Cyclone Separator Pressure Drop: Measurement And Minimization Methods

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Evolution and Objectives

Cyclone separators have a rich history dating back to the late 19th century when they were first introduced for dust collection in industrial settings. The evolution of cyclone separators has been driven by the need for more efficient and cost-effective particle separation methods across various industries. Initially, these devices were primarily used in sawmills and flour mills to remove wood chips and grain dust from air streams.

As industrial processes became more complex, the demand for improved cyclone separator performance grew. This led to significant advancements in cyclone design and operation throughout the 20th century. Key milestones include the development of high-efficiency cyclones in the 1940s and the introduction of computational fluid dynamics (CFD) for cyclone design optimization in the 1980s.

The primary objective of cyclone separator technology has always been to achieve efficient particle separation while minimizing pressure drop. Pressure drop is a critical factor as it directly impacts energy consumption and overall system efficiency. Over the years, researchers and engineers have focused on optimizing cyclone geometry, inlet configurations, and outlet designs to enhance separation efficiency while reducing pressure losses.

In recent decades, the focus has shifted towards developing cyclone separators capable of handling finer particles and higher gas flow rates. This has been driven by increasingly stringent environmental regulations and the need for more efficient industrial processes. The advent of advanced materials and manufacturing techniques has also contributed to the evolution of cyclone separators, allowing for more precise and complex designs.

The current objectives in cyclone separator technology revolve around several key areas. First, there is a continued emphasis on improving separation efficiency, particularly for submicron particles. Second, researchers are exploring novel methods to minimize pressure drop without compromising separation performance. Third, there is a growing interest in developing cyclone separators that can operate effectively under a wider range of process conditions, including high temperatures and corrosive environments.

Additionally, the integration of cyclone separators with other separation technologies, such as electrostatic precipitators or fabric filters, is being explored to create hybrid systems that offer superior performance. The development of smart cyclone separators, equipped with sensors and real-time monitoring capabilities, is another emerging trend aimed at optimizing operation and maintenance in industrial settings.

As industrial processes became more complex, the demand for improved cyclone separator performance grew. This led to significant advancements in cyclone design and operation throughout the 20th century. Key milestones include the development of high-efficiency cyclones in the 1940s and the introduction of computational fluid dynamics (CFD) for cyclone design optimization in the 1980s.

The primary objective of cyclone separator technology has always been to achieve efficient particle separation while minimizing pressure drop. Pressure drop is a critical factor as it directly impacts energy consumption and overall system efficiency. Over the years, researchers and engineers have focused on optimizing cyclone geometry, inlet configurations, and outlet designs to enhance separation efficiency while reducing pressure losses.

In recent decades, the focus has shifted towards developing cyclone separators capable of handling finer particles and higher gas flow rates. This has been driven by increasingly stringent environmental regulations and the need for more efficient industrial processes. The advent of advanced materials and manufacturing techniques has also contributed to the evolution of cyclone separators, allowing for more precise and complex designs.

The current objectives in cyclone separator technology revolve around several key areas. First, there is a continued emphasis on improving separation efficiency, particularly for submicron particles. Second, researchers are exploring novel methods to minimize pressure drop without compromising separation performance. Third, there is a growing interest in developing cyclone separators that can operate effectively under a wider range of process conditions, including high temperatures and corrosive environments.

Additionally, the integration of cyclone separators with other separation technologies, such as electrostatic precipitators or fabric filters, is being explored to create hybrid systems that offer superior performance. The development of smart cyclone separators, equipped with sensors and real-time monitoring capabilities, is another emerging trend aimed at optimizing operation and maintenance in industrial settings.

Industrial Demand Analysis

The demand for cyclone separators with optimized pressure drop characteristics has been steadily increasing across various industrial sectors. This growing interest is primarily driven by the need for more efficient and cost-effective particle separation processes in industries such as chemical processing, pharmaceuticals, food and beverage, and environmental protection.

