How To Implement Emission Monitoring For Cyclone Separator Lines

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Emission Monitoring Background

Cyclone separators have been widely used in industrial processes for decades, primarily for separating particulate matter from gas streams. As environmental regulations have become increasingly stringent, the need for effective emission monitoring in these systems has grown significantly. The background of cyclone separator emission monitoring is rooted in the dual objectives of process optimization and environmental compliance.

Initially, cyclone separators were designed primarily for their efficiency in particle separation, with little emphasis on emissions control. However, as awareness of air pollution and its impacts on human health and the environment increased, regulatory bodies began to implement stricter emission standards for industrial processes. This shift in focus necessitated the development of robust monitoring systems for cyclone separator lines.

The evolution of emission monitoring for cyclone separators has been driven by advancements in sensor technology, data analytics, and environmental science. Early monitoring methods were often manual and intermittent, providing limited insight into real-time emissions. As technology progressed, continuous emission monitoring systems (CEMS) became more prevalent, offering real-time data on particulate matter concentrations and other pollutants.

The implementation of emission monitoring in cyclone separator lines presents unique challenges due to the high-velocity, turbulent nature of the gas flow within these systems. Traditional monitoring techniques often struggle with accuracy and reliability in such environments, leading to the development of specialized sensors and sampling methods tailored for cyclone separators.

One of the key drivers for improved emission monitoring has been the increasing focus on PM2.5 and ultrafine particles, which pose significant health risks. Cyclone separators, while effective for larger particles, may allow smaller particles to escape, making accurate monitoring of these emissions crucial for regulatory compliance and public health protection.

The integration of emission monitoring with process control systems has also become a critical aspect of cyclone separator operation. Real-time emission data allows for dynamic adjustments to separator parameters, optimizing both separation efficiency and emissions control. This synergy between process optimization and environmental compliance has become a cornerstone of modern industrial operations.

As industries continue to seek more sustainable and efficient processes, the role of emission monitoring in cyclone separator lines has expanded beyond mere compliance. It now serves as a valuable tool for process optimization, energy efficiency improvements, and the development of cleaner technologies. The ongoing evolution of emission monitoring technologies promises to further enhance our ability to manage and mitigate industrial emissions, contributing to a cleaner and more sustainable industrial future.

Initially, cyclone separators were designed primarily for their efficiency in particle separation, with little emphasis on emissions control. However, as awareness of air pollution and its impacts on human health and the environment increased, regulatory bodies began to implement stricter emission standards for industrial processes. This shift in focus necessitated the development of robust monitoring systems for cyclone separator lines.

The evolution of emission monitoring for cyclone separators has been driven by advancements in sensor technology, data analytics, and environmental science. Early monitoring methods were often manual and intermittent, providing limited insight into real-time emissions. As technology progressed, continuous emission monitoring systems (CEMS) became more prevalent, offering real-time data on particulate matter concentrations and other pollutants.

The implementation of emission monitoring in cyclone separator lines presents unique challenges due to the high-velocity, turbulent nature of the gas flow within these systems. Traditional monitoring techniques often struggle with accuracy and reliability in such environments, leading to the development of specialized sensors and sampling methods tailored for cyclone separators.

One of the key drivers for improved emission monitoring has been the increasing focus on PM2.5 and ultrafine particles, which pose significant health risks. Cyclone separators, while effective for larger particles, may allow smaller particles to escape, making accurate monitoring of these emissions crucial for regulatory compliance and public health protection.

The integration of emission monitoring with process control systems has also become a critical aspect of cyclone separator operation. Real-time emission data allows for dynamic adjustments to separator parameters, optimizing both separation efficiency and emissions control. This synergy between process optimization and environmental compliance has become a cornerstone of modern industrial operations.

As industries continue to seek more sustainable and efficient processes, the role of emission monitoring in cyclone separator lines has expanded beyond mere compliance. It now serves as a valuable tool for process optimization, energy efficiency improvements, and the development of cleaner technologies. The ongoing evolution of emission monitoring technologies promises to further enhance our ability to manage and mitigate industrial emissions, contributing to a cleaner and more sustainable industrial future.

