Cyclone Separator Multi-Stage Systems: Design And Sizing Rules

AUG 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cyclone Separator Evolution

The evolution of cyclone separators has been a significant journey in the field of particle separation technology. Initially developed in the late 19th century, these devices have undergone substantial improvements in design and efficiency over the years. The early cyclones were simple, single-stage units primarily used in industrial applications for removing large particles from gas streams.

As industrial processes became more complex and environmental regulations more stringent, the need for more efficient separation systems grew. This led to the development of multi-stage cyclone systems in the mid-20th century. These systems incorporated multiple cyclones in series or parallel configurations, allowing for enhanced particle removal across a wider range of particle sizes.

The 1960s and 1970s saw significant advancements in cyclone theory and design. Researchers like Barth, Muschelknautz, and Leith made substantial contributions to understanding cyclone dynamics and developing mathematical models for predicting cyclone performance. These models laid the foundation for more systematic approaches to cyclone design and optimization.

The introduction of computational fluid dynamics (CFD) in the 1980s and 1990s revolutionized cyclone separator design. CFD simulations allowed engineers to visualize and analyze complex flow patterns within cyclones, leading to innovative designs with improved separation efficiency and reduced pressure drop. This period also saw the emergence of high-efficiency cyclones with modified inlet and outlet configurations.

In recent years, the focus has shifted towards developing advanced multi-stage systems that can handle increasingly demanding separation requirements. Modern multi-stage cyclone systems often incorporate hybrid designs, combining cyclones with other separation technologies such as filters or electrostatic precipitators. These hybrid systems aim to achieve higher overall collection efficiencies across a broader range of particle sizes.

The latest trends in cyclone separator evolution include the development of miniaturized cyclones for microfluidic applications and the integration of smart sensors and control systems for real-time performance monitoring and optimization. Additionally, there is growing interest in using advanced materials and surface treatments to enhance cyclone performance and durability.

As environmental concerns continue to drive technological advancements, the evolution of cyclone separators is likely to focus on further improving energy efficiency, reducing emissions, and adapting to new industrial processes and environmental regulations. The ongoing research in areas such as biomimicry and nanotechnology may also lead to novel cyclone designs inspired by natural separation processes.

As industrial processes became more complex and environmental regulations more stringent, the need for more efficient separation systems grew. This led to the development of multi-stage cyclone systems in the mid-20th century. These systems incorporated multiple cyclones in series or parallel configurations, allowing for enhanced particle removal across a wider range of particle sizes.

The 1960s and 1970s saw significant advancements in cyclone theory and design. Researchers like Barth, Muschelknautz, and Leith made substantial contributions to understanding cyclone dynamics and developing mathematical models for predicting cyclone performance. These models laid the foundation for more systematic approaches to cyclone design and optimization.

The introduction of computational fluid dynamics (CFD) in the 1980s and 1990s revolutionized cyclone separator design. CFD simulations allowed engineers to visualize and analyze complex flow patterns within cyclones, leading to innovative designs with improved separation efficiency and reduced pressure drop. This period also saw the emergence of high-efficiency cyclones with modified inlet and outlet configurations.

In recent years, the focus has shifted towards developing advanced multi-stage systems that can handle increasingly demanding separation requirements. Modern multi-stage cyclone systems often incorporate hybrid designs, combining cyclones with other separation technologies such as filters or electrostatic precipitators. These hybrid systems aim to achieve higher overall collection efficiencies across a broader range of particle sizes.

The latest trends in cyclone separator evolution include the development of miniaturized cyclones for microfluidic applications and the integration of smart sensors and control systems for real-time performance monitoring and optimization. Additionally, there is growing interest in using advanced materials and surface treatments to enhance cyclone performance and durability.

As environmental concerns continue to drive technological advancements, the evolution of cyclone separators is likely to focus on further improving energy efficiency, reducing emissions, and adapting to new industrial processes and environmental regulations. The ongoing research in areas such as biomimicry and nanotechnology may also lead to novel cyclone designs inspired by natural separation processes.

