How To Optimize Cyclone Separator Geometry For Fine Particles

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Evolution and Objectives

Cyclone separators have been a cornerstone of industrial particle separation for over a century, evolving significantly since their inception in the late 1800s. Initially designed for removing sawdust from air in woodworking shops, these devices have found widespread applications across various industries, including chemical processing, mining, and environmental protection.

The evolution of cyclone separators has been driven by the increasing demand for more efficient and cost-effective particle separation methods, particularly for fine particles. Early designs focused on basic separation principles, utilizing centrifugal force to separate particles from gas streams. However, as industrial processes became more complex and environmental regulations more stringent, the need for improved performance in handling smaller particle sizes became apparent.

Throughout the 20th century, researchers and engineers made significant strides in understanding the fluid dynamics within cyclone separators. This led to the development of more sophisticated geometries and design modifications aimed at enhancing separation efficiency, reducing pressure drop, and minimizing wear. The advent of computational fluid dynamics (CFD) in the latter part of the century revolutionized cyclone design, allowing for more precise optimization of geometric parameters.

In recent years, the focus has shifted towards optimizing cyclone separators for fine particle separation, a challenging task due to the complex interplay between particle size, gas flow patterns, and separator geometry. This optimization effort is crucial for industries dealing with submicron particles, where traditional cyclone designs often fall short in terms of collection efficiency.

The primary objectives in cyclone separator evolution for fine particles include:

1. Enhancing collection efficiency for particles smaller than 10 microns

2. Reducing pressure drop to minimize energy consumption

3. Improving the overall separation performance across a wide range of particle sizes

4. Developing designs that are less prone to fouling and easier to maintain

5. Creating more compact and versatile separators for space-constrained applications

To achieve these objectives, researchers are exploring various avenues, including novel inlet designs, body shape modifications, and the integration of secondary flow patterns. Additionally, there is growing interest in hybrid systems that combine cyclone separators with other separation technologies to tackle the challenges posed by fine particles.

As we move forward, the evolution of cyclone separators continues to be driven by the need for more efficient and sustainable industrial processes. The ongoing research in this field aims to push the boundaries of particle separation technology, paving the way for next-generation cyclone designs capable of meeting the increasingly demanding requirements of modern industries.

The evolution of cyclone separators has been driven by the increasing demand for more efficient and cost-effective particle separation methods, particularly for fine particles. Early designs focused on basic separation principles, utilizing centrifugal force to separate particles from gas streams. However, as industrial processes became more complex and environmental regulations more stringent, the need for improved performance in handling smaller particle sizes became apparent.

Throughout the 20th century, researchers and engineers made significant strides in understanding the fluid dynamics within cyclone separators. This led to the development of more sophisticated geometries and design modifications aimed at enhancing separation efficiency, reducing pressure drop, and minimizing wear. The advent of computational fluid dynamics (CFD) in the latter part of the century revolutionized cyclone design, allowing for more precise optimization of geometric parameters.

In recent years, the focus has shifted towards optimizing cyclone separators for fine particle separation, a challenging task due to the complex interplay between particle size, gas flow patterns, and separator geometry. This optimization effort is crucial for industries dealing with submicron particles, where traditional cyclone designs often fall short in terms of collection efficiency.

The primary objectives in cyclone separator evolution for fine particles include:

1. Enhancing collection efficiency for particles smaller than 10 microns

2. Reducing pressure drop to minimize energy consumption

3. Improving the overall separation performance across a wide range of particle sizes

4. Developing designs that are less prone to fouling and easier to maintain

5. Creating more compact and versatile separators for space-constrained applications

To achieve these objectives, researchers are exploring various avenues, including novel inlet designs, body shape modifications, and the integration of secondary flow patterns. Additionally, there is growing interest in hybrid systems that combine cyclone separators with other separation technologies to tackle the challenges posed by fine particles.

As we move forward, the evolution of cyclone separators continues to be driven by the need for more efficient and sustainable industrial processes. The ongoing research in this field aims to push the boundaries of particle separation technology, paving the way for next-generation cyclone designs capable of meeting the increasingly demanding requirements of modern industries.

Fine Particle Separation Market Analysis

The fine particle separation market has been experiencing significant growth in recent years, driven by increasing industrial applications and environmental regulations. The global market for cyclone separators, a key technology in fine particle separation, is projected to reach substantial value by 2025, with a compound annual growth rate exceeding 5% during the forecast period.