Market Demand Analysis

The market demand for emission monitoring in cyclone separator lines has been steadily increasing due to stricter environmental regulations and growing awareness of industrial pollution. Industries such as cement production, power generation, and chemical processing heavily rely on cyclone separators for particulate matter removal, making emission monitoring crucial for compliance and operational efficiency.

Environmental agencies worldwide have implemented more stringent emission standards, driving the need for accurate and reliable monitoring systems. The United States Environmental Protection Agency (EPA) and the European Union's Industrial Emissions Directive (IED) have set specific limits for particulate matter emissions, compelling industries to adopt advanced monitoring technologies.

The global market for emission monitoring systems is experiencing significant growth, with a particular focus on continuous emission monitoring systems (CEMS) for industrial applications. This growth is driven by the need to meet regulatory requirements, optimize process efficiency, and reduce environmental impact. The cyclone separator segment represents a substantial portion of this market, as these devices are widely used in various industries for air pollution control.

Key factors contributing to the market demand include the need for real-time monitoring, improved accuracy in emission measurements, and the integration of data analytics for predictive maintenance and process optimization. Industries are increasingly seeking solutions that can provide continuous, reliable data on particulate matter emissions from cyclone separators to ensure compliance and avoid costly penalties.

The Asia-Pacific region, particularly China and India, is expected to witness the highest growth in demand for emission monitoring systems due to rapid industrialization and increasing environmental concerns. North America and Europe continue to be significant markets, driven by stringent regulations and the need to upgrade existing monitoring infrastructure.

Technological advancements in sensor technologies, data processing, and wireless communication have further fueled the demand for sophisticated emission monitoring solutions. Industries are looking for systems that can seamlessly integrate with their existing process control and data management systems, providing comprehensive insights into their environmental performance.

The COVID-19 pandemic has temporarily slowed market growth due to disruptions in industrial operations and supply chains. However, the long-term outlook remains positive as industries focus on sustainability and environmental responsibility. The market is expected to recover and continue its growth trajectory as economies rebound and environmental regulations become increasingly stringent.

Environmental agencies worldwide have implemented more stringent emission standards, driving the need for accurate and reliable monitoring systems. The United States Environmental Protection Agency (EPA) and the European Union's Industrial Emissions Directive (IED) have set specific limits for particulate matter emissions, compelling industries to adopt advanced monitoring technologies.

The global market for emission monitoring systems is experiencing significant growth, with a particular focus on continuous emission monitoring systems (CEMS) for industrial applications. This growth is driven by the need to meet regulatory requirements, optimize process efficiency, and reduce environmental impact. The cyclone separator segment represents a substantial portion of this market, as these devices are widely used in various industries for air pollution control.

Key factors contributing to the market demand include the need for real-time monitoring, improved accuracy in emission measurements, and the integration of data analytics for predictive maintenance and process optimization. Industries are increasingly seeking solutions that can provide continuous, reliable data on particulate matter emissions from cyclone separators to ensure compliance and avoid costly penalties.

The Asia-Pacific region, particularly China and India, is expected to witness the highest growth in demand for emission monitoring systems due to rapid industrialization and increasing environmental concerns. North America and Europe continue to be significant markets, driven by stringent regulations and the need to upgrade existing monitoring infrastructure.

Technological advancements in sensor technologies, data processing, and wireless communication have further fueled the demand for sophisticated emission monitoring solutions. Industries are looking for systems that can seamlessly integrate with their existing process control and data management systems, providing comprehensive insights into their environmental performance.

The COVID-19 pandemic has temporarily slowed market growth due to disruptions in industrial operations and supply chains. However, the long-term outlook remains positive as industries focus on sustainability and environmental responsibility. The market is expected to recover and continue its growth trajectory as economies rebound and environmental regulations become increasingly stringent.

Current Challenges

Implementing emission monitoring for cyclone separator lines presents several significant challenges that require innovative solutions and careful consideration. One of the primary obstacles is the harsh operating environment within cyclone separators. These devices often handle high-temperature, high-pressure, and corrosive gas streams, which can quickly degrade or damage conventional monitoring equipment. This necessitates the development of robust sensors and monitoring systems capable of withstanding these extreme conditions while maintaining accuracy and reliability over extended periods.