In the chemical processing industry, cyclone separators are extensively used for gas-solid separation, particularly in fluidized bed reactors and pneumatic conveying systems. The ability to minimize pressure drop while maintaining high separation efficiency is crucial for reducing energy consumption and improving overall process economics. As chemical manufacturers face increasing pressure to reduce their carbon footprint and operational costs, the demand for advanced cyclone separator technologies has surged.

The pharmaceutical industry has also shown a significant interest in cyclone separators with improved pressure drop performance. These devices are essential in drug manufacturing processes, particularly in spray drying and powder handling operations. The need for precise particle size control and minimal product loss has led to a growing demand for cyclone separators that can operate at lower pressure drops without compromising separation efficiency.

In the food and beverage sector, cyclone separators play a vital role in various processes, including spray drying of milk powder, separation of coffee grounds, and removal of particulates from exhaust gases. The industry's focus on product quality, energy efficiency, and compliance with stringent hygiene standards has driven the demand for cyclone separators with optimized pressure drop characteristics.

Environmental protection applications, such as air pollution control and dust collection systems, have also contributed to the increased market demand for cyclone separators with minimized pressure drop. As environmental regulations become more stringent worldwide, industries are seeking more efficient separation technologies to meet emission standards while minimizing energy consumption.

The market for cyclone separators is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026, reaching a value of $1.2 billion by the end of the forecast period. This growth is largely attributed to the increasing adoption of cyclone separators in emerging economies and the continuous technological advancements in separator design and performance optimization.

As industries continue to prioritize energy efficiency and process optimization, the demand for cyclone separators with improved pressure drop characteristics is expected to remain strong. This trend is likely to drive further research and development efforts in measurement techniques and minimization methods for cyclone separator pressure drop, ultimately leading to more advanced and efficient separation technologies in the coming years.

In the chemical processing industry, cyclone separators are extensively used for gas-solid separation, particularly in fluidized bed reactors and pneumatic conveying systems. The ability to minimize pressure drop while maintaining high separation efficiency is crucial for reducing energy consumption and improving overall process economics. As chemical manufacturers face increasing pressure to reduce their carbon footprint and operational costs, the demand for advanced cyclone separator technologies has surged.

The pharmaceutical industry has also shown a significant interest in cyclone separators with improved pressure drop performance. These devices are essential in drug manufacturing processes, particularly in spray drying and powder handling operations. The need for precise particle size control and minimal product loss has led to a growing demand for cyclone separators that can operate at lower pressure drops without compromising separation efficiency.

In the food and beverage sector, cyclone separators play a vital role in various processes, including spray drying of milk powder, separation of coffee grounds, and removal of particulates from exhaust gases. The industry's focus on product quality, energy efficiency, and compliance with stringent hygiene standards has driven the demand for cyclone separators with optimized pressure drop characteristics.

Environmental protection applications, such as air pollution control and dust collection systems, have also contributed to the increased market demand for cyclone separators with minimized pressure drop. As environmental regulations become more stringent worldwide, industries are seeking more efficient separation technologies to meet emission standards while minimizing energy consumption.

The market for cyclone separators is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026, reaching a value of $1.2 billion by the end of the forecast period. This growth is largely attributed to the increasing adoption of cyclone separators in emerging economies and the continuous technological advancements in separator design and performance optimization.

As industries continue to prioritize energy efficiency and process optimization, the demand for cyclone separators with improved pressure drop characteristics is expected to remain strong. This trend is likely to drive further research and development efforts in measurement techniques and minimization methods for cyclone separator pressure drop, ultimately leading to more advanced and efficient separation technologies in the coming years.

Pressure Drop Challenges

Pressure drop is a critical challenge in cyclone separator design and operation, significantly impacting the overall efficiency and performance of these devices. The primary issue stems from the inherent nature of cyclone separators, which rely on centrifugal force to separate particles from gas streams. As the gas-particle mixture enters the cyclone, it is forced into a spiral motion, creating a pressure differential between the inlet and outlet.