Industrial Demand Analysis

The industrial demand for cyclone separator multi-stage systems has been steadily increasing across various sectors due to their efficiency in particle separation and gas cleaning processes. These systems are particularly crucial in industries such as petrochemicals, cement production, power generation, and food processing, where the removal of particulate matter from gas streams is essential for both product quality and environmental compliance.

In the petrochemical industry, multi-stage cyclone separators play a vital role in catalyst recovery and flue gas cleaning. The demand for these systems has grown as refineries and chemical plants strive to improve their operational efficiency and meet stringent emission standards. The ability of multi-stage cyclone separators to handle high-temperature and high-pressure environments makes them indispensable in these applications.

The cement industry has also seen a surge in demand for cyclone separator multi-stage systems. These systems are integral to the preheater towers in modern cement plants, where they efficiently separate hot gases and particulates. As the global construction sector continues to expand, particularly in developing economies, the demand for cement production capacity has driven the need for more advanced and efficient cyclone separator systems.

Power generation, especially coal-fired power plants, represents another significant market for multi-stage cyclone separators. These systems are employed in flue gas desulfurization units and as pre-cleaners for electrostatic precipitators. With the ongoing focus on reducing emissions from power plants, the demand for more effective particulate removal technologies, including multi-stage cyclone separators, has increased.

In the food processing industry, cyclone separator multi-stage systems are essential for tasks such as pneumatic conveying of powders and granules, as well as dust collection in grain handling facilities. The growing emphasis on food safety and quality has led to increased adoption of these systems to ensure cleaner processing environments and prevent cross-contamination.

The market for cyclone separator multi-stage systems is also being driven by advancements in design and sizing rules. Improved computational fluid dynamics (CFD) modeling and simulation tools have enabled manufacturers to optimize cyclone designs for specific applications, resulting in higher separation efficiencies and lower pressure drops. This has expanded the potential applications of these systems and increased their appeal across industries.

Furthermore, the global focus on environmental protection and sustainability has bolstered the demand for cyclone separator multi-stage systems. As regulations on particulate emissions become more stringent worldwide, industries are investing in more effective air pollution control technologies. Multi-stage cyclone separators offer a cost-effective solution for meeting these regulatory requirements, particularly when used in combination with other air cleaning technologies.

In the petrochemical industry, multi-stage cyclone separators play a vital role in catalyst recovery and flue gas cleaning. The demand for these systems has grown as refineries and chemical plants strive to improve their operational efficiency and meet stringent emission standards. The ability of multi-stage cyclone separators to handle high-temperature and high-pressure environments makes them indispensable in these applications.

The cement industry has also seen a surge in demand for cyclone separator multi-stage systems. These systems are integral to the preheater towers in modern cement plants, where they efficiently separate hot gases and particulates. As the global construction sector continues to expand, particularly in developing economies, the demand for cement production capacity has driven the need for more advanced and efficient cyclone separator systems.

Power generation, especially coal-fired power plants, represents another significant market for multi-stage cyclone separators. These systems are employed in flue gas desulfurization units and as pre-cleaners for electrostatic precipitators. With the ongoing focus on reducing emissions from power plants, the demand for more effective particulate removal technologies, including multi-stage cyclone separators, has increased.

In the food processing industry, cyclone separator multi-stage systems are essential for tasks such as pneumatic conveying of powders and granules, as well as dust collection in grain handling facilities. The growing emphasis on food safety and quality has led to increased adoption of these systems to ensure cleaner processing environments and prevent cross-contamination.

The market for cyclone separator multi-stage systems is also being driven by advancements in design and sizing rules. Improved computational fluid dynamics (CFD) modeling and simulation tools have enabled manufacturers to optimize cyclone designs for specific applications, resulting in higher separation efficiencies and lower pressure drops. This has expanded the potential applications of these systems and increased their appeal across industries.