Another critical challenge lies in the dynamic nature of cyclone separator operations. The flow patterns and particle distributions within these systems can be highly variable, depending on factors such as input composition, flow rates, and operational parameters. This variability makes it difficult to establish consistent baseline measurements and interpret monitoring data accurately. Consequently, advanced data analysis techniques and adaptive algorithms are required to account for these fluctuations and provide meaningful emission insights.

The presence of particulate matter in the gas stream poses an additional hurdle for emission monitoring. Cyclone separators are designed to remove particles from gas flows, but some fine particles may still be present in the outlet stream. These particles can interfere with monitoring equipment, causing sensor fouling or producing false readings. Developing effective filtration or compensation methods to mitigate the impact of particulates on monitoring accuracy is crucial for reliable emission assessment.

Furthermore, the need for real-time or near-real-time monitoring presents technical challenges. Many industrial processes require continuous emission data to ensure compliance with environmental regulations and optimize operational efficiency. However, achieving high-frequency, accurate measurements in the complex environment of a cyclone separator line demands sophisticated instrumentation and data processing capabilities. Balancing the need for rapid data acquisition with the constraints of sensor response times and data transmission speeds remains a significant challenge.

The integration of emission monitoring systems with existing cyclone separator infrastructure also presents logistical and engineering challenges. Retrofitting monitoring equipment into operational facilities often requires careful planning to minimize disruptions to production processes. Additionally, ensuring seamless data integration with plant control systems and environmental reporting platforms necessitates the development of standardized communication protocols and interfaces.

Lastly, the cost-effectiveness of emission monitoring solutions for cyclone separator lines remains a concern for many industries. While regulatory pressures drive the need for comprehensive monitoring, the implementation of advanced sensing and analysis technologies can represent a significant investment. Striking a balance between monitoring accuracy, system reliability, and economic feasibility is crucial for widespread adoption of emission monitoring in cyclone separator applications.

Another critical challenge lies in the dynamic nature of cyclone separator operations. The flow patterns and particle distributions within these systems can be highly variable, depending on factors such as input composition, flow rates, and operational parameters. This variability makes it difficult to establish consistent baseline measurements and interpret monitoring data accurately. Consequently, advanced data analysis techniques and adaptive algorithms are required to account for these fluctuations and provide meaningful emission insights.

The presence of particulate matter in the gas stream poses an additional hurdle for emission monitoring. Cyclone separators are designed to remove particles from gas flows, but some fine particles may still be present in the outlet stream. These particles can interfere with monitoring equipment, causing sensor fouling or producing false readings. Developing effective filtration or compensation methods to mitigate the impact of particulates on monitoring accuracy is crucial for reliable emission assessment.

Furthermore, the need for real-time or near-real-time monitoring presents technical challenges. Many industrial processes require continuous emission data to ensure compliance with environmental regulations and optimize operational efficiency. However, achieving high-frequency, accurate measurements in the complex environment of a cyclone separator line demands sophisticated instrumentation and data processing capabilities. Balancing the need for rapid data acquisition with the constraints of sensor response times and data transmission speeds remains a significant challenge.

The integration of emission monitoring systems with existing cyclone separator infrastructure also presents logistical and engineering challenges. Retrofitting monitoring equipment into operational facilities often requires careful planning to minimize disruptions to production processes. Additionally, ensuring seamless data integration with plant control systems and environmental reporting platforms necessitates the development of standardized communication protocols and interfaces.

Lastly, the cost-effectiveness of emission monitoring solutions for cyclone separator lines remains a concern for many industries. While regulatory pressures drive the need for comprehensive monitoring, the implementation of advanced sensing and analysis technologies can represent a significant investment. Striking a balance between monitoring accuracy, system reliability, and economic feasibility is crucial for widespread adoption of emission monitoring in cyclone separator applications.

Existing Monitoring Solutions

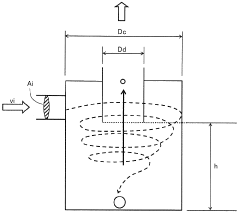

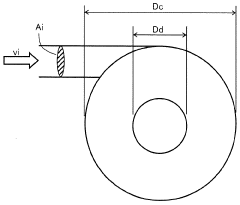

01 Cyclone separator design for emission reduction

Improved cyclone separator designs focus on enhancing separation efficiency and reducing emissions. These designs may include modifications to the cyclone body, inlet, or outlet configurations to optimize particle separation and minimize the release of pollutants.- Cyclone separator design for emission reduction: Improved cyclone separator designs focus on enhancing particle separation efficiency and reducing emissions. These designs may include modifications to the cyclone body, inlet, or outlet configurations to optimize flow patterns and increase collection efficiency of fine particles.