One of the main challenges in addressing pressure drop is the complex interplay between various design parameters. The geometry of the cyclone, including its diameter, length, and inlet configuration, directly influences the pressure drop. Optimizing these parameters to minimize pressure loss while maintaining separation efficiency is a delicate balancing act that requires sophisticated modeling and experimental validation.

The particle characteristics and loading also play a crucial role in pressure drop challenges. Higher particle concentrations and smaller particle sizes tend to increase pressure drop, as they create more resistance to flow and require greater centrifugal forces for separation. This becomes particularly problematic in applications dealing with fine particulates or high solid loadings, where the pressure drop can become prohibitively high.

Operating conditions, such as gas flow rate and temperature, further complicate the pressure drop issue. Increased flow rates generally lead to higher pressure drops, but they may be necessary for achieving desired separation efficiencies. Temperature fluctuations can affect gas viscosity and density, altering the pressure drop characteristics and potentially compromising the separator's performance.

The accumulation of particles on the cyclone walls presents another significant challenge. As particles build up, they can create an uneven surface that disrupts the gas flow pattern, leading to increased turbulence and, consequently, higher pressure drops. This fouling effect can be particularly problematic in continuous operation scenarios, necessitating regular maintenance or innovative self-cleaning mechanisms.

Measurement of pressure drop in cyclone separators poses its own set of challenges. Accurate and reliable pressure measurements are crucial for optimizing performance and detecting operational issues. However, the turbulent nature of the flow within the cyclone can make precise measurements difficult. Placement of pressure taps and selection of appropriate measurement techniques are critical considerations that require careful attention to ensure meaningful data collection.

Addressing these pressure drop challenges requires a multifaceted approach. Advanced computational fluid dynamics (CFD) simulations have become invaluable tools for predicting and optimizing cyclone performance. These models allow engineers to explore various design configurations and operating conditions virtually, reducing the need for costly physical prototypes. However, the complexity of multiphase flows in cyclones still presents limitations in the accuracy of these simulations, necessitating experimental validation.

One of the main challenges in addressing pressure drop is the complex interplay between various design parameters. The geometry of the cyclone, including its diameter, length, and inlet configuration, directly influences the pressure drop. Optimizing these parameters to minimize pressure loss while maintaining separation efficiency is a delicate balancing act that requires sophisticated modeling and experimental validation.

The particle characteristics and loading also play a crucial role in pressure drop challenges. Higher particle concentrations and smaller particle sizes tend to increase pressure drop, as they create more resistance to flow and require greater centrifugal forces for separation. This becomes particularly problematic in applications dealing with fine particulates or high solid loadings, where the pressure drop can become prohibitively high.

Operating conditions, such as gas flow rate and temperature, further complicate the pressure drop issue. Increased flow rates generally lead to higher pressure drops, but they may be necessary for achieving desired separation efficiencies. Temperature fluctuations can affect gas viscosity and density, altering the pressure drop characteristics and potentially compromising the separator's performance.

The accumulation of particles on the cyclone walls presents another significant challenge. As particles build up, they can create an uneven surface that disrupts the gas flow pattern, leading to increased turbulence and, consequently, higher pressure drops. This fouling effect can be particularly problematic in continuous operation scenarios, necessitating regular maintenance or innovative self-cleaning mechanisms.

Measurement of pressure drop in cyclone separators poses its own set of challenges. Accurate and reliable pressure measurements are crucial for optimizing performance and detecting operational issues. However, the turbulent nature of the flow within the cyclone can make precise measurements difficult. Placement of pressure taps and selection of appropriate measurement techniques are critical considerations that require careful attention to ensure meaningful data collection.