Furthermore, the global focus on environmental protection and sustainability has bolstered the demand for cyclone separator multi-stage systems. As regulations on particulate emissions become more stringent worldwide, industries are investing in more effective air pollution control technologies. Multi-stage cyclone separators offer a cost-effective solution for meeting these regulatory requirements, particularly when used in combination with other air cleaning technologies.

Technical Challenges

Cyclone separator multi-stage systems face several technical challenges in their design and sizing. One of the primary issues is the optimization of separation efficiency across multiple stages. As particles progress through successive cyclones, their size distribution and concentration change, requiring careful consideration of each stage's design parameters.

The pressure drop across the system presents another significant challenge. Each additional stage contributes to the overall pressure loss, potentially increasing energy consumption and operational costs. Balancing the trade-off between separation efficiency and pressure drop is crucial for system performance and economic viability.

Particle re-entrainment is a persistent problem in multi-stage cyclone systems. As separated particles accumulate in collection hoppers, there is a risk of them being re-entrained into the gas stream, particularly in high-throughput applications. This phenomenon can reduce overall separation efficiency and necessitates innovative design solutions for particle discharge and hopper geometry.

Scale-up and scale-down of cyclone separator systems pose considerable challenges. While single-stage cyclone performance can be reasonably predicted using established scaling laws, the behavior of multi-stage systems is more complex. Interactions between stages and changes in particle characteristics as they progress through the system make it difficult to accurately predict performance at different scales.

Material selection and wear resistance are critical considerations, especially in applications involving abrasive particles. The high-velocity particle-wall interactions in cyclones can lead to erosion and degradation of internal surfaces, potentially compromising separation efficiency and system longevity. Selecting appropriate materials and implementing wear-resistant coatings or linings is essential but can significantly impact system cost and complexity.

The design of inter-stage connections and flow distribution systems presents unique challenges in multi-stage configurations. Ensuring uniform flow distribution between stages and minimizing turbulence and pressure losses in connecting ducts is crucial for maintaining overall system efficiency.

Computational modeling and simulation of multi-stage cyclone systems remain challenging due to the complex, three-dimensional, turbulent nature of the flow and particle dynamics. Developing accurate models that can predict performance across a range of operating conditions and particle characteristics is an ongoing area of research and development in the field.

The pressure drop across the system presents another significant challenge. Each additional stage contributes to the overall pressure loss, potentially increasing energy consumption and operational costs. Balancing the trade-off between separation efficiency and pressure drop is crucial for system performance and economic viability.

Particle re-entrainment is a persistent problem in multi-stage cyclone systems. As separated particles accumulate in collection hoppers, there is a risk of them being re-entrained into the gas stream, particularly in high-throughput applications. This phenomenon can reduce overall separation efficiency and necessitates innovative design solutions for particle discharge and hopper geometry.

Scale-up and scale-down of cyclone separator systems pose considerable challenges. While single-stage cyclone performance can be reasonably predicted using established scaling laws, the behavior of multi-stage systems is more complex. Interactions between stages and changes in particle characteristics as they progress through the system make it difficult to accurately predict performance at different scales.

Material selection and wear resistance are critical considerations, especially in applications involving abrasive particles. The high-velocity particle-wall interactions in cyclones can lead to erosion and degradation of internal surfaces, potentially compromising separation efficiency and system longevity. Selecting appropriate materials and implementing wear-resistant coatings or linings is essential but can significantly impact system cost and complexity.

The design of inter-stage connections and flow distribution systems presents unique challenges in multi-stage configurations. Ensuring uniform flow distribution between stages and minimizing turbulence and pressure losses in connecting ducts is crucial for maintaining overall system efficiency.

Computational modeling and simulation of multi-stage cyclone systems remain challenging due to the complex, three-dimensional, turbulent nature of the flow and particle dynamics. Developing accurate models that can predict performance across a range of operating conditions and particle characteristics is an ongoing area of research and development in the field.