- Multi-stage cyclone systems: Multi-stage cyclone systems are employed to further reduce emissions by using a series of cyclones with progressively finer separation capabilities. This approach allows for more effective removal of particles across a wider size range, improving overall emission control.

- Integration of filtration systems: Combining cyclone separators with additional filtration systems, such as bag filters or electrostatic precipitators, can significantly enhance emission control. This integrated approach allows for the capture of finer particles that may escape the cyclone separator alone.

- Monitoring and control systems: Advanced monitoring and control systems are implemented to optimize cyclone separator performance and minimize emissions. These systems may include sensors, real-time data analysis, and automated adjustments to maintain optimal operating conditions.

- Emission reduction through process optimization: Optimizing the overall process that incorporates cyclone separators can lead to reduced emissions. This may include adjusting operating parameters, improving material handling, and implementing best practices in maintenance and operation to ensure consistent performance and minimal emissions.

02 Integration of filtration systems with cyclone separators

Combining cyclone separators with additional filtration systems can significantly reduce emissions. This approach may involve incorporating filter elements or secondary separation stages to capture fine particles that might otherwise escape the cyclone.Expand Specific Solutions03 Emission monitoring and control systems

Advanced monitoring and control systems are implemented to measure and regulate emissions from cyclone separators. These systems may include sensors, analyzers, and automated control mechanisms to ensure compliance with emission standards and optimize separator performance.Expand Specific Solutions04 Wet scrubbing technology for cyclone separators

Incorporating wet scrubbing technology into cyclone separator systems can enhance emission control. This approach involves using liquid sprays or mists to capture and remove fine particles and gaseous pollutants from the air stream.Expand Specific Solutions05 Energy-efficient cyclone separator designs

Developing energy-efficient cyclone separator designs that maintain high separation efficiency while reducing power consumption. These designs may incorporate features such as improved flow patterns, reduced pressure drop, or energy recovery systems to minimize overall emissions and environmental impact.Expand Specific Solutions

Key Industry Players

The emission monitoring for cyclone separator lines market is in a growth phase, driven by increasing environmental regulations and industrial demand for efficient particulate matter control. The market size is expanding, with a projected CAGR of 5-7% over the next five years. Technologically, the field is advancing rapidly, with companies like CiDRA Corporate Services and Smiths Detection-Watford leading in innovative sensor technologies and data analytics. China Petroleum & Chemical Corp. and Sinopec Safety Engineering Research Institute are making significant strides in integrating these systems into large-scale industrial operations. Academic institutions such as Osaka University and China University of Mining & Technology are contributing to technological advancements through research collaborations with industry players.

CiDRA Corporate Services, Inc.

Technical Solution: CiDRA has developed a non-invasive, clamp-on emission monitoring system for cyclone separator lines. Their technology utilizes array processing techniques to measure particulate emissions in real-time. The system employs acoustic sensors that detect the sound produced by particles impacting the pipe wall, allowing for continuous monitoring without disrupting the process flow[1]. This approach enables operators to optimize cyclone performance and detect potential issues before they lead to significant emissions[2]. The system can be easily retrofitted to existing cyclone separators without requiring process shutdowns or modifications to the piping[3].

Strengths: Non-invasive installation, real-time monitoring, and easy retrofitting. Weaknesses: May be affected by external noise sources and requires calibration for different particle types.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a robust emission monitoring system for cyclone separators used in their refining and petrochemical operations. Their approach combines traditional particulate matter sensors with advanced gas chromatography for comprehensive emission analysis. The system utilizes high-temperature resistant probes that can withstand the harsh conditions often found in industrial cyclone separators[10]. Sinopec's solution also incorporates real-time data transmission to a centralized control system, allowing for immediate response to any emission anomalies. The company has implemented machine learning algorithms to analyze historical emission data and predict potential equipment failures or process inefficiencies that could lead to increased emissions[11].