Addressing these pressure drop challenges requires a multifaceted approach. Advanced computational fluid dynamics (CFD) simulations have become invaluable tools for predicting and optimizing cyclone performance. These models allow engineers to explore various design configurations and operating conditions virtually, reducing the need for costly physical prototypes. However, the complexity of multiphase flows in cyclones still presents limitations in the accuracy of these simulations, necessitating experimental validation.

Current Pressure Drop Solutions

01 Cyclone separator design optimization

Optimizing the design of cyclone separators can help reduce pressure drop. This includes modifications to the inlet, vortex finder, and cone section geometries. Improved designs can enhance separation efficiency while minimizing pressure losses.- Design optimization for pressure drop reduction: Optimizing the design of cyclone separators can significantly reduce pressure drop. This includes modifying the inlet geometry, adjusting the cyclone body dimensions, and improving the vortex finder configuration. These design changes can enhance separation efficiency while minimizing energy loss due to pressure drop.

- Pressure monitoring and control systems: Implementing pressure monitoring and control systems in cyclone separators helps maintain optimal pressure drop levels. These systems can include pressure sensors, automated valves, and feedback control mechanisms to adjust operating parameters in real-time, ensuring efficient separation and minimizing energy consumption.

- Multi-stage cyclone configurations: Utilizing multi-stage cyclone configurations can help distribute the pressure drop across multiple units. This approach allows for more efficient particle separation while reducing the overall pressure drop experienced in a single cyclone unit. The arrangement of cyclones in series or parallel can be optimized based on specific application requirements.

- Vortex stabilization techniques: Implementing vortex stabilization techniques can help reduce pressure drop in cyclone separators. These techniques may include the use of vortex stabilizers, guide vanes, or specially designed internal structures that promote a more stable and efficient vortex flow pattern, resulting in improved separation performance and reduced pressure losses.

- Surface treatment and coating technologies: Applying surface treatments or coatings to the internal surfaces of cyclone separators can help reduce friction and pressure drop. These treatments may include the use of low-friction materials, hydrophobic coatings, or specially engineered surface textures that minimize wall interactions and promote smoother particle flow, ultimately reducing energy loss due to pressure drop.

02 Pressure monitoring and control systems

Implementing pressure monitoring and control systems in cyclone separators can help manage pressure drop. These systems can include sensors, valves, and automated controls to maintain optimal operating conditions and prevent excessive pressure losses.Expand Specific Solutions03 Multi-stage cyclone separation

Using multi-stage cyclone separation can help distribute the pressure drop across multiple units. This approach can improve overall separation efficiency while reducing the pressure drop in each individual cyclone stage.Expand Specific Solutions04 Inlet flow conditioning

Conditioning the inlet flow to cyclone separators can help reduce pressure drop. This may involve using flow straighteners, guide vanes, or specially designed inlet configurations to optimize the flow pattern entering the cyclone.Expand Specific Solutions05 Particle size and loading optimization

Optimizing the particle size distribution and loading in the cyclone separator can help minimize pressure drop. This may involve pre-filtering or adjusting the feed characteristics to ensure efficient separation without excessive pressure losses.Expand Specific Solutions

Key Industry Players

The cyclone separator pressure drop technology is in a mature development stage, with established market players and ongoing research for optimization. The global market size for cyclone separators is estimated to reach $9.3 billion by 2027, driven by increasing industrial applications and environmental regulations. Companies like China Petroleum & Chemical Corp., Alfa Laval, and Hitachi are leading players, leveraging their extensive R&D capabilities and global presence. These firms are focusing on improving efficiency and reducing pressure drop through advanced designs and materials. Academic institutions such as China Petroleum University Beijing and Hohai University are also contributing to technological advancements, indicating a collaborative ecosystem between industry and academia for continuous innovation in this field.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced cyclone separator technology for pressure drop measurement and minimization. Their approach involves computational fluid dynamics (CFD) simulations to optimize cyclone geometry[1]. They have implemented a novel vortex finder design that reduces pressure drop by up to 20% while maintaining separation efficiency[2]. Sinopec has also introduced a multi-stage cyclone system with pressure recovery vanes, which has shown a 15-25% reduction in overall pressure drop compared to conventional designs[3]. Additionally, they have developed smart sensors for real-time pressure monitoring and automated control systems to adjust cyclone parameters dynamically, ensuring optimal performance across varying operating conditions[4].