Current Design Approaches

01 Multi-stage cyclone separator design

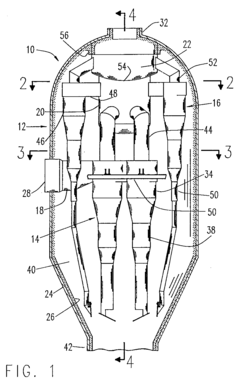

Multi-stage cyclone separators are designed to improve separation efficiency by using multiple cyclones in series or parallel configurations. This design allows for better particle separation across different size ranges and can handle higher throughput. The arrangement of cyclones can be optimized based on the specific application and particle characteristics.- Multi-stage cyclone separator design: Multi-stage cyclone separator systems are designed to improve separation efficiency by using multiple cyclones in series or parallel configurations. This design allows for better particle separation across different size ranges and can handle higher throughput volumes. The arrangement of cyclones can be optimized based on the specific application and particle characteristics.

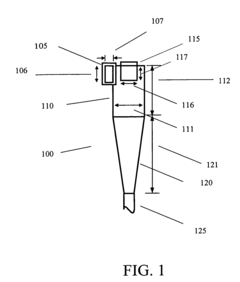

- Sizing and optimization of cyclone separators: Proper sizing of cyclone separators is crucial for optimal performance. This involves calculating dimensions such as inlet area, body diameter, and cone length based on the desired cut size, flow rate, and pressure drop. Computational fluid dynamics (CFD) simulations and empirical models are often used to optimize the design and predict separation efficiency.

- Integration of auxiliary components: Auxiliary components such as pre-separators, dust collectors, and recirculation systems can be integrated into multi-stage cyclone systems to enhance overall performance. These components help in removing larger particles before entering the cyclones, capturing fine particles, and improving the system's efficiency by recirculating partially separated streams.

- Material selection and construction: The choice of materials for cyclone separators is critical for durability and performance. Abrasion-resistant materials are often used for high-wear areas, while corrosion-resistant materials may be necessary for certain applications. The construction method, including welding techniques and surface treatments, can impact the separator's efficiency and lifespan.

- Control systems and monitoring: Advanced control systems and monitoring equipment are implemented in multi-stage cyclone separator systems to optimize performance and ensure consistent operation. These may include pressure sensors, flow meters, and particle analyzers that provide real-time data for adjusting operating parameters and scheduling maintenance.

02 Sizing and optimization of cyclone separators

Proper sizing of cyclone separators is crucial for optimal performance. This involves calculating dimensions such as inlet area, body diameter, and cone length based on the desired cut size, flow rate, and pressure drop. Computational fluid dynamics (CFD) simulations and empirical models are often used to optimize the design and predict separation efficiency.Expand Specific Solutions03 Integration of auxiliary components

Auxiliary components such as pre-separators, filters, and collection hoppers can be integrated into multi-stage cyclone systems to enhance overall performance. These components can help remove larger particles before entering the cyclones, capture fine particles that escape the cyclones, and efficiently collect separated particles.Expand Specific Solutions04 Material selection and construction

The choice of materials for cyclone separators is important for durability and efficiency. Wear-resistant materials are often used in high-abrasion applications, while corrosion-resistant materials are selected for chemical processing. The construction method, including welding techniques and surface treatments, can impact the separator's performance and lifespan.Expand Specific Solutions05 Control systems and monitoring

Advanced control systems and monitoring technologies are implemented in multi-stage cyclone separator systems to optimize performance and ensure consistent operation. These may include pressure sensors, flow meters, and particle analyzers that provide real-time data for adjusting operating parameters and scheduling maintenance.Expand Specific Solutions