The demand for efficient fine particle separation technologies is particularly strong in industries such as pharmaceuticals, food processing, and chemical manufacturing. These sectors require high-precision separation processes to ensure product quality and meet stringent regulatory standards. Additionally, the growing focus on air quality control and emission reduction in various industrial processes has further boosted the market for advanced cyclone separators.

In the energy sector, the shift towards cleaner energy sources has created new opportunities for fine particle separation technologies. Coal-fired power plants are increasingly adopting advanced cyclone separators to reduce particulate emissions and comply with stricter environmental regulations. Similarly, the oil and gas industry is utilizing cyclone separators for gas-liquid separation and sand removal in offshore operations.

The Asia-Pacific region is emerging as a key market for fine particle separation technologies, driven by rapid industrialization and urbanization in countries like China and India. These nations are implementing stricter air quality standards, necessitating the adoption of advanced separation technologies across various industries. North America and Europe continue to be significant markets, with a focus on upgrading existing facilities and implementing more efficient separation systems.

Technological advancements in cyclone separator design are shaping market trends. Manufacturers are developing innovative geometries and materials to enhance separation efficiency for fine particles. There is a growing demand for compact, high-efficiency cyclone separators that can handle a wide range of particle sizes and flow rates. Additionally, the integration of smart sensors and control systems in cyclone separators is gaining traction, allowing for real-time monitoring and optimization of separation processes.

The market is also witnessing a shift towards modular and customizable cyclone separator systems. This trend is driven by the need for flexible solutions that can be easily adapted to different industrial processes and space constraints. Furthermore, there is an increasing focus on developing cyclone separators with lower pressure drops, which can significantly reduce energy consumption and operating costs for end-users.

The demand for efficient fine particle separation technologies is particularly strong in industries such as pharmaceuticals, food processing, and chemical manufacturing. These sectors require high-precision separation processes to ensure product quality and meet stringent regulatory standards. Additionally, the growing focus on air quality control and emission reduction in various industrial processes has further boosted the market for advanced cyclone separators.

In the energy sector, the shift towards cleaner energy sources has created new opportunities for fine particle separation technologies. Coal-fired power plants are increasingly adopting advanced cyclone separators to reduce particulate emissions and comply with stricter environmental regulations. Similarly, the oil and gas industry is utilizing cyclone separators for gas-liquid separation and sand removal in offshore operations.

The Asia-Pacific region is emerging as a key market for fine particle separation technologies, driven by rapid industrialization and urbanization in countries like China and India. These nations are implementing stricter air quality standards, necessitating the adoption of advanced separation technologies across various industries. North America and Europe continue to be significant markets, with a focus on upgrading existing facilities and implementing more efficient separation systems.

Technological advancements in cyclone separator design are shaping market trends. Manufacturers are developing innovative geometries and materials to enhance separation efficiency for fine particles. There is a growing demand for compact, high-efficiency cyclone separators that can handle a wide range of particle sizes and flow rates. Additionally, the integration of smart sensors and control systems in cyclone separators is gaining traction, allowing for real-time monitoring and optimization of separation processes.

The market is also witnessing a shift towards modular and customizable cyclone separator systems. This trend is driven by the need for flexible solutions that can be easily adapted to different industrial processes and space constraints. Furthermore, there is an increasing focus on developing cyclone separators with lower pressure drops, which can significantly reduce energy consumption and operating costs for end-users.

Current Cyclone Geometry Limitations

Cyclone separators have been widely used in various industries for particle separation, but their efficiency in handling fine particles remains a significant challenge. The current limitations of cyclone geometry primarily stem from the complex interplay between fluid dynamics and particle behavior within the separator.

One of the main constraints is the trade-off between separation efficiency and pressure drop. Traditional cyclone designs often struggle to maintain high separation efficiency for fine particles without incurring excessive pressure losses. This limitation becomes particularly pronounced when dealing with particles smaller than 10 microns, as the centrifugal forces acting on these particles are often insufficient to overcome the drag forces exerted by the fluid flow.

The geometry of the inlet section presents another critical limitation. Conventional tangential inlets may not provide optimal flow distribution for fine particle separation, leading to reduced collection efficiency. The inlet velocity and its uniformity across the cyclone cross-section significantly impact the particle trajectory and, consequently, the separation performance.

