallel configurations, allowing for better separation of particles across different size ranges and improving the overall collection efficiency.Expand Specific Solutions03 Flow control mechanisms

Incorporating flow control mechanisms such as vortex finders, guide vanes, or baffles to optimize the flow pattern within the cyclone separator. These elements can help stabilize the vortex, reduce turbulence, and improve particle separation efficiency.Expand Specific Solutions04 Surface modifications

Enhancing cyclone separator efficiency through surface modifications of internal components. This can include applying special coatings or textures to reduce particle adhesion, minimize wall losses, and improve overall separation performance.Expand Specific Solutions05 Intelligent control systems

Implementing intelligent control systems and sensors to monitor and adjust cyclone separator parameters in real-time. This approach allows for adaptive operation based on changing inlet conditions, optimizing efficiency across various operating scenarios.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The cyclone separator efficiency market is in a mature stage, with established players and well-defined technologies. The global market size for cyclone separators is estimated to be around $1.5 billion, driven by increasing industrial applications and environmental regulations. Technologically, companies like MANN+HUMMEL GmbH and Donaldson Filtration Deutschland GmbH are leading innovation in design variables and cut-size metrics. Dyson Technology Ltd. has made significant advancements in consumer-grade cyclone technology. Academic institutions such as China Petroleum University Beijing and Kunming University of Science & Technology are contributing to research and development in this field, particularly for industrial applications in petrochemical and mining sectors.

MANN+HUMMEL GmbH

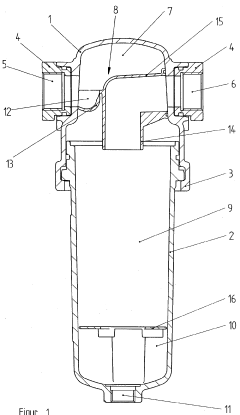

Technical Solution: MANN+HUMMEL has developed advanced cyclone separator technology for automotive and industrial applications. Their design focuses on optimizing the cyclone geometry and inlet configuration to enhance separation efficiency. They utilize computational fluid dynamics (CFD) simulations to analyze and improve the flow patterns within the cyclone[1]. Their approach involves adjusting key design variables such as the cyclone body diameter, cone angle, and vortex finder dimensions to achieve optimal cut-size metrics. MANN+HUMMEL's cyclones incorporate a tangential inlet design that promotes a strong rotational flow, enhancing particle separation[2]. They have also implemented a multi-stage cyclone system for improved fine particle capture, with each stage optimized for different particle size ranges[3].

Strengths: Extensive experience in filtration systems, advanced CFD simulation capabilities, and a multi-stage approach for enhanced efficiency. Weaknesses: Potential limitations in extremely fine particle separation and higher manufacturing costs for complex multi-stage systems.

Dyson Technology Ltd.

Technical Solution: Dyson has innovated in cyclone separator technology, particularly for household and commercial vacuum cleaners. Their approach focuses on creating a series of small, high-efficiency cyclones arranged in a radial array. This design, known as Radial Root Cyclone™ technology, utilizes multiple tiers of cyclones to progressively separate particles of decreasing size[1]. Dyson's cyclones are engineered with precise dimensions and angles to maximize centrifugal forces and minimize turbulence. They have optimized the cyclone entry points to create a smooth transition from axial to rotational flow, reducing energy losses[2]. Dyson has also developed a unique shrouded cyclone design that helps maintain high tangential velocities deeper into the cyclone, improving the capture of fine particles[3]. Their latest designs incorporate digital motors to create powerful airflow through the cyclone array, further enhancing separation efficiency.

Strengths: Innovative multi-cyclone designs, expertise in fine particle separation, and integration with high-speed digital motors. Weaknesses: Primary focus on consumer applications may limit adaptability to large-scale industrial processes.