Key Industry Players

The cyclone separator multi-stage systems market is in a growth phase, driven by increasing demand for efficient particle separation across industries. The global market size is estimated to be in the hundreds of millions of dollars, with steady expansion projected. Technologically, the field is moderately mature but continues to evolve, with companies like ExxonMobil Chemical Patents, Dyson Technology, and MANN+HUMMEL leading innovation. These firms are developing advanced designs for improved efficiency and adaptability. Academic institutions such as China Petroleum University Beijing and Lanzhou University are also contributing to research and development, fostering collaboration between industry and academia to push the boundaries of cyclone separator technology.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed advanced multi-stage cyclone separator systems for petrochemical applications. Their design incorporates a series of cyclones with decreasing diameters to progressively separate particles of different sizes. The system utilizes computational fluid dynamics (CFD) modeling to optimize flow patterns and separation efficiency[1]. ExxonMobil's approach includes innovative vortex finder designs and particle re-entrainment prevention mechanisms. They have implemented a "smart" control system that adjusts operating parameters based on real-time particle load and composition data, enhancing overall performance and adaptability[3].

Strengths: High separation efficiency across a wide range of particle sizes; adaptive control system for optimized performance. Weaknesses: Complex design may lead to higher manufacturing and maintenance costs; potential for increased pressure drop across multiple stages.

Dyson Technology Ltd.

Technical Solution: Dyson has pioneered multi-cyclone technology in consumer appliances, particularly vacuum cleaners. Their approach involves a series of progressively smaller cyclones arranged in stages. The first stage removes larger particles, while subsequent stages capture increasingly finer dust. Dyson's design incorporates precise cyclone geometry, optimized through extensive computational and empirical testing[2]. They have developed proprietary "Radial Root Cyclone" technology, which uses cyclones with conical frusta shapes to maximize centrifugal forces. Dyson's latest iterations include up to 18 cyclones working in parallel within a compact form factor, achieving separation efficiencies of over 99.97% for particles as small as 0.3 microns[4].

Strengths: Highly efficient separation in a compact design; proven technology in consumer products. Weaknesses: May be less suitable for industrial-scale applications; limited to relatively low flow rates and particle loads compared to industrial systems.

Innovative Sizing Methodologies

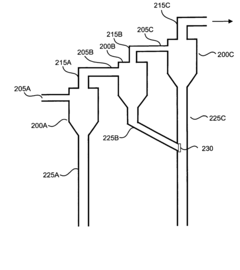

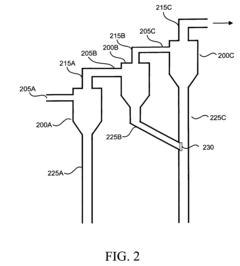

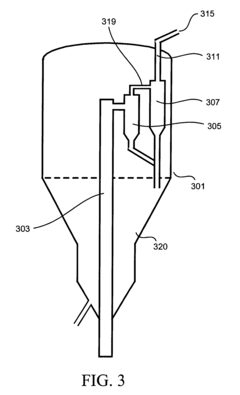

Multi-stage cyclone separator system with intermediate manifold

PatentInactiveEP0595132A3

Innovation

- The cyclone system allows for independent selection of cyclone numbers between stages and flexible placement of upper cyclones, eliminating direct connections and incorporating an integrated manifold and support structure to accommodate differential thermal expansion, thereby minimizing interferences and optimizing space usage.

Gas-solids separation device and method

PatentActiveUS7329309B2

Innovation

- The implementation of a multi-stage cyclone separator configuration where the dipleg output flows of multiple cyclone stages are merged into a single output conduit, maintaining a sufficient solid particle flux and preventing catalyst bridging, while allowing for efficient operation even with low solids content.

Environmental Regulations

Environmental regulations play a crucial role in shaping the design and implementation of cyclone separator multi-stage systems. These regulations are established to protect air quality, reduce emissions, and minimize the environmental impact of industrial processes. In recent years, there has been a significant tightening of environmental standards worldwide, particularly concerning particulate matter emissions.

The United States Environmental Protection Agency (EPA) has set stringent standards for particulate matter emissions under the Clean Air Act. These regulations specify maximum allowable concentrations of PM2.5 and PM10 in ambient air. As a result, industries utilizing cyclone separators must ensure their systems meet or exceed these standards to maintain compliance.