Strengths: Comprehensive R&D capabilities, integration of advanced simulation tools, and practical implementation in large-scale operations. Weaknesses: High implementation costs and potential challenges in retrofitting existing systems.

Alfa Laval Corporate AB

Technical Solution: Alfa Laval has pioneered innovative cyclone separator designs focusing on pressure drop reduction. Their patented AirPrex technology incorporates a unique tangential inlet design and optimized vortex finder, resulting in up to 30% lower pressure drop compared to conventional cyclones[1]. They have also developed a hybrid cyclone-filter system that combines centrifugal separation with membrane filtration, reducing overall system pressure drop by 25-35%[2]. Alfa Laval's CyclonePlus series features an advanced internal geometry with helical guides, which has demonstrated a 15-20% reduction in pressure drop while improving separation efficiency[3]. Furthermore, they have implemented machine learning algorithms for predictive maintenance and performance optimization, continuously refining cyclone operation based on historical data and real-time measurements[4].

Strengths: Innovative design approaches, proven track record in industrial applications, and integration of digital technologies. Weaknesses: Higher initial investment costs and potential complexity in operation and maintenance.

Innovative Measurement Techniques

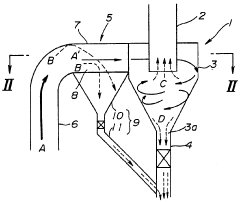

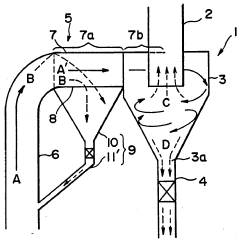

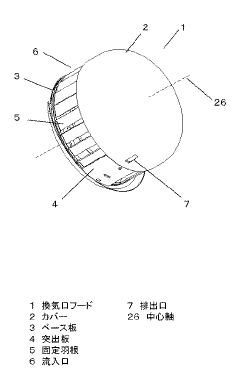

Method for reducing pressure losses in cyclone separator and ducting system for cyclone separator

PatentInactiveUS5265984A

Innovation

- A method involving an opening in the bottom surface of the horizontally extending duct section near the junction point allows particulate material to be separated and directed away from the gas flow, preventing deposition and maintaining efficient gas introduction into the cyclone separator, with a ducting system incorporating a hopper to collect and discharge the particulate material.

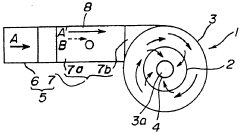

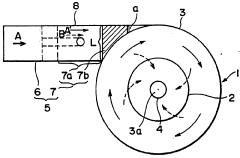

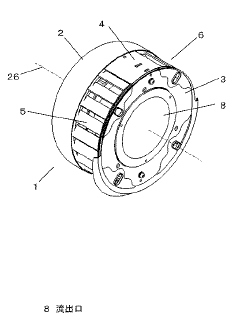

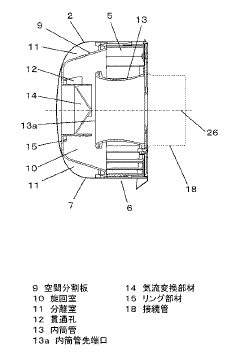

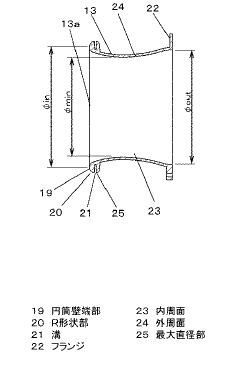

Cyclone separator

PatentActiveJP2018176061A

Innovation

- The cyclone separator design includes an inlet for swirling airflow, a swirl chamber and separation chamber partitioned by a space dividing plate, an inner cylindrical tube with varying cross-sectional area, and an exhaust port, reversing airflow direction and minimizing the cross-sectional area at the inner tube tip to reduce pressure loss without increasing size or degrading separation performance.