The cone section of the cyclone also poses challenges for fine particle separation. The current designs may not effectively maintain the necessary centrifugal forces throughout the entire length of the cone, resulting in re-entrainment of already separated particles. This phenomenon is particularly problematic for fine particles, which are more susceptible to being carried upward by the ascending vortex.

Furthermore, the vortex finder geometry and its interaction with the main cyclone body create limitations in fine particle collection. The current designs may not adequately prevent short-circuiting of particles directly from the inlet to the vortex finder, bypassing the separation process entirely. This issue is exacerbated for fine particles due to their lower inertia and higher susceptibility to flow disturbances.

The dust collection and discharge mechanisms in existing cyclone designs also present limitations for fine particle handling. The current geometries may not effectively prevent re-entrainment of collected fine particles from the dust hopper back into the main flow, reducing overall separation efficiency.

Lastly, the scaling of cyclone separators for industrial applications while maintaining high efficiency for fine particles remains a significant challenge. The current geometric designs often fail to translate laboratory-scale performance to larger, industrial-scale units without compromising separation efficiency or incurring prohibitive pressure drops.

One of the main constraints is the trade-off between separation efficiency and pressure drop. Traditional cyclone designs often struggle to maintain high separation efficiency for fine particles without incurring excessive pressure losses. This limitation becomes particularly pronounced when dealing with particles smaller than 10 microns, as the centrifugal forces acting on these particles are often insufficient to overcome the drag forces exerted by the fluid flow.

The geometry of the inlet section presents another critical limitation. Conventional tangential inlets may not provide optimal flow distribution for fine particle separation, leading to reduced collection efficiency. The inlet velocity and its uniformity across the cyclone cross-section significantly impact the particle trajectory and, consequently, the separation performance.

The cone section of the cyclone also poses challenges for fine particle separation. The current designs may not effectively maintain the necessary centrifugal forces throughout the entire length of the cone, resulting in re-entrainment of already separated particles. This phenomenon is particularly problematic for fine particles, which are more susceptible to being carried upward by the ascending vortex.

Furthermore, the vortex finder geometry and its interaction with the main cyclone body create limitations in fine particle collection. The current designs may not adequately prevent short-circuiting of particles directly from the inlet to the vortex finder, bypassing the separation process entirely. This issue is exacerbated for fine particles due to their lower inertia and higher susceptibility to flow disturbances.

The dust collection and discharge mechanisms in existing cyclone designs also present limitations for fine particle handling. The current geometries may not effectively prevent re-entrainment of collected fine particles from the dust hopper back into the main flow, reducing overall separation efficiency.

Lastly, the scaling of cyclone separators for industrial applications while maintaining high efficiency for fine particles remains a significant challenge. The current geometric designs often fail to translate laboratory-scale performance to larger, industrial-scale units without compromising separation efficiency or incurring prohibitive pressure drops.

Existing Cyclone Optimization Techniques

01 Inlet design optimization

The geometry of the cyclone separator's inlet plays a crucial role in its efficiency. Optimizing the inlet design can improve particle separation and reduce pressure drop. This may involve adjusting the inlet angle, shape, or size to enhance the cyclonic flow and particle trajectory.- Inlet design and flow optimization: The geometry of the cyclone separator's inlet plays a crucial role in optimizing particle separation efficiency. Design features such as tangential or spiral inlets, along with carefully calculated inlet velocities, can enhance the centrifugal force and improve overall performance. Proper inlet design also helps in reducing pressure drop and preventing re-entrainment of separated particles.

- Cone and cylinder proportions: The dimensions and proportions of the cyclone separator's conical and cylindrical sections significantly impact its separation efficiency. Optimizing the length-to-diameter ratio of the cylindrical section and the angle of the conical section can enhance particle collection and reduce turbulence. These geometric considerations affect the residence time of particles and the strength of the vortex within the separator.

- Vortex finder design: The geometry of the vortex finder, including its length, diameter, and shape, is critical for maintaining the separation efficiency of the cyclone. Proper design of the vortex finder helps in preventing short-circuiting of particles and ensures that only cleaned gas exits through the top of the separator. Innovations in vortex finder geometry can lead to improved collection efficiency and reduced pressure drop.

- Multi-cyclone arrangements: Incorporating multiple cyclones in parallel or series configurations can enhance overall separation efficiency. The geometry of individual cyclones within these arrangements, as well as their spatial organization, affects the system's performance. Multi-cyclone designs can handle higher gas flow rates and achieve better particle size separation compared to single large cyclones.