Key Patents in Cyclone Separator Efficiency

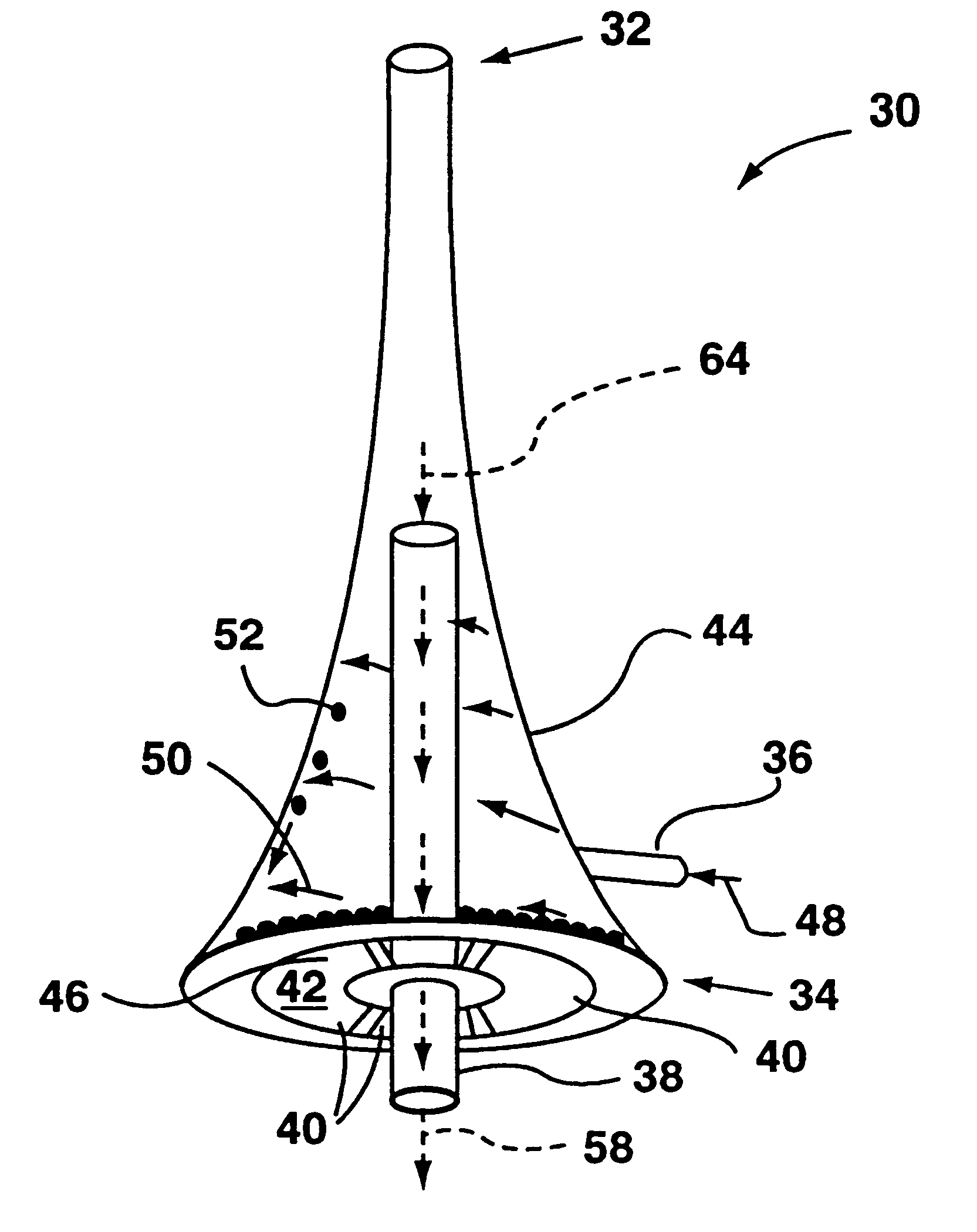

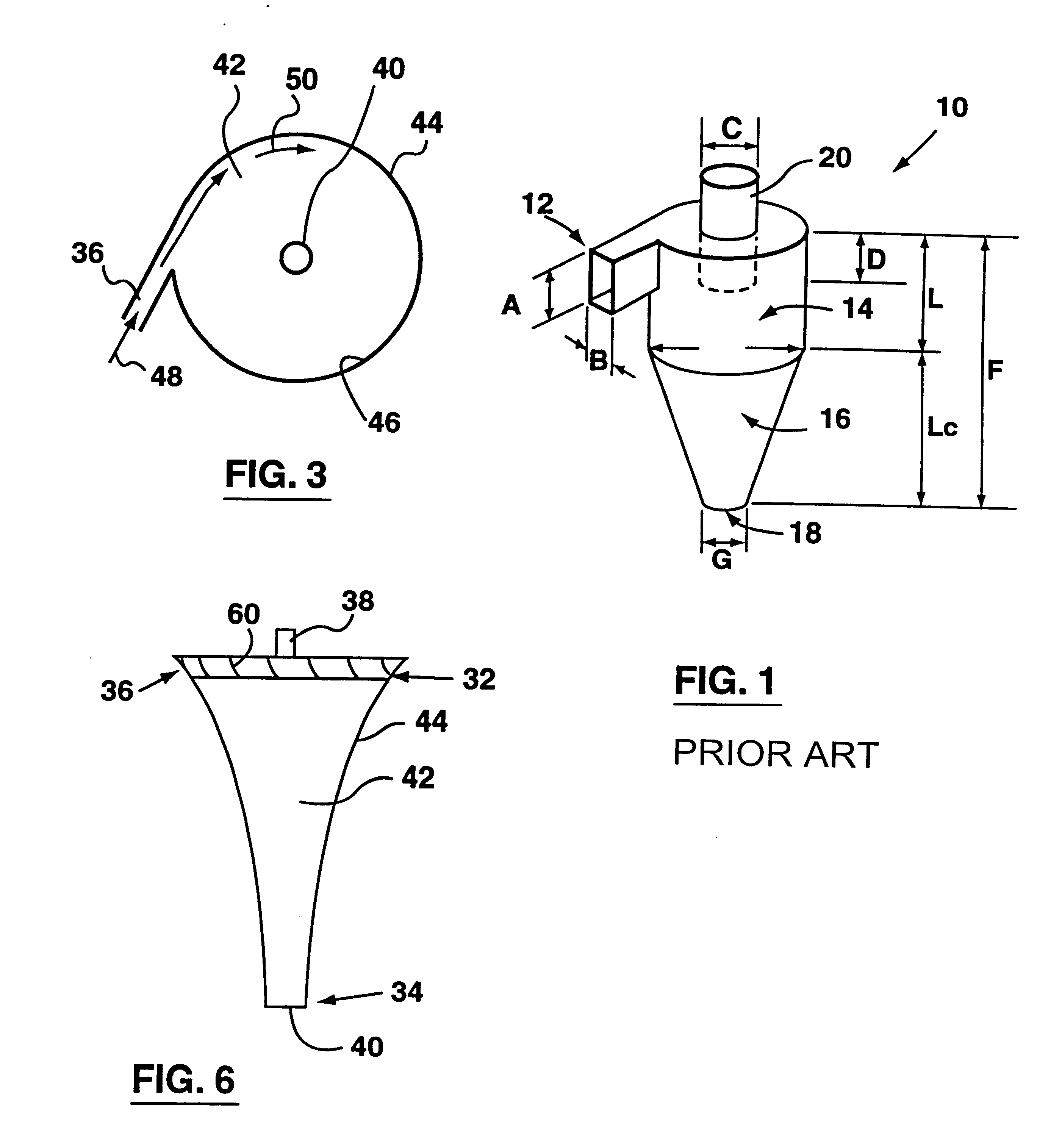

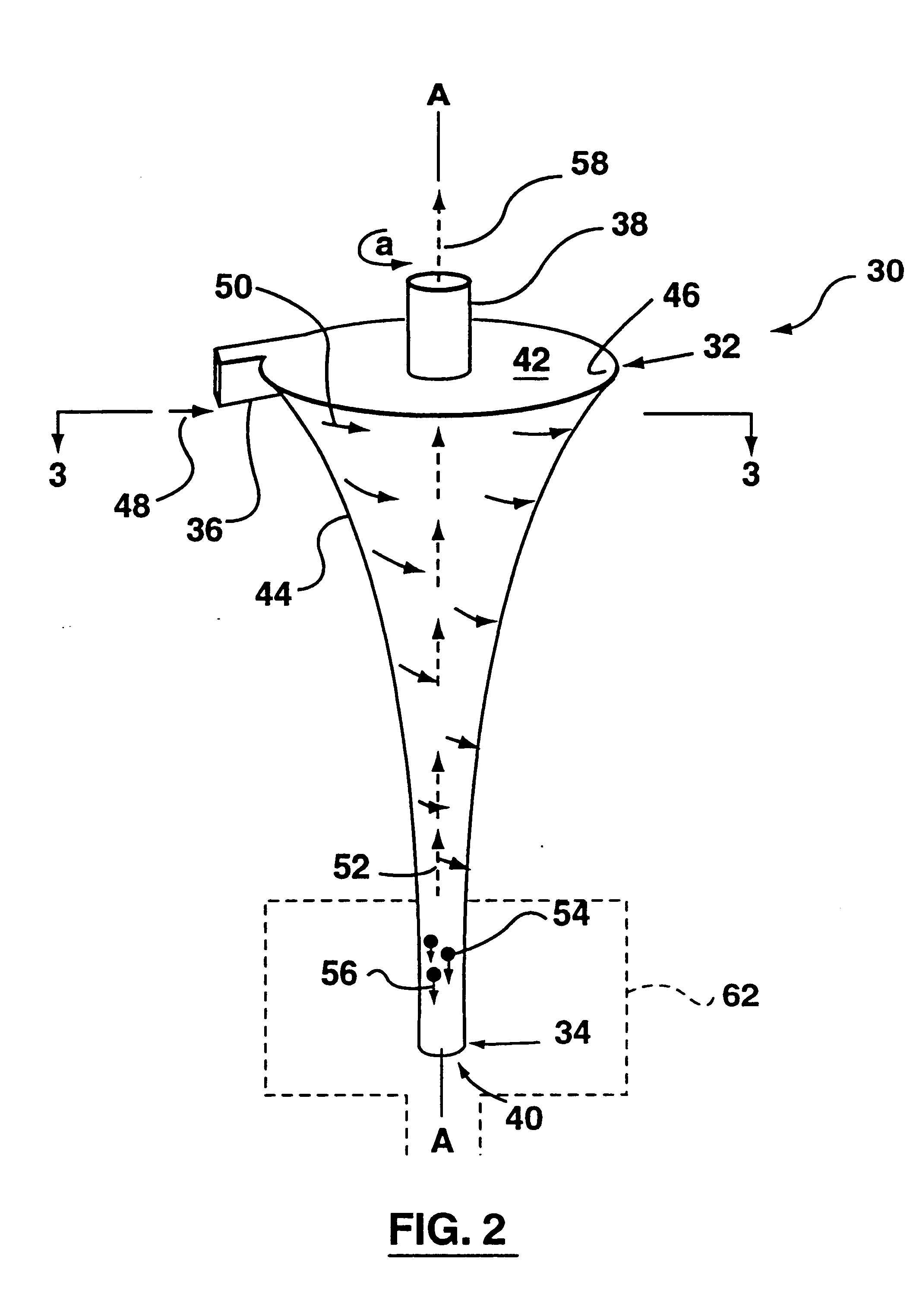

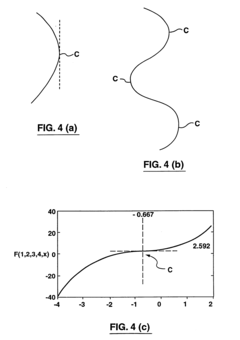

Cyclone separator having a variable longitudinal profile

PatentInactiveUS6596046B2

Innovation

- A non-frusto-conical cyclone separator with a continuously varying inner surface defined by a continuous n-differentiable curve, allowing continuous variation of the L/d and Lc/d parameters along the cyclone axis, enabling efficient separation of a wider range of particle sizes in a single unit.