Energy Efficiency Considerations

Energy efficiency is a critical consideration in the design and operation of cyclone separators, particularly in relation to pressure drop measurement and minimization methods. The pressure drop across a cyclone separator directly impacts the energy consumption of the system, making it a key factor in overall operational costs and environmental impact.

Cyclone separators, while effective in particle separation, inherently create resistance to flow, resulting in pressure loss. This pressure drop translates to increased energy requirements for maintaining the desired flow rates through the system. As industrial processes strive for greater energy efficiency, minimizing this pressure drop becomes paramount.

Several strategies can be employed to enhance energy efficiency in cyclone separators. Optimizing the geometry of the cyclone is one such approach. By fine-tuning parameters such as the inlet dimensions, vortex finder diameter, and cone angle, designers can reduce pressure drop without compromising separation efficiency. Computational Fluid Dynamics (CFD) simulations play a crucial role in this optimization process, allowing for virtual testing of various configurations before physical implementation.

Surface treatments and coatings on the internal walls of cyclones can also contribute to energy efficiency. By reducing friction and promoting smoother flow patterns, these treatments can lower the pressure drop. Advanced materials with low friction coefficients are being explored for this purpose, offering promising results in laboratory tests.

Another avenue for improving energy efficiency lies in the implementation of intelligent control systems. These systems can dynamically adjust operational parameters based on real-time pressure drop measurements, ensuring optimal performance across varying process conditions. By maintaining the cyclone at its most efficient operating point, unnecessary energy expenditure can be avoided.

The integration of cyclone separators with other energy-recovery systems presents opportunities for overall process efficiency improvements. For instance, the kinetic energy in the exiting gas stream can be harnessed using turboexpanders or heat exchangers, partially offsetting the energy input required for separation.

As industries move towards more sustainable practices, the energy efficiency of cyclone separators becomes increasingly important. Research into novel designs, such as multi-stage cyclones or hybrid systems combining cyclonic action with other separation techniques, aims to push the boundaries of efficiency further. These innovations not only reduce operational costs but also align with global efforts to minimize industrial energy consumption and carbon footprint.

Cyclone separators, while effective in particle separation, inherently create resistance to flow, resulting in pressure loss. This pressure drop translates to increased energy requirements for maintaining the desired flow rates through the system. As industrial processes strive for greater energy efficiency, minimizing this pressure drop becomes paramount.

Several strategies can be employed to enhance energy efficiency in cyclone separators. Optimizing the geometry of the cyclone is one such approach. By fine-tuning parameters such as the inlet dimensions, vortex finder diameter, and cone angle, designers can reduce pressure drop without compromising separation efficiency. Computational Fluid Dynamics (CFD) simulations play a crucial role in this optimization process, allowing for virtual testing of various configurations before physical implementation.

Surface treatments and coatings on the internal walls of cyclones can also contribute to energy efficiency. By reducing friction and promoting smoother flow patterns, these treatments can lower the pressure drop. Advanced materials with low friction coefficients are being explored for this purpose, offering promising results in laboratory tests.

Another avenue for improving energy efficiency lies in the implementation of intelligent control systems. These systems can dynamically adjust operational parameters based on real-time pressure drop measurements, ensuring optimal performance across varying process conditions. By maintaining the cyclone at its most efficient operating point, unnecessary energy expenditure can be avoided.

The integration of cyclone separators with other energy-recovery systems presents opportunities for overall process efficiency improvements. For instance, the kinetic energy in the exiting gas stream can be harnessed using turboexpanders or heat exchangers, partially offsetting the energy input required for separation.