- Dust collection and discharge systems: The geometry of the dust collection and discharge components at the bottom of the cyclone separator is crucial for maintaining separation efficiency. Design considerations include the shape and size of the dust hopper, the angle of the discharge cone, and the mechanism for removing collected particles. Proper design prevents re-entrainment of separated particles and ensures continuous operation of the cyclone separator.

02 Cone and cylinder proportions

The relative dimensions of the conical and cylindrical sections of a cyclone separator significantly impact its performance. Adjusting the length, diameter, and taper angle of these sections can optimize separation efficiency for different particle sizes and flow rates.Expand Specific Solutions03 Vortex finder configuration

The vortex finder, or outlet tube, is a critical component in cyclone separator geometry. Its length, diameter, and position within the separator can be optimized to enhance separation efficiency and reduce short-circuiting of particles to the outlet.Expand Specific Solutions04 Multi-stage cyclone arrangements

Implementing multiple cyclone stages or arranging cyclones in series or parallel can improve overall separation efficiency. The geometry of each stage can be tailored to target specific particle size ranges, enhancing the overall performance of the system.Expand Specific Solutions05 Internal flow guide structures

Incorporating internal structures such as helical guides, baffles, or deflectors within the cyclone separator can enhance particle separation. These structures can be designed to modify the flow pattern, increase residence time, or create secondary vortices to improve separation efficiency.Expand Specific Solutions

Key Cyclone Separator Manufacturers

The optimization of cyclone separator geometry for fine particles is a critical area of research in the field of particle separation technology. The industry is in a mature stage, with ongoing efforts to improve efficiency and performance. The global market for cyclone separators is substantial, driven by increasing industrial applications and environmental regulations. Technologically, the field is advancing, with companies like UOP LLC, ABB Stal AB, and Kvaerner Process Systems leading innovation. Academic institutions such as Huazhong University of Science & Technology and China Petroleum University Beijing are contributing significantly to research. The focus is on enhancing separation efficiency for fine particles through advanced computational modeling and experimental techniques, indicating a high level of technological sophistication in this domain.

UOP LLC

Technical Solution: UOP LLC has developed advanced cyclone separator designs optimized for fine particle separation. Their approach involves computational fluid dynamics (CFD) modeling to simulate particle trajectories and optimize the cyclone geometry. They have implemented a novel vortex finder design that enhances separation efficiency for particles below 10 microns[1]. UOP's cyclones feature a tapered body with an optimized inlet configuration to create a strong centrifugal force field. The company has also introduced a patented anti-re-entrainment baffle system that prevents fine particles from being re-entrained into the clean gas stream[2]. Additionally, UOP has developed multi-cyclone systems with optimized spacing and flow distribution to handle high throughput applications while maintaining separation performance for fine particles[3].

Strengths: Advanced CFD modeling capabilities, patented anti-re-entrainment technology, expertise in large-scale industrial applications. Weaknesses: Higher cost compared to conventional designs, may require more frequent maintenance due to complex geometry.

Dyson Technology Ltd.

Technical Solution: Dyson Technology Ltd. has pioneered innovative cyclone separator designs for fine particle removal in their vacuum cleaners and air purifiers. Their approach focuses on creating a series of small, high-efficiency cyclones arranged in a parallel configuration. This multi-cyclone system, known as Radial Root Cyclone™ technology, uses optimized cyclone geometry to generate powerful centrifugal forces for separating fine dust particles[1]. Dyson's cyclones feature a narrow, elongated conical shape with a carefully calculated taper angle to maximize particle separation efficiency. They have also developed a unique air inlet design that creates a high-velocity spinning airflow, enhancing the centrifugal effect[2]. Additionally, Dyson has implemented advanced manufacturing techniques to produce cyclones with extremely smooth internal surfaces, reducing particle adhesion and improving overall performance[3].

Strengths: Expertise in compact, high-efficiency cyclone designs, proven technology in consumer products. Weaknesses: May not be directly applicable to large-scale industrial applications, limited experience with very fine particles (<1 micron).