Similarly, the European Union has implemented the Industrial Emissions Directive (IED), which sets emission limits for various pollutants, including particulate matter. This directive applies to a wide range of industrial activities and requires the use of Best Available Techniques (BAT) to minimize emissions. Cyclone separator multi-stage systems must be designed and sized to meet these BAT requirements.

In developing countries, environmental regulations are also becoming more stringent. For instance, China has introduced the Air Pollution Prevention and Control Action Plan, which aims to significantly reduce particulate matter emissions from industrial sources. This has led to increased adoption of advanced cyclone separator technologies in various industries.

The global trend towards more stringent environmental regulations has driven innovation in cyclone separator design. Manufacturers are now focusing on developing multi-stage systems that can achieve higher separation efficiencies, particularly for fine particles. This includes the integration of advanced materials, optimized geometries, and improved flow dynamics to enhance performance while meeting regulatory requirements.

Compliance with environmental regulations often requires continuous monitoring and reporting of emissions. As a result, cyclone separator systems are increasingly being equipped with advanced sensors and data analytics capabilities. These features allow for real-time monitoring of system performance and enable operators to make adjustments to maintain compliance with emission standards.

The sizing of cyclone separator multi-stage systems is directly influenced by environmental regulations. Engineers must consider factors such as the required emission reduction levels, the characteristics of the particulate matter to be separated, and the specific regulatory limits applicable to the industry and location. This often leads to the implementation of larger or more complex multi-stage systems to achieve the necessary separation efficiency.

In conclusion, environmental regulations serve as a key driver for the design and sizing of cyclone separator multi-stage systems. As these regulations continue to evolve and become more stringent, the industry must adapt by developing more efficient and effective separation technologies to ensure compliance and minimize environmental impact.

The United States Environmental Protection Agency (EPA) has set stringent standards for particulate matter emissions under the Clean Air Act. These regulations specify maximum allowable concentrations of PM2.5 and PM10 in ambient air. As a result, industries utilizing cyclone separators must ensure their systems meet or exceed these standards to maintain compliance.

Similarly, the European Union has implemented the Industrial Emissions Directive (IED), which sets emission limits for various pollutants, including particulate matter. This directive applies to a wide range of industrial activities and requires the use of Best Available Techniques (BAT) to minimize emissions. Cyclone separator multi-stage systems must be designed and sized to meet these BAT requirements.

In developing countries, environmental regulations are also becoming more stringent. For instance, China has introduced the Air Pollution Prevention and Control Action Plan, which aims to significantly reduce particulate matter emissions from industrial sources. This has led to increased adoption of advanced cyclone separator technologies in various industries.

The global trend towards more stringent environmental regulations has driven innovation in cyclone separator design. Manufacturers are now focusing on developing multi-stage systems that can achieve higher separation efficiencies, particularly for fine particles. This includes the integration of advanced materials, optimized geometries, and improved flow dynamics to enhance performance while meeting regulatory requirements.

Compliance with environmental regulations often requires continuous monitoring and reporting of emissions. As a result, cyclone separator systems are increasingly being equipped with advanced sensors and data analytics capabilities. These features allow for real-time monitoring of system performance and enable operators to make adjustments to maintain compliance with emission standards.

The sizing of cyclone separator multi-stage systems is directly influenced by environmental regulations. Engineers must consider factors such as the required emission reduction levels, the characteristics of the particulate matter to be separated, and the specific regulatory limits applicable to the industry and location. This often leads to the implementation of larger or more complex multi-stage systems to achieve the necessary separation efficiency.

In conclusion, environmental regulations serve as a key driver for the design and sizing of cyclone separator multi-stage systems. As these regulations continue to evolve and become more stringent, the industry must adapt by developing more efficient and effective separation technologies to ensure compliance and minimize environmental impact.