Cyclone separator having inlet flow duct

PatentWO2010081715A1

Innovation

- A cyclone separator design featuring a turbulence chamber with a round cross-section and guide means as an inclined channel, which channels the fluid flow both downwards and tangentially within the vortex space, combined with an adjustable throttle element and an optional expansion space, to maintain constant efficiency across varying flow rates.

Environmental Impact and Regulations

Cyclone separators, widely used in industrial processes for particulate matter removal, have significant environmental implications and are subject to various regulations. The efficiency of these devices directly impacts air quality and emissions control, making them a focal point for environmental protection efforts.

In many countries, stringent air quality standards have been established to limit particulate matter emissions. These regulations often specify maximum allowable concentrations of PM10 and PM2.5 in ambient air. Cyclone separators play a crucial role in helping industries meet these standards by effectively removing larger particles from gas streams.

The United States Environmental Protection Agency (EPA) has set National Ambient Air Quality Standards (NAAQS) for particulate matter, which indirectly influence the design and operation of cyclone separators. Industries must ensure that their emissions control systems, including cyclones, are capable of meeting these standards to maintain compliance.

In the European Union, the Industrial Emissions Directive (IED) sets emission limit values for various pollutants, including particulate matter. This directive encourages the use of Best Available Techniques (BAT) in industrial processes, which often include high-efficiency cyclone separators as part of integrated pollution prevention and control strategies.

The environmental impact of cyclone separators extends beyond air quality. The collected particulate matter must be properly disposed of or recycled, depending on its composition and potential hazards. This aspect is regulated by waste management laws and guidelines, which vary by region and industry.

Energy consumption is another environmental consideration for cyclone separators. As pressure drop across the cyclone increases with improved separation efficiency, there is a trade-off between particle removal and energy use. This balance is becoming increasingly important as industries strive to reduce their carbon footprint and meet energy efficiency targets set by environmental regulations.

In developing countries, where air pollution is often a severe problem, the implementation of cyclone separators is seen as a cost-effective solution for improving air quality. However, the lack of stringent regulations or enforcement in some regions can lead to the use of less efficient designs, highlighting the need for global standards and technology transfer.

As environmental regulations continue to evolve, there is a growing emphasis on continuous monitoring and reporting of emissions. This trend is driving the integration of cyclone separators with advanced monitoring systems to ensure real-time compliance and optimize performance. Future regulations are likely to focus on even finer particle sizes, potentially requiring improvements in cyclone design or the use of cyclones in combination with other separation technologies.

In many countries, stringent air quality standards have been established to limit particulate matter emissions. These regulations often specify maximum allowable concentrations of PM10 and PM2.5 in ambient air. Cyclone separators play a crucial role in helping industries meet these standards by effectively removing larger particles from gas streams.

The United States Environmental Protection Agency (EPA) has set National Ambient Air Quality Standards (NAAQS) for particulate matter, which indirectly influence the design and operation of cyclone separators. Industries must ensure that their emissions control systems, including cyclones, are capable of meeting these standards to maintain compliance.

In the European Union, the Industrial Emissions Directive (IED) sets emission limit values for various pollutants, including particulate matter. This directive encourages the use of Best Available Techniques (BAT) in industrial processes, which often include high-efficiency cyclone separators as part of integrated pollution prevention and control strategies.

The environmental impact of cyclone separators extends beyond air quality. The collected particulate matter must be properly disposed of or recycled, depending on its composition and potential hazards. This aspect is regulated by waste management laws and guidelines, which vary by region and industry.

Energy consumption is another environmental consideration for cyclone separators. As pressure drop across the cyclone increases with improved separation efficiency, there is a trade-off between particle removal and energy use. This balance is becoming increasingly important as industries strive to reduce their carbon footprint and meet energy efficiency targets set by environmental regulations.

In developing countries, where air pollution is often a severe problem, the implementation of cyclone separators is seen as a cost-effective solution for improving air quality. However, the lack of stringent regulations or enforcement in some regions can lead to the use of less efficient designs, highlighting the need for global standards and technology transfer.

As environmental regulations continue to evolve, there is a growing emphasis on continuous monitoring and reporting of emissions. This trend is driving the integration of cyclone separators with advanced monitoring systems to ensure real-time compliance and optimize performance. Future regulations are likely to focus on even finer particle sizes, potentially requiring improvements in cyclone design or the use of cyclones in combination with other separation technologies.