Strengths: Designed for harsh industrial environments, integrated with process control systems. Weaknesses: May be less adaptable to non-petrochemical applications, potentially higher cost due to specialized components.

Core Emission Sensing Technologies

Separating device and method for detecting a material accumulation in such a separating device

PatentActiveEP3319731A1

Innovation

- A radar device is integrated into the cyclone to emit and receive electromagnetic radiation, allowing for the detection of substance accumulation at the outlet by comparing reflected radiation values with reference values, enabling early identification of blockages and distinguishing between static and dynamic buildup.

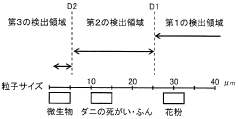

Detection device and detection method

PatentWO2012150672A1

Innovation

- A detection device using a cyclone separation mechanism and a discharge electrode to separate and collect biological particles by size, with a measuring system that applies heat to distinguish biological particles through fluorescence intensity changes.

Regulatory Compliance

Regulatory compliance is a critical aspect of implementing emission monitoring for cyclone separator lines. The Environmental Protection Agency (EPA) in the United States and similar regulatory bodies in other countries have established strict guidelines for industrial emissions control. These regulations aim to minimize the environmental impact of industrial processes and protect public health.

For cyclone separator lines, compliance with air quality standards is paramount. The Clean Air Act and its amendments set forth National Ambient Air Quality Standards (NAAQS) that industries must adhere to. These standards cover six principal pollutants: particulate matter, sulfur dioxide, nitrogen dioxide, carbon monoxide, ozone, and lead. Cyclone separators, primarily used for particulate matter removal, must be monitored to ensure they meet the prescribed emission limits for PM10 and PM2.5.

The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) provide specific requirements for various industrial sectors. Facilities operating cyclone separators must comply with these standards, which may include continuous emission monitoring systems (CEMS) or periodic stack testing.

Compliance also extends to reporting and record-keeping requirements. Facilities must maintain accurate logs of emission data, equipment maintenance, and any deviations from permitted levels. Many jurisdictions require regular submission of emission reports, often through electronic reporting systems like the EPA's Compliance and Emissions Data Reporting Interface (CEDRI).

Implementing a robust emission monitoring system for cyclone separator lines involves more than just installing sensors. It requires a comprehensive approach that includes proper calibration, regular maintenance, and quality assurance procedures. The EPA's Performance Specification standards outline the criteria for installing and operating CEMS, ensuring data accuracy and reliability.

Facilities must also be prepared for compliance audits and inspections. This involves maintaining a well-documented quality assurance program, including regular performance evaluations of the monitoring equipment. Training personnel in proper monitoring procedures and regulatory requirements is essential for maintaining ongoing compliance.

As environmental regulations continue to evolve, staying informed about changes and potential future requirements is crucial. Many industries are moving towards more stringent emission controls, and proactive compliance strategies can help facilities adapt to new standards more efficiently. This may include investing in advanced monitoring technologies or exploring innovative emission reduction techniques that go beyond current regulatory requirements.

For cyclone separator lines, compliance with air quality standards is paramount. The Clean Air Act and its amendments set forth National Ambient Air Quality Standards (NAAQS) that industries must adhere to. These standards cover six principal pollutants: particulate matter, sulfur dioxide, nitrogen dioxide, carbon monoxide, ozone, and lead. Cyclone separators, primarily used for particulate matter removal, must be monitored to ensure they meet the prescribed emission limits for PM10 and PM2.5.

The EPA's New Source Performance Standards (NSPS) and National Emission Standards for Hazardous Air Pollutants (NESHAP) provide specific requirements for various industrial sectors. Facilities operating cyclone separators must comply with these standards, which may include continuous emission monitoring systems (CEMS) or periodic stack testing.

Compliance also extends to reporting and record-keeping requirements. Facilities must maintain accurate logs of emission data, equipment maintenance, and any deviations from permitted levels. Many jurisdictions require regular submission of emission reports, often through electronic reporting systems like the EPA's Compliance and Emissions Data Reporting Interface (CEDRI).

Implementing a robust emission monitoring system for cyclone separator lines involves more than just installing sensors. It requires a comprehensive approach that includes proper calibration, regular maintenance, and quality assurance procedures. The EPA's Performance Specification standards outline the criteria for installing and operating CEMS, ensuring data accuracy and reliability.