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) plays a crucial role in the design and optimization of cyclone separator multi-stage systems. This advanced simulation technique allows engineers to model and analyze the complex fluid flow patterns within these systems, providing valuable insights into their performance and efficiency.

CFD simulations for cyclone separators typically involve solving the Navier-Stokes equations, which govern fluid motion, along with additional models for turbulence and particle tracking. These simulations can accurately predict the velocity fields, pressure distributions, and particle trajectories within the separator, enabling engineers to evaluate and improve the design.

One of the primary advantages of using CFD in cyclone separator design is the ability to visualize the flow patterns and identify areas of high turbulence or recirculation. This information is invaluable for optimizing the geometry of the separator, including the inlet design, vortex finder dimensions, and cone angle. By iteratively adjusting these parameters in the CFD model, designers can maximize separation efficiency while minimizing pressure drop.

Multi-stage cyclone systems present additional challenges for CFD modeling due to the complex interactions between stages. Advanced CFD techniques, such as multi-phase flow models and Lagrangian particle tracking, are employed to accurately simulate the behavior of particles as they move through the system. These models can account for particle-particle interactions, wall collisions, and the effects of turbulence on particle dispersion.

CFD simulations also enable the investigation of scaling effects in cyclone separators. By running simulations at different scales, engineers can develop and validate sizing rules that ensure consistent performance across a range of operational conditions. This is particularly important for multi-stage systems, where the performance of each stage must be carefully balanced to achieve optimal overall separation efficiency.

Furthermore, CFD can be used to study the impact of various operating conditions on cyclone performance. By simulating different inlet velocities, particle size distributions, and gas properties, engineers can develop a comprehensive understanding of the system's behavior under various scenarios. This information is crucial for creating robust design and sizing rules that can be applied across a wide range of applications.

In recent years, the integration of CFD with other computational techniques, such as Discrete Element Method (DEM) for particle-particle interactions and Finite Element Analysis (FEA) for structural analysis, has further enhanced the capabilities of cyclone separator design tools. These coupled simulations provide a more holistic view of the system's performance, considering both fluid dynamics and mechanical aspects simultaneously.

CFD simulations for cyclone separators typically involve solving the Navier-Stokes equations, which govern fluid motion, along with additional models for turbulence and particle tracking. These simulations can accurately predict the velocity fields, pressure distributions, and particle trajectories within the separator, enabling engineers to evaluate and improve the design.

One of the primary advantages of using CFD in cyclone separator design is the ability to visualize the flow patterns and identify areas of high turbulence or recirculation. This information is invaluable for optimizing the geometry of the separator, including the inlet design, vortex finder dimensions, and cone angle. By iteratively adjusting these parameters in the CFD model, designers can maximize separation efficiency while minimizing pressure drop.

Multi-stage cyclone systems present additional challenges for CFD modeling due to the complex interactions between stages. Advanced CFD techniques, such as multi-phase flow models and Lagrangian particle tracking, are employed to accurately simulate the behavior of particles as they move through the system. These models can account for particle-particle interactions, wall collisions, and the effects of turbulence on particle dispersion.

CFD simulations also enable the investigation of scaling effects in cyclone separators. By running simulations at different scales, engineers can develop and validate sizing rules that ensure consistent performance across a range of operational conditions. This is particularly important for multi-stage systems, where the performance of each stage must be carefully balanced to achieve optimal overall separation efficiency.

Furthermore, CFD can be used to study the impact of various operating conditions on cyclone performance. By simulating different inlet velocities, particle size distributions, and gas properties, engineers can develop a comprehensive understanding of the system's behavior under various scenarios. This information is crucial for creating robust design and sizing rules that can be applied across a wide range of applications.

In recent years, the integration of CFD with other computational techniques, such as Discrete Element Method (DEM) for particle-particle interactions and Finite Element Analysis (FEA) for structural analysis, has further enhanced the capabilities of cyclone separator design tools. These coupled simulations provide a more holistic view of the system's performance, considering both fluid dynamics and mechanical aspects simultaneously.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!