Economic Feasibility and ROI Analysis

The economic feasibility and return on investment (ROI) analysis for cyclone separators is crucial for industries considering their implementation. The initial investment in cyclone separators can vary significantly based on size, materials, and complexity of the system. However, these devices generally offer a lower capital cost compared to other particle separation technologies, making them an attractive option for many applications.

Operating costs for cyclone separators are relatively low, primarily consisting of energy consumption for the pressure drop and maintenance expenses. The energy costs are directly related to the pressure drop across the cyclone, which is influenced by design variables such as inlet velocity, body diameter, and cone angle. Optimizing these parameters can lead to substantial energy savings over the separator's lifetime.

Maintenance costs are typically minimal due to the absence of moving parts, contributing to the overall cost-effectiveness of cyclone separators. Regular inspections and occasional cleaning are usually sufficient to maintain optimal performance. This low maintenance requirement translates to reduced downtime and labor costs, enhancing the long-term economic benefits.

The ROI for cyclone separators can be substantial, especially in industries where efficient particle separation leads to improved product quality, reduced waste, or compliance with environmental regulations. For instance, in the cement industry, cyclones used for preheating and precalcining can significantly reduce fuel consumption, leading to considerable cost savings and a rapid ROI.

The payback period for cyclone separators varies depending on the application but is often relatively short. In many cases, the initial investment can be recovered within 1-3 years through improved process efficiency, reduced material losses, and lower energy consumption. For example, in the wood processing industry, cyclones used for dust collection can lead to material recovery and improved air quality, resulting in both economic and environmental benefits.

When evaluating the economic feasibility, it's essential to consider the long-term benefits of improved cut-size metrics. A more efficient cyclone separator can lead to better product quality, reduced downstream processing costs, and potentially open new market opportunities. These factors, while sometimes challenging to quantify precisely, can significantly enhance the overall ROI.

In conclusion, the economic feasibility and ROI of cyclone separators are generally favorable, particularly when the design variables are optimized for the specific application. The combination of low capital costs, minimal maintenance requirements, and potential for significant process improvements makes cyclone separators an economically attractive solution for many industries dealing with particle separation challenges.

Operating costs for cyclone separators are relatively low, primarily consisting of energy consumption for the pressure drop and maintenance expenses. The energy costs are directly related to the pressure drop across the cyclone, which is influenced by design variables such as inlet velocity, body diameter, and cone angle. Optimizing these parameters can lead to substantial energy savings over the separator's lifetime.

Maintenance costs are typically minimal due to the absence of moving parts, contributing to the overall cost-effectiveness of cyclone separators. Regular inspections and occasional cleaning are usually sufficient to maintain optimal performance. This low maintenance requirement translates to reduced downtime and labor costs, enhancing the long-term economic benefits.

The ROI for cyclone separators can be substantial, especially in industries where efficient particle separation leads to improved product quality, reduced waste, or compliance with environmental regulations. For instance, in the cement industry, cyclones used for preheating and precalcining can significantly reduce fuel consumption, leading to considerable cost savings and a rapid ROI.

The payback period for cyclone separators varies depending on the application but is often relatively short. In many cases, the initial investment can be recovered within 1-3 years through improved process efficiency, reduced material losses, and lower energy consumption. For example, in the wood processing industry, cyclones used for dust collection can lead to material recovery and improved air quality, resulting in both economic and environmental benefits.

When evaluating the economic feasibility, it's essential to consider the long-term benefits of improved cut-size metrics. A more efficient cyclone separator can lead to better product quality, reduced downstream processing costs, and potentially open new market opportunities. These factors, while sometimes challenging to quantify precisely, can significantly enhance the overall ROI.

In conclusion, the economic feasibility and ROI of cyclone separators are generally favorable, particularly when the design variables are optimized for the specific application. The combination of low capital costs, minimal maintenance requirements, and potential for significant process improvements makes cyclone separators an economically attractive solution for many industries dealing with particle separation challenges.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!