Innovative Cyclone Geometry Patents

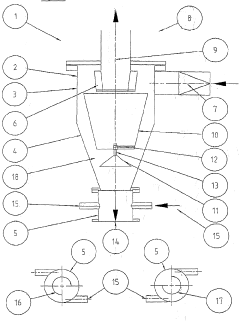

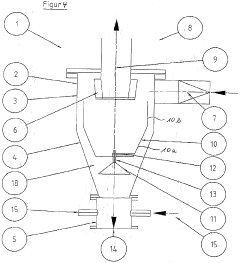

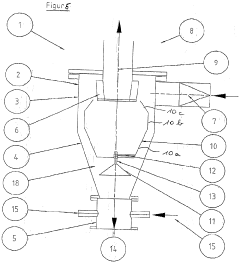

Cyclone separator with central built-in element

PatentInactiveEP1294488A1

Innovation

- A cyclone separator with a central, conically installed component forming a defined gap with the housing, allowing for controlled flow control and adjustable gap size to influence particle size distribution, enhancing classification properties and enabling specific control over fines content.

Cyclone separator with central built-in element

PatentWO2001097976A1

Innovation

- A cyclone separator with a conical installation forming a defined gap with the housing, allowing for controlled flow control and adjustable gap size to influence particle size distribution, enhancing classification properties and enabling specific control over fines content.

CFD Simulation in Cyclone Design

Computational Fluid Dynamics (CFD) simulation has become an indispensable tool in the design and optimization of cyclone separators for fine particle separation. This advanced numerical technique allows engineers to model and analyze the complex fluid flow patterns and particle trajectories within cyclone geometries, providing valuable insights into separator performance without the need for extensive physical prototyping.

CFD simulations in cyclone design typically involve solving the Navier-Stokes equations coupled with particle tracking models. The Reynolds-Averaged Navier-Stokes (RANS) approach, combined with appropriate turbulence models such as k-ε or Reynolds Stress Model (RSM), is commonly employed to capture the turbulent flow characteristics within the cyclone. For more accurate predictions of particle behavior, Lagrangian particle tracking methods are often integrated into the CFD framework.

One of the key advantages of CFD in cyclone optimization is the ability to perform parametric studies efficiently. By systematically varying geometric parameters such as inlet dimensions, vortex finder length, and cone angle, researchers can evaluate their impact on separation efficiency and pressure drop. This approach enables the identification of optimal cyclone configurations for specific operating conditions and particle size distributions.

Recent advancements in CFD techniques have further enhanced the accuracy and applicability of simulations in cyclone design. Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) methods, although computationally intensive, offer improved predictions of turbulent flow structures and particle-fluid interactions. These high-fidelity simulations can reveal intricate flow phenomena, such as the formation of secondary vortices and their influence on particle separation.

Moreover, CFD simulations facilitate the investigation of novel cyclone designs and modifications. For instance, researchers have used CFD to study the effects of adding guide vanes, multiple inlets, or helical roof sections on cyclone performance. These virtual experiments provide valuable insights into potential design improvements without the need for costly physical prototypes.

The integration of CFD with optimization algorithms has opened new avenues for cyclone design. Techniques such as genetic algorithms, response surface methodology, and artificial neural networks can be coupled with CFD simulations to automate the search for optimal cyclone geometries. This approach allows for the exploration of a vast design space and the identification of non-intuitive solutions that may outperform conventional designs.

CFD simulations in cyclone design typically involve solving the Navier-Stokes equations coupled with particle tracking models. The Reynolds-Averaged Navier-Stokes (RANS) approach, combined with appropriate turbulence models such as k-ε or Reynolds Stress Model (RSM), is commonly employed to capture the turbulent flow characteristics within the cyclone. For more accurate predictions of particle behavior, Lagrangian particle tracking methods are often integrated into the CFD framework.

One of the key advantages of CFD in cyclone optimization is the ability to perform parametric studies efficiently. By systematically varying geometric parameters such as inlet dimensions, vortex finder length, and cone angle, researchers can evaluate their impact on separation efficiency and pressure drop. This approach enables the identification of optimal cyclone configurations for specific operating conditions and particle size distributions.

Recent advancements in CFD techniques have further enhanced the accuracy and applicability of simulations in cyclone design. Large Eddy Simulation (LES) and Direct Numerical Simulation (DNS) methods, although computationally intensive, offer improved predictions of turbulent flow structures and particle-fluid interactions. These high-fidelity simulations can reveal intricate flow phenomena, such as the formation of secondary vortices and their influence on particle separation.