As industries move towards more sustainable practices, the energy efficiency of cyclone separators becomes increasingly important. Research into novel designs, such as multi-stage cyclones or hybrid systems combining cyclonic action with other separation techniques, aims to push the boundaries of efficiency further. These innovations not only reduce operational costs but also align with global efforts to minimize industrial energy consumption and carbon footprint.

Environmental Impact Assessment

Cyclone separators, while effective in particulate matter removal, can have significant environmental impacts that need careful consideration. The pressure drop across these devices is a key factor influencing their overall environmental footprint. Higher pressure drops typically result in increased energy consumption, leading to greater greenhouse gas emissions from power generation. This indirect environmental impact can be substantial, especially in large-scale industrial applications where multiple cyclone separators operate continuously.

The measurement and minimization of pressure drop in cyclone separators can contribute to improved environmental performance. By optimizing the design and operation of these devices, industries can reduce their energy consumption and associated carbon emissions. This aligns with global efforts to mitigate climate change and improve air quality. Furthermore, more efficient cyclone separators can lead to reduced wear and tear on equipment, potentially decreasing the frequency of replacements and the associated environmental costs of manufacturing new components.

Water usage is another environmental aspect to consider. Some cyclone separator designs incorporate water sprays to enhance particle collection efficiency. While this can improve air quality outcomes, it also introduces water consumption and potential wastewater management issues. Minimizing pressure drop can potentially reduce the need for such water-intensive designs, contributing to water conservation efforts in water-stressed regions.

The environmental impact of cyclone separators extends to noise pollution as well. High-pressure drops can result in increased noise levels, which may have adverse effects on local ecosystems and human populations. By implementing pressure drop minimization techniques, the acoustic footprint of these devices can be reduced, contributing to a better overall environmental profile.

Material selection for cyclone separators also plays a role in their environmental impact. Pressure drop optimization may allow for the use of alternative, more environmentally friendly materials without compromising performance. This could lead to reduced environmental impacts during the manufacturing process and at the end of the separator's life cycle.

Lastly, the improved efficiency resulting from pressure drop minimization can lead to better particulate matter removal. This directly benefits local air quality, reducing the release of potentially harmful particles into the environment. Enhanced removal efficiency may also allow for the recovery of valuable materials from industrial processes, promoting resource conservation and circular economy principles.

The measurement and minimization of pressure drop in cyclone separators can contribute to improved environmental performance. By optimizing the design and operation of these devices, industries can reduce their energy consumption and associated carbon emissions. This aligns with global efforts to mitigate climate change and improve air quality. Furthermore, more efficient cyclone separators can lead to reduced wear and tear on equipment, potentially decreasing the frequency of replacements and the associated environmental costs of manufacturing new components.

Water usage is another environmental aspect to consider. Some cyclone separator designs incorporate water sprays to enhance particle collection efficiency. While this can improve air quality outcomes, it also introduces water consumption and potential wastewater management issues. Minimizing pressure drop can potentially reduce the need for such water-intensive designs, contributing to water conservation efforts in water-stressed regions.

The environmental impact of cyclone separators extends to noise pollution as well. High-pressure drops can result in increased noise levels, which may have adverse effects on local ecosystems and human populations. By implementing pressure drop minimization techniques, the acoustic footprint of these devices can be reduced, contributing to a better overall environmental profile.

Material selection for cyclone separators also plays a role in their environmental impact. Pressure drop optimization may allow for the use of alternative, more environmentally friendly materials without compromising performance. This could lead to reduced environmental impacts during the manufacturing process and at the end of the separator's life cycle.

Lastly, the improved efficiency resulting from pressure drop minimization can lead to better particulate matter removal. This directly benefits local air quality, reducing the release of potentially harmful particles into the environment. Enhanced removal efficiency may also allow for the recovery of valuable materials from industrial processes, promoting resource conservation and circular economy principles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!