Facilities must also be prepared for compliance audits and inspections. This involves maintaining a well-documented quality assurance program, including regular performance evaluations of the monitoring equipment. Training personnel in proper monitoring procedures and regulatory requirements is essential for maintaining ongoing compliance.

As environmental regulations continue to evolve, staying informed about changes and potential future requirements is crucial. Many industries are moving towards more stringent emission controls, and proactive compliance strategies can help facilities adapt to new standards more efficiently. This may include investing in advanced monitoring technologies or exploring innovative emission reduction techniques that go beyond current regulatory requirements.

Environmental Impact Assessment

The implementation of emission monitoring for cyclone separator lines has significant environmental implications that require thorough assessment. Cyclone separators are widely used in industrial processes to remove particulate matter from gas streams, but they can still release emissions that may impact air quality and human health. Monitoring these emissions is crucial for ensuring compliance with environmental regulations and minimizing ecological footprints.

The primary environmental concern associated with cyclone separator emissions is the release of fine particulate matter (PM2.5 and PM10) into the atmosphere. These particles can have detrimental effects on air quality, contributing to smog formation and potentially causing respiratory issues in nearby populations. Additionally, depending on the industrial process, the emissions may contain hazardous air pollutants (HAPs) or volatile organic compounds (VOCs) that pose further risks to human health and the environment.

Implementing effective emission monitoring systems for cyclone separators can help quantify and characterize these pollutants, enabling better management and mitigation strategies. Continuous emission monitoring systems (CEMS) can provide real-time data on particulate matter concentrations, allowing for immediate corrective actions if emissions exceed permissible limits. This proactive approach can significantly reduce the overall environmental impact of industrial operations utilizing cyclone separators.

Furthermore, accurate emission monitoring facilitates the assessment of long-term environmental effects, such as the potential for acid rain formation or the contribution to regional air quality issues. By gathering comprehensive data on emission patterns and concentrations, industries can develop more effective pollution control strategies and optimize their cyclone separator operations to minimize environmental impact.

The implementation of emission monitoring also supports the principles of environmental justice by providing transparent data on industrial emissions to local communities. This information can be crucial for addressing concerns about disproportionate environmental burdens on vulnerable populations and fostering trust between industrial facilities and neighboring residents.

In conclusion, the environmental impact assessment of implementing emission monitoring for cyclone separator lines reveals its critical role in environmental protection, regulatory compliance, and sustainable industrial practices. By providing accurate and timely data on emissions, these monitoring systems enable more effective environmental management and contribute to the overall goal of reducing the ecological footprint of industrial operations.

The primary environmental concern associated with cyclone separator emissions is the release of fine particulate matter (PM2.5 and PM10) into the atmosphere. These particles can have detrimental effects on air quality, contributing to smog formation and potentially causing respiratory issues in nearby populations. Additionally, depending on the industrial process, the emissions may contain hazardous air pollutants (HAPs) or volatile organic compounds (VOCs) that pose further risks to human health and the environment.

Implementing effective emission monitoring systems for cyclone separators can help quantify and characterize these pollutants, enabling better management and mitigation strategies. Continuous emission monitoring systems (CEMS) can provide real-time data on particulate matter concentrations, allowing for immediate corrective actions if emissions exceed permissible limits. This proactive approach can significantly reduce the overall environmental impact of industrial operations utilizing cyclone separators.

Furthermore, accurate emission monitoring facilitates the assessment of long-term environmental effects, such as the potential for acid rain formation or the contribution to regional air quality issues. By gathering comprehensive data on emission patterns and concentrations, industries can develop more effective pollution control strategies and optimize their cyclone separator operations to minimize environmental impact.

The implementation of emission monitoring also supports the principles of environmental justice by providing transparent data on industrial emissions to local communities. This information can be crucial for addressing concerns about disproportionate environmental burdens on vulnerable populations and fostering trust between industrial facilities and neighboring residents.

In conclusion, the environmental impact assessment of implementing emission monitoring for cyclone separator lines reveals its critical role in environmental protection, regulatory compliance, and sustainable industrial practices. By providing accurate and timely data on emissions, these monitoring systems enable more effective environmental management and contribute to the overall goal of reducing the ecological footprint of industrial operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!