Moreover, CFD simulations facilitate the investigation of novel cyclone designs and modifications. For instance, researchers have used CFD to study the effects of adding guide vanes, multiple inlets, or helical roof sections on cyclone performance. These virtual experiments provide valuable insights into potential design improvements without the need for costly physical prototypes.

The integration of CFD with optimization algorithms has opened new avenues for cyclone design. Techniques such as genetic algorithms, response surface methodology, and artificial neural networks can be coupled with CFD simulations to automate the search for optimal cyclone geometries. This approach allows for the exploration of a vast design space and the identification of non-intuitive solutions that may outperform conventional designs.

Environmental Impact of Cyclones

Cyclone separators, widely used in industrial processes for particle removal, have significant environmental implications. These devices play a crucial role in reducing particulate emissions, thereby mitigating air pollution and its associated health risks. By efficiently separating fine particles from gas streams, cyclones contribute to improved air quality in industrial settings and surrounding communities.

The environmental impact of cyclones extends beyond air quality improvement. Their use in various industries, such as power generation, cement production, and chemical processing, helps these sectors comply with stringent environmental regulations. This compliance not only reduces the ecological footprint of industrial operations but also promotes sustainable manufacturing practices.

Cyclone separators are particularly effective in capturing fine particles, which are often the most harmful to human health and the environment. By removing these particles from exhaust gases, cyclones prevent their release into the atmosphere, where they could contribute to respiratory issues, visibility reduction, and climate change effects. The efficiency of cyclones in capturing fine particles is crucial for minimizing the environmental impact of industrial processes.

Moreover, the use of cyclone separators can lead to resource conservation. In many industries, the particles separated by cyclones are valuable materials that can be recycled or reused. This recovery process not only reduces waste but also decreases the demand for raw materials, contributing to overall resource efficiency and sustainability.

The environmental benefits of cyclones are further enhanced by their relatively low energy consumption compared to other particle separation technologies. This energy efficiency translates to reduced carbon emissions associated with the operation of pollution control systems, aligning with global efforts to combat climate change.

However, the environmental impact of cyclones is not without challenges. The disposal of collected particles, especially those containing hazardous materials, requires careful management to prevent secondary pollution. Additionally, the optimization of cyclone geometry for fine particles is crucial to maximize their environmental benefits while minimizing potential negative impacts.

In conclusion, cyclone separators play a vital role in environmental protection by effectively removing fine particles from industrial emissions. Their widespread adoption contributes significantly to air quality improvement, resource conservation, and sustainable industrial practices. As research continues to optimize cyclone performance for fine particles, their positive environmental impact is expected to further increase, supporting global efforts towards cleaner and more sustainable industrial operations.

The environmental impact of cyclones extends beyond air quality improvement. Their use in various industries, such as power generation, cement production, and chemical processing, helps these sectors comply with stringent environmental regulations. This compliance not only reduces the ecological footprint of industrial operations but also promotes sustainable manufacturing practices.

Cyclone separators are particularly effective in capturing fine particles, which are often the most harmful to human health and the environment. By removing these particles from exhaust gases, cyclones prevent their release into the atmosphere, where they could contribute to respiratory issues, visibility reduction, and climate change effects. The efficiency of cyclones in capturing fine particles is crucial for minimizing the environmental impact of industrial processes.

Moreover, the use of cyclone separators can lead to resource conservation. In many industries, the particles separated by cyclones are valuable materials that can be recycled or reused. This recovery process not only reduces waste but also decreases the demand for raw materials, contributing to overall resource efficiency and sustainability.

The environmental benefits of cyclones are further enhanced by their relatively low energy consumption compared to other particle separation technologies. This energy efficiency translates to reduced carbon emissions associated with the operation of pollution control systems, aligning with global efforts to combat climate change.

However, the environmental impact of cyclones is not without challenges. The disposal of collected particles, especially those containing hazardous materials, requires careful management to prevent secondary pollution. Additionally, the optimization of cyclone geometry for fine particles is crucial to maximize their environmental benefits while minimizing potential negative impacts.

In conclusion, cyclone separators play a vital role in environmental protection by effectively removing fine particles from industrial emissions. Their widespread adoption contributes significantly to air quality improvement, resource conservation, and sustainable industrial practices. As research continues to optimize cyclone performance for fine particles, their positive environmental impact is expected to further increase, supporting global efforts towards cleaner and more sustainable industrial operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!